Health and Safety Standards

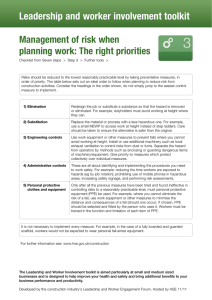

advertisement