Introduction to PCB

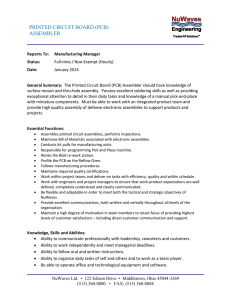

advertisement

PRESENTED BY RUBY KUMARI B.SC(MATHS),B.E(ECE) PCB is an acronym for Printed Circuit Board. Printed Circuit Board is a plate used for placing the different elements that conform an electrical circuits that contains the electrical interconnection between them. It is a board that has lines and pads that connects various points together. Before printed circuits became the common component used in electronics, Point to point construction was used. This means some bulky and unreliable designs that required large sockets and regular replacement. Most of these issues were directly addressed when PCB went into direct production. Pcbs are rugged, inexpensive and can be highly reliable. Mass manufacturing . Professional. Reduced space and time. Bulky construction The first Printed Circuit Board can be traced all the back on early 1900 and a patent for Printed wire. In 1925 that Charles Ducas first submitted a patent that involved creating an electrical path directly on an insulated surface. It was a revolutionary idea because it could eliminate complex wiring and provide consistent results. Still, they didn’t really catch on until after WWII, when Dr. Paul Eisler in Austria began making the first real operational printed circuit boards in 1943. PCBs may be classified in many different ways according to their various attributes. One fundamental structure common to all of them is that they must provide electrical conductor paths that interconnect components to be mounted on them. There are two basic ways to form these conductors: Subtractive. In the subtractive process, the unwanted portion of the copper foil on the base substrate is etched away, leaving the desired conductor pattern in place. Additive. In the additive process, formation of the conductor pattern is accomplished by adding copper to a bare (no copper foil) substrate in the pattern and places desired. This can be done by plating copper, screening conductive paste, or laying down insulating wire onto the substrate on the predetermined conductor paths. The PCB classifications given in next slide take into consideration all these factors, i.e., fabrication processes as well as substrate materials. Column 1 shows the classification of PCBs by the nature of the substrate. Column 2 shows the classification of PCBs by the way the conductor pattern is imaged. Column 3 shows the classification of PCBs by their physical nature. Column 4 shows the classification of PCBs by the method of conductor formation. Column 5 shows the classification of PCBs by the number of conductor layers. Column 6 shows the classification of PCBs... Single sided PCB. Double sided PCB. Multilayer PCB. Rigid –flex PCB. Flexible PCB. High frequency PCB. Low frequency pcb componen t Conducting wires or traces. Populated PCB or assembled single sided pcb Single sided PCB without assembly or single sided bare board For single sided PCB, the components are on one side, conducting wires are on other sides as shown in image of previous slide. Single sided PCB is the most simple and basic PCB. With the appearance of electronic transistor, single side PCB was developed in the early 1950,which is mainly manufactured in U.S.A. In 1956 single sided PCB technology was made big progress with the appearance of professional PCB manufacturer from Japan. The raw material for manufacturing single sided PCB include FR1,CEM1,CEM3,FR4. Top side Bottom side For double sided board components can be on both the sides(Top & Bottom).conducting wires can be on both the sides. Double sided board means the conductor patterns appear on both sides of the board. However if we use the conductor patterns on both sides, there should be proper circuit to connect two sides. The bridge between the circuits is called via. Those vias are plated with metal, such as tin, copper, gold, etc. Because the area of double sided PCB is two fold of the area of single sided, and the conductor pattern can cross with each other, so it suits to be used on more complex circuits. Double sided Pcb boards are a common tool in both production and prototype circuits. They allow a higher density in components and make laying of tracks an easier process. Same as a regular circuit board, Double sided boards are made with a substrate of non conductive material, over which a layer of copper is placed on top of it, and in the case of double sided boards, the copper is also layered on the bottom side of the substrate. As with any type of circuit board, there are advantages to the use of one type over another. Double sided boards, as I said earlier, allow a higher density of component. This is because you have a whole extra layer where you can add tracks to connect the components, freeing space on the other to place the components closer together or add extra connections for IC with high pin counts. Another advantage of using double sided boards is the increased heat dissipation that an extra layer of copper provides, this can be achieved in the etching process, only removing enough copper to create the tracks, leaving the extra copper instead of removing it completely. The decision to use double sided boards needs to be considered very carefully, because of the added complexity in production and handling of the finished board, as well as the costs