9007 9000

9015 910

9015 940

9017 910

9017 960

9017 920

9017 900

9017 930

9017 950

9017 940

9022 900

9021 910

9022 940

9025 900

9025 9000

9025 910

9025 920

9025 940

9025 950

9027 920

9027 910

9027 940

9027 900

9027 960

9027 9600

9027 9601

9027 8000

9038 900

9038 901

9040 910

9040 9206

9040 9209

9040 9203

9040 9201

9040 9000

9040 900

9045 910

9045 920

F 20/7 H1C-E2

F 20/15 H1C

F 20/15 H1C-3

F 20/17 H1C

F 20/17 H1CT

F 20/17 H1C-1

F 20/17 H1CT2-1

F 20/17 H1C-2

F 20/17 H1CT-2

F 20/17 H1C-3

F 20/22 H1C-1

F 20/22 H1C-2

F 20/22 H1CT-A

F 20/25 H1C

F 20/25 H1C-B

F 20/25 H1CT

F 20/25 H1CT 2

20 FP 25 H1C-R

20 FP 25 H1CT-R

F 20/27 H1C

F 20/27 H1CT 70

F 20/27 H1C-T2

F 20/27 H1C-E1

F 20/27 H1CM

F 20/27 H1CM1

F 20/27 H1CM2

F 20/27 H1CM3

20 FP 38 H1C-R

20 FP 38 H1CT-R

F 20/40 H1C

F 20/40 H1CT

F 20/40 H1CT-3

F 20/40 H1CT2 (C)

F 20/40 H1CT2 (P)

F 20/40 H1C-E1 WT

F 20/40 H1C-E1

F 20/44 H1C

F 20/44 H1CT

DIN EN 60952-1

DIN EN 60952-2

IEC 952-1

IEC 952-2

MIL-B-26 220 C

MIL-StD 810 C

Prl. 56 101 A

BS 3G 205

MS 24 496-2

MS 24 497-2

MS 24 498-2

DIN 29 831

DIN 29 832

DIN 29 834

DIN 29 998

VG 95 238 T2/

8/10/19/24/29/

TS 20 320/15-25

AS 80 33 A

Standards

Specification

MS 3509

BAC 102

MS 18 093

MS 3509

special

BAC 102

MS 18093

special

MS 18093

MS 3509

special

DPXB-8-33 S-0301

MS 18 093

MS 3509

special

Connector

20

24

44

40

38

27

25

22

17

7

15

186

190

174

248

480

495

254

254

248

168.4

168.5

363

479

466

362

248

254

174

125

119

119

197

197

321

424

424

254

254

363

147

158

253

260

145

195

124

195

325

198

368

198

24.5

27.5

27.6

28.0

28.5

28.6

29.5

35.0

36.4

36.5

36.6

37.6

37.5

204

218

237.5

220

226

262

268

262

21.0

25.5

25.6

25.7

12.5

16.5

16.5

16.9

17.1

16.9

17.2

17.0

17.1

17.3

23.5

226

200

180

170

180

223.5

188

188

130

196

200

196

EnerSys is dedicated to providing customers with the best

solutions and after-sales support for their business, wherever

you do business, EnerSys can support your requirements

through our vast network of approved maintenance

distributors.

European Headquarters:

EnerSys EMEA

EH Europe GmbH

Löwenstrasse 32

8001 Zürich

Switzerland

Phone: +41 44 215 74 10

Fax:

