De Novo Design To Synthesize Lanthipeptides Involving Cascade Cysteine Reactions: SapB Synthesis as an Example

advertisement

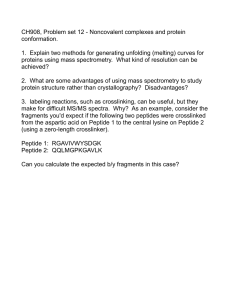

Note Cite This: J. Org. Chem. 2018, 83, 7528−7533 pubs.acs.org/joc De Novo Design To Synthesize Lanthipeptides Involving Cascade Cysteine Reactions: SapB Synthesis as an Example Huai Chen,† Yuan Zhang,† Qian-Qian Li,† Yu-Fen Zhao,† Yong-Xiang Chen,† and Yan-Mei Li*,†,‡ † Key Lab of Bioorganic Phosphorus Chemistry & Chemical Biology, Department of Chemistry, Tsinghua University, Beijing 100084, P.R. China ‡ Beijing Institute for Brain Disorders, Beijing 100069, P.R. China Downloaded via TSINGHUA UNIV on September 19, 2018 at 06:58:08 (UTC). See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles. S Supporting Information * ABSTRACT: Lanthipeptides are a family of ribosomally synthesized peptides that have crucial biological functions. However, due to their complicated structures, the total synthesis of lanthipeptides is challenging. Here, a novel strategy to construct lanthipeptides is described, which involves cascade reactions of cysteine, including Cys disalkylation elimination, Michael reaction, and native chemical ligation. We utilized this strategy to synthesize lanthipeptide SapB as an example. This methodology has the potential to obtain lanthipeptides and their analogues for biological research and drug discovery. R ibosomally synthesized and post-translationally modified peptides (RiPPs), which have a variety of structures and functions, have attracted increasing attention for biological research and drug discovery in recent years.1 Lanthipeptides, which are widely produced by various bacteria, are one of the largest and best-studied families of RiPPs.2 Lanthionine (Lan) and/or 3-methyllanthionine (MeLan) motifs are the characteristic structural features in lanthipeptides (Figure 1a).3 These thioether-containing cross-links result in the complicated polycyclic topologies of lanthipeptides. These thioether bridges are formed by the Michael-type addition reaction between cysteine (Cys) and dehydroalanine (Dha) or dehydrobutyrine (Dhb), which is usually generated from dehydration of serine (Ser) or threonine (Thr) with the assistance of enzymes in the producing organisms (Figure 1a).2b,4 Many lanthipeptides have antimicrobial ability against various Gram-positive bacteria, even some antibiotic-resistant bacteria.2b,5 In addition, some lanthipeptides have some other biofunctions.2b,6 For example, duramycin and cinnamycin can inhibit phospholipase A2 in eukaryotic organisms to maintain normal lipid metabolism;7 labyrinthopeptin A1 manifests favorable activities against HIV and HSV;8 SapB and SapT may function as biosurfactants to promote the growth of aerial hyphae.9 Therefore, obtaining lanthipeptides for biological and medicinal research is a promising field. Nevertheless, it is difficult to isolate lanthipeptides from natural sources for in-depth study and therapeutic use due to the small amount of production.10 Therefore, various methods have been developed, both biologically and chemically, to produce lanthipeptides and their analogues.3,11 Among these methods, total chemical synthesis provides a powerful approach to bypass the biosynthetic system, expanding a more extensive chemical space for biological research and drug development. However, because of the complicated structures, total synthesis of lanthipeptides remains a formidable challenge. To tackle the challenge, several advances have been reported. Shiba and co-workers reported a pioneering work for the total synthesis of a natural lanthipeptide, nisin A, Figure 1. (a) Structures of Dha, Dhb, Lan, and MeLan. Construction of Lan/MeLan residues in biological systems. (b) Structure of SapB (1). The green residues are Dha, and the red residues are Lan. The stereochemistry of the sites with a blue star has not been determined. Special Issue: Organic and Biocompatible Transformations in Aqueous Media © 2018 American Chemical Society Received: January 29, 2018 Published: June 12, 2018 7528 DOI: 10.1021/acs.joc.8b00259 J. Org. Chem. 2018, 83, 7528−7533 Note The Journal of Organic Chemistry in solution phase in 1988 (Scheme 1a).12 However, the approach was impeded for further development due to its two Dha residues in its molecule (Figure 1b).9a The relatively simple