JIV-IING

advertisement

April 12, 1960

v. F. DAHLGREYN

METHOD OF PREPARATION

OF THERMO

'RESI N comm PRINTED CIRC

2,932,599

STIC

Filed May 9, 1955

II

ALKALINE

BATH

COPPER

I

2

BLACK

CUPRIC OXIDE

I

0

RINSE

+

3\HCI

+'

FeCI3

I

RINSE

I,

THERMOSETTING

Fig. 2

4\‘NoCN

PHENOLIC RESIN

I

RINSE

i

5\OXIDIZ|NG

*

AGENT

I

RINSE

s\

N6

7

N

\

CURED

TH

OSETT

PHENO

LA

_,

RE

ATE

II

8\

PRESS

RE

NOLIC

BLACK

OXID

CuO

RIC

-| COPPER

‘II

I

COOL

9\

JIV-IING

_T?.

REMOVE

|o

FLUORO

CHLOR

ETHYL

-

THER

ET

PHENOLIC RE

COPPER

TRI- FLUORO

L0

TRI-FLUORO

-

YL

8w PRESS

|

COOL

I

Fig

|

CURED

THERMOSETTING

PHENOLIC RESIN

Victor F. Du

INVEN

III/Kama

Attorney

en

I

United States Patent 0

ICC

1

2,932,599

Patented Apr. 12, 1960

2

greater tendency to flow at a temperature substantially less

than the given temperature is placed in contact with the

2,932,599

imprinted surface. The plastic resins are pressed together

METHOD OF PREPARATION OF THERMOPLASTIC

at a temperature substantially less than the given tem

perature to force the second plastic resin into the follicles

to provide a bond therebetween.

In accordance with the invention there is further pro

vided a method of bonding a thermoplastic resin to a

RESIN COATED PRINTED CIRCUIT

Victor F. Dahlgren, West Windham, N.H., assignor, by

mesne assignments, to Sanders Associates, Incorpo

rated, Nashua, N.H., a corporation of Delaware

thermosetting resin. The method comprises oxidizing

10 the surfaces of a thin sheet of copper to provide the

Application May 9, 1955, Serial No. 507,032

surfaces with a homogeneous coating of black cupric

10 Claims. (Cl. 154-129)

oxide. The cupric oxide coated copper sheet is placed

The present invention relates to printed circuits. More 15

particularly, the invention relates to printed circuits

covered with insulating material.

In the prior art, printed circuits are typically formed

by a?ixing thin copper, sheets with a suitable adhesive to

an insulator base formed from a thermosetting resin such 20

as XXXP-Phenolic (a paper base, phenolic resin lami—

in contact with an uncured sheet of thermosetting resin.

A sufficient degree of heat and pressure is applied to

cure the thermosetting resin and press the copper and the

thermosetting resin sheets together, forming thereby an

imprint of the cupric oxide in the thermosetting resin.

The cupric oxide coated copper clad resin sheet is then

cooled. Cupric oxide coated copper is removed from

the resin sheet to expose the plurality of randomly dis

posed follicles in the resin provided by the imprint. The

nate). The copper is then etched away, leaving a con

thermoplastic resin is placed in contact with the imprinted

ductive pattern in the con?guration of the desired circuit.

surface.

A su?lcient degree of heat and pressure is ap

Thermosetting resins are characteristically excessively hy

plied

to

the

thermoplastic and thermosetting resins to force

groscopic. Under high humidity conditions, insulation re 25 the thermoplastic

resin into the follicles. The thermo<

sistance between conductors is substantially reduced. A

plastic and thermosetting resins are then cooled to pro

relatively new material, tri~?uoro-chloro-ethylene, termed

vide the bond therebetween.

herein “KeL-Ff’. as trade marked and manufactured by

In another embodiment of the invention there is pro

the M. W. Kellogg Company, is substantially superior to

such thermosetting resin material in that it has a very 80 vided a method of insulating a printed circuit with tri

