Adoption of Overhead Rigid Conductor Rail System in MTR Extensions

advertisement

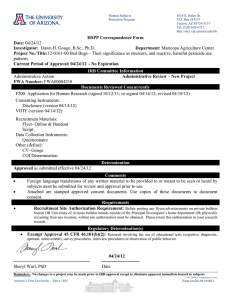

Journal of International Council on Electrical Engineering ISSN: (Print) 2234-8972 (Online) Journal homepage: http://www.tandfonline.com/loi/tjee20 Adoption of Overhead Rigid Conductor Rail System in MTR Extensions Man Kit Mak To cite this article: Man Kit Mak (2012) Adoption of Overhead Rigid Conductor Rail System in MTR Extensions, Journal of International Council on Electrical Engineering, 2:4, 463-466, DOI: 10.5370/JICEE.2012.2.4.463 To link to this article: https://doi.org/10.5370/JICEE.2012.2.4.463 © 2012 Taylor and Francis Group, LLC Published online: 10 Sep 2014. Submit your article to this journal Article views: 2853 Citing articles: 1 View citing articles Full Terms & Conditions of access and use can be found at http://www.tandfonline.com/action/journalInformation?journalCode=tjee20 Journal of International Council on Electrical Engineering Vol. 2, No. 4, pp.463~466, 2012 463 http://dx.doi.org/10.5370/JICEE.2012.2.4.463 Adoption of Overhead Rigid Conductor Rail System in MTR Extensions Mak, Man Kit† Abstract – The conventional overhead catenary system for both 1500V d.c. traction system and 25kV a.c. traction system have been used in the existing railways of Mass Transit Railway Corporation Limited (MTRCL) in Hong Kong for over 20 years. Another type of overhead line system, the overhead rigid conductor rail system has now been increasingly used in the tunnel sections of underground metro system in Europe, Mainland China and South Korea. The non-tension and low resistance characteristics of the rigid conductor rail system have advantages in enhancing and improving various aspects including energy efficiency, reliability, maintainability and availability of the overhead line system. This paper gives an outline of the overhead rigid conductor rail system and the benefits of adopting such system for the new MTR extensions including West Island Line, Kwun Tong Line Extension, South Island Line (East) and Shatin to Central Link. The result of simulation study to demonstrate the acceptable dynamic performance for the interface with the pantograph of rolling stock for line operating speed up to 130kph is included in this paper. Keywords: Rigid conductor rail, Catenary, ORCR, OCS 1. Introduction The Overhead Rigid Conductor Rail (ORCR) System for railway has been used in Europe since the 80’s. It has been adopted in the tunnel sections of underground metro system in the low voltage range from 750V d.c. to 3000V d.c. and for heavy rails at the high voltage range from 15kV a.c. to 25kV a.c. The ORCR system for 1500V d.c. system and 25kV a.c. system inside tunnels has been widely adopted, not only in Europe, but also in Asia, especially in Mainland China and South Korea. The operating speed for ORCR system has been up to 100kph for d.c. system and 160kph in a.c. system. There are benefits in adopting ORCR system in MTR extensions as compared to the conventional overhead catenary system (OCS) which have been used in existing railways for both 1500V d.c. system and 25kV a.c. system for over 20 years. The benefits include capital cost saving and improvements in energy efficiency, maintainability, reliability and availability. 2. General Description of ORCR System † Corresponding Author: Project Division, MTR Corporation Limited , Hong Kong (mkmak@mtr.com.hk) Received: September 27, 2012; Accepted: September 28, 2012 The ORCR system comprises an aluminium conductor profile with a copper alloy grooved contact wire inserted with special conducting grease at the bottom pinch as shown in Fig. 1. The characteristics of the aluminium conductor profile are summarised as below: Nominal Cross sectional area Profile Height Top Width Weight Vertical Inertia Horizontal Inertia Module of elasticity Coefficient of linear expansion Maximum Resistance at 20oC 2214 mm2 110 mm 85 mm 5.9 kg/m 110 cm4 335 cm4 69000 N/mm2 24 x 10-6 oC-1 0.0149Ω/km This profile bears similarity to the messenger wire in conventional overhead catenary system (OCS) in supporting the contact wire and has been standardised among different manufacturers. The aluminium conductor profile as well as the contact wire need not be in tension to maintain the required level. Thus there is no tensioning device such as balance weight assembly and associated termination accessories for the ORCR system. The continuous