SECTION 16450 GROUNDING 16450

advertisement

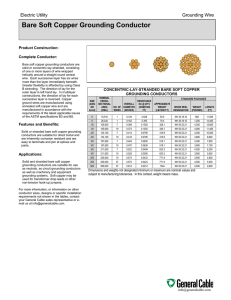

SECTION 16450 GROUNDING PART 1. GENERAL 1.1 SCOPE OF WORK: A. 1.2 1.3 1.4 Furnish labor, materials, equipment and incidentals necessary to install a complete grounding system. Work and shall include the following systems: 1. Power system grounding. 2. Communication system grounding. 3. Electrical equipment and raceway grounding and bonding. RELATED SECTIONS: A. Section 16010 – General Provisions for Electrical Work B. Section 16120 – Wire and Cable C. Section 16670 - Lightning Protection Systems SUBMITTALS: A. General: Submit each item in this Article according to the Conditions of the Contract and Division 1 Specification Sections. B. Product Data for grounding rods, connectors and connection materials, and grounding fittings. C. Qualification data for firms and persons specified in “Quality Assurance” Article to demonstrate their capabilities and experience. Include lists of completed projects with project names and addresses, names and addresses of architects and owners, and other information specified. D. Field tests and observation reports certified by the testing organization and indicating and interpreting the test reports for compliance with performance requirements. QUALITY ASSURANCE: A. Testing Agency Qualifications: A “Nationally Recognized Testing Laboratory” (NRTL) as defined in OSHA Regulation 1910.7, or full member company of the InterNational Electrical Testing Association (NETA). 1. Testing Agency Field Supervision: Use persons currently certified by NETA or the National Institute of Certification in Engineering Technologies to supervise on-site testing specified in Part 3. B. Comply with NFPA 70. C. Comply with UL 467. D. Listing and Labeling: Provide products specified in this Section that are listed and labeled. 16450-1 SECTION 16450 GROUNDING 1. The Terms “Listed” and “Labeled”: As defined in the National Electrical Coe, Article 100. PART 2. PRODUCTS 2.1 MANUFACTURERS: A. 2.2 1. Apache Grounding: Nashville Wire Products. 2. Boggs; H.L. Boggs & Co. 3. Chance: A.B. Chance Co. 4. Erico Inc.; Electrical Products Groug. 5. Ideal Industries, Inc. 6. Kearney. 7. O-Z/Gedney Co. 8. Raco, Inc. 9. Thomas & Betts, Electrical. GROUNDING AND BONDING PRODUCTS: A. 2.3 Manufacturers: Subject to compliance with requirements, provide products by one of the following: Governing Requirements: Where types, sizes, ratings, and quantities indicated are in excess of National Electrical Code (NEC) requirements, the more stringent requirements and the greater size, rating, and quantity indications govern. WIRE AND CABLE GROUNDING CONDUCTORS: A. Comply with Division 16 Section “Wires and Cables.” Conform to NEC Table 8, except as otherwise indicated, for conductor properties, including insulation. B. Equipment Grounding Conductors: Insulated with green color insulation. C. Grounding-Electrode conductors: Stranded cable. D. Underground Conductors: Bare, tinned, stranded, except as otherwise indicated. E. Bare Copper Conductors: conform to the following: 1. Solid Conductors: ASTM B 3. 2. Assembly of Stranded Conductors: ASTM B 8. 3. Tinned Conductors: ASTM B 33. 16450-2 SECTION 16450 GROUNDING 2.4 2.5 2.6 MISCELLANEOUS CONDUCTORS: A. Grounding Bus: Bare, annealed-copper bars of rectangular cross section. B. Braided Bonding Jumpers: Copper tape, braided No. 30 AWG bare copper wire, terminated with copper ferrules. C. Bonding Straps: Soft copper, 0.05 inch thick and 2 inches wide, except as indicated. CONNECTOR PRODUCTS: A. Pressure Connectors: High-conductivity-plated units. B. Bolted Clamps: Heavy-duty type. C. Exothermic-Welded Connections: Provided in kit form and selected per manufacturer’s written instructions for specific types, sizes, and combinations of conductors and connected items. GROUNDING ELECTRODES AND TEST WELLS: A. Grounding Rods: Copper-clad steel. 1. Size: ¾ inch by 120 inches. B. Plate Electrodes: Copper, square or rectangular shape. Minimum 0.10 inches thick, size as indicated. C. Test Wells: Fabricate from 15-inch long, square-cut sections of 8-inch diameter, Schedule 80, PVC pipe. PART 3. EXECUTION 3.1 APPLICATION: A. Equipment Grounding Conductors: Comply with NEC Article 250 for types, sizes, and quantities of equipment grounding conductors, except where specific types, larger sizes, or more conductors than required by NEC are indicated. 1. Install equipment grounding conductor with circuit conductors of the items below in addition to the required by Code: a. Feeders and branch circuits. b. Single-phase motor or appliance branch circuits. c. Three-phase motor or appliance branch circuits. d. Flexible raceway runs. e. Armored and metal-clad cable runs. 16450-3 SECTION 16450 GROUNDING B. 3.2 2. Computer Outlet Circuits: Install separate equipment grounding conductor in branch circuit runs from computer area power panels or power-distribution units. 