+41 44 215 74 11

www.enersys.com

Enersys_Hawker_Safety_Plus_Power_Range_June-2012_Version1_EN

23.8 kW

22.5 kW

20.2 kW

18.8 kW

15.7 kW

14.0 kW

11.8 kW

8 kW

11.5 kW

FP44H1C 3453 240

FP40H1C 3403 240

239.0

208.0

FP38H1C 3383 240

35.5

180.0

80

27.5 208.0

FP27H1C 3273 200

1.2

80.5

FP25H1C 3253 230

164.5

80

FP22H1C 3223 200

27

171.5

60

FP17H1C 3163 200

27

109.5

FP7H1C 3073 240

FP15H1C 3153 240

1.60

1.50

1.20

1.10

0.86

0.67

0.40

0.65

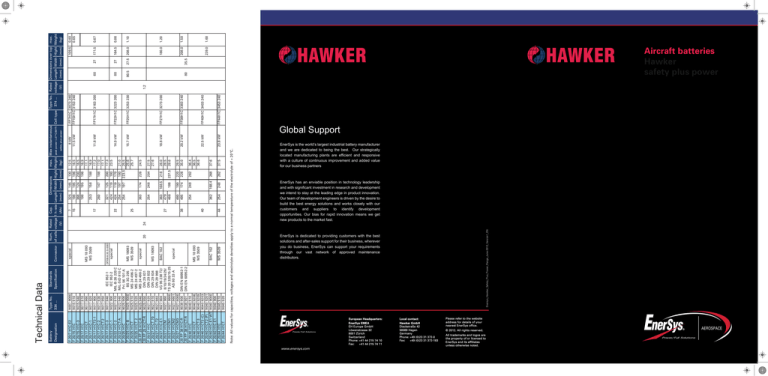

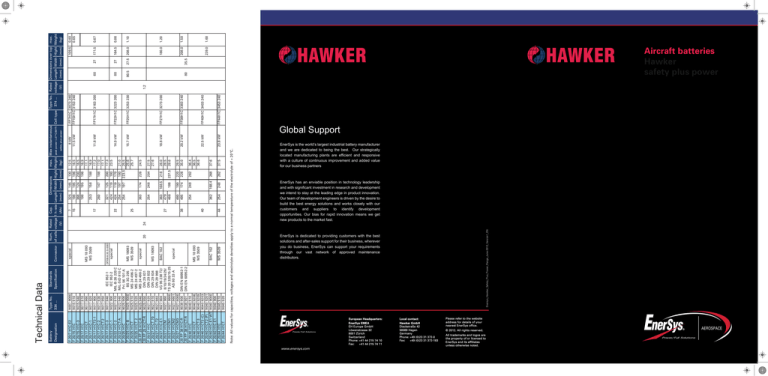

Num. Rated

Cap.

Dimensions

max. Max instantaneous

Type No. Rated Dimensions over top max.

of cells voltage 1 h rate Length Width Hight Weight peak power (+27°C/80°F) Cell type 374 ... voltage Length Width Hight Weight

(V)

(Ah)

(mm) (mm) (mm) (kg)

(V)

(mm) (mm) (mm) (kg)

safety plus power

Note: All values for capacities, voltages and electrolyte densities apply to a normal temperature of the electrolyte of + 20 °C.

Type No.

334 ...

Battery

Designation

Technical Data

Aircraft batteries

Hawker

safety plus power

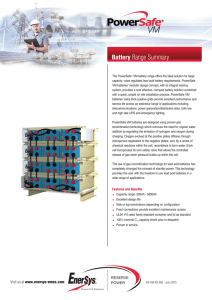

Global Support

EnerSys is the world’s largest industrial battery manufacturer

and we are dedicated to being the best. Our strategically

located manufacturing plants are efficient and responsive

with a culture of continuous improvement and added value

for our business partners

EnerSys has an enviable position in technology leadership

and with significant investment in research and development

we intend to stay at the leading edge in product innovation.

Our team of development engineers is driven by the desire to

build the best energy solutions and works closely with our

customers and suppliers to identify development

opportunities. Our bias for rapid innovation means we get

new products to the market fast.

Local contact:

Hawker GmbH

Dieckstraße 42

58089 Hagen

Germany

Phone: +49 (0)23 31 372-0

Fax:

+49 (0)23 31 372-183

Please refer to the website

address for details of your

nearest EnerSys office.

© 2012. All rights reserved.

All trademarks and logos are

the property of or licensed to

EnerSys and its affiliates

unless otherwise noted.

AEROSPACE

Technology for maximum

safety and power

Aircraft batteries for

every application

The Battery

The Construction

manufacturing

Hawker safety

plus power

THE WORLD IS BECOMING

SMALLER. AIRCRAFT TRAVEL

THOUSANDS OF KILOMETRES IN A

MATTER OF HOURS. AIR ROUTES

CONNECT ENTIRE CONTINENTS. A

The cell is the basic component of the

nickel cadmium battery, as with other

accumulators, and consists of positive

and negative electrodes, with a sinter

plate design, separators, electrolyte,

cell container and a vent.