current rating of the standard rigid conductor rail, i.e. the aluminium conductor profile with the single contact wire is 3,000A and the resistivity at 20oC is 0.032Ω-mm2/m. This capacity is particularly advantageous for metro with 1500V d.c. system where high current 464 Adoption of Overhead Rigid Conductor Rail System in MTR Extensions capacity is required. For the 1500V d.c. 3000A OCS, a total of six overhead copper wires including 2 x 120mm2 contact wires plus 4 x 150mm2 messenger/auxiliary feeder wires are needed to achieve the required capacity. In addition, the copper loss of ORCR system is about 40% less than OCS for 1500V d.c. system due to its lower resistance. Fig. 2. Arrangement of transition section. Fig.1. Cross section of aluminium conductor profile. Staggers, which are arranged in a zig-zag manner on conventional overhead catenary system to spread the wear on pantograph carbon strips, will be configured in a sinusoidal curved shape in ORCR system. A maximum off-set value of about 250mm and 400mm from track centre is normally adopted to spread more evenly on the carbon strips for 1500V d.c. system and 25kV a.c. system respectively. There are two types of transition arrangements which will allow smooth passage from catenary system to ORCR system and vice versa without creating hard points in the system: (1) Transition Section – It gradually reduces the inertia and increases the flexibility as it gets near the conventionally suspended contact wire by the progressively cutting out the profile to enable smooth transition from OCS to ORCR and vice versa. This transition section arrangement is shown in Fig. 2 and has been widely used. (2) Parallel Running of Two Systems – The two systems are arranged in parallel and mechanically separated from each other. The arrangement is shown in Fig. 3. In the overlap section, the catenary contact wire is gradually increasing its inertia and flexibility to match with ORCR to allow smooth transition from one system to another. Fig. 3. Paralleling the two systems as transition. Hinged Arm Arrangement for 25kV a.c. System Roof Mounted Arrangement for 1500V d.c. System Fig. 4. Supports for ORCR system. These transition devices are proven in numerous d.c. and a.c. traction railway projects for passing from OCS to ORCR and vice versa. The aluminium conductor profile as adopted in 1500V d.c. system is similar to the 25kV a.c. system. The only difference between 1500V d.c. system and 25kV a.c. Mak, Man Kit 465 system is the support arrangement of the aluminium conductor profile. In 1500V d.c. system, the profile is normally suspended from the roof whilst hinged arms are used in 25kV a.c. system in order to reduce the headroom requirement. The two typical support arrangements are shown in Fig. 4. 3. Simulation Study on ORCR and Pantograph Interface Performance Computer simulation studies have been carried out to ensure the ORCR and pantograph compatibility. The model of the pantograph mounted on the existing IKK trains which are running on the West Rail Line in Hong Kong was adopted. Maximum operating speed of 130kph with 400mm stagger was simulated. The simulation study was performed on the interaction between pantograph and the ORCR system based on various considerations, such as turnout location, transition section from conventional catenary system to ORCR system, section insulator, ORCR expansion joint and neutral section location. The results of the simulations for the transition from OCS to ORCR and the neutral section location are highlighted in Fig. 5 and 6 respectively. The simulation results indicated that the contact force is positive and below the maximum contact force of 250N for operating speed up to 130kph. The dynamic behaviour of the pantographs is satisfactory and fully complies with the international standard EN50119 “Electric Traction Overhead Contact Lines”. Fig. 6. Contact force of pantograph – neutral section. 