topology and post-translational modifications of SapB make it a good model to verify the viability of our strategy. Based on our design, SapB was divided into two segments: SapB(1−9) and SapB(10−21). During Fmoc-SPPS of the two segments, we used four types of Cys building blocks with orthogonal protecting groups. The other amino acid building blocks were all commonly used in Fmoc-SPPS. The special Dha residues were formed from Cys in situ through the elimination reaction under bisalkylating conditions either on the solid support or in the solution phase.20 The synthesis of SapB(10−21) began with the loading of Fmoc-Asn(Trt)-OH onto 2-chlorotrityl resin, followed by standard coupling of the next 11 residues sequentially, with a Fmoc-Cys(Trt)-OH at site 20, a Fmoc-Cys(Acm)-OH at site 16, a Fmoc-Cys(StBu)-OH at site 13, and a Boc-Thz-OH at site 10 (Figure 2a). These cysteine residues could be Scheme 1. Strategies for the Total Synthesis of Lanthipeptides tedious procedure and low yield. Chemical synthesis of lanthipeptides on solid resins has also been explored. Tabor and co-workers reported several approaches to achieve orthogonally protected Lan/MeLan derivatives, which could be used to synthesize lanthipeptides fragments via 9fluorenylmethoxycarbonyl solid-phase peptide synthesis (Fmoc-SPPS).13 Vederas’ group and van der Donk’s group also utilized the orthogonally protected Lan/MeLan to construct several full-length lanthipeptides, such as lacticin S, lacticin 481, epilancin 15X, and their analogues (Scheme 1b).10,14 However, the overall yields were not high enough, and the synthesis of orthogonally protected building blocks was still challenging. The biomimetic method, which forms the Lan/MeLan by intermolecular Michael addition reaction, has also been approached both in solid phase and in solution.15 When there are multiple Cys and Dha/Dhb in the peptide sequence, it is difficult to construct the correct polycyclic structure of the target lanthipeptide by this method.15c To overcome these obstacles, it is necessary to develop a facile and effective method to achieve the synthesis. We found that the generation of Dha16 and Lan11a could be formed chemically in peptides through cysteine-based reactions. Thus, we de novo designed a novel strategy to synthesize full-length lanthipeptides utilizing several commercially available orthogonally protected Cys building blocks. Through cascade cysteine-based reactions, including Cys elimination to Dha in situ,16 biomimetic Michael addition reaction,15,17 and native chemical ligation (NCL),18 multiple Lan bridge cycles and Dha residues in the peptides can be achieved (Scheme 1c). With the ability of orthogonal deprotections, we can accurately control the reaction sites of Cys and Dha to form the desired structures. In addition, all of the amino acid building blocks are commercially available. Therefore, this strategy has the potential to construct complicated polycyclic topologies of lanthipeptides and their analogues through de novo design. The model lanthipeptide we chose was SapB, which was discovered from Streptomyces coelicolor in 1991.19 Although the exact structure of SapB has not been reported,4d this 21 amino acid peptide was determined to have two Lan bridge rings and Figure 2. (a) Synthesis of SapB(10−21). (b) Synthesis of SapB(1−9) peptide hydrazide. (c) HPLC traces of 3 and 4 at 215 and 254 nm. (d) CD spectra of 3 and 4. (e) HPLC trace (215 nm) and ESI-MS data of 5. (f) HPLC trace (215 nm) and ESI-MS data of 7. 7529 DOI: 10.1021/acs.joc.8b00259 J. Org. Chem. 2018, 83, 7528−7533 Note The Journal of Organic Chemistry environment.4c,15d,21 The former diastereoisomer in HPLC was selected as 9 for the following reactions. The last two Cys residues (Cys6 and Cys16) with Acm groups were deprotected with CH3COOAg in a solution of H2O/CH3COOH (v/v = 1:1) at 37 °C for 6 h followed by adding DTT.24 The obtained peptide 10 was treated with DBAA to convert the two free Cys to Dha (Figure 3a). The reaction was monitored with deprotected orthogonally when we needed to achieve different purposes. With the full sequence assembled on the solid resin, we first chose the residue Cys13 with a StBu group as the precursor of Dha, as the StBu could be easily removed by reducing reagent on resin. 