Sintered metal, made using nickel

powder with a porosity of around 80%,

acts as a carrier for the active mass in

the negative and positive electrodes.

This structure is stiffened by inserting a

perforated nickel plate. The active

material is introduced into the highly

porous composite carrier in a liquid

state, with the positive electrodes

immersed in a nickel salt solution and

the negative electrodes immersed in a

cadmium salt solution.

FAILURE IN THE AIRBORNE ENERGY

SUPPLY SYSTEM CAN RESULT IN

CATASTROPHE. IT IS VITAL THAT

ALL INSTRUMENTS ARE IN

Extremely thin separators segregate

the positive and negative electrodes.

Each separator incorporates a ‘gas

barrier’ which is very temperature-

Expertise you can

depend on

The battery typically consists of 20

cells housed inside a battery case. All

hardware, including the container and

cover, is made from stainless steel

while the interior of the battery

container is lined with heat resistant

plastic. Soft rubber, which acts as a

retainer for the cells, lines the cover

and high conductivity nickel plated

copper connectors are used for

resistant, preventing thermal damage

to the cell even at high ambient

temperatures or excessive charging

voltages (known as thermal run-away).

The positive and negative electrodes

are combined, with alternate layers of

separators, into a plate block containing the appropriate terminals. The plate

block is then inserted into a cell

container and cover formed from heat

resistant plastic (Polyamide). Finally,

the container and cover are welded

together using a special process to

form a sealed unit.

As an added safety measure, each cell

is fitted with a special vent to ensure

that the gases produced during charging can escape before excessive

pressure builds as well as prevent the

leakage of electrolyte should the

battery be inverted.

The Expertise

The Design

1. Negative electrode

2. Positive electrode

3. Separator

4. Plate block

5. Negative pole bolt

6. Positive pole bolt

7. Electrolyte level indicator

8. Baffle

9. Pole bolt sealing ring

inter-cell

connections.

Tubes

attached to the battery’s side allow

venting to take place, and a plug

mounted on the front of the battery

container connects it to the aircraft’s

electrical system. In addition, all

batteries

may

be

fitted

with

temperature sensors for thermal

monitoring.

Hawker

has

a

reputation

for

unbeatable experience and unrivalled

expertise in the manufacture of aircraft

batteries. Hawker batteries ensure the

utmost reliability for both commercial

aircrafts and military fighter jets.

Hawker safety plus power is the result

of many years’ research into creating a

battery that delivers a perfect power

supply to all monitoring and control

instruments; one that can be relied

upon to operate at optimum capacity

even under extreme conditions.

The materials used in Hawker batteries

are subject to stringent laboratory

tests, and every stage of the

manufacturing process meets the

criteria set out in the ISO 9001 quality

standard. Finally, the Hawker nickel

cadmium aircraft batteries comply

with the highest requirements of

airworthiness as set out by EASA /

FAA / AR IAC / OEMs and Ministry of

Defence.

The Advantages

10. Cell cover

11. Sealing ring

12. Vent

13. Nut

14. Spring washer

15. Nut

16. Limiting cap

17. Pole bolt sealing ring

18. Cell container

• Low internal resistance allows a high current discharge,

giving excellent power output for Auxiliary Power Unit

(APU) operating in temperatures between -30°C and

+70°C.

• High capacity at low temperatures and rapid recharge

with constant voltage to 100% capacity ensures

exceptional reliability even in emergency conditions.

• Initial high current and a constant voltage supply,

CONSTANT OPERATIONAL

resulting from Hawker’s exclusive technology of thin

electrodes with a very low internal resistance, delivers

optimum charge during flight.

READINESS

• The specially designed separator material remains

stable even in high temperatures, ensuring a high level

of safety and producing no ‘thermal run-away’.

(Overcharging tests [28,5 V / 50 °C / 500h] show no

defects to the separator material as well as to the

complete cells.)

• Optimum storage conditions of +10°C to +35°C and

45% to 75% humidity facilitate a long life expectancy.

• The cell design, with its high electrolyte content, gives

rise to very low levels of self-discharge.

• Low water consumption, a plentiful supply of electrolyte

and no decrease in useable capacity results in longer

periods without maintenance.