?uoro-chloro-ethylene. The method comprises immers

low permeability to humidity as well as enhanced in

ing

a thin sheet of clean copper in an oxidizing bath

sulation resistance. It has been a great problem to ?nd

comprising a hot aqueous solution consisting essentially

a suitable means for causing Kel—F to adhere to other

of an alkali selected from the group consisting of sodium

systems.

hydroxide and potassium hydroxide and a chlorite selected

In my copending application ?led October 1, 1954, 35 from the group consisting of sodium chlorite and potas

Serial No. 459,841, a method is disclosed for causing

sium chlorite to provide the copper with a homogeneous

copper to adhere to Kel-F. In US. Patent No. 2,551,591

coating

of black cupric oxide. The oxidized copper sheet

issued to S. G. Foord, May 8, 1951, a method is dis

is placed in contact with an uncured sheet of phenolic

closed for bonding polyethylene to copper vby means of

resin laminate. A predetermined degree of heat and

a layer of cuprous oxide. Foord expressly omits the

pressure

is applied to the sheets to cure the resin and press

use of cupric oxide which is essential to the present in—

the copper and resin sheets together, forming thereby

vention.

an imprint of the cupric oxide in the resin. The cupric

It is an object of the present invention to provide an

oxide coated copper clad phenolic laminate is then cooled.

improved method of bonding thermosetting resins to

Cupric oxide coated copper is removed from the sheet

thermoplastic resins.

45 of phenolic laminate to expose the plurality of follicles

‘ It is a further object of the present invent-ion to pro

in the resin provided by the imprint. A sheet of tri

vide a method of bonding Kel-F to a phenolic resin

?uoro-chloro-ethylene is placed in contact with the im

laminate.

printed surface of the phenolic laminate. A sufficient

A still further object of the invention is to provide an

of heat and pressure is applied to the tri-?uoro

improved method for insulating a printed circuit with 50 degree

chloro-ethylene and phenolic laminate to force the tri

Kel-F.

.

a It is a further vobject of the invention to provide an im~

proved printed circuit insulated with Kel-F.

' Other and further objects of the invention will be ap

?uoro-chloro-ethylene into the follicles. The tri-?uoro

chloro~ethylene and phenolic laminate are then cooled

to provide the bond therebetween. .

parent from. the following description of preferred methods 55 Further, in accordance with the invention there is pro

vided, as an article of manufacture, an insulated printed

and embodiments thereof, taken in connection with the

circuit. The circuit comprises a sheet of phenolic resin

accompanying drawing.

lnaccordance with the invention there is presented a

paper laminate to the surface of which are af?xed thin

cupric oxide coated copper conductors. An insulating

method of bonding plastic resin having substantially

different flow characteristics relative to temperature. In 60 cover sheet of tri-?uoro-chloro-ethylene is bonded to the

laminate and the copper conductors with the conductors

accordance with the method a surface of a body of cop

held in insulated spaced relation between the sheets.