2 was treated with dithiothreitol (DTT) and N,N-diisopropylethylamine (DIPEA) in DMF to afford the free thiol. Afterward, 2,5-dibromoadipamide (DBAA) was used to convert the free thiol into the desired Dha.16 Followed by the standard global deprotection and resin cleavage using the TFA cocktail, the Dha13 containing peptide 3 was obtained. The crude peptide was purified with semipreparative RP-HPLC to give the purified 3. Because the Trt group was removed by the TFA cocktail, the second free Cys20 was released. Thus, there was a Cys and a Dha existing simultaneously in 3, and Michael addition reaction could be induced. We dissolved 3 in alkaline aqueous buffer A (50 mM Na2HPO4, pH 8.5) at room temperature and shook it for 1.5 h to induce the Michael reaction to form the first Lan bridge ring. As the molecular weight of 3 and 4 was the same, these two molecules could not be identified by MS. We monitored the reaction with analytical RP-HPLC and observed that the retention time had a small shift detected with the absorption at 215 nm, which suggested a new compound was produced. When detected at 254 nm, the absorption peak almost disappeared compared to 3, which might be due to the consumption of Dha (Figure 2c). We also affirmed that there was no free thiol in the new compound by testing it with Ellman’s reagent (Figure S7). The circular dichroism (CD) spectra showed that the new compound had a more helical structure than peptide 3 (Figure 2d). All together, these results indicated that 3 was fully converted, undergoing a Michael reaction between Cys20 and Dha13 to form a cyclic peptide 4. We further analyzed 4 with a C18 analytical column and observed two diastereoisomers at a ratio about 6:1 (Figure S8). The stereoselectivity might due to the generation of an endocyclic enolate with an adjacent chiral center.4c,21 We treated the major product with MeONH2·HCl and tris(2carboxyethyl)phosphine hydrochloride (TCEP·HCl) at pH 4.0, and the Thz in 4 was deprotected to release the third Cys10 (Figure 2e). This newly generated N-terminal free Cys could be used for the following NCL reaction. Separately, SapB(1−9) peptide hydrazide22 was prepared through Fmoc-SPPS with a Fmoc-Cys(StBu)-OH at site 3 and a Fmoc-Cys(Acm)-OH at site 6. The StBu group on 6 was removed and then converted to Dha3 by the above method, followed by treatment with a TFA cocktail and purification with RP-HPLC to give purified 7 (Figure 2b,f). With the two requisite peptide segments in hand, we adopted the method reported by Liu23 to approach the NCL. However, we found that several byproducts appeared under the conditions. By identifying them with ESI-MS, we considered that these byproducts were derived from the Michael addition of 4-mercaptophenylacetic acid (MPAA) with 8 and N-terminal peptide MPAA thioester (Figure S9). To reduce the side reactions, we adjusted the pH of the reaction system from 6.5 to 5.5. Favorably, with the conversion maintained, the side reactions were significantly inhibited. After NCL, the second Lan bridge (Dha3 and Cys10) was formed by dissolving 8 in the alkaline aqueous buffer A and shaking it for 2 h. We observed two equal peaks in the HPLC trace, which indicated that the newly generated chiral center was racemized (Figure S10). The difference between two Michael addition steps might be due to the different chemical Figure 3. (a) NCL of peptides 5 and 7 and following reactions. (b) HPLC trace (215 nm) and ESI-MS data of 1 (SapB). analytical HPLC and ESI-MS (Figure 3b). After reaction and purification, the full-length lanthipeptide 1 (SapB) was obtained, with a yield of 9.8% based on peptide 3 over six steps. In summary, we de novo designed a strategy based on cascade reactions of Cys residues to synthesize full-length multicyclic lanthipeptides. The multiple Cys residues could be deprotected orthogonally when we need to achieve desired reactions. We have demonstrated a facile synthesis of SapB by this strategy. To the best of our knowledge, this is the first example to synthesize SapB. This strategy has several advantages: (1) all the amino acid building blocks needed to synthesize lanthipeptides are commercially available; (2) with the controllable orthogonal deprotections, it has the potential to construct complicated polycyclic topologies that extensively exist in lanthipeptides by de novo design; (3) given the reasonable yield of each step, it can be used to obtain a milligram scale