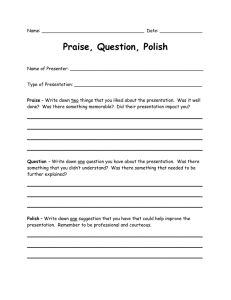

FrenchPolishing

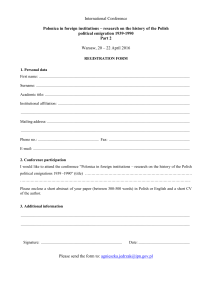

advertisement