AEROSPACE

Technology for maximum

safety and power

Aircraft batteries for

every application

The Battery

The Construction

manufacturing

Hawker safety

plus power

THE WORLD IS BECOMING

SMALLER. AIRCRAFT TRAVEL

THOUSANDS OF KILOMETRES IN A

MATTER OF HOURS. AIR ROUTES

CONNECT ENTIRE CONTINENTS. A

The cell is the basic component of the

nickel cadmium battery, as with other

accumulators, and consists of positive

and negative electrodes, with a sinter

plate design, separators, electrolyte,

cell container and a vent.

Sintered metal, made using nickel

powder with a porosity of around 80%,

acts as a carrier for the active mass in

the negative and positive electrodes.

This structure is stiffened by inserting a

perforated nickel plate. The active

material is introduced into the highly

porous composite carrier in a liquid

state, with the positive electrodes

immersed in a nickel salt solution and

the negative electrodes immersed in a

cadmium salt solution.

FAILURE IN THE AIRBORNE ENERGY

SUPPLY SYSTEM CAN RESULT IN

CATASTROPHE. IT IS VITAL THAT

ALL INSTRUMENTS ARE IN

Extremely thin separators segregate

the positive and negative electrodes.

Each separator incorporates a ‘gas

barrier’ which is very temperature-

Expertise you can

depend on

The battery typically consists of 20

cells housed inside a battery case. All

hardware, including the container and

cover, is made from stainless steel

while the interior of the battery

container is lined with heat resistant

plastic. Soft rubber, which acts as a

retainer for the cells, lines the cover

and high conductivity nickel plated

copper connectors are used for

resistant, preventing thermal damage

to the cell even at high ambient

temperatures or excessive charging

voltages (known as thermal run-away).

The positive and negative electrodes

are combined, with alternate layers of

separators, into a plate block containing the appropriate terminals. The plate

block is then inserted into a cell

container and cover formed from heat

resistant plastic (Polyamide). Finally,

the container and cover are welded

together using a special process to

form a sealed unit.

As an added safety measure, each cell

is fitted with a special vent to ensure

that the gases produced during charging can escape before excessive

pressure builds as well as prevent the

leakage of electrolyte should the

battery be inverted.

The Expertise

The Design

1. Negative electrode

2. Positive electrode

3. Separator

4. Plate block

5. Negative pole bolt

6. Positive pole bolt

7. Electrolyte level indicator

8. Baffle

9. Pole bolt sealing ring

inter-cell

connections.

Tubes

attached to the battery’s side allow

venting to take place, and a plug

mounted on the front of the battery

container connects it to the aircraft’s

electrical system. In addition, all

batteries

may

be

fitted

with

temperature sensors for thermal

monitoring.

Hawker

has

a

reputation

for

unbeatable experience and unrivalled

expertise in the manufacture of aircraft

batteries. Hawker batteries ensure the

utmost reliability for both commercial

aircrafts and military fighter jets.

Hawker safety plus power is the result

of many years’ research into creating a

battery that delivers a perfect power

supply to all monitoring and control

instruments; one that can be relied

upon to operate at optimum capacity

even under extreme conditions.

The materials used in Hawker batteries

are subject to stringent laboratory

tests, and every stage of the

manufacturing process meets the

criteria set out in the ISO 9001 quality

standard. Finally, the Hawker nickel

cadmium aircraft batteries comply

with the highest requirements of

airworthiness as set out by EASA /

FAA / AR IAC / OEMs and Ministry of

Defence.

The Advantages

10. Cell cover

11. Sealing ring

12. Vent

13. Nut

14. Spring washer

15. Nut

16. Limiting cap

17. Pole bolt sealing ring

18. Cell container

• Low internal resistance allows a high current discharge,

giving excellent power output for Auxiliary Power Unit

(APU) operating in temperatures between -30°C and

+70°C.

• High capacity at low temperatures and rapid recharge

with constant voltage to 100% capacity ensures

exceptional reliability even in emergency conditions.

• Initial high current and a constant voltage supply,

CONSTANT OPERATIONAL

resulting from Hawker’s exclusive technology of thin

electrodes with a very low internal resistance, delivers

optimum charge during flight.