4. Maintainability, Reliability and Availability 4.1 Maintainability The conventional catenary system requires many differrent types of components. The ORCR system will only require fewer components (less than 30 items). As the aluminium conductor profile is tandardized among different manufacturers, the components from different manufacturers are interchangeable. Thus, the inventory of spare ORCR components will be relatively less as long as significant length of ORCR is installed. In general practice, the average percentage worn out of the cross sectional area of contact wire before replacement is 20% for OCS. As the contact wire for ORCR system is non-tensioned, it is acceptable to have worn out up to 50%. The service life of the contact wire for OCS is around 25 years whilst service life of 30 years is expected for ORCR system. The maintenance cost of ORCR system will be much less than that of the OCS. The maintenance cost of ORCR system is about one-third of that for OCS. 4.2 Reliability Fig. 5. Contact force of pantograph – transition from OCS to ORCR. The major advantage of ORCR system is its nontensioned characteristic. It will not cause the dewirement of contact wire, which normally results in severe damage of overhead line system and train disruption. In case a support of a span length of ORCR fails, the adjacent supports on both sides will temporarily hold the system and the train will still be able to pass through the faulty ORCR section at a reduced speed. Adoption of Overhead Rigid Conductor Rail System in MTR Extensions 466 From experience, components fell down fouling the pantograph and the associated chain effect is the major factor in reliability. ORCR requires less components and moving parts compared with OCS and thus will improve the reliability. Another major characteristic of ORCR system is its fire withstanding performance inside the tunnel. With the same fire intensity, the tensioned overhead catenary wires will be broken whilst the ORCR system can stay intact and ready for use after cooling down. 4.3 Availability In case of overhead line incident, the extent of damage on ORCR system will be limited whilst the extent of damage on OCS will involve one tension length. The recovery time taken for the replacement of ORCR system compared with the conventional catenary system will be much shorter. The recovery time can be reduced from several hours to less than an hour. 5. Capital Cost Saving The major capital cost savings for the adoption of ORCR system are as follows: Elimination of the tunnel niches to house the tension weight assemblies. Reduction of headroom for overhead line equipment installation zone in tunnel leading to a small tunnel diameter. The internal diameter of the bored tunnel using Tunnel Boring Machine (TBM) construction method can be reduced from 6.84m to 6.3m by adopting ORCR system as compared to OCS for 25kV a.c. system. 6. Application to MTR Extensions There are four new extensions including West Island Line (WIL), Kwun Tong Line Extension (KTE), South Island Line (East) (SIL(E)) and Shatin to Central Link (SCL) in Hong Kong. The West Island Line is under construction phase and the other three extensions are under design phase. The traction system, operating speed and alignment adopted for the four new extensions are summarised as below: Extensions WIL KTE SIL(E) SCL Traction System 1500V d.c. 1500V d.c. 1500V d.c. 25kV a.c. Maximum Operating Speed 80 kph 80 kph 80 kph 130 kph Alignment Tunnel Tunnel Tunnel/ Viaduct Tunnel/ Viaduct The ORCR system can be fully applied to the four new extensions according to the operating speed, traction system and alignment adopted for the extensions. The total construction length of the 1500V d.c. ORCR system is about 20km for WIL, KTE and SIL(E) and the total construction length of the 25kV a.c. ORCR system is about 32km for SCL. 7. Conclusion The ORCR system will be adopted in the four new MTR extensions. The benefits of adopting the ORCR system are summarised as below: • The ORCR can significantly reduce the chance of dewirement due to non-tension characteristics of the contact wire under fault and fire incidents. • Recovery time from OHL incidence can be reduced from several hours down to less than an hour. • ORCR can achieve higher reliability than those of OCS. • No hard points will be introduced in the transition sections from OCS to ORCR systems and vice versa. • The copper loss for ORCR system is less than OCS to provide good energy efficiency. • Good current collection between pantograph and contact wire under dynamic conditions for speed up to 130kph. • Overall project cost saving for using ORCR system can be achieved as tunnel size is smaller for 25kV a.c. system and niches to house balance weight assembly can be eliminated. • Reduced maintenance cost as compared to OCS. Mak, Man Kit received MSc degree in Control System from Imperial College of Science and Technology, University of London.