pet is oxidized to provide a coating of primarily black

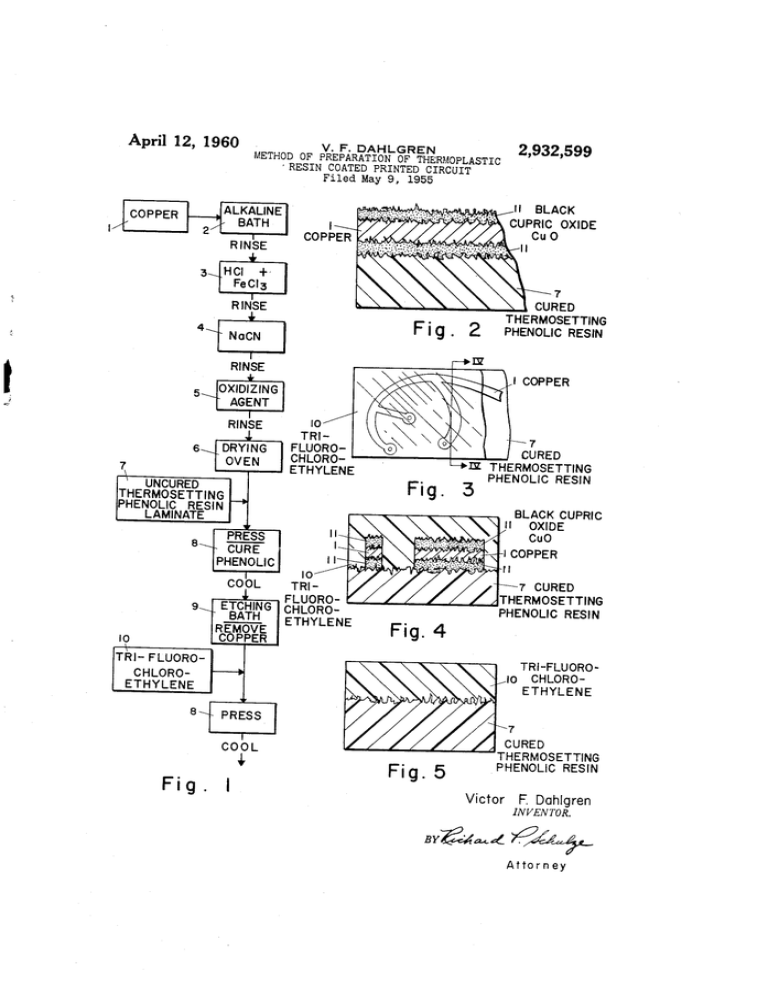

In the accompanying drawing:

.

cupric oxide. The oxide coated copper surface is placed

Fig. 1 is a ?ow chart illustrating the preferred method

in contact with a surface of first plastic resin having a

?ow characteristic at a given temperature. The plastic 65 of the invention;

Fig. 2 is a sectional view of cupric oxide coated cop

‘and cooper are laminated together by means of‘a suf?cient

per clad phenolic resin;

degree of heat and pressure to form thereby an. imprint of

Fig. 3 is a plan View of a Kel-F-coated printed circuit;

the cupric oxide in the plastic. The laminated copper

Fig.

4 is a sectional view of the printed circuit taken

plastic is then cooled. The cupric oxide coated cooper is

along the lines ‘IV-IV in Fig. 3; and

removed from the plastic to expose the plurality of 70

Fig. 5 is a sectional view of a sheet of Kel-F bonded

randomly disposed follicles-in said plastic provided by. the

"imprint," A surface‘ of, a second plastic resin having a

to a thermosetting resin.

.

Referring now to the drawing and with particular refer

2,932,599

,

r

.

3

‘

XXXP from blistering, for example 5 pounds per square

ence to Fig. 1, the thin sheets of copper 1 are ?rst pre

inch pressure with the press 8;

(20) Baking at a temperature in excess of 215° C.

for 40 seconds to force the Kel-F into the exposed fol

licles in the resin provided by the imprint of the removed

pared in the following manner:

(1) Immersing the sheets of copper 1 in a mild alkaline

bath 2 such as Dy-Clene EW Metal Cleaner, as manufac

tured by MacDermid, Inc., Waterbury, Connecticut for

five seconds;

cupric oxide coated copper;

.

,

.

(21) Water cooling the printed circuit in the press;

' (2) Rinsing in cold, running water for ?ve seconds;

" (3) Dipping for 15 seconds in a 10 percent solution

and

>

(22) Removing the Kel~F insulated printed circuit

3 of hydrochloric acid (HCl) which has dissolved in it

from

the press.

'

10

8 ounces per gallon of ferric chloride (FeOl3);

in Fig. 3 a plan view of the insulated printed circuit

(4) Rinsing in cold, running water ‘for ?ve seconds;

is shown. The Kel-F ‘inside diameter is shown incom

(5) Immersing in a 10 percent solution 4 of sodium

plete to expose the copper 1 and cured thermosetting

cyanide (NaCN) for 15 seconds;

phenolic resin laminate 7. In the sectional'v'iew of Fig.

’ (6) Rinsing in cold, running water;

('7) Immersing in an oxidizing agent 5, such as a so

15

lution of 11/2 pounds per gallon of water of Ebonol “C”

Special as manufactured by Enthone Company, New

4, the cupric oxide, CuO, coating 11 is shown greatly

magni?ed.