associated can make using a double sided board a sub optimal choice to use in an electronic circuit project. The biggest consideration is manufacturing costs, because most manufacturers will charge extra setup fees for processing the extra side, not only on etching and soldermask, but also on component layouts added in the silkscreen process. Other added expenses could derive from the design process itself, since several additional design considerations must be taken into account to ensure proper functioning of the finished product, such as inductive losses and parasitic capacitance affecting the performance of analog and high speed digital circuits. If after these considerations using a double sided circuit board is the right choice, then the advantages will really help your finished circuit stand out and be more functional. In order to enlarge the area of conductor pattern, multilayer PCB uses more single or double boards. It uses several piece of double sided boards, and a dielectric layer is put between every layer of boards. The layers of one PCB represent the layer of conductor patterns. The amount of the layers is always even number. Technically we can make PCBs up to 100 layers. For via, if we use it on double sided PCB, the whole boards will be drilled. While on multilayer PCB, if you just want to connect some traces, via may will waste trace space of some layers. Then we use buried vias and blind vias to solve this problem, because they are only drilled through several layers. a. Buried vias only connect inner PCBs, so we can’t see them from the surface. b. Blind vias connects several layers PCB with surface PCB. In multilayer PCB, the whole board directly connects the ground line and power (used for preventing affection of the transmission signals on the signal). So we divide layers into signal, power, or ground. If the components on PCB need different power supply, this kind of PCB would have more than two layers of power and wire layers. Rigid Flex circuits gives the ability to design your circuitry to fit the device, instead of building a device to fit the circuit board. Rigid Flex circuits are designed for the rigors of aerospace, medical and military applications, with dependable reliability. Flex assemblies have the ability to be folded or creased and positioned into the smallest areas makes miniaturization of many devices possible, while offering a substantial weight reduction Each type of flex circuit offers different advantages. While some types of flex circuits can offer lower production costs, others have additional increased functionality. Flex and Rigid-Flex circuits gives the ability to design your circuitry to fit the device, instead of building a device to fit the circuit board. They are designed for the rigors of aerospace, medical and military applications, with dependable reliability. Flex and Rigid-Flex circuits gives the ability to design your circuitry to fit the device, instead of building a device to fit the circuit board. They are designed for the rigors of aerospace, medical and military applications, with dependable reliability. Flex circuits offer multiple advantages for anyone considering to use this technology in a future project or if you’re trying to decide on re-engineering your current design. Below you will find some key benefits of using flex and rigid-flex circuit technology. Flexible circuit boards fit where no other solutions can. Flexible circuit boards are thin and light weight which enables a substantial packaging size reduction. They have the ability to be folded or creased and positioned into the smallest areas makes miniaturization of many devices possible. Space requirements can be minimized by applying the freedom of 3D packaging geometry. Utilizing a flex circuit solution into your design can offer a substantial weight reduction benefit over using wires and wire harnesses. Flexible circuits can be used to replace wiring reduces the errors common in hand wired assemblies. The increasing complexity of electronic components and switches continually requires faster signal flow rates, and thus higher transmission frequencies. Because of short pulse rise times in electronic components, it has also become necessary for high frequency (HF) technology to view conductor widths as an electronic component. Depending on various parameters, HF signals are reflected on circuit board, meaning that the impedance (dynamic resistance) varies with respect to the sending component. To prevent such capacitive effects, all parameters must be exactly specified, and implemented with the highest level of process control. Critical for the impedances in high frequency circuit boards are principally the conductor trace geometry, the layer buildup, and the dielectric constant (er) of the materials used. In recent years, semiconductor packaging has evolved with an increased demand for greater functionality, smaller size, and added utility. A modern PCBA design has two main methods for mounting components onto a PCB: Through-Hole Mounting and Surface Mounting. Through-hole mounting is the process by which component leads are placed into drilled holes on a bare PCB. The process was standard practice until the rise of surface mount technology (SMT) in the 1980s, at which time it was expected to completely phase out through-hole. Yet, despite a severe