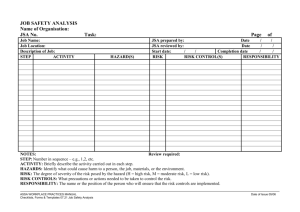

JSA (Mechanical Jobs)

advertisement

Sheet 2: Sheet1 Job Safety Analysis Main activity : Vehicle Entry inside the plant for loading/unloading material Plant : JSA Sheet No: 1 Date of JSA : S No 1 Sub Activity Preparation & Checking 2 Entry inside plant Hazards & Risks Fire explosion due to spark generated Control Measures to be implemented Vehicle must have a valid permit for entry inside red roads. Vehicle must be certified for use by P&M department. Driver must have safe driving licence. Spark Arrestor must be healthy Check LEL inproposed route of vehicle Switch off engine and evacuate if F&G Alarm is sounded Vehicle will move at speed of less than 10kmph. Vehicle will not enter paved area of plant; if such an entry is required, necessary permission from plant ______________/production ______________ will be necessary. Damage to work place Identify all pits near to the route, due to hitting against barricade/highlight if required. pipe/equipment Use wheel jammers to avoid accidental movement of vehicle Keep vehicle on gear when parked. Do not leave vehicle unattended when parked near plant & machinery. Follow vehicle entry procedure. Do not allow people to move in route of vehicle Vehicle reverse horn must be working and an Injury to people around assisstant must guide reversing. Use correct tools. Use mandatory PPEs 3 Loading/Unloading of material 4 All Sub Activities (1-3) Do not use bare handsd to handle heavy material. Injury to people during Use crane/Hydra wherever required. material handling Do not drop material from height Use correct lifting/lowering devices. Use correct tools. Use propper PPEs. Physical Injury while working Use correct tools. Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 3: Sheet2 Job Safety Analysis Main activity : PM of Pumps Plant : JSA Sheet No: Date of JSA : S No Sub Activity Hazards & Risks Coupling guard removal 1 and checking pump free rotation Injury during pump Foundation bolt tightness dismantling due to 2 checking improper electrical isolation 3 Checking tightness of thrower grub screw Control Measures to be implemented Electrical isolation will be done from substation. Electrical isolation tag shall be available with the permit. Field engineer shall cross check isolation by pressing start button before commencing of job 4 Cleaning of the breather Checking Coupling 5 condition 6 Checking Lube oil/seal oil/greasing 7 Casing bolt tightness checking 8 Checking seal flush line for choking & cleaning Physical injury to workers Use correct tools. Use mandatory PPEs Health hazard due to handling grease/oil (long exposure) Use Chemical resistant gloves. Wash hands after job Exposure to toxic gases/HC Draining of equipment will be required Physical Injury while working Use correct tools Use mandatory PPEs. Checking cooling water 9 line for choking & cleaning 10 All Sub Activities (1-9) Done by : Name :______________________________ Designation: AM Sign __________________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 4: Sheet3 Job Safety Analysis Main activity : PM/Maintenance of Fin Fans Plant : JSA Sheet No: 1 Date of JSA : S No Sub Activity 1 Opening Safety guard of fan 2 Foundation bolt tightness checking Checking tightness of 3 thrower grub screw 4 Cleaning of the breather Working inside fin 5 fan plenum chamber Hazards & Risks Control Measures to be implemented Injury due to movement of fan Electrical isolation will be done from substation. Follow LOTO procedue. Electrical isolation tag shall be available with the permit. Field engineer shall cross check isolation by pressing start button. Despite electrical isolation fan might move due to wind velocity, to arrest such movement, tie fan blades or provide mechanical lock. Exposure to noise Use ear plugs. Use mandatory PPEs Hazards of confined space (Fire O2 deficiency, Toxic Substances) Follow Confined space entry procedure Check O2 level at fixed intervals and note down the same in permit Ensure presence of standby persons all the time Ensure entry & exit record of persons Fall from height Use platform to go inside plenum chamber Heat stress due to hot pipes/equipment Drink water at regular intervals Avoid going near finned tubes Persons to come out at regular intervals 6 Greasing of bearings health hazard due to handling oil & grease Use Chemical resistant gloves. Wash hands after job 7 All Sub Activities (1-6) Physical Injury while working Use correct tools Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign _________________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 5: Sheet4 Job Safety Analysis Main activity : Insulation Removal and Refixing Plant : JSA Sheet No: 1 Date of JSA : S Sub Activity No 1 2 Cladding Removal Insulation Removal Insulation 3 Refixing 4 Cladding Refixing Hazards & Risks Control Measures to be implemented Injury due to use of sharp equipment and sharp edges of cladding sheet Use proper tools for cutting/bending. Tie or keep weight on cladding removed to prevent flying off Health Hazard due to exposure to insulation material Insulation material is injurious to health Use dust mask, gloves, and full body apron for handling. Fire (oil soaked insulation fire) Insulation being removed might be oil soaked and may catch fire when exposed to air. Check that it is free from oil. Keep fire extinguisher ready if oil is present Injury/Leakage due to insulation material falling from height Do not collect insulation material in too large bags which make handling difficult. Use rope to lower bags of collected insulation material. Keep area underneath barricaded Burn due to contact with hot surfaces Pipeline/equipment inside will be hot use leather gloves. Health Hazard due to exposure to insulation material Insulation material is injurious to health Use dust mask, gloves, and full body apron for handling. Burn due to contact with hot surfaces Pipeline/equipment inside will be hot use leather gloves. Injury due to use of sharp equipment and sharp edges of cladding sheet Use proper tools for cutting/bending. Tie or keep weight on cladding removed to prevent flying off Use certified scaffolding/hydraulic platforms/troleys with wheel lock Area must be barricaded. No superfluous material All Sub to be kept at work site 5 Activities (1- Injury due to fall from height Use tray for small tools 4) Tools, tackles etc are not to be carried with hands while climbing; use pouch,belt, other lifting/lowering device Ladder must be free of oil/grease and must be firmly placed to prevent slip Ladder to be provided perpendicular to the working platform wherever possible Gloves with good gripmust be used while climbing While climbing always maintain 3 point contact Physical Injury while working Use correct tools. Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 6: Sheet5 Job Safety Analysis Main activity : PM of Steam Turbines Plant : JSA Sheet No: 1 Date of JSA : S No 1 Sub Activity Hazards & Risks Isolation of the turbine and depressurization Coupling guard removal and Physical injury during decoupling due to decoupling improper isolation Checking free rotation of 3 turbine rotor 2 Checking the tightness of 4 foundation bolts and supports Control Measures to be implemented Isolate inlet and outlet of the turbine and depressurize through drain lines Check that the turbine is in unlatched condition Provide chain lock to steam inlet and outlet isolation valves Injury due to improper tools Use correct tools. 