'

'

"

It will be apparent that in place of the resin-impreg

nated paper, an epoxy resin or silicone resin may just

Haven, Connecticut, for 10 minutes at l90-205° F. to

as well be used. In the place of the impregnated paper,

provide a homogeneous coating of black cupric oxide

impregnated

glass cloth may be used to withstand higher

20

(CuO) on the copper surfaces. The Ebonol “C” Special

temperature operation.

'

‘

'

i

is substantially described in US. Patent #2,364,993 is

It has been found that polytetrailuoroethylene, fa

sued to ‘Walter R. Meyer;

miliarly termed “Te?on” as trade marked and manu

(8) Immersing in cold, running water;

(9) Rinsing in hot, running water for 10 to 20 sec

onds;

,

factured by E. I. du 'Pont de Nemours and Company,

25 may be utilized in place of the Kel~F at a press tem

p

(10) Baking in a preheated oven 6 above 212° F

until all traces of moisture are removed.

7 The sheets of cupric oxide coated copper are bonded

perature of approximately 625 ° F.

'

,

In Fig. 5 the cross-section of lamination of a thermo

plastic resin and a thermosetting resin is shown. Cured

or thermoset phenolic resin 7 is bonded to tri-?uoroe

to a thermosetting resin, for example, a laminate of

,

_

'

paper impregnated with a phenolic resin such as XXXP 30 chloro-ethylene 10 as illustrated.

The use of a thermoplastic overcoat vof the type de

Phenolic, in the following manner:

scribed to encapsulate printed circuits greatly decreases

(11) Placing a sheet of metallic foil, such as alu

'

the hygroscopic characteristics of commonly used ther

minum, on the platen of a press 8, such as manufactured

by Wabash Press Company, Wabash, Indiana. The

mosetting plastic materials by'cutting down their ex

XXXP-Phenolic and the platen;

(12) Placing, for example, six stacked sheets of un

cured XXXP-type phenolic resin impregnated paper,

each, for example, 6 inches long, 2 inches wide and

ings increase the resistivity between electrical conductors

aluminum foil is. used to prevent adherences between the 35 posed surface areas. Te?on or Kel-F insulating coat

on the surface of a printed circuit. The Te?on or Kel-F

insulating coating may be utilized as a resist mask for

plating,v and soldering purposes. Such coatings permit

sealing joints as between a baseplate and a printed circuit

.010 of an inch thick, on the aluminum foil to provide 40 cable,

whereby soldering and sealing can be accomplished

an uncured thermosetting laminate 7;

simultaneously. The present» invention naturally lends

(13) Placing the cupric oxide coated sheet of copper

itself to ?ush mounting of printed circuits.

While there has been hereinbefore describedwhat are

45 at present considered preferred embodiments of the in

sure;

vention, it will be apparent that many and various

, (l4) Baking at 300-3500 F. under pressure for 20'

changes and modi?cations may be made with respect

minutes to cure the resin and provide the cup'ric oxide

to the embodiments illustrated, without departing from

imprint in the resin of the top sheet of the laminate;

the spirit of the invention. It will be understood, ‘there

(15) Water cooling the copper and resin laminate

under maintained pressure in the press to prevent blister 60 fore, that all such changes andv modi?cations as fall

fairly within the scope of the present invention, as de

ing of the XXXP-resin;

t?ned in the appended claims, are to be considered as a

(l6) Removing the cupric oxide coated copper clad

part of the present invention.

resin laminate from the press 8 and the aluminum foil

in contact with the sheets of resin impregnated paper

and applying 300-1000 pounds per square inch of pres~

What is claimed is:

' from the laminate.