of lanthipeptides. However, the major flaw of this strategy is the stereochemistry of the Michael addition. It is known that addition reactions to Dha in peptides and 7530 DOI: 10.1021/acs.joc.8b00259 J. Org. Chem. 2018, 83, 7528−7533 Note The Journal of Organic Chemistry proteins will lead to epimeric mixtures.16,20a,25 The diastereomeric ratio may be affected by local chemical environment, but how to control the stereoselectivity needs to be further explored. In spite of this, the strategy provides a potential and promising methodology to obtain lanthipeptides and their analogues for biological research and drug development. ■ [M + 2H]2+ 641.7, found 641.3. MS (ESI+) calcd for 4: C49H80N14O20S3 [M + H]+ 1282.4, found 1282.8; [M + 2H]2+ 641.7, found 641.4. MS (ESI+) calcd for 5: C48H80N14O20S3 [M + H]+ 1270.4, found 1269.8; [M + 2H]2+ 635.7, found 635.3. Synthesis of Peptide 7. 2-Chlorotrityl resin (0.80 g, 0.911 mmol/g) was washed with DCM × 3 and DMF × 3 and then incubated with 5% N2H4·H2O/DMF (v/v) for 30 min twice. After being washed, 5% CH3OH/DMF (v/v) was used to cap the unreacted sites on the resin for 10 min. After being washed with DCM × 3 and DMF × 3, 0.2 mmol Fmoc-Leu-OH was used to couple the resin with 0.2 mmol HATU, 0.2 mmol HOAt, and 0.4 mmol DIPEA for 60 min. A solution of DMF/Ac2O/pyridine = 3:2:1 was used to cap the unreacted sites for 30 min after coupling. Fmoc was removed using 20% piperidine solution in DMF. The following amino acids (4 equiv) were coupled with HATU/HOAt/DIPEA (4 equiv/4 equiv/8 equiv) activation and monitored by Kaiser test reagent. The coupling reaction was carried out for 45 min, and the Fmoc deprotection was for 5 min + 10 min. When the last FmocThr(tBu)-OH coupling and Fmoc deprotection were finished, the resin was incubated with a solution of DTT (5 equiv) and DIPEA (10 equiv) in 5 mL of DMF at 37 °C for 6 h to remove the StBu group. After being washed with DCM × 3 and DMF × 3, 4 mL of DMF, K2CO3 (5 equiv), and DBAA (4 equiv) were added to the resin and incubated at 37 °C overnight. Fifteen milliliters of a TFA cocktail including TFA/TIPS/H2O = 95:2.5:2.5 was used to cleave the peptide from the resin. After being precipitated from cold ether, the precipitate was dissolved in CH3CN/H2O = 1:1 at a concentration of 5 mg/mL, purified with semipreparative RP-HPLC at a gradient of 15−50% B over 30 min, and then lyophilized. Next, 15.25 mg of 7 was obtained with a yield of 7.6% based on resin loading. 7 was identified with analytical RP-HPLC at a gradient of 10−50% B over 30 min and ESI-MS. MS (ESI+) calcd for 7: C42H77N15O11S [M + H]+ 1001.2, found 1000.7; [M + 2H]2+ 501.1, found 500.9. Synthesis of SapB (1). Peptide 7 (0.85 mg, 0.85 μmol, 1.55 equiv) was dissolved in 200 μL of buffer B and then placed in a −20 °C ice-salt bath. Ten microliters of NaNO2 aqueous solution (0.85 M, 15.5 equiv) was added into the peptide solution and reacted at −20 °C for 20 min. Next, 2.52 mg of MPAA (14.8 μmol, 27 equiv) was dissolved in 200 μL of buffer C and then added to the peptide solution. After 10 s vortex, the pH was adjusted to 5.5, and then 0.70 mg of peptide 5 (0.55 μmol, 1 equiv) was added. The reaction was carried out on a 37 °C thermostatic metal bath with 300 rpm for 4 h. One hundred microliters of TCEP·HCl aqueous solution (0.45 M, 50 equiv) was added to the reaction solution and incubated for 5 min. The reaction solution was monitored using analytical RP-HPLC at a gradient of 15−50% B over 30 min. With purification using analytical RP-HPLC at a gradient of 15−50% B over 30 min, 0.51 mg of peptide 8 was obtained after being lyophilized. 8 was dissolved and cyclized in 300 μL of buffer A in a 2 mL Eppendorf tube at 25 °C for 2 h. With purification using analytical RP-HPLC at a gradient of 15−50% B over 30 min, the former diastereoisomer in HPLC was selected as 9 and lyophilized. 9 was dissolved in 300 μL of H2O/CH3COOH = 1:1 solution, and 50 equiv of CH3COOAg was added to the solution and incubated at 37 °C for 6 h. Next, 150 equiv of DTT was used to quench the reaction by incubating it with the reaction solution for 5 min and then centrifuged for 5 min at 6000 rpm. The supernatant was purified using analytical RP-HPLC at a gradient of 15−50% B over 30 min. The obtained 10 was dissolved in 200 μL of buffer A, and 20 μL of DBAA (0.5 M in DMF) was added to the peptide solution. The resulting solution reacted at 25 °C for 1 h and then 37 °C for 3 h. With purification using analytical RP-HPLC at a gradient of 15−50% B over 30 min, 0.17 mg of purified SapB (peptide 1) was obtained after being lyophilized. The yield was about 9.8% based on the amount of 3. 