5 Check LO 6 Check trip function correctness 7 Flush governer & check for leakage 8 Check freeness of governing Burn Injury system arm link 9 Check freeness of control valve spindle 10 Check Coupling condition 11 Check for steam leakage 12 All Sub Activities (1-11) Use full body aprons Stay away from hot lines Health Hazard dur to handling oil/grease Use Chemical resistant gloves. Wash hands after job Physical Injury while working Use correct tools Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 7: Sheet6 Job Safety Analysis Main activity : Pump seal/bearing replacement/overhauling Plant : JSA Sheet No: 1 Date of JSA : S No Sub Activity Hazards & Risks Control Measures to be implemented Exposure to HC/Toxic gas release due to improper isolation Isolation procedure will be planned,reviewed and implemented by FS/FE. All valves will be tight closed and tagged Remote and local push buttons of XV should be in stopped condition (if applicable) Lock to be provided for suction and disc XVs (if applicable) Ensure no hot work is in progress in radius of 15m Injury /Electric Shock during pump dismantling due to improper electrical isolation Electrical isolation to be done from substation Electrical isolation tag should be available with permit FE shall crosscheck isolation by pressing start button before commencement of job LOTO procedure to be followed. Preparing the pump for handover. 1 Electrical & Mechanical isolations Wherever possible draining/venting wil be done to closed system/flare. Completion of draining to be Exposure to HC/Toxic ensured by checking the level rise 2 Draining of pump holdup liquid release fue to improper in CBD vessels. draining methods Ensure with open drain with help of personal H2S meter If hot service allow sufficient time to cool after isolation Blinding of pump 3 suction/discharge lines and seal flush lines Exposure to HC/Toxic release due to holdup material or passing valve Stay in upwind direction FE will physically show the correct flange to be opened First loosen the flange on the side away from the body, check for any leakage. Use LEL/H2S detectors. If valve seems passing immediately tighten the flange. Keep arrangement (tray/bucket) ready for collecting oil Check seal pot level has been fully drained Keep cartridge mask ready for escape If holdup material is expected to be more (for gas services) use airline mask Use full body apron, gloves and mask Fire hazard due to holdup material falling on hot lines Collect holdup oil in trays Use wet blankets over hot surfaces Fire due to oil soaking insulation Don’t allow oil into insulation Check that the insulation cladding faces/ends are not damaged Remove oil soaked insulation after the job Injury due to improper tool/lifting methods Use certified and right capacity slings/chains (if required) Use spanner tied with strings Protect SBCs nearby during lowering Do not engage too many persons Use correct hand tools Injury during pump Pump Coupling guard removal dismantling due to 4 and decoupling improper electrical isolation Pump Removal/Opening: Injury to workers Coupling hub removal Opening bearing housing and 5 bearing removal Dismantling seal assembly Health hazard due to Cleaning of seal flush lines handling oil/grease See Sno 1 Use correct tools Use mandatory PPEs. Proper lifting procedure to be followed if applicable Use Chemical resistant gloves. Wash hands after job Dispose all oily rags in accordance with procedure Pump Assembling installation, deblinding, warm-up, 6 alignment, checking & coupling As above All Above control applies 7 All Sub Activities (1-6) Physical Injury while working Use correct tools. Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 8: Sheet7 Job Safety Analysis Main activity : Pump Decoupling for motor replacement etc Plant : JSA Sheet No: 1 Date of JSA : S No Sub Activity Pump coupling guard 1 removal and decoupling Pump Alignment 2 Checking and coupling after job completion 3 All Sub Activities (1-2) Done by : Hazards & Risks Control Measures to be implemented Injury during pump dismantling due to improper electrical isolation Electrical isolation to be done from substation Electrical isolation tag should be available with permit FE shall crosscheck isolation by pressing start button before commencement of job. LOTO procedure to be followed. Injury to workers Use correct tools. Use mandatory PPEs. Proper lifting procedure to be followed if applicable Health hazard due to handling oil/grease Use Chemical resistant gloves. Wash hands after job Dispose all oily rags in accordance with procedure Electrical isolation to be done from substation Injury during pump Electrical isolation tag should be couplingdue to improper available with permit electrical isolation FE shall crosscheck isolation by pressing start button before commencement of job. LOTO procedure to be followed. Injury to workers Use correct tools. Use mandatory PPEs. Proper lifting procedure to be followed if applicable Health hazard due to handling oil/grease Use Chemical resistant gloves. Wash hands after job Dispose all oily rags in accordance with procedure Physical Injury while working Use correct tools. Use mandatory PPEs. Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 9: Sheet8 Job Safety Analysis Main activity : Hose connection & Disconnection Plant : JSA Sheet No: 1 Date of JSA : S No 1 Sub Activity End blind removal from line Hazards & Risks Asphyxiation due to exposure of Nitrogen Control Measures to be implemented Ensure isolation valve is tightly closed Stay in upwind direction First loosen the flange on the side away from the body, check for any leakage. Keep escape route clear use airline mask if the valve is suspected passing Tie hose with static object. Use standard Connection of hose Injury to persons due and correct tools 2 between nitrogen line and to improper tools and Rated hoses are to be used during process location hitting of hose purges and are to be fastened to platform or railing 3 Depressurisation and disconnection of hose Asphyxiation due to exposure of Nitrogen Ensure isolation valve is tightly closed. Stay in upwind direction First loosen the flange on the side away from the body, and allow it to depressurize. Do not engage more persons use airline mask if the valve is suspected passing 4 Execution of job at height Injury due to fall from (if applicable) height 5 All Sub Activities (1-4) Physical Injury while working Use certified scaffolding/hydraulic platforms/troleys with wheel lock Area must be barricaded. No superfluous material to be kept at work site Use tray for small tools Tools, tackles etc are not to be carried with hands while climbing; use pouch,belt, other lifting/lowering device Ladder must be free of oil/grease and must be firmly placed to prevent slip Ladder to be provided perpendicular to the working platform wherever possible Gloves with good gripmust be used while climbing While climbing always maintain 3 point contact Use correct tools. Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 10: Sheet9 Job Safety Analysis Main activity : Blinding/Deblinding Job Plant : JSA Sheet No: 1 Date of JSA : S No 1 2 Sub Activity Hazards & Risks Asphyxiation due to exposure of Nitrogen Ensure the valves are tightly closed and tagged; LOTO procedure to be followed. Ensure the line is depressurised. Stay in upwind direction. FE to physically show correct flange to be opened First loosen the flange on side away from body, check for any leakage Keep escape route clear. Use airline mask. Do not engage too many persons Injury due to improper tool/lifting methods Only standard and approved blinds to be used with complete bolting and new gaskets. Use certified and right capacity slings/ chains (if required). Use spanner tied with strings. Protect SBCs nearby during lowering. Use standard hand tools Opening of flanges and blind removal/installation Execution of job at height Injury due to fall (if applicable) from height 3 All Sub Activities (1-2) Control Measures to be implemented Physical Injury while working Use certified scaffolding/hydraulic platforms/troleys with wheel lock Area must be barricaded. No superfluous material to be kept at work site Use tray for small tools Tools, tackles etc are not to be carried with hands while climbing; use pouch,belt, other lifting/lowering device Ladder must be free of oil/grease and must be firmly placed to prevent slip Ladder to be provided perpendicular to the working platform wherever possible Gloves with good gripmust be used while climbing While climbing always maintain 3 point contact Use correct tools. Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 11: Sheet10 Job Safety Analysis Main activity : Flange tightening in loop under pressure test with Nitrogen Plant : JSA Sheet No: 1 Date of JSA : S No Sub Activity Hazards & Risks Control Measures to be implemented Stay in upwind direction. FE to physically show correct flange to be opened Asphyxiation due to First loosen the flange on side away from body, exposure of Nitrogen check for any leakage 1 Tightening of flanges Keep escape route clear. Use airline mask Do not engage too many persons Injury due to improper tool Execution of job at 2 height (if applicable) 3 All Sub Activities (12) Use spanner tied with strings. Protect SBCs nearby during lowering. Use standard hand tools Use certified scaffolding/hydraulic platforms/troleys with wheel lock Area must be barricaded. No superfluous material to be kept at work site Use tray for small tools Tools, tackles etc are not to be carried with hands while climbing; use pouch,belt, other Injury due to fall from lifting/lowering device height Ladder must be free of oil/grease and must be firmly placed to prevent slip Ladder to be provided perpendicular to the working platform wherever possible Gloves with good gripmust be used while climbing While climbing always maintain 3 point contact Physical Injury while working Use correct tools. Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 12: Sheet11 Job Safety Analysis Main activity : PSV Removal/Fixing Plant : JSA Sheet No: 1 Date of JSA : S No Sub Activity Opening the 1 flanges for PSV removal Hazards & Risks Control Measures to be implemented Stay in upwind direction FE will physically show the correct flange to be opened First loosen the flange on the side away from the body, check for any leakage. Use LEL/H2S detectors. If valve seems passing immediately tighten Exposure to HC/Toxic the flange. Keep arrangement (tray/bucket) release due to holdup ready for collecting oil material or passing valves Keep tray/bucket ready for collecting oil. Keep cartridge mask ready for escape If holdup material is expected to be more (for gas services) use airline mask Use full body apron, gloves and mask Ensure Checklist is filled for PSV droppng and follow SOP Collect holdup oil in trays. Use wet blankets Fire hazrad due to holdup over hot surfaces material falling on hot Keep fire hose ready and continuously wet lines (if applicable) the line expecting pyrophoric materila inside 2 Blinding Fire (oil soaked insulation fire) Insulation being removed might be oil soaked and may catch fire when exposed to air. Check that it is free from oil. Keep fire extinguisher ready if oil is present Check that the insulation cladding faces/ends are not damaged Injury due to improper tool/lifting methods Use job specific standard tools and PPEs Injury due to improper tool/lifting methods Only standard and approved blinds to be used with complete bolting and new gaskets. Use standard tools Injury/Property damage 3 PSV Dropping/Lifting due to improper lifting methods 4 End blind removal from flanges Use certified and right capacity slings/chains Ensure that valves are tightly closed and tagged follow LOTO procedure Ensure line is depressurised and drained Stay in upwind direction FE will physically show the correct flange to be opened First loosen the flange on the side away from the body, check for any leakage. Use Exposure to HC/Toxic LEL/H2S detectors. release due to holdup If valve seems passing immediately tighten material or passing valves the flange. Keep arrangement (tray/bucket) ready for collecting oil Keep tray/bucket ready for collecting oil Keep cartridge mask ready for escape If holdup material is expected to be more (for gas services) use airline mask Use full body apron, gloves and mask Ensure Checklist is filled for PSV droppng and follow SOP Collect holdup oil in trays. Use wet blankets Fire hazrad due to holdup over hot surfaces material falling on hot Keep fire hose ready and continuously wet lines (if applicable) the line expecting pyrophoric materila inside Fire (oil soaked insulation fire) Insulation being removed might be oil soaked and may catch fire when exposed to air. Check that it is free from oil. Keep fire extinguisher ready if oil is present Check that the insulation cladding faces/ends are not damaged Injury due to improper tool/lifting methods Use job specific standard tools and PPEs 5 PSV Boxup 6 Injury due to improper tool/lifting methods All Sub Activities (1- Physical Injury while 5) working Do not use finger to align the flange holes. Use standard tools Ensure the rating of gaskets Use correct tools. Use mandatory PPEs. Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 13: Sheet12 Job Safety Analysis sheet BLINDING & DEBLINDING Plant : JSA Sheet No: 1 Date of JSA : S. No. 1 Sub Activity Opeing of flanges and blind removal / installation Hazards and Risks Control measure to be implemented Ensure the valves are tightly closed and tagged. Follow LOTO Ensure the line is depressurised, properly drained, Pruged,flushed Exposure to HC/Toxic Ensure there is no condensate pocket left release due to holdup after steam out. material or passing valves Stay in upwind direction. Execute will physically show the correct flange to be opened First loosen the flange on side away from the body, Check for any leakage. Use LEL/H2S detectors if seems like passing valve, immediately tighten the flange Keep arrangement (tray? Bucket) ready for collecting oil keep cartage mask ready for escape. Use full bodyappron,gloves and goggles if hold up material is expected to be more (for gas service) use air line mask Only standard and approved blinds to be used with complete bolting and new gaskets Fire hazard due to holdup Collect holdup oil trays. Use wet blankets material falling on hot over hot trays. Ensure no hot work in 15 lines meter radius fire due to Oil soaking insulation Don not allow oil into insulation. check that the insulation cladding faces/ends are not damaged Injury due to improper tool/lifting method Use certified and right capacity slings/chain (if require) Use spanner tied with strings. Protect SBCs nearby during lowering Do not engage too many person. Use correct hand tools 2 Execution of job at Injury due to fall from height (if Applicable) height (if applicable) Use certified scaffolding/hydraulic platforms/trolleys with lock Area must be barricaded. No superfluous material to be kept at work site. Use tray for small tools. Tools, tackles etc. are not to be carried with hands climbing. Use pouch, belt or other lifting/lowering devices. Ladder must be freet of oil/grease and must be firmly placed to prevent slip Ladder to be provided perpendicular to the working platform wherever possible gloves with good grip must be used while climbing. 3 All sub activities(1-2) Physical Injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 14: Sheet13 Job Safety Analysis sheet Main activity : Buffing (Power Brush) for Surface Cleaning Plant : JSA Sheet No: 1 Date of JSA : S. No. Sub Activity Hazards and Risks Control measure to be implemented Use certified scaffolding/Hydraulic Injury due to from height platforms/trolleys with wheel lock (if Applicable) Use safety full body harness (this shall apply when job is at height and to all sub activates) Electrical Shock Hazards 1 Buffing of Surfaces Electrical machine must be certified by competent authority and have valid certificate All electrical connections to be crosschecked for loose fittings etc. Earthing of the equipment must be done. check expiry date of the wheel before fixing new wheel always run the wheel for one minute idle, while fixing the new wheel for the first time. Injury due to breakage of Always take a ring test for vitrified before mounting grinding wheel a new wheel Always store the buffing wheels properly Never stand in straight line of buffing wheel. Use the special spanner for tightening the wheel LET must be checked in the area periodically Fire Hazards due possible DCP cylinder to be kept ready for use. (Hot work spark generation permit require) Exposure to noise Wear earplug, as while grinding noise level will go beyond 85 dB Health hazards due to dust Use Dust mask 2 All sub activities Physical Injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 15: Sheet14 Job Safety Analysis sheet Main activity : Hot Bolting of pipe line/equipment Flanges Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. 