drop in popularity over the years, through-hole technology has proven resilient in the age of SMT, offering a number of advantages and niche applications: namely, reliability. Through-hole components are best used for high-reliability products that require stronger connections between layers. Whereas SMT components are secured only by solder on the surface of the board, through-hole component leads run through the board, allowing the components to withstand more environmental stress. This is why through-hole technology is commonly used in military and aerospace products that may experience extreme accelerations, collisions, or high temperatures. Through-hole technology is also useful in test and prototyping applications that sometimes require manual adjustments and replacements. There are two types of through-hole components:Axial and Radial lead components. Axial leads run through a component in a straight line ("axially"), with each end of the lead wire exiting the component on either end. Both ends are then placed through two separate holes in the board, allowing the component to fit closer, flatter fit. Radial lead components, on the other hand, protrude from the board, as its leads are located on one side of the component. Both through-hole component types are "twin" lead components, and both have their distinct advantages. While axial lead components are used for their snugness to the board, radial leads occupy less surface area, making them better for high density boards. Generally, axial lead configuration may come in the form of carbon resistors, electrolytic capacitors, fuses, and light-emitting diodes (LEDs). Radial lead components are available as ceramic disk capacitors. Advantages: THM provides stronger mechanical bonds than SMT, making through-hole ideal for components that might undergo mechanical stress, such as connectors or transformers. Good for test and prototyping. Disadvantages: On the bare PCB side, THM requires the drilling holes, which is expensive and time consuming. THM also limits the available routing area on any multilayer boards, because the drilled holes must pass through all the PCB’s layers. On the assembly side, component placement rates for THM are a fraction of surface mount placement rates, making THM prohibitively expensive. Further, THM requires the use of wave, selective, or hand-soldering techniques, which are much less reliable and repeatable than reflow ovens used for surface mount. Most of all, through-hole technology requires soldering on both sides of the board, as opposed to surface-mounts, which only -- for the most part -- require attention to one side of the board. SMT the process by which components are mounted directly onto the surface of the PCB. Known originally as “planar mounting,” the method was developed in the 1960s and has grown increasingly popular since the 1980s. Nowadays, virtually all electronic hardware is manufactured using SMT. It has become essential to PCB design and manufacturing, having improved the quality and performance of PCBs overall, and has reduced the costs of processing and handling greatly. The key differences between SMT and through-hole mounting are (a) SMT does not require holes to be drilled through a PCB, (b) SMT components are much smaller, and (c) SMT components can be mounted on both side of the board. Active component —1. A component which adds energy to the signal it passes. 2. A device that requires an external source of power to operate upon its input signal(s). 3. Any device that switches or amplifies by the application of low-level signals. Examples of active devices which fit one or more of the above definitions: transistors, rectifiers, diodes, amplifiers, oscillators, mechanical relays and almost all IC's Analog circuit — A circuit in which the output varies as a continuous function of the input, as contrasted with digital circuit. Anode —1. The positive element such as the plate of a vacuum tube; the element to which the principal stream of electrons flows. 2. In a cathode-ray tube, the electrodes connected to a source of positive potential. These anodes are used to concentrate and accelerate the electron beam for focusing. Aperture—1. An indexed shape with a specified x and y dimension, or line-type with a specified width, used as a basic element or object by a photoplotter in plotting geometric patterns on film. The index of the aperture is its Position (a number used in an aperture list to identify an aperture) or D code . 2. A small, thin, trapezoidal piece of plastic used to limit and shape a light source for plotting light patterns on film, and mounted in a mechanical disk called an " aperture wheel" which in turn is mounted on the lamp head of a vector photoplotter. An aperture is mostly opaque, but with a transparent portion that controls the size and shape of the light pattern. A vector photoplotter plots images from a CAD database on photographic film in a darkroom by drawing each line with a continuous lamp shined through an annular-ring aperture, and creating each shape (or pad) by flashing the lamp through a specially sized and shapedaperture. 