Zenith Award for Energy Brix and Yokogawa

advertisement

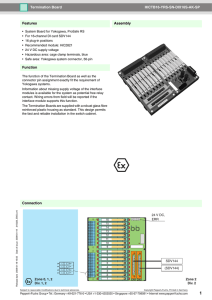

The Newsletter of Yokogawa in Australasia Third Quarter 2009 The Energy Brix power plant in Morwell, Vic. Zenith Award for Energy Brix and Yokogawa The Foundation in Australia 3 2 Automation Replacement Completed at Large Onshore Oilfield 4 Integration Made Easy 5 Integrating DCS & SCADA Migrating to Centum usung SIOS Product Releases 7 Photograph by Luke Shortal 1 6 State of the Art Analysis A Century of Excellence Expert Safety Training News Tid Bits 8 Zenith Award for Energy Brix and Yokogawa Yokogawa Australia and our customer Energy Brix Australia Corporation (EBAC) have won the 2009 PACE Zenith Award in the Transport, Power and Infrastructure category. This is the third year in a row that a Yokogawa Australia project has been a finalist in the Zenith Awards. This year’s award was for the project to modernise the control systems at the Energy Brix power station in Morwell, Victoria. Completed in 2008, the project was successful in: reducing station operating costs generating additional power for export improving plant operating flexibility providing modern conditions for plant operators reducing station maintenance costs operating and improving plant emissions. “This project was quite remarkable for the complexity and innovation of the engineering involved in installing 21st Continued on page 2 Product Releases century control systems technology onto older plant,” said John Hewitt, Managing Director of Yokogawa Australia. “Not only has the project increased the reliability of the electricity supply, it has done so while The Yokogawa DL9000/DL9700/9500 series and SB5000, simultaneously improving with the LXI compliant Ethernet option (/C9 or /C12) protection of the plant, installed, are now fully compliant with LXI Class C. LXI (Lan eXtensions for Instrumentation) is a reducing maintenance costs communication platform for test and measurementand optimising the use of instruments, built on LAN technology. It provides raw fuels.” steam range and a low pressure condensing turbine.This complex interactive configuration contrasts with most modern plants, where boilers and turbines are installed as unit plants in a much simpler one-to-one arrangement. LXI Support for Yokogawa Digital Oscilloscopes, MSOs and Serial Bus Analysers Yokogawa has been providimproved transfer speeds with enhanced ing control systems for power usability and lower cost than traditional plants for many years. However, instrument interfaces. It’s easy to migrate Energy Brix presented some over from traditional GPIB systems, because LXI utilises existing technologies such asunique challenges, particularly for Peter Morrow, General Manager of Yokogawa’s younger engineers. VXI-11 or IVI. EBAC (left) and Philip Nicholson, MoreEngineer than 20 of test and measurement Some of them were working for the Principal Yokogawa manufacturers provide LXI first time with a power plant equipped Australia (centre) accepted thecompliant products, PACE Award fromof Jeremy andZenith the total number supported products withissteam ranges and pass-out turbines Needham Mitsubishi Electric, alreadyof above 1100. As a new communication — where all boilers feed a common sponsors of the Transport, Power platform for applications requiring high transfer steam range supplying multiple turbines, and Infrastructure category. speed, low cost and usability, LXI will become some of which then supply a process more widespread in the future and Yokogawa will be including this feature on many more new products. One significant achievement of the project was the automated optimisation of energy used for total plant operation, replacing what had been a much more manual approach.This was made possible by the installation of digital controllers on the turbines and load sharing controllers on the boilers. The PACE Zenith Awards were established in 2004 by Process Control and Engineering (PACE) magazine to publicly recognise companies that show leadership in engineering and technological excellence and innovation. The awards are presented annually, with a record number of entries received in 2009. Yokogawa projects have previously won awards in 2005, 2007 and 2008. The Foundation in Australia The Fieldbus Foundation visited Australia within the region and the rest of the Main Benefits of Foundation in August to meet with local equipment world. of liquids Fieldbus Technology suppliers, with a view to establishing an Mr Hisashi Sasajima, Vice President for reduced wiring and installation Yokogawa has developed a retractable fitting available electrodes with PG 13.5mm Australian Marketing Committee to pro- sensor Asia Pacific, and Mr Shane Parr,pH Chairman costs that the offersfeatures a flexibleand approach to online analytical or DIN connections, as well as mote benefits of liquid of the Asia