samsung2ndgenerationsixsigmabreakdown-140718103935-phpapp02

advertisement

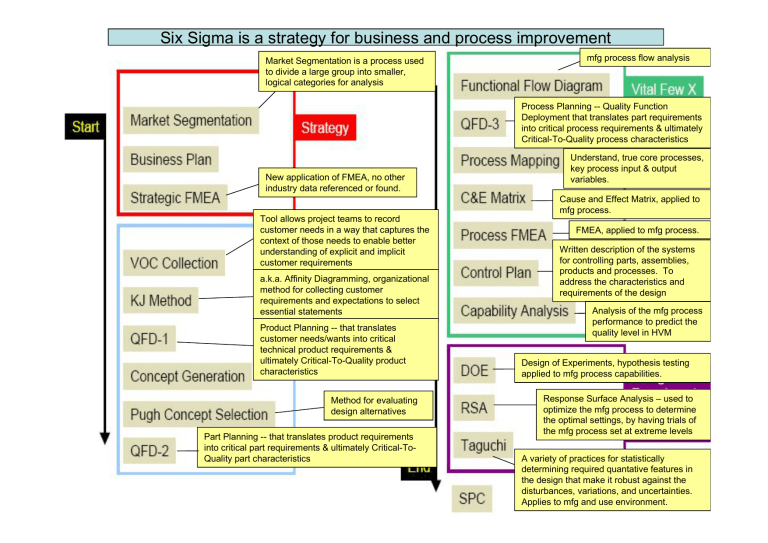

Six Sigma is a strategy for business and process improvement Market Segmentation is a process used to divide a large group into smaller, logical categories for analysis mfg process flow analysis Process Planning -- Quality Function Deployment that translates part requirements into critical process requirements & ultimately Critical-To-Quality process characteristics New application of FMEA, no other industry data referenced or found. Tool allows project teams to record customer needs in a way that captures the context of those needs to enable better understanding of explicit and implicit customer requirements a.k.a. Affinity Diagramming, organizational method for collecting customer requirements and expectations to select essential statements Product Planning -- that translates customer needs/wants into critical technical product requirements & ultimately Critical-To-Quality product characteristics Method for evaluating design alternatives Part Planning -- that translates product requirements into critical part requirements & ultimately Critical-ToQuality part characteristics Understand, true core processes, key process input & output variables. Cause and Effect Matrix, applied to mfg process. FMEA, applied to mfg process. Written description of the systems for controlling parts, assemblies, products and processes. To address the characteristics and requirements of the design Analysis of the mfg process performance to predict the quality level in HVM Design of Experiments, hypothesis testing applied to mfg process capabilities. Response Surface Analysis – used to optimize the mfg process to determine the optimal settings, by having trials of the mfg process set at extreme levels A variety of practices for statistically determining required quantative features in the design that make it robust against the disturbances, variations, and uncertainties. Applies to mfg and use environment.