8, 9, 10, and 1 were identified with RP-HPLC and ESIMS. MS (ESI+) calcd for 8: C90H153N27O31S4 [M + 2H]2+ 1119.8, found 1119.6. MS (ESI+) calcd for 9: C90H153N27O31S4 [M + 2H]2+ 1119.8, found 1119.8. MS (ESI+) calcd for 10: C84H143N25O29S4 [M + 2H] 2+ 1048.7, found 1048.6. MS (ESI+) calcd for 1: C84H139N25O29S2 [M + 2H]2+ 1014.6, found 1014.6; [M + 3H]3+ 676.7, found 676.7. EXPERIMENTAL SECTION General. All the chemical reagents used here except DBAA were purchased from commercial resources and used without further purification. Amino acids mentioned below were used for peptide synthesis: Fmoc-Asn(Trt)-OH, Fmoc-Cys(Trt)-OH, Fmoc-Thr(tBu)-OH, Fmoc-Ile-OH, Fmoc-Cys(Acm)-OH, Fmoc-Leu-OH, Fmoc-Ser(tBu)-OH, Fmoc-Cys(StBu)-OH, Fmoc-Asp(OtBu)-OH, Fmoc-Gly-OH, Boc-Thz-OH, Fmoc-Ala-OH, Fmoc-Arg(Pdf)-OH. HPLC-grade CH3CN, CH3OH, and TFA were purchased from commercial suppliers and used for peptide purification and analysis. Peptide synthesis was completed manually using a peptide synthesis bubbler vessel. Peptides were purified using semipreparative reversephase high-performance liquid chromatography (RP-HPLC) at a flow rate of 10 mL/min after cleaved from resins. The semipreparative column was a reversed-phase C18 column (YMC, 5 μm, 250 mm × 20 mm). All the peptides were analyzed using analytical HPLC with a reversed-phase C8 or C18 column (YMC, 5 μm, 150 mm × 4.6 mm) at a flow rate of 0.8 mL/min. The two solutions for HPLC are (A) water with 0.06% TFA and (B) CH3CN/H2O = 4:1 with 0.06% TFA. Peptides were identified by ESI-MS using a Thermo MSQ Plus singlequadrupole electrospray ionization mass spectrometer. CH3CN/H2O = 1:1 with 0.06% formic acid was utilized as the solution at a flow rate of 0.4 mL/min. Reaction buffers used in the procedure: buffer A: 50 mM Na2HPO4, pH 8.5; buffer B: 6 M Gn·HCl, 200 mM Na2HPO4, pH 3.0; buffer C: 6 M Gn·HCl, 200 mM Na2HPO4, pH 7.4. Synthesis of Peptide 5. 2-Chlorotrityl resin (1.01 g, 0.911 mmol/g) was swelled in 6 mL of DCM for 0.5 h. Then, 0.25 mmol Fmoc-Asn(Trt)-OH was dissolved in 5 mL of DCM with 3 drops of DMF and 220 μL of DIPEA, and this solution was incubated with the resin in the peptide synthesis bubbler vessel for 2 h. After being washed with DCM three times, a solution of DCM/CH3OH/DIPEA = 17:2:1 was used to cap the unreacted sites for 5 min × 3. Fmoc was removed using 20% piperidine solution in DMF. The following amino acids (4 equiv) were coupled with HATU/HOAt/DIPEA (4 equiv/4 equiv/8 equiv) activation and monitored by a Kaiser test reagent. The coupling reaction was carried out for 45 min, and the Fmoc deprotection was for 5 min + 10 min. When the last Boc-Thz-OH coupling was finished, the resin was incubated with a solution of DTT (5 equiv) and DIPEA (10 equiv) in 5 mL of DMF at 37 °C for 6 h to remove the StBu group. After being washed with DCM × 3 and DMF × 3, 4 mL of DMF, K2CO3 (5 equiv), and DBAA (4 equiv) were added to the resin and incubated at 37 °C overnight. Fifteen milliliters of a TFA cocktail including TFA/TIPS/H2O = 95:2.5:2.5 was used to deprotect and cleave the peptide from the resin. After being precipitated from cold ether, the precipitate was dissolved in HFIP at a concentration of 10 mg/mL, purified with semipreparative RPHPLC at a gradient of 15−50% B over 30 min, and then lyophilized. Next, 12.02 mg of 3 was obtained with a yield of 3.8% based on resin loading. Then, 2.00 mg of peptide 3 was dissolved in 1 mL of buffer A and then divided equally in two 2 mL Eppendorf tubes. The tubes were placed on at 25 °C thermostatic metal bath and shaken at 300 rpm for 1.5 h. The reaction solution was monitored with an analytical C8 column RP-HPLC at a gradient of 10−50% B over 30 min, and full conversion of 3 was observed. The major diastereoisomer was separated with a C18 analytical column at a gradient of 15−45% B over 30 min, and then it was treated with MeONH2·HCl (150 equiv) and TCEP·HCl (40 equiv), followed by adjusting the pH to 4.0, and then the resulting solution was shaken at 37 °C for another 24 h. After purification with analytical RP-HPLC at a gradient of 10−50% B over 30 min, 1.51 mg of pure peptide 5 was obtained with the isolated yield of 75.7%. 