1 Hot bolting of flanges Hazards and Risks Control measure to be implemented Hot burns/heat stress due to working on hot flanges Flanges may be hot, leather gloves and full body aprons must be used Adequate drinking water must be available and people at work are to be rotated Exposure to Hot HC vapor release/toxic gas release Do not overtight or loosen the flange bolts to the extent or leak Loosen/fasten only one bolt at a time Job to be done under complete supervision. Keep escape route clesr Struck by (Insury) working tools Use standard tools. Use rope strings for holding spanner Use Correct and without damage sling/rope to lower elbow Execution of job 2 height (if applicable) 3 Injury due to fall from height (if applicable) All sub activities (1- Physical Injury while 2) working Use certified scaffolding/hydraulic platforms/trolleys with wheel lock Area must be barricaded. No superfluous material to be kept at work site. Use tray for small tools. Tools, tackles etc. are not be carried with hands while climbing. Use pouch, belt or other lifting/lowering device Ladder must be free of oil/grease and must be firmly placed to prevent slip Ladder to be provided perpendicular to the working platform wherever possible Gloves with good grip must be used while climbing while climbing maintain 3 point contract always Use Correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 16: Sheet15 Job Safety Analysis sheet Main activity : Scaffolding Removal Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity Hazards and Risks Control measure to be implemented No. 1 Damage to workplace due to hitting on pipes, specially SBCs Scaffolding material which removed should not block escape route All SBSs at work locaiton must be identified Depending on critically, SBC may be marked by wraping with barricading tape Adequate care must be taken to avoid hitting on SBCs. Do not kept pipes/clamps over the cable trays Injury due to fall (slip/trip) while climbing up/down Tools,tackles etc are not to be carried with hands while climbing up/down. Use pouch, belt or other lifting/lowering device. Ladder must be free of oil/grease. Do not use scaffolding braces for climbing down, Use ladders Gloves with good grip must be used while climbing up/down Use safety belt during climbing up or down ladder Sturck (injury) by falling objects Standard lifting procedure to be used for lifting/lowering objects Scaffolding rods/planks should not be manually shifted. Do not keep planks loose at height No person to be allowed to stand under weight being lefted. Area must be barricaded If scaffoling removal is above normal walkways, use safety net Injury due to fall (slip/trip) from the worklocation Use safety full body harness Injury due to sudden collapse of scaffolding Ensure proper tightening of bolts and nuts and follow sequence of dismantling( dismantling should be done from top) Removal of Scaffolding Use trolly for shifting the scaffolding material. Do not use bare hands. Shifting of Injury due to improper For shifting scaffolding material from height eg, 2 scaffolding material handling coke drum structure , use rope and pully after dismentaling arrrangement with sufficient manning and barricading; tie rodsproperly to avoid slips Injury due to improper Materials to be kept at one location away from keeping walking area. Area to be barricated. 3 All sub activities (1- Physical Injury while 2) working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 17: Sheet16 Job Safety Analysis sheet Main activity : Scaffolding Erection / Modification Plant : JSA Sheet No: 1 Date of JSA : S. No. Sub Activity Shifting of 1 scaffolding material 2 Erection of Scaffolding Hazards and Risks Control measure to be implemented Injury due to improper handling Use trolley the scaffolding material. Do not use bare hands For shifting scaffolding material to height eg, Coke drum structure, use rope and pully arrangement with sufficient manning and barricading; tie rods properly to avoid slips injury due to improper house keeping Material to be kept at one location away from walking area. Area to be barricaded. Scaffolding erected should not block identified escape routes of the plant All SBCs work location must be identified Depending on critically, SBC may be marked Damage to workplace due by wrapping with barricading tape to hitting/climbing on Adequate care must be taken to avoid hitting pipes, specially SBCs on SBCs Scaffolding pipes must be at least 6" away form all SBCs and process line Do not kept pipes/clamps over the cable trays Injury due to fall (Slip/trip) while climbing up tools, tackles etc. are not to be carried with hands while climbing. Use pouch, belt or other lifting device. Ladder must be free of Oil/grease Do not use Scaffolding branches for climbing up, use ladders Gloves with good grip must be used while climbing. 3 All sub activities (1-2) Struck (Injury) be falling objects Standard lifting procedure to be used for lifting objects Scaffolding rods/planks should not be manually shifted (do not shift with hands alone). Do not keep planks loose at height. Area must be barricaded No persons to be allowed to stand under weight being lifted if Scaffolding errection is above normal walkways, use safety net injury due to fall (Slip/trip) from the work location Use Safety full body harness injury due to sudden collapse of incomplete Scaffolding Ensure proper tightening of bolts and nuts and follow sequence of erection. Physical Injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 18: Sheet17 Job Safety Analysis sheet Main activity : PM of ID/FD fan Plant : JSA Sheet No: 1 Date of JSA : S. No. Sub Activity Coupling guard removal and 1 checking rotor free rotation Hazards and Risks Injury during decouplinf of fan due to improper electrical isolation Control measure to be implemented Electrical isolation will be done from substation Electrical Isolation tag shall be available with the permit Operator shall cross check isolation by pressing start button before commencing of the job 2 Foundation bolt tightness checking Electrical isolation will be done from substation Injury during Electrical Isolation tag shall be available with the decouplinf of fan due permit Operator shall cross check isolation by to improper electrical pressing start button before commencing of the isolation job 3 Cleaning of the breather Physical injury while working and due to fall from height Use correct tools. Use mandatory PPEs. Use platform to approach 4 Physical injury while Checking coupling working and due to condition at height fall from height Use correct tools. Use mandatory PPEs. Use platform to approach Checking lube oil / 5 seal oil / greasing Health hazards (Long term exposure) due Use chemical resistant hand gloves. Wash hand to handling of oil / properly after the job grease Casing bolt 6 tightness checking Health hazards (Long term exposure) due Use chemical resistant hand gloves. Wash hand to handling of oil / properly after the job grease Checking damper 7 freeness and greasing Health hazards (Long term exposure) due Use chemical resistant hand gloves. Wash hand to handling of oil / properly after the job grease Checking cooling water line for 8 choking and cleaning Health hazards (Long term exposure) due Use chemical resistant hand gloves. Wash hand to handling of oil / properly after the job grease 9 All sub activities (18) Physical injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 19: Sheet18 Job Safety Analysis sheet Main activity : Hydrojetting of heater transfer line Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. 