Pacific thread Executive Advisory measurements in a wide range of process industries. reduced control/equipment room Yokogawa’s SC4A conductivity and ISC40 Foundation Fieldbus to the local market. Council, visited Australia to share the space (no marshalling) inductive conductivity sensors (with a The Yokogawa PR10 has been designed for online The Foundation has been championed Foundation’s vision. built-in protection cage for the latter). process applications where the sensor has to be easy integration with asset in Australia for many years by the All delegates to the meeting were management systems removed safely without interrupting process continuity For dissolved oxygen measurements, Foundation Fieldbus End Users’ Council, enthusiastic and agreed to the formation – in anaerobic, toxic orfeels pressurised environments, for the Yokogawa-Hamilton Visiferm, saving in operations and however the Foundation that a sepof a Marketing Committee. Mr Tom Rolton example. The PR10 is suited to pH, ORP, conductivity, maintenance through superior Oxyferm and Oxygold sensors can be arate Marketing Committee would pro- of Emerson was elected Chairman of the diagnostic availability inductive conductivity and dissolved oxygen installed. These sensors are vide a supplementary function and more Committee. He will be assisted by measurements. in nitrogen focussed approach to promotion of the Committee memberstypically Shaun used Loesch of blanketing applications, The unit is available with a wide range of adaptors, technology. Such a structure is similar to ABB, Lindsay Hadland of Yokogawa, and where the optional flush valves and flanges, and the insertion Andrew depth can thatball existing in many other countries Siabe of Rockwell. port will allow regular adjusted to achieve optimum measurement conditions. moisturising of the sensor to Total disassembly without interruption to the process is Local suppliers meet with prevent the membrane from Fieldbus Foundation executives. possible when the ball valve is closed, and safe drying out. retraction is possible at pressures up to 5barG. Retractable sensor fitting for analytical measurement For ease of maintenance, a scraper is built in, and maintenance time is further reduced because fewer O-rings are needed for a good process seal. An optional flush port makes it easy to keep pH and dissolved oxygen sensors moist and clean, and also provides access for calibration. The PR10 will accommodate most commercially 2 6 Applications for the Yokogawa PR10 include the chemical industry, power plants, pulp and paper manufacture, water and effluent treatment, pharmaceuticals and the semiconductor industry. Automation State of the replacement art analysis completed at Western Europe’s largest onshore oilfield Delta Electricity has ordered two Yokogawa generator analyser panels for installation at its Munmorah Power Station Yokogawa UK has successfully completed on the NSW Central Coast. a full replacement of the control and At thissystems plant, hydrogen to 2) is used safety for BP’s(HWytch Farm cool the generators. The merits of H as a 2 oilfield project in Dorset. coolant are its capacity to cool while Developed by BP,Wytch Farm is Western causing only minimal drag or friction Europe’s largest onshore oil field, with between the generators’ moving parts, estimated recoverable reserves of 480 thus increasing efficiency. The potential million barrels. It is located in one of the downside, however, is that if the H2 most environmentally sensitive areas of becomes mixed with oxygen, it can the UK. become explosive, and thus a significant The Wytch Farm oilfield comprises safety hazard. three separate oil reservoirs that lie under In normal operation, the gas blanket Poole Harbour and Poole Bay in Dorset inside the generator is monitored to on the south coast of England. The ensure that the H2 is pure. When the operation, comprising a central oil generator needs to be shut down for gathering station and a number of remote maintenance, the hydrogen is removed by well sites, was established in the early flushing it out with carbon dioxide (CO2); 1980s, and the recently completed the CO2, in turn, is flushed out with automation replacement project was part breathable air so that access to the of a development plan that will enable its generator is safe. When the generator is operational life to be extended. put back into service, the process is Yokogawa was selected by BP as the reversed: air is flushed out with CO2, main automation contractor (MAC) for then the CO2 is swept away with H2.The the project, and the Yokogawa project process is referred to as the Generator team worked closely with the BP team Purge Cycle. during the project implementation. The major challenges were the initial definition of the project scope and requirements in a front-end engineering and (FEED) It included Rota design Yokogawa