3, 4, and 5 were identified with RP-HPLC and ESI-MS. MS (ESI+) calcd for 3: C49H80N14O20S3 [M + H]+ 1282.4, found 1281.7; 7531 DOI: 10.1021/acs.joc.8b00259 J. Org. Chem. 2018, 83, 7528−7533 Note The Journal of Organic Chemistry Synthesis of 2,5-Dibromoadipamide. DBAA was synthesized using the reported method16 with a yield of 43.2%: 1H NMR (DMSO-d6, 400 MHz) δ = 1.81−2.11 (4H, m, CH2CH2), 4.37 (2H, m, 2 × CHBr), 7.35 (2H, s), 7.73 (2H, s) (2 × NH2); 13C NMR (DMSO-d6, 400 MHz) δ = 32.47, 32.58 (2 × CH2), 48.23, 48.51 (2 × CHBr), 169.79, 169.85 (2 × CO); MS (ESI+) calcd for DBAA C6H10Br2N2O2 [M + H]+ 302.9, found 302.9. CD Analysis of 3 and 4. The peptide solutions were prepared at a concentration of 0.5 mg/mL in buffer (10 mM NaH2PO4/Na2HPO4, pH 5.0). The CD spectra were measured in the standard procedure with a Chirascan Plus CD. Ellman Reagent Test of 3 and 4. Peptide 3 or 4 (0.10 mg) was dissolved in 200 μL of buffer (50 mM NaH2PO4/Na2HPO4, pH 5.0). Ten equivalents of 5,5′-dithiobis(2-nitrobenzoic acid) (Ellman’s reagent) was added to each peptide solution and then shaken at 25 °C for 30 min. The reactions were monitored using analytical RPHPLC at a gradient of 10−50% B over 30 min and ESI-MS. ■ (2) (a) Breukink, E.; de Kruijff, B. Lipid II as a Target for Antibiotics. Nat. Rev. Drug Discovery 2006, 5, 321−332. (b) Willey, J. M.; van der Donk, W. A. Lantibiotics: Peptides of Diverse Structure and Function. Annu. Rev. Microbiol. 2007, 61, 477−501. (c) Donia, M. S.; Fischbach, M. A. Small Molecules from the Human Microbiota. Science 2015, 349, 1254766. (3) Tabor, A. B. Recent Advances in Synthetic Analogues of Lantibiotics: What Can We Learn from These? Bioorg. Chem. 2014, 55, 39−50. (4) (a) Ortega, M. A.; Hao, Y.; Zhang, Q.; Walker, M. C.; van der Donk, W. A.; Nair, S. K. Structure and Mechanism of the tRNAdependent Lantibiotic Dehydratase NisB. Nature 2015, 517, 509− 512. (b) Ortega, M. A.; van der Donk, W. A. New Insights into the Biosynthetic Logic of Ribosomally Synthesized and Post-translationally Modified Peptide Natural Products. Cell Chem. Biol. 2016, 23, 31−44. (c) Chatterjee, C.; Paul, M.; Xie, L. L.; van der Donk, W. A. Biosynthesis and Mode of Action of Lantibiotics. Chem. Rev. 2005, 105, 633−683. (d) Repka, L. M.; Chekan, J. R.; Nair, S. K.; van der Donk, W. A. Mechanistic Understanding of Lanthipeptide Biosynthetic Enzymes. Chem. Rev. 2017, 117, 5457−5520. (5) Urban, J. H.; Moosmeier, M. A.; Aumuller, T.; Thein, M.; Bosma, T.; Rink, R.; Groth, K.; Zulley, M.; Siegers, K.; Tissot, K.; Moll, G. N.; Prassler, J. Phage Display and Selection of Lanthipeptides on the Carboxy-Terminus of the Gene-3 minor Coat Protein. Nat. Commun. 2017, 8, 1500. (6) Mohr, K. I.; Volz, C.; Jansen, R.; Wray, V.; Hoffmann, J.; Bernecker, S.; Wink, J.; Gerth, K.; Stadler, M.; Muller, R. Pinensins: the First Antifungal Lantibiotics. Angew. Chem., Int. Ed. 2015, 54, 11254−11258. (7) Marki, F.; Hanni, E.; Fredenhagen, A.; Vanoostrum, J. Mode of Action of the Lanthionine-Containing Peptide Antibiotics Duramycin, Duramycin-B and Duramycin-C, and Cinnamycin as Indirect Inhibitors of Phospholipase-A2. Biochem. Pharmacol. 1991, 42, 2027−2035. (8) Ferir, G.; Petrova, M. I.; Andrei, G.; Huskens, D.; Hoorelbeke, B.; Snoeck, R.; Vanderleyden, J.; Balzarini, J.; Bartoschek, S.; Bronstrup, M.; Sussmuth, R. D.; Schols, D. The Lantibiotic Peptide Labyrinthopeptin A1 Demonstrates Broad Anti-HIV and Anti-HSV Activity with Potential for Microbicidal Applications. PLoS One 2013, 8, e64010. (9) (a) Kodani, S.; Hudson, M. E.; Durrant, M. C.; Buttner, M. J.; Nodwell, J. R.; Willey, J. M. The SapB Morphogen is a LantibioticLike Peptide Derived from the Product of the Developmental Gene RamS in Streptomyces Coelicolor. Proc. Natl. Acad. Sci. U. S. A. 2004, 101, 11448−11453. (b) Kodani, S.; Lodato, M. A.; Durrant, M. C.; Picart, F.; Willey, J. M. SapT, a Lanthionine-Containing Peptide Involved in Aerial Hyphae Formation in the Streptomycetes. Mol. Microbiol. 