1 2 Line preparation before hand over Hazards and Risks Control measure to be implemented System/loop must be completely isolated, tagged, de-pressurized, drained, blinded, steam/water flushed before handing it over for HJ. Also ensure required elbows Exposure to H2S. Steam flash have been dropped and kept tied in safe due to improper isolation location Ensure all purge steam are isolated Ensure there is no condensate pocket left after steam fushing (if applicable) Fire hazards due to nonflame proof equipment and/or diesel operated engine Electric mechine must be certified by competent authority and have valid certificate All electrical connection to be crosschecked for loose fitting, etc. Earthing of the equipment must be done. LEL must be checked in the area periodically DCP cylinder to be kept ready for use Fire water hose is readily available Damage to work place and/or injury due to overpressurization of hose The hydrojeting mechine at all times should have safety equipment in tested and good working condition Pressure gauges, Safety Valves etc. should be calibrated every 3 months. HP Hoses should have valid test certificate for pressure test and visually checked for Trial of hydrojetting machine cuts/damage etc. before putting it in use every time. Hydrojetting machine must be looked at safe distance from pipes/equipment hydrojetting operator shall have minimum 3 years of hydrojetting experience Area must be kept barricaded All pipes/ material laid on ground level are wrapped with barricating tape or painted Laying of hoses and Injury due to fall scaffolding completion and certification preparing for (slip/trip)due to running done much in advance 3 hydrojetting/ against laid pipes/cables or While climbing up ladder maintain 3 point removal hoses after due to use of incomplete contact HJ scaffolding Gloves with good grip muct be used while climbing Adequate lighting ensured Healthiness of the manchine and hoses to be used are verfied prior to use cover the hoses with metal pipe wherever possible vehicle movement is there and provide caution tape over the pipe Ensure exertnal padding of hoses Mechanical failure oh hoses wherever it touches metal surfaces of the hyrojetting machine All rotating/moving parts of the machine are guarded Connecting between two hoses are safety locking chain to be provided sway arrester wherever possible Continious monitoring to be done when the machine is in operation 4 Hydrojetting of trasfer line Injury arising out of high pressure jet All trip systems of the machine are verified to the working prior to use stand by person available near pressure realising pedesdal with walkie talkie All PPEs as specified in the work permit to be used (faceshields, PVC approns, rubber gloves, gum boots) Use certified scaffolding Use safety full body harness with double life line Injury due to fall from height While cilmbing up ladder maintain 3 point contact Gloves with good grip must be used while climbing Injury due to coke flakes hitting/flying Hydrojetter to be used face shield and other mandatory PPEs Area must be barricaded Minimum number of persons to be present at work site; people around to be kept informed 5 Ergonomics hazards due to non approachable locations Proper scaffolding to be prepared considering the approach to working person. Material falling from height and damage the pipeline and causes injury Ensure dropped elbows are tied & kept in safe location. Ensure no human movement below hydrojetting area No superfluous material to be kept at work site Use tray for small tools. The tools spares wherever possible. All sub activities (1Physical Injury while working 4) Use correct tools .Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 20: Sheet19 Job Safety Analysis sheet Main activity : Burner (PG/FG) dropping Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Isolation of 1 Burner. Hazards and Risks Exposure to toxic/ HC gas due to improper isolation. Control measure to be implemented Identification of the burner must be done by field executive proper isolation of the burner,by double isolation and tagging portable H2S meter to be kept by working person Opening of 2 the line flanges 3 Dropping of burner Identification of the burner must be done by field executive Flammable gas release/fire due proper isolation of the burner,by double to wrong burner flange isolation and tagging opening or passing of isolation flanges be gradually loosend first to check wales for leakage, if any. Portable H2S meter to be kept with working person Injury due to fall from movable trolley Trolley to be properly positioned and lock to be applied to wheels Property damage (burner damage) Excess strength should not be applied to remove out the burner if it gets stuck somewhere. Handlinng burner properly while lifting and lowering Injury due to fall from movable trolley Trolley to be properly positioned and lock to be applied to wheels physical injury to personnel on work Standard job specific tools must be used Draft must be kept negative all the time. Use leather gloves as burn tip will be hot Injury due to hot surfaces of the Use full sleeve apporns burner assembly/ tracing steam Use face shield to gaurd against any hot lines or flash back from the box material falling from the burner block Ergonomic hazard while lifting or lowering the burner block All sub Physical injury while working 4 activities (1-3) Burner block to be supported by 2 persons Use correct tool. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 21: Sheet20 Job Safety Analysis sheet Main activity : Heat Exchanger Tube Insertion Plant : JSA Sheet No: 1 Date of JSA : S. No. Sub Activity Hazards and Risks Injury to People Tubes shifting during material 1 nearby exchanger handling. Manually Injury to people around Control measure to be implemented Do not use bare hands to handle material. Do not drop the material from height. Secure material properly from hitting the long tubes to people and any equipment/machine around. Do not allow the excess person in the work area. Communication should be proper in between Physical injury by persons who are invoved in the activity. Maintain making contact good housekeeping in work area. The area with12m tube with should be free from unwanted hardwares i.e reemer. Injury due to electrical cables, extention boards etc. Portable handling of protable electrical tools should have cables longer enough electrical machine. to keep its extention board out of work area. The tubes should not kept within visinity of high movement area and should be barricaded. Baffle's holes clearance for tube insertion by 2 reemring with or/and without Portable electrical tool. Fire Hazard due to spark generation while using portable electrical machine for reemering LEL must be checked in the area periodically. DCP cylinder to be kept ready for use. (Hot work permit required). Portable Electric machine and related extention boards and/or distribution boards must be certified by competent authority and have valid certificate. Electric shock from portable electric mechine. Portable Electric machine and related extention boards and/or distribution boards must be certified by competent authority and have valid certificate. All Electric connectionc to be crosschecked for loose fittings etc. Earthing of the distribution boards must be done. Injury due to fall from If required, prepare scaffolding plateform. Refer height when working and comply to RA of scaffolding errection. Use on height Full body Harness 3 Tubes Insertion and Physical injury while Do not allow the excess person in the work area. alligenment tube insertion Injury while using hammer Communication should be proper in between persons who are invoved in the activity on both end of exchangers. Maintain good housekeeping in work area. The area should be free from unwanted hardwares i.e electrical cables, extention boards etc. Use only inspected tools. Do not use contaminated or oil handgloves. Ensure a proper grip to the handle of hammer. Injury due to fall from If required, prepare scaffolding plateform. Refer height when working and comply to RA of scaffolding errection. Use on height Full body Harness 4 All sub activities (1- Physical injury while 3) working Use correct toolS. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 22: Sheet21 Job Safety Analysis sheet Main activity : Hydrotest of Pipes /Equipment Plant : JSA Sheet No: 1 Date of JSA : S. No. Sub Activity Hazards and Risks 1 Preparing for hydrotest Health hazard due to Control measure to be implemented Ensure equipment is positively isolated (blindding and connection pump/hoses) exposure to HC/toxic gas Injury due to use of improper tools Injury due to failure of fittings used for hydrotest 2 Hydrotest Use standard job specific tools and PPEs Ensure Blinds used area of correct rating to withstand hydrotest pressure Avoid threaded connections and plugs. Check for all fittings before hydrotest includes gaskets Check for pump hoses for any kind of damage. Only one person will check for leakages Barricade the area of hydrotest . Do not allow too many person around during pressurisation Injury due to fall from height Refer and comply to Work at Height (if applicable) JSA (this will apply to all subactivities) Property damage due to overpressurisation Be clear about the hydrotest pressure; do not pressurize beyond hydrotest pressure Use standard and calibrated gauges only Fire/electrical hazard due to nonflame proof equipment and/or diesel operated engine Electric machine must be certified by competent authority and have valid certificate All Electric connectionc to be crosschecked for loose fittings etc. Earthing of the equipment must be done LEL must be checked in the area periodically. DCP cylinder to be kept ready for use Equipment damage Provide adequate venting to avoid equipment going to vaccum during draining Injury during depressurisation Keep body away from the fluid path. Open valve slowly 3 Depressurisation 4 All sub activities (1-3) from all HC (process) connections. Ensure line or equipment is free from HC/toxic gas i.e check LEL and H2S. Physical injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 23: Sheet22 Job Safety Analysis sheet Main activity : Valve Servicing (other than gland and bonnet) Plant : JSA Sheet No: 1 Date of JSA : S. No. Sub Activity Hazards and Risks Physical Injury due to improper tools 1 Use job specific tools and PPEs Stay away from hot lines Use certified scafolding/Hydraulic Fall due to not following platforms/trolleys with wheel lock Valve work at height Use safety full body harness with double york/stem/gear box procedure (if lifeline Use tray for small tools. Maintain 3 servicing applicable) point contact while climbing the ladders Health hazard due to handling grease (long exposure) 2 Control measure to be implemented All sub activities (1) Physical injury while working Use chemical resistant gloves and wash hands properly Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 24: Sheet23 Job Safety Analysis sheet Main activity : Removal of structure by cutting Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Hazards and Risks Job preparation (lifting and 1 shifting of Injury due to fall from height material from Ground level) Structural member 2 removal by gas cutting Injury due to fall fronm height Explosion due to mishandling of the cylinder/Fire due to gas release hose and fitting Burn injury due to mishandling flame Fire hazards due to combustile material around Control measure to be implemented Tools, tackles etcare not be carried with hands while climbing. Use pouch, belt or other lifting/loweing device. Ladder must be free of oil/grease Gloves with good grip must be used for climbing While climbing or stepping down the ladder three point contact must be there Scaffolding must be ready for use and certified. Use safety fullbody harness with double lifeline Provide proper scaffolding as per Scaffolding Procedure Always use safety full body harness. Cylinder must be kept chained on trolly. Cylinder must have safety cap Hoses should not be in damaged condition. It should be tested periodically for fitness and clamped at all joints. There should be flask back arrestors on either side Torch must be in good working condition. When not in use , Isolate from the cylinder Safe lying of hoses without sharp bends and not near to sharp edges Alawys Keep the flame away from the body. Use leather gloves Use dark goggles The spark coming out may lead to fire if any inflammbles material is lying near by Barricade area with Fire blanket. Clear the area of all flammble substances within 8 m radius Keep DCP cylinder as standby. Keep fire hoses ready. Keep the area wet, if required Periodically monitor LEL and record Dimentalling of 3 structure members Lifting and shifting of 4 structural members 5 Injury due to fall from heightingInjuruy due to fallng of structural member from height Physical injury due to slippage/damage of spanners Use Certified scaffolding. Use Full body Harness. Block the monkey ladder access of antisurge platform. Ensure proper tieing of the structural member with rope /chain pulley beforre operating thebolts. Use only tested lifting machine & tackles. Barricate the area. Use only inspected tools. Use correct tools. Physical injury during shifting of structural member/grating. Damage of near by instruments Barricate the possible affecting area. Ensure proper tieing of the member during lowering. Use tested Lifting tools & tackles for dropping structural members Jobs to be executed under proper supervision. Inform area executive before starting the jobs All sub activities Physically Injury while working (1-4) Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign _________________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 25: Sheet24 Job Safety Analysis sheet Main activity : Hackshaw cutting o Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Hazards and Risks Control measure to be implemented Exposure to Chemical ( toxic/ flammble gas release) Hachshaw 1 cutting (manual ) Hackshaw cutting to be employed on lines which are difficult to flush out. Attempt to be made fush the lines to the extent possible to aviod uncontrolled/ excessive relesae of HC/toxic gas during cutting Arrangement to be made for continous remote venting / drianing of the line. All care must be taken expecting toxic gas/HC release. Air line mask to be used during cutting. Area to a diameter of 15m atleast to be evacuated. Not hot work to be allowed in the area LEL & H2S to be continously monitored in the area. Keep running water ready for dilutioin Drain abd vent arrangement to be provided on the line Fire /explosion due at remote location to excessive Hc gas Cutting surface to be continiously cooled by pouring release water Cut injury to working personnel No person to be allowed to stand undre weight being lifted Area must be barricated. No superflous material to be kept at work site. Use tray foe small tools. The tools , spares wherever possible 2 3 Use gloves during cutting. Keep hand at safe distance from the sharpm edges All sub Physically Injury activities (1-2) while working Done by : Use correct tools. Use mandatory PPEs Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 26: Sheet25 Job Safety Analysis sheet Main activity : Non flameproof Electrical Equipment usage inside plant Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Operation of Non falmeproof 1 Electrical Equipment- 2 All sub activities (1) Hazards and Risks Control measure to be implemented Electrical shock Hazards Electrical machine must be certified by competent authority and have valid certificate All electrical connection to be crooschecked for loose fitting,etc Earthing of the equipment must be done Fire Hazard due possible spark generation LEL must be checked in the area periodically DCP cylinder to be kept ready for use ( Hot work permit required ) Physically Injury while working Use correct tools Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 27: Sheet26 Job Safety Analysis sheet Main activity : Hydrojetting of exchangers Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Trail of 1 hydrojetting machine Hazards and Risks Control measure to be implemented Electric mechine must be certified by competent authority and have valid certificate All electrical connection to be crosschecked for loose fitting, etc. Earthing of the equipment must be done. LEL must be checked in the area periodically DCP cylinder to be kept ready for use. Fire water hose is readily available The hydrojeting mechine at all times should have safety equipment in tested and good Fire hazards