,

l. The method of bonding a thermoplastic resin to a

I The XXXP-Phenolic may, of course, be copper clad 55 thermosetting resin comprising, oxidizing the surfaces

on both sides merely by placing sheets of copper both

of a thin sheet of copper .to provide said surfaces with

above and below the sheets of impregnated paper. The

cup'ric oxide coated copper clad phenolic sheet is shown '

in crosssection in Fig. 2. The cupric oxide shown is

greatly‘ magni?ed to more clearly illustrate its imprint

upon the phenolic resin. The cupric oxide coated cop

per clad phenolic laminate is then prepared to provide‘

_ a‘ printed circuit in the desired con?guration and im

a homogeneous coating of black cupric oxide; placing

said cupric oxide coated copper sheet in contact with

an uncured sheet of thermosetting resin; applying a suf

ticient degree of heat and pressure to cure'said thermo

setting resin and press said copper and said thermosetting

resin sheets together, forming thereby an imprint. of said

mersed, for'example, in an acid etching bath 9 in ac

cupric oxide in said thermosetting resin; cooling said

cupric oxide coated copper cladresin sheet; removing

cordance with well-known, conventional photoetching

'cupric oxide coated copper from said resin .sheet to

techniques.’

’

.

~

‘

Theprinted circuit thus prepared is covered with an

insulating sheet 10 of Kel-F in the following manner:

expose the plurality of randomly disposed follicles in

said resin provided by said imprint; placing said thermo

plastic resin in contact with said imprinted surface; and

(17) Placing the printed circuit'on the platen of the 70 applying a sufficient degree of heat and pressure to said

thermoplastic and thermosetting resins to 'force said ther

moplastic resin into said follicles to provide said bond

press 8.;

_ (18) Placing a sheet of Kel-F, for example, 6, inches

long, 2 inches Wide and .002 of an inch thick, over the

therebetween.

'

g

.

t

2. The method of bonding tri-?uoro-chloro-ethylene

‘ (19) Applying su?icient pressure to prevent the 75 to aphenolic-resinilaminate comprising, immersing athin

printed circuit;

5

2,982,599

sheet of clean copper in an oxidizing bath to provide

the copper with a homogeneous coating of black cupric

oxide; placing said oxidized copper sheet in contact with

an uncured sheet of phenolic resin laminate; applying a

predetermined degree of heat and pressure to cure said

phenolic resin and press said copper and phenolic laminate

6

nate; applying a predetermined degree of heat and pressure

to cure said resin and press said copper and resin sheets

together, forming thereby an imprint of said cupric oxide

in said resin; cooling said cupric oxide coated copper clad

phenolic laminate; removing selected areas of cupric oxide

coated copper from said sheet of phenolic laminate to

sheet together, forming thereby an imprint of said cupric

oxide in said laminate; cooling said cupric oxide coated

copper clad phenolic laminate; removing cupric oxide

provide a predetermined conductive pattern and expose

phenolic laminate to force said tri-?uoro-chloro-ethylene

into said follicles; and cooling said t-ri-?uoro-ehloro

ethylene and phenolic laminate to provide said bond

chloro-ethylene and phenolic laminate to provide said

bond therebetween.

6. The method of bonding plastic resins having sub~

stantially different flow characteristics relative to tempera

the plurality of follicles in said phenolic laminate sheet

coated copper from said sheet of phenolic laminate to 10 provided by the exposed areas of said imprint; placing tri

‘ uoro-chloro-ethylene in contact with said imprinted sur

expose the plurality of follicles in said phenolic laminate

face of said phenolic laminate; applying a su?icient degree

sheet provided by said imprint; placing tri-?uoro-chloro

of heat and pressure to said tri-?uoro~chloro-ethylene

ethylene in contact with said imprinted surface of said

and said phenolic laminate to force said tri-?uoro-chloro

phenolic laminate; applying a su?icient degree of heat

and pressure to said tri-?uoro-chloro-ethylene and said 16 ethylene into said follicles; and cooling said tri-?uoro

therebetween.