3. A line of textual data in an aperture list describing the index names (D code and position), the shape, the usage (flash or draw) and the X and Y dimensions of an aperture. Some aperture lists leave out certain of those types of data. For example, laser photoplotters don't need to know whether an aperture is a flash or draw, so a modern-day aperture list might leave that datum out. Aperture list —1. An ASCII text data file which describes the size and shape of the apertures used by a photoplotter for any one photoplot. 2. A print-out of this file. 3. A binary version of this file. [Also called "aperture table."] Aperture wheel —A component of a Vector photoplotter , it is a metal disk having cut-outs with brackets and screw holes arranged near its rim for attaching apertures . Its center hole is attached to a motorized spindle on the lamp head of the photoplotter. When a D code denoting a particular position on the wheel is retreived from a Gerber File by the photoplotter, the wheel is caused to rotate so that the aperture in that position is placed between the lamp and the film. In preparation for a photoplotting, the aperture wheel is set up by a technician who reads a printed aperture list, selects the correct aperture from a set of them stored in a box with compartments and, using a small screw driver, installs the aperture onto the position on the wheel which is called for on the list. This process is subject to human error and is one of the disadvantages of vector photoplotters as compared with laser photoplotter. Artwork —Artwork for printed circuit design is photoplotted film (or merely the Gerber files used to drive the photoplotter), NC Drill file and documentation which are all used by a board house to manufacture a bare printed circuit board. Assembly —1. The process of positioning and soldering components to a PCB 2. Act or process of fitting together parts to make a whole. . AWG —American Wire Gauge. A PCB Designer needs to know diameters of wire gauges to properly size E-Pads. The American Wire Gauge, formerly known as the Brown and Sharpe (B + S) Gauge, originated in the wire drawing industry. The gauge is calculated so that the next largest diameter always has a cross-sectional area that is 26% greater. Assembly house —A manufacturing facility for attaching and soldering components to a printed circuit. Ball grid array — (Abbrev. BGA). A flip- chip type of package in which the internal die terminals form a grid-style array, and are in contact with solder balls ( solder bumps), which carry the electrical connection to the outside of the package. The PCB footprint will have round landing pads to which the solder balls will be soldered when the package and PCB are heated in a reflow oven. Advantages of the ball grid array package are (1) that its size is compact and (2) its leads do not get damaged in handling (unlike the formed "gull-wing" leads of a QFP' ) and thus has a long shelf life. Disadvantages of the BGA are 1) they, or their solder joints, are subject to stressrelated failure. For example, the intense vibration of rocket-powered space vehicles can pop them right off the PCB, 2) they can not be hand-soldered (they require a reflow oven), making first-article prototypes a bit more expensive to stuff, 3) except for the outer rows, the solder joints can not be visually inspected and 4) they are difficult to rework. Base —The electrode of a transistor which controls the movements of electrons or holes by means of an electric field on it. It is the element which corresponds to the control grid of an electron tube. Board —printed circuit board. Also, a CAD database which represents the layout of a printed circuit. BOM [pronounced "bomb"]—Bill of Materials. A list of components to be included on an assembly such as a printed circuit board. For a PCB the BOM must include reference designator for the components used and descriptions which uniquely identify each component. A BOM is used for ordering parts and, along with an assembly drawing, directing which parts go where when the board is stuffed. Body —The portion of an electronic component exclusive of its pins or leads. CAD —Computer Aided Design. A system where engineers create a design and see the proposed product in front of them on a graphics screen or in the form of a computer printout or plot. In electronics, the result would be a printed circuit layout. CADCAM —Simply a concatenation of the two terms CAD and CAM. CAE —Computer Assisted Engineering. In electronics work, CAE refers to schematic software packages. CAF —Conductive Anodic Filamentation (or Conductive Anodic Filament growth) - An electrical short which occurs in PCBs when a conductive filament forms in the laminate dielectric material between two adjacent conductors under an electrical bias. CAF is a potentially dangerous source of electrical failure in the PCB. As PCB designs have increased in density, with hole-to-hole spacings reduced to 25 mils or less, CAF has become an everyday concern. CAM —Computer Aided Manufacturing. CAM files — CAM means Computer Aided Manufacturing. These are the data files used directly in the manufacture of printed wiring. . The types of CAM files are 1) Gerber file, which controls a photoplotter, 2) NC Drill file, which controls an NC Drill machine and 3) fab and assembly drawings in soft form (pen-plotter files). CAM files represent the valuable final product of PCB design. They are handed off to the board house which further refines and manipulates CAM data in their processes, for example in step- and-repeat panelization. Some PCB design software companies refer to all plotter or printer files as CAM files , although some of the plots may be check plots which are not used in manufacture. Card —another name for a printed circuit board. Capture —Extract information automatically through the use of software, as opposed to hand-entering of data into a computer file. Cathode —1. In an electron tube the electrode through which a primary source of electrons enters the interelectrode space. 