due to nonflame working condition proof equipment and/or Pressure gauges, Safety Valves etc. should be diesel operated engine calibrated every 3 months. Damage to work place Foot valve should be inspected bry mech CES and/or injury due to person and should have valid certificate. HP overpressurization of hose Hoses should have valid test certificate for pressure test and visually checked for cuts/damage etc. before putting it in use every time. Hydrojetting machine must be looked at safe distance from pipes/equipment Minimum personnel to be allowed for trial Hydrojetting operator shall have minimum 3 years of hydrojetting experience Area must be kept barricaded Laying of hoses and 2 preparing for hydrojetting 3 Hyrojetting 4 Injury due to fall (slip/trip)due to running against laid pipes/cables or due to use of incomplete scaffolding Area must be barricated. Scaffolding completion and certification done in advance. Adequate lighting ensured Mechanical failure for hoses or the Hyrojetting machine Injury due to coke particles hitting/flying healthiness of the machine and hoses to be used are verfied prior to use Cover the hoses with metal pipe wherever possible vehisle movement is there and provide caution tape over the pipe. Ensure external padding of hoses wherever it touches metal surfaces All rotating /moving parts of the machine are gaurded Connecting betwen two hoses are safety locking chain to be provided. Sway arrester wherever possible Continious monitoring to be done when the machine is in operation . The area around the Hyrojetting should be properly cordoned with rope/ chian to prevent unauthorized persons entering into hyrojetting area. diesel engine operated hyrojetting machines should have flame arrestor on exhaust All PPE's ae specified in the work permit to be used ( gum boots ). Area must be barricated Minimum number of persons to be present at work site; All sub Physically Injury while working activities (1-3) Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 28: Sheet27 Job Safety Analysis sheet Main activity : Bundle pulling of Heat Exchanger Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Channel cover & 1 channel opening Hazards and Risks Control measure to be implemented Ensure that decontamination done effectively. Fire due to pyrophoric Keep water hose ready iron Exchanger must be kept wet to prevent residual pyrophoric iron from lighting Continuously wet the tubes surface during Fire due to pyrophoric bundle pull out operation. (Ensure water flow is iron minimum and it is continuously draining outside. Water should not hold inside exhanger ) Fire hazard due bundle puller/ crane operartion Inside plant Tube bundle 2 pulling using puller /crane Get Hot work permit, check LEL in 15mt of surrounding area Spark arrestor must be installed in healthy condition. Inhibit nearby DGX for vehicle movement Refer and comply to RA for Crane/Hyrda deployment Shell must be locked with Puller Lock. Puller lock sling must be properly bolted with exchanger flange. Exchanger Saddle support should be properly Properly damage/ supported Injury due to improper Use correct I-Bolt at Exchanger an dcertified lifting/pulling of slings for Pulling tube bundle bundle Properly aligns sling with puller and exchanger. Bundle tube baffle must be safely rested Refer and comply to RA for crane /Hyrdra deployment. Keep the area barricaded Use standard and job specific tools. Use certified Injury due to improper chain blocks and slings. Do not move under lifted tools/handling loads. Periocally monitor LEL within 15mts of sorrounding Fire hazard due to area and record. combustible material Refer comply to RA for hot work (Gas around cutting/grinding/welding) on structure/ New line Temporary Support errection 3 structurre provision Injury due to fall from If required ,.prepare scaffolding platform. Use full as per requirement height body harness Injury due to falling of Ensure proper tieing of the structural member structural member with rope / chain pulley. from height Use only tested Lifting tools & tackles. Barricate the area If required pepare a working scaffolding platform below the structural members Physicaly injury due to slippage/ damage of spanners Use only inspected tools. Use correct tools. 4 All sub activities (1- Physically Injury while 3) working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 29: Sheet28 Job Safety Analysis sheet Main activity : Heat Exchange tubes removal by gas cutting Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Hazards and Risks Control measure to be implemented Physical Injury while shifting the cylinders Mobilise the gas Cylinders in trolly, and don’t roll it Prepartion 1 for cutting of Fall from height while tubes lining up cylinder hoses in trays Use full body harness while climbing in ladder 2 Gas cutting Ensure integrity of working platform and there should be no gap between planks Fall from the Height during Use Certified scaffolding. cutting Ensure there is more ways of access and no pipings are obstructing the escape route Cylinder must be kept chained on trolly and identified with labels. Cylinder must have safety cap Hoses should not be in damaged condition. It shuold be tested periodically for fitness and Explosion due to clamped at all joints mishandling of the There should be flash back arrestors on either side. cylinder/ Fire due to gas Torch must be in good working condition When not release by improper hose in use, isolate from the cylinder. ( Ensure the tag and fittings no. in cylinder before isolating ) Safe laying of hoses without sharp bends and near to sharp edges Hose laying should be through cable tray to avoid bend and damage to the hoses Burn injury due to to mishandling flame Always keep the flame away from the body and nearby working crew. Use leather gloves Use dark goggles Asphyxiation due to vapours generated during cutting Use dusk mask. Interchange the working persons frequently and allow them to breath fresh air Do not allow person to stand at tube bundle both ends, where more vapours will come during cutting Fire due to any HC hold up inside tubes and exposure of phyrophoric material Keep the area wet. Keep DCP extinguisher and Fire hoses ready Fire hazards due to combustible material around The spark coming out may lead to fire if any inflammble material is lying near by Barricade area with fire blanket or Aluminum sheets Clear the area of all flammble substance within 8m radius Keep DCP cylinder as standby. Keep the area wet, if required Periocally monitor LEL and record Burn injury due to hot surface 3 Removal of tubes Shifting oe 4 cut piece tubes Use leather gloves Physical Injury due to sharp edges Do not pull the tubes bu touching at edges. Take care of nearby working crew while pulling the tubes Dust Exposure Wear Dust mask. Remove the sediments over tubes before pulling the tubes Stop the work and clean the area frequently. if require do hydrojetting to clean the surface of tubes Burn injury due to mishandling of cut tubes Always keep the cut tubes away from the body. Dip the hot cut tubes in water for cooling Use leather gloves Physical injury while shifting Shift the cut tubes in trolly are using fork lift ( Refer RA 120 for Using Fork lift) Trolley/ Fork lift should not be overloaded All sub 5 activities (14) Physically Injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 30: Sheet29 Job Safety Analysis sheet Main activity : Housekeeping inside plant Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. 