Railway Maintenance Plan Review: ECM, CMMS, and LSA

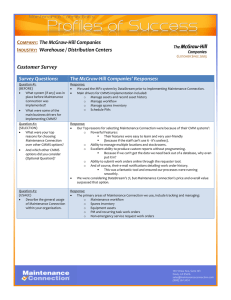

advertisement

Christian DANIEL SNCF RAILWAY REVIEW Let’s describe here the triptych of the Railway Business (Figure 1 : The Railway Triptych), on the right leaf we have the owners (as ROSCO..), on the left leaf we have the train operators and finally in the centre leaf the Maintenance. A closer look to our triptych could divide each leaf into 2 panels. The left top panel is featuring the upcoming rules ISO 55000 (from PAS 55 of BSI) to border the relations between train owners, train operators and the relevant franchising process. The middle top panel is featuring the “Entity in Charge Of Maintenance” (European regulation 2011/445 and the future extensions to the passenger traffic) and the right leaf one’s is supporting the existing “Bible of the interoperability & safety rules” from ERA. A closer look at the center leaf lower panel reveals a blur image of a major issue “The Maintenance Plan”. I will give here some “readings” for a comprehensive and mutual sharing of a potential definition of a Maintenance Plan. Let’s go back to the actors described in the top middle leaf from the E.C.M. The 4 main blocks are the functions of the E.C.M (Entity in Charge of Maintenance) : - Management (leading the 3 following others) Maintenance Development Maintenance Delivery Fleet Management ISO 55 000 / PAS 55 ERA Safety & Interoperability Regulation 2011 / 445 and future extensions Customer’s satisfaction Certification Organism (ANS , Accepted Body , Recognized. BODY) Safety Management System Safety Management System Train Operating Company Rolling Stock Mileage Drivers Train Management ERA Safety & Interoperability ECM Management Maintenance Delivery Fleet Maintenance Development Management Vehicle Parts Owner Train Manufacturer Depot Workshop Left Leaf Center Leaf Right Leaf Figure 1 : The Railway Triptych The “Maintenance Plan” is not visible at the forefront but is structuring the hinges between leafs. A “Maintenance Plan” is a container that should answer the following basic questions: - What : Describe the Maintenance item Why: Describe the job [Preventive / Corrective / Damage … ] Where : In depot / On service / In workshop When : It is the periodicity of the operation Who : Detailed the skill to operate How : Detailed the logistic support The staffs which realize the job in the depot MUST understand the meaning of these simple questions. .The two formers of these questions have a greater weigh into the exchange between business process (we could define them as data and the 4’s others as medata). “WHAT” describes a maintenance item on a rolling stock vehicle so we need two structures: - One to describe the “Class data” ; at the evidence we are facing a gap to standardize this data One to describe the Maintenance item breakdown; ISO 15380 [Railway applications - Designation system for railway vehicles - Part 2: Product groups] is a good opportunity to share the same meaning between all the actors and during the lifetime of the rolling stock. 1 Christian DANIEL SNCF RAILWAY REVIEW “WHY” describes the Maintenance Operation. Generally it is coded by a name; each company using its own code to describe and refer operations. CMMS (Computerized Maintenance Management System) hosts Maintenance Plan (MP) but we can sum-up two categories of MP model: a) Each operation refers to a specific route (with a sequence of task) b) Each operation cross references a list of predefined task. (as described in Figure 2 : Maintenance Plan content) Figure 2 : Maintenance Plan content The a) model gives a feel of simplicity but in case of MP engineering changes, this model gives more modifications in the records from each MP. Routes also are describing activities in a depot, we could reach some limits if a group of depot shares the same routes The b) model is giving more flexibility and simplicity for metadata and engineering changes. “WHEN” is the trigger of the OPERATION. Generally for a Preventive MP Operation it is based on mileage/time meters while Corrective MP is triggered after a fault isolation procedure. Others units are available for Preventive MP Operation but generally they are labelled “Condition Monitoring” [Hours, millimetres …] “WHO” and “HOW” describes the logistic support for the Maintenance Operation. I could recommend the huge work form Aerospace & Defence industries: The 3000L International procedure specification for logistic support analysis. The list of the elements in LSA (Logistic Support Analysis) output during the Maintenance Tasks Analysis (MTA) is: 1) 2) 3) 4) 5) 6) 7) 8) 9) Skill Generic Tools / Specific Tools / Test Equipment Infrastructure Information Technology Support Documentation / Technical Publication Training Parts and expendable Packaging / Handling / Storage / Transport Scrapped Products The LSA Business Process (see Figure 3 :LSA Business Process) places also the Maintenance Plan in the middle of the scene. The Maintenance Plan is structured with the tasks (and the LSA Records) and links to 2 Christian DANIEL SNCF RAILWAY REVIEW documentations (via Technical Publication). The feed-back refines the 9 records with the documentation contents. MAINTENANCE CONCEPT DESIGN DATA’S Reliabilty LOGISTIC SUPPORT Optimisation 9 Records MAINTENANCE PLAN TECHNICAL CONTENTS REPOSITORY Technical Documentation PUBLICATION OF TECHNICAL DOCUMENTATION 9 LSA Items : 1) Skill 2) Generic & Specific Tools / Test Equipment 3) Infrastructure 4) Information Technology Support 5) Documentation / Technical Publication 6) Training 7) Parts and expendable 8) Packaging / Handling / Storage / Transport 9) Scrapped Products FEED_BACK PROCESS MAINTENANCE IN SERVICE Figure 3 :LSA Business Process The Maintenance business process (Figure 4 :Maintenance Plan Business Process) enlarges the activities for each main actor: - - The train manufacturer who issues the first “Maintenance Plan” with the following contents o Preventive Operations scheduled operations (which prevent failure modes) “special events” operations o Corrective Operations Failure (to recover after an isolated fault) Standard Repair (mount and dismount Casualty : Damage Operation after shock or derailment The “Maintenance Development” which organises the sub-data of the Maintenance Plan and actuates the data by analysing feedback from the maintenance Staff The “Maintenance Delivery” which inputs the Maintenance Plan into the CMMS to create “Work Orders” The Maintenance Plan is The key referential data for a CMMS (the second one is the fleet). The daily trains operated by a train operator supplies the CMMS with the mileage. The CMMS compare the threshold of each operation for each rolling stock to the technical limits and create the corresponding preventive work orders. Faults are resolved by isolating the defected parts thus corrective work orders are created manually in the CMMS. The MP could be addressed in 2 formats: - A simple format describing only OPERATION and the relative limits (alias SMP : Simplified Maintenance Plan) A detailed format describing links between Task versus Operation and the logistic support items for each task of each operation (alias DMP : Detailed Maintenance Plan) The choice between SMP & DMP is a matter of 2 elements: - The availability of the data The capacity of the CMMS to operate such data. The DMP allows Life Cycle Cost estimations, an example will be analysed later 3 Christian DANIEL SNCF RAILWAY REVIEW Work Order Process Train Manufacturer Owner Maintenance Development Train Operator Maintenance Task Analysis Fleet Trains Tasks LSA Records Operation= Tasks Maintenance Plan « Call For Change » Fault Management DMP New release Mileage Maintenance Plan « As Design » Maintenance Plan « As built » SMP CMMS Work Orders Service Experience Figure 4 :Maintenance Plan Business Process The registration 2011/445 is requesting namely two major data from the actor “Maintenance Development” to the actor “Maintenance Delivery”: Maintenance Plan and Configuration. These are records from specific and heavy Engineering studies. The methodologies to achieve these records are supplementary and CMMS have to separate these records to be compliant with the relevant standard. Maintenance plans refer to a definition of work while configuration data refer to a physical description /organisation of the rolling stock. The standard ISO 10007 determines business process for configuration management. It also specifies that Configuration Management exchanges Data with Maintenance in Operation. Maintenance Plan is organised with maintenance Items on maintenance breakdown and in the same declination, configuration management produces Configuration Breakdown and Configuration items. The overlaid data are populated with LRU (Line Replaceable Unit) which have a meter for Maintenance purpose. Development Data Entry for a Maintenance Management System Maintenance Development Class of Rolling Stock Maintenance Delivery Rolling Stock Fleet Maintenance Breakdown Configuration Installed items Mileage Maintenance Item Overlaid data Trigger + Technical Limits Maintenance Plan Configuration Definition Items CMMS Configuration Definition Breakdown Figure 5 : when Maintenance Plan Overlays Configuration data 4 Christian DANIEL SNCF RAILWAY REVIEW The « Big Picture » of Maintenance Plan (Figure 6: CMMS: Data Management) depicts the major activities around a CMMS at a depot location: a) b) c) d) Maintenance Plan Configuration Changes Services. Only Services activities are not CMMS relevant (but some could manage it). The 3 formers activities are the pillars of any CMMS. We have demonstrated that these 3 activities are resulting from independent studies and independent constrains so CMMS have to preserve these functional independences. ECM : DESIGN REVIEW & RELIABILITY NSA , Europe : LAWS ECM : MAINTENANCE CONCEPT TECHNICAL ENGINEERING SAFETY RECORDS CHANGES CONFIGURATION Change Management Rolling Stock Manufacturer : DESIGN DATA’S Train Operating Company : Operating Conditions LOGISTIC SUPPORT ANALYSIS AND RECORD Train Operating MAINTENANCE PLAN SERVICES Corrective Maintenance Replenishment IT Updates Preventive Maintenance Configuration Management Special Events Scheduled Damage Standard Repair Failures Casualty Work Orders tracked on CMMS OPERATE & MAINTAIN FLEET Figure 6: CMMS: Data Management A DMP (Detailed Maintenance Plan) offers any train owner to simulate the maintenance cost over long period (as long as the entire life). In case of franchising process some matters appear when the length of franchise reaches the first critical component overhaul. In the example (Figure 7:LCC Estimate) , we have estimate the preventive maintenance cost per month. The red line giving a average cost , the pointed out elements (10 , 15 , 17 , 20 years) will introduce non linearity in the franchising cost. The better the DMP will be at the beginning of franchising, the smoother will be the exchange between the train operator and the owner (are these maintenance items to include, to exclude or to challenge?). A third partner has perhaps the key to these challenges: the Maintenance Development. The Maintenance development has to analyze continuously defects, faults and wears to issue at constant period a new DMP for these maintenance items. The quality of the service experience is a key factor to validate the hypothesis made of the train manufacturer level; whatever the recalculation will be (optimistic or pessimistic) , it will impact the franchising process. 5 Christian DANIEL SNCF RAILWAY REVIEW K€ Figure 7:LCC Estimate My conclusion: MP (SMP or DMP) is a key dynamic data which structure the Maintenance Process of a fleet. Many business processes are based on these data and they could be considered as a framework for many actors. Exchanging data means also standardization to achieve updating of the business processes. We are now entering a new scheme were actors jump from a organisation to another and gaining more standardization in the data will solve planning and cost issues in fleet transfers. But we have also to look to the best of breed of the “S Series : S1000D/S2000M/S3000L” and see how we could decline these methodologies to our railways industry. It’s may be the right time now to open our LSA think tanks. 6