READINESS

• The specially designed separator material remains

stable even in high temperatures, ensuring a high level

of safety and producing no ‘thermal run-away’.

(Overcharging tests [28,5 V / 50 °C / 500h] show no

defects to the separator material as well as to the

complete cells.)

• Optimum storage conditions of +10°C to +35°C and

45% to 75% humidity facilitate a long life expectancy.

• The cell design, with its high electrolyte content, gives

rise to very low levels of self-discharge.

• Low water consumption, a plentiful supply of electrolyte

and no decrease in useable capacity results in longer

periods without maintenance.

AEROSPACE

Technology for maximum

safety and power

Aircraft batteries for

every application

The Battery

The Construction

manufacturing

Hawker safety

plus power

THE WORLD IS BECOMING

SMALLER. AIRCRAFT TRAVEL

THOUSANDS OF KILOMETRES IN A

MATTER OF HOURS. AIR ROUTES

CONNECT ENTIRE CONTINENTS. A

The cell is the basic component of the

nickel cadmium battery, as with other

accumulators, and consists of positive

and negative electrodes, with a sinter

plate design, separators, electrolyte,

cell container and a vent.

Sintered metal, made using nickel

powder with a porosity of around 80%,

acts as a carrier for the active mass in

the negative and positive electrodes.

This structure is stiffened by inserting a

perforated nickel plate. The active

material is introduced into the highly

porous composite carrier in a liquid

state, with the positive electrodes

immersed in a nickel salt solution and

the negative electrodes immersed in a

cadmium salt solution.

FAILURE IN THE AIRBORNE ENERGY

SUPPLY SYSTEM CAN RESULT IN

CATASTROPHE. IT IS VITAL THAT

ALL INSTRUMENTS ARE IN

Extremely thin separators segregate

the positive and negative electrodes.

Each separator incorporates a ‘gas

barrier’ which is very temperature-

Expertise you can

depend on

The battery typically consists of 20

cells housed inside a battery case. All

hardware, including the container and

cover, is made from stainless steel

while the interior of the battery

container is lined with heat resistant

plastic. Soft rubber, which acts as a

retainer for the cells, lines the cover

and high conductivity nickel plated

copper connectors are used for

resistant, preventing thermal damage

to the cell even at high ambient

temperatures or excessive charging

voltages (known as thermal run-away).

The positive and negative electrodes

are combined, with alternate layers of

separators, into a plate block containing the appropriate terminals. The plate

block is then inserted into a cell

container and cover formed from heat

resistant plastic (Polyamide). Finally,

the container and cover are welded

together using a special process to

form a sealed unit.

As an added safety measure, each cell

is fitted with a special vent to ensure

that the gases produced during charging can escape before excessive

pressure builds as well as prevent the

leakage of electrolyte should the

battery be inverted.

The Expertise

The Design

1. Negative electrode

2. Positive electrode

3. Separator

4. Plate block

5. Negative pole bolt

6. Positive pole bolt

7. Electrolyte level indicator

8. Baffle

9. Pole bolt sealing ring

inter-cell

connections.

Tubes

attached to the battery’s side allow

venting to take place, and a plug

mounted on the front of the battery

container connects it to the aircraft’s

electrical system. In addition, all

batteries

may

be

fitted

with

temperature sensors for thermal

monitoring.

Hawker

has

a

reputation

for

unbeatable experience and unrivalled

expertise in the manufacture of aircraft

batteries. Hawker batteries ensure the

utmost reliability for both commercial

aircrafts and military fighter jets.

Hawker safety plus power is the result

of many years’ research into creating a

battery that delivers a perfect power

supply to all monitoring and control

instruments; one that can be relied

upon to operate at optimum capacity

even under extreme conditions.

The materials used in Hawker batteries

are subject to stringent laboratory

tests, and every stage of the

manufacturing process meets the

criteria set out in the ISO 9001 quality

standard. Finally, the Hawker nickel

cadmium aircraft batteries comply

with the highest requirements of

airworthiness as set out by EASA /

FAA / AR IAC / OEMs and Ministry of

Defence.