3. The method of insulating a printed circuit with tri 20 ture, comprising: oxidizing a surface of a body of copper

to provide a coating of primarily black cupric oxide;

placing said cupric-oxide-coated-copper surface in contact

of clean copper in an oxidizing bath to provide the copper

?uoro-chloro-ethylene comprising, immersing a thin sheet

with a surface of a ?rst plastic resin having a ?ow charac

teristic at a given temperature; applying a su?icient

sheet of phenolic resin laminate; applying a predeter 25 degree of heat and pressure to laminate said plastic and

copper together, forming thereby an imprint of said cupric

mined degree of heat and pressure to cure said resin

oxide in said plastic; cooling said laminated copper plastic;

and press said copper and resin sheets together, forming

removing said cupric-oxide-coated-copper from said plas

thereby an imprint of said cupric oxide in said resin;

tic to expose the plurality of randomly disposed follicles

cooling said cupric oxide coated copper clad phenolic

with a homogeneous coating of black cupric oxide; placing

said oxidized copper sheet in contact with an uncured

laminate; removing selected areas of cupric oxide coated 30 in said plastic provided by said imprint; placing a surface

of a second plastic resin having a greater tendency to

copper from said sheet of phenolic laminate to provide

?ow at a temperature substantially less than said given

a predetermined conductive pattern and expose the

temperature in contact with said imprinted surface; and

plurality of follicles in said phenolic laminate sheet

pressing said plastic resins together at a temperature

formed by the exposed areas of said imprint; placing

tri-?uoro-chloro-ethylene in contact with said, imprinted 35 substantially less than said ?rst given temperature to

force said second plastic resin into said follicles to provide

surface of said phenolic laminate; applying a sufficient

said bond therebetween. ‘

degree of heat and pressure to said tri-?uoro-chloro

7. The method of bonding tri-?uoro-chloro-ethylene

ethylene and said phenolic laminate to force said tri

to a thermosetting resin laminate comprising, immersing

?uoro-chloro-ethylene into said follicles; and cooling said

tri-?uoro-chloro-ethylene and phenolic laminate to provide 40- a thin sheet of clean copper in an oxidizing bath to

thermosetting resin comprising, immersing a thin sheet

provide the copper with a homogeneous coating of black

cupric oxide; placing said oxidized copper sheet in contact

with an uncured sheet of thermosetting resin laminate;

of clean copper in an oxidizing bath comprising a hot

aqueous solution consisting essentially of an alkali selected

of heat and pressure to cure said resin and press said

said bond therebetween.

4. The method of bonding a thermoplastic resin to a

from the group consisting of sodium hydroxide and

potassium hydroxide and a chlorite selected from the

group consisting of sodium chlorite and potassium chlorite

to provide said surfaces with a homogeneous coating of

applying resin laminate; applying a predetermined degree

copper and laminate sheets together, forming thereby an

imprint of said cupric oxide in said laminate; cooling

said cupric oxide coated copper clad laminate; removing

cupric oxide coated copper from said sheet of laminate

to expose the plurality of follicles in said laminate sheet

black cupric oxide; placing said cupric oxide coated 50

provided by said imprint; placing tri-?uoro-chloro-ethylene

copper sheet in contact with an uncured sheet of thermo

in contact with said imprinted surface of said laminate;

setting resin; applying a su?icient degree of heat and

pressure to said thermosetting resin and press said copper

applying a sufficient degree of heat and pressure to said

and thermosetting resin sheets together, forming thereby

tri-?uoro-chloro-ethylene and said laminate to force said

said thermoplastic and thermosetting resins to provide

mined degree of heat and pressure to cure said phenolic

tri-?uoro-chloro-ethylene into said follicles; and cooling

an imprint of said cupric oxide in said thermosetting

said tri-?uoro-chloro-ethylene and laminate to provide

resin; cooling said cupric oxide coated copper clad resin

said bond therebetween.

sheet; removing cupric oxide coated copper from said

8. The method of bonding a thermoplastic resin to a

resin sheet to expose the plurality of randomly disposed

phenolic resin laminate comprising, immersing a thin sheet

follicles in said resin provided by said imprint; placing

said thermoplastic resin in contact with said imprinted iii) of clean copper in an oxidizing bath to provide the copper

with a homogeneous coating of black cupric oxide; placing

surface; applying a su?‘icient degree of heat and pressure

said oxidized copper sheet in contact with an uncured

to said thermoplastic and thermosetting resins to force

sheet of phenolic resin laminate; applying a predeter

said thermoplastic resin into said follicles; and cooling

said bond therebetween.