1 2 3 Hazards and Risks Control measure to be implemented slip injury due to rags rags & garbags to be kept in identified bins , insure that / garbage / grease spllied oil / grease are cleaned immideately, wash the or oil hands with soap at the end of work injury due to material lying here & material to bekept at identified & safe places , scrap housekeeping there materialto be sent to scrap bins afetr housekeeping injury due to sharp edges of wires or structures use mandatory PPEs dust use dust mask along with mandatory PPEs burn injury due to hot surface 4 use mandatory PPEs, use leather gloves if require Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 31: Sheet30 Job Safety Analysis sheet Main activity : Fan/ blower fixing on manways for air circulation Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. lifting the fan/ blower 1 2 fixing the fan /blower on the manway Hazards and Risks Control measure to be implemented use correct & certified slings/ wire properly damage /injury due rope to improper lifting methods keep body away from lifted load Don't move under lift at load struck by (injury) tools while working use standerd tools , use rope string for holding spaner exposure to toxic gas/ nitrogen carry personal H2s metre , check O2 level at manway , keep SCBA set ready, Stand in upwind direction or side of manway 3 Electrical connection on the fan/ blower 4 all sub activities (1 to 3) elecrical fire hazards Job to be done under different permit with relavent electrical JSA physical injury while working use correct tools, use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign __________________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 32: Sheet31 Job Safety Analysis sheet Main activity : Material handling manualy Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Hazards and Risks lifting of material on trolley, shifting of material on trolley 1 injury to people during material handling Control measure to be implemented Do not use barehands to handle material use portable lifting trolley and shifting on trolley only, Use crane hydra wherever required if material is heavy Refer & follow respective RA for lifting with crane/ hydra Don't drop material from height, use correct lifting lowering devices Secure material properly on trolley fixing & removal of 2 chain blocks for lifting injury due to fall from height the material manualy 3 lifting of material using chain pulley all sub activities (1 to 4 3) wear safety full body harness clamped to fix structure & not to the pipings , use certified ladder Maintain three point contact while climbing the ladders Use certified ,valid & with no damage slings ,chain pulley blocks for lifting Don't use edged support for slings Use rigid & firm support for hooking the slings /chain damage to the equipment near by Don't load any scaffolding or lines other temporary structure directly or indirectly by slings /chains Area to be barricated during lifting Keep minimum person during lifting toxic gas, hydrocarbon release due to hitting nearby pipelines,instruments tubings clearly identified the lifting route well in advanced an marked all SBCs , wrap with barricating tape if deemed necessary use standard lifting devices , For critical lift JE /FS will personally supervise the job physical injury while working use correct tools, use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 33: Sheet32 Job Safety Analysis sheet Main activity : Conditioning monitoring of equipment Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. recording vibration reasings with designnated meter 1 Hazards and Risks check all rotating /moving parts are injury due to body parts adequately guarded ,don't move close to getting traped between the rotating parts,use hand gloves & goggles moving machinery ,don't wear loose fitting attire or neckwears use only authorised spark free devices for fire/explosion due to use measurement in hazards areas ,check of non flame proff tolls measurement devices is certified burn injury due to touching nearby hot surface 4 All sub activities (1) Control measure to be implemented Physical injury while working use leather gloves near hot service pumps Use correct tool. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 34: Sheet33 Job Safety Analysis sheet Main activity : Manway opening and boxup of process equipments Plant : JSA Sheet No: 1 Date of JSA : S. No. Sub Activity Hazards and Risks Human error Opening 1 the manway Control measure to be implemented Identify the correct manway to be opend from the permit description Field Executive should physically show the right manway to be opend The equipment and connected process lines are made free from HC and toxic material using deconamination techniques There should not be any condensate pocket left in the loop after steaming . All the process , utility & insert gas connection must be disconnected & positively blinded with standard blind before opening manway. All such location Chemical (toxic/ must be identified & marked clearly on P&ID & flammabled/insert gas) separate blind list must be prepared. The same must release / fire due to be check jointly by permit issuer &requestor before residual HC/toxic gas left in allowing Man Entry Keep Escape set ready for the vessel escape in case of residual H2S release USE Air line mask or SCBA, if advised in the permit. Stop Hot job in radius of 15 meters First gently loosen the flange; body position should be away from the opening such that residual steam/gas released do not affect. First keep the manway 20-30% open. Put "DO NOT ENTER WITHOUT PERMIT" board Struck by (injury) tools while Use standard tools. Use rope strins for holding working spanner 2 Boxup of manway Persons trapped inside Ensure all the persons who were worked inside came out from the vessel /Equipment. Crosscheck the same from Man-entry register. Give sound and ensure no reply from inside Struck by (injury) tools while Use standard tools. Use rope strins for holding working All sub activities 3 (1-2) spanner Physical Injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ____________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved ) Sheet 35: Sheet34 Job Safety Analysis sheet Main activity : Work at height Plant : JSA Sheet No: 1 Date of JSA : S. Sub Activity No. Hazards and Risks Control measure to be implemented Approach to be identified in such a way that emergency egrees route is avilable Alternate escape route to be identified depending on criticallity of the job Scaffolding errrected should not block identified Escape routes of the plant ALL SBCs at work location must be identified Damage to workplace Identifying the best Electrical and instrument cable must be due to hitting/ approach to work identified and scaffolding pipes should noy climbing on pipes, 1 location and touch these cables Adequate care must be specially SBCs in turn it scaffolding taken to avoid hitting on SBCs Scaffoding pipes release of toxic gases / preparation must be atleast at least 6'' away from SBCs fire JSA avilable for scaffolding prepartion and dismantlling to be referred Scaffodling must meet all standard requirement. Scaffolding certification must be done Scaffolding check list must be filled. ALL above also applies if Hyraullic platform / trolley is being used Tools , tackles etc are not to be carried with hands while climbing. Use pouch, belt or other lifting / lowering device Ladder must be free of oil/ greese and must be firmly placed tp prevent slip Shifting of tools, Injury due to fall ( Ladder to be provided perpendicular to the 2 tackles, spare etc to slip/trip) while climbing working platform wherever possible work location up Gloves with good grip must be used while climbing Keep landing area near the ladder free form looses pipes and other scaffolding material While climbing maintain 3 point contact always Execution of the job at height 3 4 All sub activities (13) Struck by falling objects No person to be allowed to stand under weight being lifted Area must be barricated. No superfluous mateiral to be kept at work site. Use tary for small tools. Tie tools, spare wherever possible Injury due to fall ( slip/trip) from the working platform Use certified scaffolding / Hydraulic platform / trolleys with wheel locl Use safety full body harness with double lifeline Physically Injury while working Use correct tools. Use mandatory PPEs Done by : Name :______________________________ Designation: AM Sign ________________________ Date: Name :_______________________________ Designation: ______________ Sign _________________________ Date: (Note: JSA Sheet to be done by issuer and requestor of work permit . In case of need, representative from other discipline should also be involved )