will study. be celebrating 100a site survey, document verification, years of production of high quality changeover and interface with flowmeters planning for industrial applications existing infrastructure. This was followed next month. Founded as Deutsche by the implementation of a smooth hot cutover to the new integrated control An RAMC02 and safety system Rotameter during the from Rota commissioning phase. Using traditional gas analysis techniques, three separate analysers would be needed to monitor all stages During the FEED phase, the Yokogawa of operation and the purge cycle. FEED team was resident at Wytch Farm for But, using state of the art site survey work, liaising with the BP technology from Yokogawa, only a engineers and collecting the engineering single GD402 GastoDensity Analyser data necessary complete the is FEED required. Delta however chose use before commencement of theto detailed two analysers for operational reasons. design. A one-team approach by BP The GD402 is exceptionally stable and by and Yokogawa was achieved reliable andthe is becoming the choice ofin an managing business relationship the power generation industry for and open, performance-focused these applications. collaborative manner. In conjunction with Delta,with “Yokogawa worked collaboratively Yokogawa has designed, the on-site BP team through the many manufactured, commissioned and and challenges of the FEED phase documented a complete process subsequent design, build and test phases, analyser that on enables deliveringsystem the system time,” the said Ian operation and purge cycle for the Bennett, project manager, Automation two Munmorah 350 Excellence, at BP Wytch Farm.MW “Lessons generators to be measured. Thethose have been learned, especially system waswith designed so that it associated the preparation of the minimises the effects of oil and moisture in the sample stream. Pressure measurement was included to provide compensation for changes in operating pressure in the generator cooling hydrogen; such compensation loop diagrams and subsequent commissioning phase, which will benefit the management and planning of future retrofit projects. We commend Yokogawa for the open and honest way they have accepted responsibility in taking the lessons process forward.” BP confirmed its satisfaction in the way Yokogawa completed the Wytch Farm distributed control system (DCS) and safety instrumented system (SIS) upgrade project. Key project performance achievements included: 100% health, safety, security, and environment performance; no plant shutdown as a result of the project; on-time delivery; a smooth and safe changeover to the new system; a ‘one team’ approach with the client project team; and a high The analyser system installed at the level of customer satisfaction. Munmorah Power Station. Wytch Farm is Western can be performed by the GD402 Analyser. Europe’s largest The first system was installed and comonshore oil field. missioned in June and a second identical system has now been delivered. Celebrating a century of excellence The integrated controlYokogawa. and safety system is based on the Yokogawa CENTUM CS 3000-Vnet/IP distributed control system, the ProSafe-RS safety system for emergency shutdown and burner management, and STARDOM networkbased controllers for use as remote terminal units. This project replaced the existing control system, safety system, dual redundant PLC system, process automation controllers, and SCADA/RTU previously used to monitor and control the gathering and processing operations. Rotawerke in the German town of Aachen in 1909, Rota Yokogawa became part of theYokogawa Electric Corporation in 1995. Wytch Farm The early years of the business were focussed on production of the recentlyinvented Rotameter, a float-based flowmeter. The company was so successful that ‘Rotameter’ is often used as a generic term for any flowmeter of this kind, not just Yokogawa’s. Today, Rota Yokogawa continues as the company’s worldwide centre of excellence for flowmeters, which now include mass flow measurement using the Coriolis principle as well as Rotameters. Manufacturing floor space has recently been enlarged by 40% with the opening of one of the most modern and innovative production lines of its kind. Production has also been increasingly automated with sizeable investment in production equipment, robots and automated test rigs. Further investment of tens of millions of Euros is planned in buildings and plant in the next few years. Today, Rota Yokogawa develops and manufactures high-quality flowmeters based on five measuring principles: floats, magnetic-inductive, vortex flowmeters, Coriolis and differential head. Calibrations are carried out in the company’s own DKD-certified facility, which also provides a calibration service to other companies. With outstanding products and an excellent business performance in recent