2. General name for any negative electrode. 3. When a semiconductor diode is biased in the forward direction, that terminal of the diode which is negative with respect to the other terminal. 4. In electrolytic plating, the workpiece being plated. CBGA —Ceramic Ball Grid Array. CEM-1 —A NEMA grade of industrial laminate having a substrate of woven glass surfaces over a cellulose paper core and a resin binder of epoxy. It has good electrical and mechanical properties, somewhat surpassed by those of FR-4. Chip-on-board —Abbreviated COB. In this technology iniegrated circuit, small portions of silicon wafers, are glued and wire bonded directly to printed circuit boards instead of first being packaged. The electronics for many massproduced toys are embeded by this system, which can be identified by the black glob of plastic sitting on the board. Underneath that glob (technical term: glob top), is a chip with fine wires bonded to both it and the landing pads on the board. Clad —A copper object on a printed circuit board. Specifying certain text items for a board to be "in clad" means that the text should be made of copper, not silkscreen Collector —1. An electrode in a transistor that collects electrons or holes. 2. In certain electron tubes, an electrode to which electrons or ions flow after they have completed their function. Component library — A representation of components as decals, stored in a computer data file which can be accessed by a PCB CAD program. Connection —One leg of a net. Also called a "pin pair" (PADS) and "from-to" (Protel). Connectivity —The intelligence inherent in PCB CAD software which maintains the correct connections between pins of components as defined by the schematic. Connector —A plug or receptacle which can be easily joined to or separated from its mate. Multiple-contact connectors join two or more conductors with others in one mechanical assembly. E-pad —"Engineering-pad." A plated-through hole or surface mount pad on a PCB placed on the board for the purpose of attaching a wire by soldering. These are usually labeled with silkscreen. E-pads are used to facilitate proto-typing, or simply because wires are used for interconnections instead of headers or terminal block. ECL —Emitter Coupled Logic. A type of unsaturated performed by emittercoupled transistors. Higher speeds may be achieved with ECL than are obtainable with standard logic circuits. ECL is costly, power hungry, and difficult to use, but it is four times faster than TTL. Electrical Object — [Protel] A graphical object (in a PCB or schematic database) to which an electrical connection can be made, such as a component pin or a wire. Emitter —An electrode on a transistor from which a flow of electrons or holes enters the region between the electrodes. EMC —electromagnetic compatibility. (1) The ability of electronic equipment to operate without degradation in an intended electromagnetic environment (2) The ability of equipment to operate in its electromagnetic environment without creating interference with other devices. . End-to-end design —a version of CADCAMCAE in which the software packages used and their inputs and outputs are integrated with each other and allow design to flow smoothly with no manual intervention necessary (other than a few keystrokes or menu selections) to get from one step to the other. Flow can occur in both directions. In the field of PCB design,end-to-end design sometimes refers to only the electronic schematic/pcb layout interface, but this is a narrow view of the potentialities of the concept. For example, end-to-end systems can also implement electronic circuit simulation, parts procurement and beyond. Excellon —NC Drill file format. An ASCII format used in a file which drives an NC Drill machine. The earliest NC Drill machines were made by Excellon Automation Company. The format is in broad use, although the company has been sold. Fab —Short for fabrication. Fabrication drawing —A drawing used to aid the construction of a printed board. It shows all of the locations of the holes to be drilled, their sizes and tolerances, dimensions of the board edges, and notes on the materials and methods to be used. Called "fab drawing" for short. It relates the board edge to at least on hole location as a reference point so that the NC Drill file can be properly lined up. FC —Flexible Circuit, flexible circuitry, flexcircuit or flex circuit. Fine line design —Printed circuit design permitting two (rarely three) traces between adjacent DIP pins. It entails the use of a either dry film solder mask or liquid photoimageable solder mask (LPI), both of which are more accurate than wet solder mask. Fine pitch —Refers to chip packages with lead pitches below 0.050". The largest pitch in this class of parts is 0.8mm, or about 0.031". Lead pitches as small as 0.5mm (0.020") are used. Finger —A gold-plated terminal of a card-edge connector. Flash —1. v. To turn a vector photoplotter lamp on for a brief but precise duration and then off, during which time the relative positions of the lamp and film remain fixed. This exposes the film with the image of a small object (the size and shape of which is controlled by the transparent portion of an aperture). 