The Advantages

10. Cell cover

11. Sealing ring

12. Vent

13. Nut

14. Spring washer

15. Nut

16. Limiting cap

17. Pole bolt sealing ring

18. Cell container

• Low internal resistance allows a high current discharge,

giving excellent power output for Auxiliary Power Unit

(APU) operating in temperatures between -30°C and

+70°C.

• High capacity at low temperatures and rapid recharge

with constant voltage to 100% capacity ensures

exceptional reliability even in emergency conditions.

• Initial high current and a constant voltage supply,

CONSTANT OPERATIONAL

resulting from Hawker’s exclusive technology of thin

electrodes with a very low internal resistance, delivers

optimum charge during flight.

READINESS

• The specially designed separator material remains

stable even in high temperatures, ensuring a high level

of safety and producing no ‘thermal run-away’.

(Overcharging tests [28,5 V / 50 °C / 500h] show no

defects to the separator material as well as to the

complete cells.)

• Optimum storage conditions of +10°C to +35°C and

45% to 75% humidity facilitate a long life expectancy.

• The cell design, with its high electrolyte content, gives

rise to very low levels of self-discharge.

• Low water consumption, a plentiful supply of electrolyte

and no decrease in useable capacity results in longer

periods without maintenance.

AEROSPACE

9007 9000

9015 910

9015 940

9017 910

9017 960

9017 920

9017 900

9017 930

9017 950

9017 940

9022 900

9021 910

9022 940

9025 900

9025 9000

9025 910

9025 920

9025 940

9025 950

9027 920

9027 910

9027 940

9027 900

9027 960

9027 9600

9027 9601

9027 8000

9038 900

9038 901

9040 910

9040 9206

9040 9209

9040 9203

9040 9201

9040 9000

9040 900

9045 910

9045 920

F 20/7 H1C-E2

F 20/15 H1C

F 20/15 H1C-3

F 20/17 H1C

F 20/17 H1CT

F 20/17 H1C-1

F 20/17 H1CT2-1

F 20/17 H1C-2

F 20/17 H1CT-2

F 20/17 H1C-3

F 20/22 H1C-1

F 20/22 H1C-2

F 20/22 H1CT-A

F 20/25 H1C

F 20/25 H1C-B

F 20/25 H1CT

F 20/25 H1CT 2

20 FP 25 H1C-R

20 FP 25 H1CT-R

F 20/27 H1C

F 20/27 H1CT 70

F 20/27 H1C-T2

F 20/27 H1C-E1

F 20/27 H1CM

F 20/27 H1CM1

F 20/27 H1CM2

F 20/27 H1CM3

20 FP 38 H1C-R

20 FP 38 H1CT-R

F 20/40 H1C

F 20/40 H1CT

F 20/40 H1CT-3

F 20/40 H1CT2 (C)

F 20/40 H1CT2 (P)

F 20/40 H1C-E1 WT

F 20/40 H1C-E1

F 20/44 H1C

F 20/44 H1CT

DIN EN 60952-1

DIN EN 60952-2

IEC 952-1

IEC 952-2

MIL-B-26 220 C

MIL-StD 810 C

Prl. 56 101 A

BS 3G 205

MS 24 496-2

MS 24 497-2

MS 24 498-2

DIN 29 831

DIN 29 832

DIN 29 834

DIN 29 998

VG 95 238 T2/

8/10/19/24/29/

TS 20 320/15-25

AS 80 33 A

Standards

Specification

MS 3509

BAC 102

MS 18 093

MS 3509

special

BAC 102

MS 18093

special

MS 18093

MS 3509

special

DPXB-8-33 S-0301

MS 18 093

MS 3509

special

Connector

20

24

44

40

38

27

25

22

17

7

15

186

190

174

248

480

495

254

254

248

168.4

168.5

363

479

466

362

248

254

174

125

119

119

197

197

321

424

424

254

254

363

147

158

253

260

145

195

124

195

325

198

368

198

24.5

27.5

27.6

28.0

28.5

28.6

29.5

35.0

36.4

36.5

36.6

37.6

37.5

204

218

237.5

220

226

262

268

262

21.0

25.5

25.6

25.7

12.5

16.5

16.5

16.9

17.1

16.9

17.2

17.0

17.1

17.3

23.5

226

200

180

170

180

223.5

188

188

130

196

200

196

EnerSys is dedicated to providing customers with the best

solutions and after-sales support for their business, wherever

you do business, EnerSys can support your requirements

through our vast network of approved maintenance

distributors.