2005, 58, 1368−1380. (10) Ross, A. C.; Liu, H. Q.; Pattabiraman, V. R.; Vederas, J. C. Synthesis of the Lantibiotic Lactocin S Using Peptide Cyclizations on Solid Phase. J. Am. Chem. Soc. 2010, 132, 462−463. (11) (a) Tabor, A. B. The Challenge of the Lantibiotics: Synthetic Approaches to Thioether-Bridged Peptides. Org. Biomol. Chem. 2011, 9, 7606−7628. (b) Shi, Y.; Yang, X.; Garg, N.; van der Donk, W. A. Production of Lantipeptides in Escherichia coli. J. Am. Chem. Soc. 2011, 133, 2338−2341. (c) Zhang, X. G.; Ni, W. J.; van der Donk, W. A. Synthesis of Nonproteinogenic Amino Acids to Probe Lantibiotic Biosynthesis. J. Org. Chem. 2005, 70, 6685−6692. (d) Liu, H. Q.; Pattabiraman, V. R.; Vederas, J. C. Synthesis and Biological Activity of Oxa-Lacticin A2, a Lantibiotic Analogue with Sulfur Replaced by Oxygen. Org. Lett. 2009, 11, 5574−5577. (e) Zambaldo, C.; Luo, X.; Mehta, A. P.; Schultz, P. G. Recombinant Macrocyclic Lanthipeptides Incorporating Non-Canonical Amino Acids. J. Am. Chem. Soc. 2017, 139, 11646−11649. (12) Fukase, K.; Kitazawa, M.; Sano, A.; Shimbo, K.; Fujita, H.; Horimoto, S.; Wakamiya, T.; Shiba, T. Total Synthesis of Peptide Antibiotic Nisin. Tetrahedron Lett. 1988, 29, 795−798. (13) (a) Bregant, S.; Tabor, A. B. Orthogonally Protected Lanthionines: Synthesis and Use for the Solid-Phase Synthesis of an ASSOCIATED CONTENT * Supporting Information S The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acs.joc.8b00259. Copies of the 1H NMR and 13C NMR spectra of DBAA; analytical HPLC and ESI-MS data of peptides 3, 4, 8, 9, and 10; analytical HPLC and ESI-MS data of Ellman reagent test; analytical HPLC and ESI-MS data of the NCL reaction between 5 and 7; analytical HPLC trace for the Michael addition reaction of 3 and 8 (PDF) ■ AUTHOR INFORMATION Corresponding Author *E-mail: liym@mail.tsinghua.edu.cn. ORCID Yong-Xiang Chen: 0000-0003-3518-0139 Yan-Mei Li: 0000-0003-1215-5010 Notes The authors declare no competing financial interest. ■ ■ ACKNOWLEDGMENTS This work was supported by the National Natural Science Foundation of China (21332006, 21672126, 81661148047). REFERENCES (1) (a) Funk, M. A.; van der Donk, W. A. Ribosomal Natural Products, Tailored to Fit. Acc. Chem. Res. 2017, 50, 1577−1586. (b) Dang, T.; Sussmuth, R. D. Bioactive Peptide Natural Products as Lead Structures for Medicinal Use. Acc. Chem. Res. 2017, 50, 1566− 1576. (c) Arnison, P. G.; Bibb, M. J.; Bierbaum, G.; Bowers, A. A.; Bugni, T. S.; Bulaj, G.; Camarero, J. A.; Campopiano, D. J.; Challis, G. L.; Clardy, J.; Cotter, P. D.; Craik, D. J.; Dawson, M.; Dittmann, E.; Donadio, S.; Dorrestein, P. C.; Entian, K. D.; Fischbach, M. A.; Garavelli, J. S.; Goransson, U.; Gruber, C. W.; Haft, D. H.; Hemscheidt, T. K.; Hertweck, C.; Hill, C.; Horswill, A. R.; Jaspars, M.; Kelly, W. L.; Klinman, J. P.; Kuipers, O. P.; Link, A. J.; Liu, W.; Marahiel, M. A.; Mitchell, D. A.; Moll, G. N.; Moore, B. S.; Muller, R.; Nair, S. K.; Nes, I. F.; Norris, G. E.; Olivera, B. M.; Onaka, H.; Patchett, M. L.; Piel, J.; Reaney, M. J. T.; Rebuffat, S.; Ross, R. P.; Sahl, H. G.; Schmidt, E. W.; Selsted, M. E.; Severinov, K.; Shen, B.; Sivonen, K.; Smith, L.; Stein, T.; Sussmuth, R. D.; Tagg, J. R.; Tang, G. L.; Truman, A. W.; Vederas, J. C.; Walsh, C. T.; Walton, J. D.; Wenzel, S. C.; Willey, J. M.; van der Donk, W. A. Ribosomally Synthesized and Post-Translationally Modified Peptide Natural Products: Overview and Recommendations for a Universal Nomenclature. Nat. Prod. Rep. 2013, 30, 108−160. 7532 DOI: 10.1021/acs.joc.8b00259 J. Org. Chem. 2018, 83, 7528−7533 Note The Journal of Organic Chemistry Analogue of Nisin Ring C. J. Org. Chem. 2005, 70, 2430−2438. (b) Mothia, B.; Appleyard, A. N.; Wadman, S.; Tabor, A. B. Synthesis of Peptides Containing Overlapping Lanthionine Bridges on the Solid Phase: An Analogue of Rings D and E of the Lantibiotic Nisin. Org. Lett. 2011, 13, 4216−4219. (c) Mohd Mustapa, M. F.; Harris, R.; Esposito, D.; Chubb, N. A. L.; Mould, J.; Schultz, D.; Driscoll, P. C.; Tabor, A. B. Synthesis of a Cyclic Peptide Containing Norlanthionine: Effect of the Thioether Bridge on Peptide Conformation. J. Org. Chem. 2003, 68, 8193−8198. (14) (a) Knerr, P. J.; van der Donk, W. A. Chemical Synthesis of the Lantibiotic Lacticin 481 Reveals the Importance of Lanthionine Stereochemistry. J. Am. Chem. Soc. 2013, 135, 7094−7097. (b) Knerr, P. J.; van der Donk, W. A. Chemical Synthesis and Biological Activity of Analogues of the Lantibiotic Epilancin 15X. J. Am. Chem. Soc. 2012, 134, 7648−7651. (c) Ross, A. C.; McKinnie, S. M.; Vederas, J. C. The Synthesis of Active and Stable Diaminopimelate Analogues of the Lantibiotic