2. n. A small image on film created in such wise or as directed by a command in a Gerber file .) The maximum size (x or y dimension)for a flash varies from one photoplotting shop to another, but is commonly ½ inch. Flexible circuitry —An array of conductors bonded to a thin, flexible dielectric. It has the unique property of being a three-dimensional circuit that can be shaped in multiplanar configurations, rigidized in specific areas, and molded to backer boards for specific applications. As an interconnect, the main advantages of flex over traditional cabling are greater reliability, size and weight reduction, elimination of mechanical connectors, elimination of wiring errors, increased impedance control and signal quality, circuit simplification, greater operating temperature range, and higher circuit density. In many applications, lower cost is another advantage of using flexible circuits. Flip-chip —A mounting approach in which the chip is inverted and connected directly to the substrate rather than using the more common wire bonding technique. Examples of this kind of flip-chip mounting are beam lead and solder bump. First article —A sample part or assembly manufactured prior to the start of production for the purpose of ensuring that the manufacturer is capable of manufacturing a product which will meet the requirements. Footprint —1. The pattern and space on a board taken up by a component. FPC —Flexible Printed Circuit, FR-1 —A low-grade version of FR-2. FR-2 —A NEMA grade of Flame-Retardant industrial laminate having a substrate of paper and a resin binder of phenolic. It is suitable for printed circuit board laminate and cheaper than the woven glass fabrics such as FR-4. FR-4 —A NEMA grade of Flame-Retardent industrial laminate having a substrate of woven-glass fabric and resin binder of epoxy. FR-4 is the most common dielectric material used in the construction of PCBs in the USA. Its dielectric constant is from 4.4 to 5.2 at below-microwave frequencies. As frequency climbs over 1 GHz, the dielectric constant of FR4gradually drops. FR-6 — Fire-Retardant glass-and-polyester substrate material for electronic circuits. Inexpensive; popular for automobile electronics. [Stammtisch Beau Fleuve Acronyms . Gerber file —ASCII data file used to control a photoplotter. Named after H. Joseph Gerber, founder of Gerber Scientific Co., who invented the original vector photoplotter. Header —The portion of a connector assembly which is mounted on a printed circuit. Hole —In a semiconductor, the term used to describe the absence of an electron; has the same electrical properties as an electron except that it carries a positive charge. Integrated circuit —1)miniaturized electronic circuit that has been manufactured as a chip(die). 2)A packaged chip. IPC —The Institute for Interconnecting and Packaging Electronic Circuits, the final American authority on how to design and manufacture printed wiring. In 1999, IPC changed its name from Institute of Interconnecting and Packaging Electronic Circuits to IPC. The new name is accompanied with an identity statement, Association Connecting Electronics Industries. MELF (Metal Electrode Face Bonded): Consisting of two terminals bonded to a cylindrical body, these SMD components are less expensive than flat chips but require special handing during assembly. Furthermore, one of their biggest disadvantages is their tendency to roll off solder pads during assembly. Generally speaking, they come in the form of diodes, resistors, and capacitors. SOT Transistors and Diodes: These are usually rectangular and easy to place, though they're a bit outdated. The most common SOTs are SOT 23, SOT 89, SOT 143, and SOT 223. Its most common packaging is tape & reel. Small outline Integrated Circuit (SOIC) – These are good SMT alternatives to the duel in-line package (DIP), due to their dramatically reduced size. In general, they take up 30 – 50% less space and 70% less thickness than an average DIP. Thin Small Outline Package (TSOP) – TSOPs are low profile packages with fine-pitch leads. TSOPs are typically meant to accommodate large silicon chips in high density packages (RAM or flash memory ICs), largely because of their low volume/high pin count. Plastic Leaded Chip Carrier (PLCC) - Connections are made on all four edges of a square package with a relatively high pin count. PLCCs can have roughly 18 – 100 leads (usually J-leads). Many of them can fit into IC sockets and can be easily replaced in the field. PLCCs have long been a popular option. Lead-less Chip Carrier (LCC) – Not to be confused with PLCC, LCCs have no leads. Rather, LCCs are soldered directly onto PCBs by their (castellation) solder pads. These are usually designed for Mil Spec because, with no leads to damage, they're quite "rugged." LCCs are great for high temperature and aerospace applications. Quad Flat Pack (QFN) – QFNs are high lead count packages (44 – 304). Its leads are typically gull wing. There are many kinds of QFNs, and they are one of the