LAB NO 6

advertisement

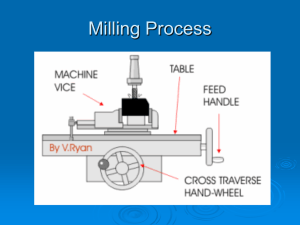

LAB NO 6 CUTTING SPEED, FEED AND DEPTH OF CUT OF MILLING MACHINE; Cutting Speed: One of the most important factor affecting the efficiency of a milling operation is cutter speed. The cutting speed of a metal may be defined as the speed in surface feet per min (ft/min) or meter per minute at which the metal may be machined efficiently. When a work is machined in a milling machine, cutter must be revolved at a specific number of rev/min, depending on its diameter, to achieve the proper cutting speed. Different types of metals vary in hardness, structure, and machinability, different cutting speeds must be used for each type of metal and various cutter materials. Several factors must be considered when determining the proper r/min at which to machine a metal. The most important are The type of work material. 1. 2. 3. 4. 5. The cutter material. The diameter of the cutter. The surface finish required. Depth of cut. The rigidity of machining and work setup. INCH CALCULATION: To get optimum use from a cutter, the proper speed at which the cutter should be revoloved must be determined. It is calculated by the formulae in inch system as; Inch Calculation: Rev/min (cutter) = = Example: 𝑪𝒖𝒕𝒕𝒊𝒏𝒈 𝑺𝒑𝒆𝒆𝒅 (𝒇𝒕) 𝑪𝒊𝒓𝒄𝒖𝒎𝒇𝒆𝒓𝒆𝒏𝒄𝒆 (𝒄𝒖𝒕𝒕𝒆𝒓) 𝑪𝒖𝒕𝒕𝒊𝒏𝒈 𝑺𝒑𝒆𝒆𝒅 ×𝟏𝟐 𝝅𝑫 = 𝑪𝒖𝒕𝒕𝒊𝒏𝒈 𝑺𝒑𝒆𝒆𝒅 × 𝟒 𝑫 Calculate the cutting speed required to revolve a 3” diameter high speed milling cutter, for cutting machine steel (90 sf/min) Cutting speed = 90 ×4 3 = 120 r.p.m. Metric Calculation: In metric system the cutting speed is calculated as; Rev/min = 𝐶𝑢𝑡𝑡𝑖𝑛𝑔 𝑆𝑝𝑒𝑒𝑑 (𝑚) ×1000 𝜋𝐷 (𝑚𝑚) = 𝐶𝑆 ×320 𝐷 FEED OF MILLING MACHINE; Milling machine feed may be defined as the distance in inches (or mm) per minute the work moves into the cutter on most milling machines, the feed is regulated in inches (or mm) per minute and is independent of spindle speed. Feed is the rate at which the work moves into the revolving cutter, and it is measured either in inches per minute or mm per min. The milling feed is determined by multiplying the chip size (chip per tooth) desired, the number of teeth in the cutter, and the r.p.m. of the cutter. Chip or feed per tooth (CPT or FPT) is the amount of material that should be removed by each tooth of the cutter as it revolves and advances into the work. The feed rate used on the milling machine depends on a variety of factors such as: 1. 2. 3. 4. 5. The depth and width of cut. The design and type of cutter. The sharpness of cutter. The strength and uniformity of the work piece. The type of finish and accuracy required. As the work advances into the cutter each successive tooth advances into the work an equal amount, producing chips of equal thickness. Inch Calculation: Feed (in/min) = N × CPT × r.p.m. Where N = number of teeth in the milling cutter CPT = Chip per tooth for a particular cutter and metal (given in table) r.p.m. = revolution per minute of the milling cutter. Example: Find the feed in inches per min using a 3.5” diameter, 12 tooth helical cutter to cut machine steel (Cutting Speed = 80) Feed = N × CPT × r.p.m. r.p.m. = 𝑪𝒖𝒕𝒕𝒊𝒏𝒈 𝑺𝒑𝒆𝒆𝒅 × 𝟒 𝑫 = 𝟖𝟎 ×𝟒 𝟑 = 91 Feed = 12 × (0.010) × 91 Feed = 10.9 in/min DEPTH OF CUT; Where a smooth, accurate finish is desired, it is good practice to take roughing and finishing cuts. Roughing cuts should be deep. Heavier cuts may be taken with a helical cutters having fewer teeth since they are stronger. Finishing cuts should be light, with a finer feed used in roughing cuts. The depth of cut should be at least 0.015 inch.