QAD Purchasing User Guide: GRS, Consignment, Performance

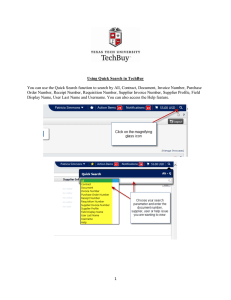

advertisement