3. Isolated Grounding-Receptacle Circuits: Install a separate insulated equipment-grounding conductor connected to the receptacle-grounding terminal. Isolate grounding conductor from raceway and from panel board grounding terminals. Terminate at the equipment grounding-conductor terminal of the applicable derived system or service, except as otherwise indicated. 4. Nonmetallic Raceways: Install an equipment-grounding conductor in nonmetallic raceways unless they are designated for telephone or data cables. 5. Air-Duct Equipment Circuits: Install an equipment-grounding conductor to duct-mounted electrical devices operating at 120 V and above, including air cleaners and heaters. Bond conductor to each unit and to air duct. 6. Water Heater, Heat-Tracing, and Antifrost Heater Circuits; Install a separate equipment-grounding conductor to each electric water heater, heat-tracing assembly, and antifrost heating cable. Bond conductor to heater units, piping, connected equipment, and components. Signal and Communication Systems: For telephone, alarm, voice and data, and other communications systems, provide a No. 4 AWG minimum insulated grounding conductor in raceway from grounding-electrode system to each service location, terminal cabinet, wiring closet, and central equipment location. 1. Service and Central Equipment Locations and Wiring Closets: Terminate grounding conductor on a ¼-by-2-by-12-inch grounding bus. 2. Terminal Cabinets: Terminate grounding conductor on cabinet grounding terminal. C. Separately Derived Systems: Where NEC requires grounding, ground according to NEC Paragraph 250-26. D. Connections to Lightning Protection System: Bond grounding conductors, including grounding-conductor conduits, to lightning protection down conductors or lightning protection grounding conductor in compliance with NEPA70. E. Common Ground Bonding with Lightning Protection System: Bond electric power system ground directly to lightning protection system grounding conductor at closest point to electric service grounding electrode. Use bonding conductor sized same as system grounding conductor and install in conduit. INSTALLATION: A. General: Ground electrical systems and equipment according to NEC requirements, except where Drawings or Specifications exceed NEC requirements. B. Grounding Rods: Locate a minimum of 1-rod length from each other and at least the same distance from any other grounding electrode. 16450-4 SECTION 16450 GROUNDING 3.3 1. Drive until tops are 2 inches below finished floor final grade, except as otherwise indicated. 2. Interconnect with grounding-electrode conductors. Use exothermic welds, except at test wells and as otherwise indicated. Make these connections without damaging copper coating or exposing steel. C. Grounding Conductors: Route along the shortest and straightest paths possible, except as otherwise indicated. Avoid obstructing access or placing conductors where they may be subjected to strain, impact, or damage. D. Underground Grounding Conductors: Use bare copper wire. Bury at least 24 inches below grade. E. Metal Water Service Pipe: Provide insulated copper grounding conductors, sized as indicated, in conduit, from building’s main service equipment, or grounding bus, to main metal water service entrances to building. Connect grounding conductors to main metal water service pipes by grounding-clamp connectors. Where a dielectric main water fitting is installed, connect grounding conductor to street side of fitting. Do not install a grounding jumper across dielectric fittings. Bond groundingconductor conduit to conductor at each end. F. Water Meter Piping: Use braided-type bonding jumpers to electrically bypass water meters. Connect to pipe with grounding-clamp connectors. G. Bond interior metal piping systems and metal air ducts to equipment grounding conductors of associated pumps, fans, blowers, electric heaters, and air cleaners. Use braded-type bonding straps. H. Test Wells: One for each driven grounding electrode, except as otherwise indicated. Set top of well flush with finished grade or floor. Fill with 1-inch-maximum-size crushed stone or gravel. I. Ufer Ground (Concrete-Encased Grounding Electrode): Fabricate according to NEC Paragraph 250-50 (c), using a minimum of 20 feet of bare copper conductor not smaller than No. 4 AWG. Where base of concrete foundations is less than 20 feet in length, coil excess conductor within base of concrete foundation. Bond grounding conductor to reinforcing steel to at least 4 locations, and to anchor bolts. Extend grounding conductor below grade and connect to building grounding grid or to a grounding electrode external to concrete. CONNECTIONS: A. General: Make connections so possibility of galvanic action or electrolysis is minimized. Select connectors, connection hardware, conductors, and connection methods so metal is direct contact will be galvanically compatible. 1. 2. 