most common surfacemount ICs. Pin Grid Array (PGA) – PGAs are typically square or rectangular, with pins arranged underneath the package. They're design was highly influential on the now ubiquitous BGA. Flip Chip – Flip chips are bare die packages, with small bottom-side solder bumps that act as leads. They are soldered directly onto the PCB. Ball Grid Array (BGA) – BGAs are perhaps one of the best performing SMT packages in use today, due to their high densities. The BGA is a descendent of the PGA, yet instead of pins, it has solder balls that can be placed directly onto the PCB. Because of their high density, BGAs are typically used to house microprocessors. Advantages: SMT allows for smaller PCB size, higher component density, and more real estate to work with. Because fewer drilling holes are required, SMT allows for lower cost and faster production time. During assembly, SMT components can be placed at rates of thousands—even tens of thousands—of placements per hour, versus less than a thousand for THM. Solder joint formation is much more reliable and repeatable using programmed reflow ovens versus through techniques. SMT has proven to be more stable and better performing in shake and vibration conditions. Disadvantages: SMT can be unreliable when used as the sole attachment method for components subject to mechanical stress (i.e. external devices that are frequently attached or detached). 1. As SMC are small in size they take less space in comparison to through hole. 2. Pin count of component is increased greatly in SMT as compared to old through hole for example the micro process used today in computers PGA, FPGA etc. 3. SMC is leadless component and can be directly mounted on board surface while through hole components required drilling to mount the components. 4. The pads on the surface in SMT are not used for connection of layers on the printed wiring boards. 5. Size of through hole component is large in comparison to SMC there component density per unit area is more in through hole component result in large size of Printed circuit board. 6. In SMT, components can be mounted on both side of PCB, this is not possible in through hole. Therefore SMC has made application possible which seems impossible with through hole. 8. With the help of SMC higher performance circuit can be made in small size which is prime requirement today. 9. Soldering of SMC is quite tough through manual soldering. Hence machines are required therefore big capital investment is required. 10. Designing, production, skills and technology required in SMT is very advance as compared to through hole technology. 11. Through hole technology is basically used in prototyping. 12. Soldering and de-soldering of through hole component is easy in comparison to SMT. Hence replacement of component is easy. When you give a PCB for fabrication, you need to specify details on PCB materials, impedance controls, finish, copper thickness and so on. Most of the details are so common that they are always assumed. However still it is better to know them. Previous slide is a screenshot of quotation submitted by a fabricator for a PCB design of size 9.870 X 9.830 cm Let us understand each term one by one and things related to them 1) 4 layers specifies NUMBER OF LAYERS - This means the number of conducting layers. The layers may be either routing layer or plane layer. The commonly used no. of layers are 1, 2, 4, 6, 8 and other even numbered layers. Odd number layer boards may be formed but they are not standard boards and doesn’t offer any savings. The PCB materials used for 3 or 4 layers would almost be same. Routing layers contains tracks while plane layer are generally used to connect power or ground. Plane layers have plane of copper from which connections are drawn up or down wherever needed. Islands can be formed on plane layers and each island may have different signal. Suppose some sets of chips on one board use 3.3 V while other use 5 V then the power plane may be partitioned into two islands of 3.3 V and 5 V. 2) FR4 specifies PCB MATERIAL TYPE – FR4 is other name for “Glass reinforced epoxy laminated sheets”. It is a commonly used PCB material. The reasons for its ubiquity as a PCB material are its high dielectric strength, high mechanical strength, light weight, resistance to moisture and other properties conducive for PCB manufacturing. FR in FR4 stands for “fire retardant”, another feather in this PCB material’s cap. 3) 1.6 mm thick specifies FINISHED BOARD THICKNESS – In multilayer PCB it is thickness after all layers have been pressed together and all the processes completed. 1.6mm is default thickness for 4 layer board. Go for higher thickness if you have heavy components on board to get better strength. Keep an eye on thickness even when you have high voltages on board. 