65 resin and press said copper and phenolic laminate sheets

together, forming thereby an imprint of said cupric oxide

5. The method of insulating a printed circuit with

tri-?uoro~chloro-ethylene comprising, immersing a thin

in said laminate; cooling said cupric oxide coated copper

sheet of clean copper in an oxidizing bath comprising a

hot aqueous solution consisting essentially of an alkali

clad phenolic laminate; removing cupric oxide coated

copper from said sheet of phenolic laminate to expose

selected from the group consisting of sodium hydroxide 70 the plurality of follicles in said phenolic laminate sheet

and potassium hydroxide and a chlorite selected from

provided by said imprint; placing a thermoplastic resin

the group consisting of sodium chlorite and potassium

in contact with said imprinted surface of said phenolic

chlorite to provide the copper with a homogeneous coating

laminate; applying a sufficient degree of heat and pressure

of black cupric oxide; placing said oxidized copper sheet

to

said thermoplastic resin and said phenolic laminate to

in contact with an uncured sheet of phenolic resin lami TI

force said thermoplastic resin into said follicles; and

2,982,599

circling said. thermoplastic resin and phenolic laminate

tolprovide said bond therebetween.

,

9. The method of bonding poly-tetra-?uoro-ethylene

to a phenolic resin laminate comprising, immersing a

thin sheet of clean copper in an oxidizing bath to provide

the copper with a homogeneous coating of black cupric'

8

copper with‘ a ‘homogeneous coating of black cnpri‘c

oxide; placing said: oxidized copper sheet in contact with

an uncured sheet'of epoxy resin laminate; applying a

predetermined degree of heat and pressure to cure said

epoxy resin and press‘ said copper and epoxy laminate

sheets together, forming thereby an imprint of said cupr-ic

oxide in said‘ laminate; cooling said cupric oxide coated

oxide; placing said- oxidized copper sheet'in contact with;

copper‘ clad epoxy laminate; removing cupricjoxide

an uncured sheet of phenolic resin laminate; applying a

coated copper from said sheet of epoxy laminate to ex

predetermined degree of‘heat and pressure to cure said

pose the plurality of follicles in said epoxy laminate sheet

10

phenolic resin and press said copper and‘ phenolic lami

provided by said imprint; placing tri-flnoro-chloro~ethyl

nate sheets together, forming thereby an imprint ‘of said

ene in contactwith said imprinted surface of said epoxy

cupric oxide in said laminate; cooling said: cupric oxide

laminate; applying a su?icient degree of heat and pres

coated copper clad phenolic laminate; removing cnpric

sure to said tri-?noro-ohloro-ethylene and said epoxy

oxide coated copper from said sheet of phenolic laminate

laminate to force said tri’?uoro-chloro-ethylene into said

to expose the plurality of follicles in said phenolic lami 15 follicles; and cooling, said tri—?uoro-ehloro-ethylene and

nate sheet provided by said imprint; placing poly'tetra-v

epoxy laminatepto provide said bond therebetween._

?uoro-ethylene in contact with said imprinted surface of

said phenolic laminate; applying a su?icient degree of

ReferencesCited in the ?le of this patent

heat and pressure to said poly-tetra-?uoro-ethylene ‘and

20

_

UNITED, STATES PATENTS

said phenolic laminate to force said poly-tetra-?uoro~

ethylene into said follicles; and cooling said poly-tetra

'Daly __U_____-_ ________ __ Apr. 10, 1934

fluoro-ethylene and phenolic laminate to provide said

bond

therebetween.

10. The method of bonding tri-v?uoro-chloroethylene

to an epoxy resin laminate comprising, immersing a thin 25

sheet of clean copper in an oxidizing bath to provide the

1,954,403

'

’

‘

2,551,591

.FOOl'd __‘___________ __'__ May 8, 1951

2,728,698

Rudner _____________ _._ Dec. 27, 1955

2,745,898

Hplllfd ______________ __'. May 15, 1956

2,768,923

Kepple et al. _' _________ __ Oct. 30, 1956