3. Use electroplated or hot-tin-coated materials to assure high conductivity and to make contact points closer in order of galvanic series. Make connections with clean, bare metal at points of contact. Make aluminum-to-steel connections with stainless-steel separators and mechanical clamps. 16450-5 SECTION 16450 GROUNDING 4. 5. 3.4 Make aluminum-to-galvanized steel connections with tin-plated copper jumpers and mechanical clamps. Coat and seal connections having dissimilar metals with inert material to prevent future penetration of moisture to contact surfaces. B. Exothermic-Welded Connections: Use for connections to structural steel and for underground connections, except those at test wells. Comply with manufacturers written instructions. Welds that are puffed up or that show convex surfaces indications improper cleaning are not acceptable. C. Equipment Grounding-Wire Terminations: for No. 8 AWG and larger, use pressuretype grounding lugs. No. 10 AWG and smaller grounding conductors may be terminated with winged pressure-type connectors. D. Noncontact Metal Raceway Terminations: Where metallic raceways terminate at metal housings without mechanical and electrical connection to housing, terminate each conduit with a grounding bushing. Connect grounding bushings with a bare grounding conductor to grounding bus or terminal in housing. Bond electrically noncontinuous conduits at both entrances and exits with grounding bushings and bare grounding conductors, except as otherwise indicated. E. Connections at Test Wells: Use compression-type connectors on conductors and make bolted-and clamped-type connections between conductors and grounding rods. F. Tighten screws and bolts for grounding and bonding connectors and terminals according to manufacturer’s published torque-tightening values. Where these requirements are not available, use those specified in UL 486A and UL 486B. G. Compression-Type Connections: Use hydraulic compression tools to provide correct circumferential pressure for compression connectors. Use tools and dies recommended by manufacturer of connectors. Provide embossing die code or other standard method to make a visible indication that a connector has been adequately compressed on grounding conductor. H. Moisture Protection: Where insulated grounding conductors are connected to grounding rods of grounding buses, insulate entire area of connection and seal against moisture penetration of insulation and cable. UNDERGROUND DISTRIBUTION SYSTEM GROUNDING: A. Manholes and Handholes: Install a driven grounding rod close to wall and set rod depth so 4 inches will extend above finished floor. Where necessary, install grounding rod before manhole is placed and provide a No. 1/0 AWG bare, tinnedcopper conductor from grounding rod into manhole through a waterproof sleeve in manhole wall. Protect grounding rods passing through concrete floor with a double wrapping of pressure sensitive tape or heat shrunk insulating sleeve from 2 inches above to 6 inches below concrete. B. Connections to Manhole Components: Connect exposed metal parts, such as inserts, cable racks, pulling irons, ladders, and cable shields within each manhole or handhole, to grounding rod or grounding conductor. Make connections with minimum No. 4 AWG stranded, hard drawn copper wire. Train conductors plumb or level around corners and fasten to manhole walls. Connect to cable armor and cable shields as recommended by manufacturer of splicing and terminations kits. 16450-6 SECTION 16450 GROUNDING C. 3.5 Grounding System: Ground pad-mounted equipment and noncurrent-carrying metal items associated with substations by connecting them to underground cable and grounding electrodes. FIELD QUALITY CONTROL: A. Independent Testing Agency: Engage an independent electrical testing organization to perform tests described below. B. Tests: Subject the completed grounding system to a megger test at each location where a maximum ground-resistance level is specified, at service disconnect enclosure grounding terminal, and at ground test wells. Measure ground resistance not less than 2 full days after the last trace of precipitation, and without the soil being moistened by any means other than natural drainage or seepage and without chemical treatment or other artificial means of reducing natural ground resistance. Perform tests by the 2-point method according to IEEEE 81. C. Maximum grounding to resistance values are as follows: 1. Equipment Rated 500 kVA and less: 10 ohms. 2. Equipment Rated 500 to 1000 kVA: 5 ohms. 3. Equipment Rated More than 1000 kVA: 3 ohms. 4. Pad-Mounted Equipment: 5 ohms. 5. Manhole Ground: 10 ohms. D. Excessive Ground Resistance: Where resistance to ground exceeds specified values, notify Owner promptly and include recommendations to reduce ground resistance and to accomplish recommended work. E. Report: Prepare test reports, certified by the testing organization, of ground resistance at each test location. Include observations of weather and other phenomena that may affect test results. Describe measures taken to improve test results. END OF SECTION 16450-7