4) 35 microns copper finish – The thickness of copper put on board. Another popular way to express is in grams or Oz. (Ounces per square foot) of copper per unit area. X Oz would mean that X Ounces were spread on the Board material and it was distributed uniformly over an area of 1 square foot.Go for higher copper thickness if the current density on board is greater than in average digital circuits. In normal boards 35 microns is good. Up till a current of 1A and copper thickness of 1 Oz, track width of 10 mils is safe. 5) No impedance Control – When signal transition time is too small or frequency is too high then tracks may behave as transmission lines. If unchecked, such tracks may cause significant power loss. For maximum power to be transferred to other end of track, length and geometry of the track should be carefully laid taking care of transmission line equations. As a rule of thumb, if the board is of FR4 PCB material with copper tracks and signal rise time is 1 nanosecond then 2 inches is a safe distance. If the track length exceeds this and signal integrity is important then consider the transmission line effects also. There are lot of free programs and excel sheet available on net that calculate impedances for prevalent geometries. If impedance control has been mentioned to the fabricator then an extra test is done on the completed PCB to check the required impedances 6) No Via Filling – Normally vias are not filled and you clearly see other side of the board through them. However, they can be filled for various reasons. One need arises when vias are to be protected from solutions, dust etc. Vias can also be filled with conducting materials to increase the current carrying capacity of via. One more reason is to level the board. Via filling is needed many a times on boards with BGA (Ball Grid array) components. If BGA pins make contact with one of the inner layer then the via can’t be placed just underneath the pin because then the solder may flow in the hole and get connected to some other layer. So Via filling is done so that solder doesn’t flow in the via and contacts are properly connected. 7) No gold tabs – At any place on the board when something makes and breaks contact repeatedly then that area wears out fast. Example is a rubber pushbutton which has contacts printed on the board. An example is the kind of buttons used in calculator. This wearing out also happens when daughter card slot are provided on main board. The contacts on this slot are rubbed when card is pushed in or out. In such cases it is wise to put gold layer on the surface which makes contact. This enhances life of the contact. A separate step is added in the PCB fabrication process if gold tabs are specified. Also remember gold is costly. 8) Green gloss (LPISM) soldermask - The first image that would come to your mind when you think of PCB is a green colour board with some shining metal contacts and some holes. The green colour is because of this soldermask. Now why is soldermask used?? Solder mask prevents spilling of liquid solder. This spilling has become a serious problem in recent times. As the pitch of the IC pins has decreased, due to this spilling the pins get shorted. To feel the miracle of soldermask, try to solder a board which doesn’t have solder mask (mostly a homemade PCB won’t have) and the one which has solder mask. You will feel a huge difference. This experience made me enjoy soldering which I hated earlier. LPISM stands for Liquid Photo imageable solder mask. It is a type of soldermask. There are soldermasks available in other colours as well. Prevalent among them are Red and blue. 10) Line Width / Spacing : 6/6 mils – This means the minimum track width would be 6 mils and minimum spading between tracks, tracks and pads and all other spacings should be greater than or equal to 6 mils. In case you don’t know mils, It is the prevalent unit of distance used in PCB world. 1 mil = 1/1000th of an inch = .0254mm. Take care of width and spacing when higher currents and voltages are expected on board. 11) Electrical test, routed – In multilayer PCB, It is not possible to do visual inspection of all the tracks for their correctness. So this test is done. Test probes are put at the end of tracks or on pads such that signals on it can be accessible. A small voltage is applied on one such probe. If that voltage is detected at the other end, it confirms that the tracks are proper. This step may not be necessary in 1 or 2 layer board but if you don’t want to compromise on quality, get this test done. 12) PCB Material-Isola 370HR-High Tg : Isola is a famous company for PCB materials and 370HR is one of their product’s name. This is an FR4 PCB material. This PCB material in addition to FR4 properties has additional advantages like superior thermal performance which helps in dissipating heat on board. The mechanical, chemical and moisture resistance properties all equal or exceed the performance of traditional FR-4 materials. “High Tg” stands for “high glass transition temperature”. This means that the PCB made of this material can sustain high temperatures. During HASL or soldering, PCBs have to sustain high temperatures and that’s where this parameter becomes important. 13) No Blind/Buried Vias – Blind Vias are those vias which join one of the outer layers (TOP or BOTTOM) with one of the inner layers. Since this via can be seen from only one side, it is called a blind via (This may not seem logical but just remember itJ). Buried vias are vias which connect one of the inner layers to another inner layer. This vias cannot be seen from any of the outer layer and hence is called buried vias. (Aha!! This is logical) Via filling as we studied above is used many a times when blind/buried vias are used. It helps level the surface just above via so that pads/tracks can be placed over the vias without the solder penetrating in.