European Headquarters:

EnerSys EMEA

EH Europe GmbH

Löwenstrasse 32

8001 Zürich

Switzerland

Phone: +41 44 215 74 10

Fax:

+41 44 215 74 11

www.enersys.com

Enersys_Hawker_Safety_Plus_Power_Range_June-2012_Version1_EN

208.0

FP38H1C 3383 240

FP40H1C 3403 240

FP44H1C 3453 240

20.2 kW

22.5 kW

23.8 kW

80

180.0

FP27H1C 3273 200

18.8 kW

1.2

80.5

FP25H1C 3253 230

15.7 kW

35.5

239.0

27.5 208.0

164.5

80

FP22H1C 3223 200

14.0 kW

27

171.5

60

FP17H1C 3163 200

11.8 kW

27

109.5

FP7H1C 3073 240

FP15H1C 3153 240

8 kW

11.5 kW

1.60

1.50

1.20

1.10

0.86

0.67

0.40

0.65

Num. Rated

Cap.

Dimensions

max. Max instantaneous

Type No. Rated Dimensions over top max.

of cells voltage 1 h rate Length Width Hight Weight peak power (+27°C/80°F) Cell type 374 ... voltage Length Width Hight Weight

(V)

(Ah)

(mm) (mm) (mm) (kg)

(V)

(mm) (mm) (mm) (kg)

safety plus power

Note: All values for capacities, voltages and electrolyte densities apply to a normal temperature of the electrolyte of + 20 °C.

Type No.

334 ...

Battery

Designation

Technical Data

Aircraft batteries

Hawker

safety plus power

Global Support

EnerSys is the world’s largest industrial battery manufacturer

and we are dedicated to being the best. Our strategically

located manufacturing plants are efficient and responsive

with a culture of continuous improvement and added value

for our business partners

EnerSys has an enviable position in technology leadership

and with significant investment in research and development

we intend to stay at the leading edge in product innovation.

Our team of development engineers is driven by the desire to

build the best energy solutions and works closely with our

customers and suppliers to identify development

opportunities. Our bias for rapid innovation means we get

new products to the market fast.

Local contact:

Hawker GmbH

Dieckstraße 42

58089 Hagen

Germany

Phone: +49 (0)23 31 372-0

Fax:

+49 (0)23 31 372-183

Please refer to the website

address for details of your

nearest EnerSys office.

© 2012. All rights reserved.

All trademarks and logos are

the property of or licensed to

EnerSys and its affiliates

unless otherwise noted.

AEROSPACE

9007 9000

9015 910

9015 940

9017 910

9017 960

9017 920

9017 900

9017 930

9017 950

9017 940

9022 900

9021 910

9022 940

9025 900

9025 9000

9025 910

9025 920

9025 940

9025 950

9027 920

9027 910

9027 940

9027 900

9027 960

9027 9600

9027 9601

9027 8000

9038 900

9038 901

9040 910

9040 9206

9040 9209

9040 9203

9040 9201

9040 9000

9040 900

9045 910

9045 920

F 20/7 H1C-E2

F 20/15 H1C

F 20/15 H1C-3

F 20/17 H1C

F 20/17 H1CT

F 20/17 H1C-1

F 20/17 H1CT2-1

F 20/17 H1C-2

F 20/17 H1CT-2

F 20/17 H1C-3

F 20/22 H1C-1

F 20/22 H1C-2

F 20/22 H1CT-A

F 20/25 H1C

F 20/25 H1C-B

F 20/25 H1CT

F 20/25 H1CT 2

20 FP 25 H1C-R

20 FP 25 H1CT-R

F 20/27 H1C

F 20/27 H1CT 70

F 20/27 H1C-T2

F 20/27 H1C-E1

F 20/27 H1CM

F 20/27 H1CM1

F 20/27 H1CM2

F 20/27 H1CM3

20 FP 38 H1C-R

20 FP 38 H1CT-R

F 20/40 H1C

F 20/40 H1CT

F 20/40 H1CT-3

F 20/40 H1CT2 (C)