Peptide Lactocin S. J. Am. Chem. Soc. 2012, 134, 2008− 2011. (15) (a) Polinsky, A.; Cooney, M. G.; Toypalmer, A.; Osapay, G.; Goodman, M. Synthesis and Conformational Properties of the Lanthionine-Bridged Opioid Peptide [D-AlaL2,AlaL5]Enkephalin as Determined by NMR and Computer Simulations. J. Med. Chem. 1992, 35, 4185−4194. (b) Toogood, P. L. Model Studies of Lantibiotic Biogenesis. Tetrahedron Lett. 1993, 34, 7833−7836. (c) Burrage, S.; Raynham, T.; Williams, G.; Essex, J. W.; Allen, C.; Cardno, M.; Swali, V.; Bradley, M. Biomimetic Synthesis of Lantibiotics. Chem. - Eur. J. 2000, 6, 1455−1466. (d) Zhou, H.; van der Donk, W. A. Biomimetic Stereoselective Formation of Methyllanthionine. Org. Lett. 2002, 4, 1335−1338. (e) Matteucci, M.; Bhalay, G.; Bradley, M. Cystine Mimetics-Solid Phase Lanthionine Synthesis. Tetrahedron Lett. 2004, 45, 1399−1401. (16) Chalker, J. M.; Gunnoo, S. B.; Boutureira, O.; Gerstberger, S. C.; Fernández-González, M.; Bernardes, G. J. L.; Griffin, L.; Hailu, H.; Schofield, C. J.; Davis, B. G. Methods for Converting Cysteine to Dehydroalanine on Peptides and Proteins. Chem. Sci. 2011, 2, 1666. (17) Breman, A. C.; Telderman, S. E.; van Santen, R. P.; Scott, J. I.; van Maarseveen, J. H.; Ingemann, S.; Hiemstra, H. Cinchona Alkaloid Catalyzed Sulfa-Michael Addition Reactions Leading to Enantiopure beta-Functionalized Cysteines. J. Org. Chem. 2015, 80, 10561−10574. (18) (a) Dawson, P. E.; Muir, T. W.; Clarklewis, I.; Kent, S. B. H. Synthesis of Proteins by Native Chemical Ligation. Science 1994, 266, 776−779. (b) Ma, M. R.; Hu, Z. W.; Zhao, Y. F.; Chen, Y. X.; Li, Y. M. Phosphorylation Induces Distinct Alpha-Synuclein Strain Formation. Sci. Rep. 2016, 6, 37130. (c) Zhang, S. Y.; Sperlich, B.; Li, F. Y.; Al-Ayoubi, S.; Chen, H. X.; Zhao, Y. F.; Li, Y. M.; Weise, K.; Winter, R.; Chen, Y. X. Phosphorylation Weakens but Does Not Inhibit Membrane Binding and Clustering of K-Ras4B. ACS Chem. Biol. 2017, 12, 1703−1710. (19) Willey, J.; Santamaria, R.; Guijarro, J.; Geistlich, M.; Losick, R. Extracellular Complementation of a Developmental Mutation Implicates a Small Sporulation Protein in Aerial Mycelium Formation by S-Coelicolor. Cell 1991, 65, 641−650. (20) (a) Wright, T. H.; Bower, B. J.; Chalker, J. M.; Bernardes, G. J. L.; Wiewiora, R.; Ng, W. L.; Raj, R.; Faulkner, S.; Vallee, M. R. J.; Phanumartwiwath, A.; Coleman, O. D.; Thezenas, M. L.; Khan, M.; Galan, S. R. G.; Lercher, L.; Schombs, M. W.; Gerstberger, S.; PalmEspling, M. E.; Baldwin, A. J.; Kessler, B. M.; Claridge, T. D. W.; Mohammed, S.; Davis, B. G. Posttranslational Mutagenesis: a Chemical Strategy for Exploring Protein Side-Chain Diversity. Science 2016, 354, aag1465. (b) Xiong, X. F.; Zhang, H.; Underwood, C. R.; Harpsoe, K.; Gardella, T. J.; Woldike, M. F.; Mannstadt, M.; Gloriam, D. E.; Brauner-Osborne, H.; Stromgaard, K. Total Synthesis and Structure-Activity Relationship Studies of a Series of Selective G Protein Inhibitors. Nat. Chem. 2016, 8, 1035−1041. (21) Okeley, N. M.; Zhu, Y. T.; van der Donk, W. A. Facile Chemoselective Synthesis of Dehydroalanine-Containing Peptides. Org. Lett. 2000, 2, 3603−3606. (22) Shi, L.; Chen, H.; Zhang, S. Y.; Chu, T. T.; Zhao, Y. F.; Chen, Y. X.; Li, Y. M. Semi-Synthesis of Murine Prion Protein by Native Chemical Ligation and Chemical Activation for Preparation of Polypeptide-Thioester. J. Pept. Sci. 2017, 23, 438−444. (23) Fang, G. M.; Li, Y. M.; Shen, F.; Huang, Y. C.; Li, J. B.; Lin, Y.; Cui, H. K.; Liu, L. Protein Chemical Synthesis by Ligation of Peptide Hydrazides. Angew. Chem., Int. Ed. 2011, 50, 7645−7649. (24) Lechner, C. C.; Agashe, N. D.; Fierz, B. Traceless Synthesis of Asymmetrically Modified Bivalent Nucleosomes. Angew. Chem., Int. Ed. 2016, 55, 2903−2906. (25) (a) Yang, A.; Ha, S.; Ahn, J.; Kim, R.; Kim, S.; Lee, Y.; Kim, J.; Soll, D.; Lee, H. Y.; Park, H. S. A Chemical Biology Route to SiteSpecific Authentic Protein Modifications. Science 2016, 354, 623− 626. (b) Freedy, A. M.; Matos, M. J.; Boutureira, O.; Corzana, F.; Guerreiro, A.; Akkapeddi, P.; Somovilla, V. J.; Rodrigues, T.; Nicholls, K.; Xie, B.; Jimenez-Oses, G.; Brindle, K. M.; Neves, A. A.; Bernardes, G. J. L. Chemoselective Installation of Amine Bonds on Proteins through Aza-Michael Ligation. J. Am. Chem. Soc. 2017, 139, 18365− 18375. 7533 DOI: 10.1021/acs.joc.8b00259 J. Org. Chem. 2018, 83, 7528−7533