- No category

Spheronization Process: Pellet Formation Mechanisms

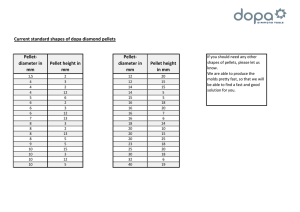

advertisement