F 20/40 H1CT2 (P)

F 20/40 H1C-E1 WT

F 20/40 H1C-E1

F 20/44 H1C

F 20/44 H1CT

DIN EN 60952-1

DIN EN 60952-2

IEC 952-1

IEC 952-2

MIL-B-26 220 C

MIL-StD 810 C

Prl. 56 101 A

BS 3G 205

MS 24 496-2

MS 24 497-2

MS 24 498-2

DIN 29 831

DIN 29 832

DIN 29 834

DIN 29 998

VG 95 238 T2/

8/10/19/24/29/

TS 20 320/15-25

AS 80 33 A

Standards

Specification

MS 3509

BAC 102

MS 18 093

MS 3509

special

BAC 102

MS 18093

special

MS 18093

MS 3509

special

DPXB-8-33 S-0301

MS 18 093

MS 3509

special

Connector

20

24

44

40

38

27

25

22

17

7

15

186

190

174

248

480

495

254

254

248

168.4

168.5

363

479

466

362

248

254

174

125

119

119

197

197

321

424

424

254

254

363

147

158

253

260

145

195

124

195

325

198

368

198

24.5

27.5

27.6

28.0

28.5

28.6

29.5

35.0

36.4

36.5

36.6

37.6

37.5

204

218

237.5

220

226

262

268

262

21.0

25.5

25.6

25.7

12.5

16.5

16.5

16.9

17.1

16.9

17.2

17.0

17.1

17.3

23.5

226

200

180

170

180

223.5

188

188

130

196

200

196

EnerSys is dedicated to providing customers with the best

solutions and after-sales support for their business, wherever

you do business, EnerSys can support your requirements

through our vast network of approved maintenance

distributors.

European Headquarters:

EnerSys EMEA

EH Europe GmbH

Löwenstrasse 32

8001 Zürich

Switzerland

Phone: +41 44 215 74 10

Fax:

+41 44 215 74 11

www.enersys.com

Enersys_Hawker_Safety_Plus_Power_Range_June-2012_Version1_EN

208.0

FP38H1C 3383 240

FP40H1C 3403 240

FP44H1C 3453 240

20.2 kW

22.5 kW

23.8 kW

80

180.0

FP27H1C 3273 200

18.8 kW

1.2

80.5

FP25H1C 3253 230

15.7 kW

35.5

239.0

27.5 208.0

164.5

80

FP22H1C 3223 200

14.0 kW

27

171.5

60

FP17H1C 3163 200

11.8 kW

27

109.5

FP7H1C 3073 240

FP15H1C 3153 240

8 kW

11.5 kW

1.60

1.50

1.20

1.10

0.86

0.67

0.40

0.65

Num. Rated

Cap.

Dimensions

max. Max instantaneous

Type No. Rated Dimensions over top max.

of cells voltage 1 h rate Length Width Hight Weight peak power (+27°C/80°F) Cell type 374 ... voltage Length Width Hight Weight

(V)

(Ah)

(mm) (mm) (mm) (kg)

(V)

(mm) (mm) (mm) (kg)

safety plus power

Note: All values for capacities, voltages and electrolyte densities apply to a normal temperature of the electrolyte of + 20 °C.

Type No.

334 ...

Battery

Designation

Technical Data

Aircraft batteries

Hawker

safety plus power

Global Support

EnerSys is the world’s largest industrial battery manufacturer

and we are dedicated to being the best. Our strategically

located manufacturing plants are efficient and responsive

with a culture of continuous improvement and added value

for our business partners

EnerSys has an enviable position in technology leadership

and with significant investment in research and development

we intend to stay at the leading edge in product innovation.

Our team of development engineers is driven by the desire to

build the best energy solutions and works closely with our

customers and suppliers to identify development

opportunities. Our bias for rapid innovation means we get

new products to the market fast.

Local contact:

Hawker GmbH

Dieckstraße 42

58089 Hagen

Germany

Phone: +49 (0)23 31 372-0

Fax:

+49 (0)23 31 372-183

Please refer to the website

address for details of your

nearest EnerSys office.

© 2012. All rights reserved.

All trademarks and logos are

the property of or licensed to

EnerSys and its affiliates

unless otherwise noted.

AEROSPACE