flixborough

advertisement

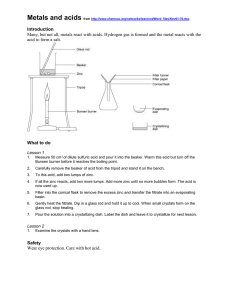

Main Cause: Temporary bypass pipe between Reactor No. 4 and Reactor No. 6 After the No.5 reactor was removed for repair, a temporary bypass pipe was installed between the No.4 reactor and the No.6 reactor. The bypass pipe required an "S" shape, because the reactors were mounted on a sort of staircase. Overview of the bypass between Reactor No. 4 and Reactor No.6 Reactor train vessels R4 to R6 with the temporary bypass pipe with the liquid levels as for full flow. (Source: Teng-yang et al., 2000.) Details of the support for the cranked by for the cranked bypass pipe Forces on bypass pipe Successive stages of a crack-initiated two-stage bellows and pipe bridge failure. Sights and Sounds in the Flixborough Bypass Pipe Bridge Failure Water Sprays A 20 inch pipe and bellows had developed an inner crack from a 6 ft crack in the mild steel cladding which had been caused by nitrate corrosion from a temporary spray of cooling water (to which nitric acid had been added for pH control). Zinc embrittlement of stainless steel Many of the stainless steel pipes taken from the disaster site had suffered cracking due to a process of embrittlement caused by zinc. The zinc had come into contact with the steel whilst it was under stress and elevated temperature. It is plain that a relatively small but fierce fire can, if there is a source of zinc nearby cause a sudden catastrophic failure. Sources of zinc Possible sources of zinc suggested were: (a) galvanised stairways and walkways (b) galvanised wire securing the lagging (c) metal primer chromate paint. How Zinc can possibly transfer to stainless steel (a) An oxide film on the stainless steel resisted zinc penetration: a crack or defect in the oxide film allowed zinc to penetrate. (b) Oxidation of zinc droplets inhibited penetration. (c) Applied stress was necessary for rapid zinc penetration. (d) In most of the experiments liquid zinc was applied to a stainless steel specimen, but zinc vapour was shown to be capable of giving embrittlement. (e) Zinc from a wire can cause embrittlement; the wire needs to be close to the specimen but contact is not essential. Contributory cause Management error Failure by the local management to understand the hazards of the cyclohexane process. No mechanical engineer on-site. Changes to a design should be overseen and authorized by properly qualified personnel Failings in technical measures Plant Modification / Change Procedures: HAZOP Design Codes Pipework: use of flexible pipes No pressure testing was carried out on the installed pipework modification. Plant Layout: positioning of occupied buildings Plant was too congested at the design stage. Poor location and poor construction of the control room. Control Room Design: structural design to withstand major hazards events