years, Rota Yokogawa is in good shape for the future. The continuous development of new and existing measuring devices will ensure that customers around the world are supplied with top quality Yokogawa flowmeters. Photo courtesy of BP Zenith Award for Energy Brix and Yokogawa cont'd 7 3 Communications Special Feature Integration made easy Process users have always found themselves with automation and control equipment from a number of different manufacturers in their plant, be it packaged with the original process equipment supply or necessary for their special purpose application. Examples may include a turbine controller from the turbine manufacturer and intelligent electrical devices associated with the electrical switchgear. In other cases, the original plant builder may not have been sufficiently disciplined to specify common automation equipment. And in still other cases, the user has elected to implement a best-in-class type of unit application solution. For whatever reason, it has always been necessary for the main automation system supplier to have to communicate with, or integrate, control equipment from a number of different suppliers into the overall control system. Yokogawa has handled these communications issues quietly and without fuss for many years. Few systems would have ever been supplied in the early days of CENTUM without at least one RS232 serial interface being installed. Modbus over serial link was generally preferred over custom serial protocols, Profibus was and still is popular with equipment of European extraction, Modbus over Ethernet is still a favourite, and OPC over Ethernet is the current communication system of choice today. CENTUM generally interfaces to third-party equipment via one of three physical connection mechanisms: 1. a communications card in the Controller – serial, Profibus, Foundation Fieldbus or Ethernet 2. a Generic Subsystem Gateway (GSGW) station on the control network, which acts as an OPC client to third-party OPC servers for the purpose of integration to subsystems 3. a System Integration OPC Client Station (SIOS) on the control network for largevolume, high-performance integration to peer-level systems 4 Integrating DCS and SCADA using SIOS DCS and SCADA have always been mutually opposing control system architectures. Each has its advantages and disadvantages and each is applied to different types of applications. Until now, it hasn’t been possible to realise the advantages of both architectures within a single system. SIOS is the most recently released product, and forms a very convenient and easy to implement methodology for communicating via OPC DA and A&E with other vendors’ higherlevel systems – including foreign DCS-type control systems. It allows co-existence of Yokogawa and competitors’ control systems on the same plant, and can facilitate migration of older style foreign legacy DCSs to the latest CENTUM VP system. Yokogawa Australia has tested SIOS on integration with a competitive DCS system with good results. SIOS has also found extensive use globally in integrating Yokogawa’s STARDOM network control system and remote terminal units with CENTUM. Both SIOS and GSGW run on a generic PC hardware platform containing Reference Interfaces (Partial List) ABB – drives, IEDs, GCs, etc Allen-Bradley – PLC5, SLC5, ControlLogix Amdel ATMOS Leak Detection ASi-Bus BentlyNevada Bristol Babcock RTU Contrec Counters and Batchers Danfoss VSD Enraf FMC Subsea Foxboro – GC, tank gauges Gastech – fire & gas sensors GE – PLCs, Multilin, Mark IV, Mark V Harris RTU HIMA Honeywell Modicon – 584, 984, Quantum Outokumpu Courier ProFace touch panels Schneider Telemechanique Siemens – S5, S7, 1135. VSD Square D Toshiba – PLC, VSD Triconex Woodward Governor CENTUM Vnet/IP communication cards. SIOS can handle 100,000 data points with 4,000 tags in GSGW. GSGW can handle OPC-DA only, while SIOS can accommodate OPC-A&E alarm and events message traffic as well. No matter which Yokogawa integration solution is adopted, the end result for the operator is complete transparency of information from across the plant Communications Glossary of Terms RS232 – serial connection standard Modbus – defacto standard serial protocol OPC – OLE for Process Control – international std comms protocols across Ethernet Profibus – a suite of field and network protocols originating in Europe Ethernet – standard office and industrial network technology Foundation Fieldbus – international standard fieldbus technology OPC-DA – OPC Data Acquisition protocol OPC-A&E – OPC Alarm & Events protocol database and function block style programming. In addition, the level of availability, redundancy and reliability in hardware and software make this the clear choice for critical applications. system and are immediately available to the user as standard CENTUM-style faceplates on the operator station. The operator is not aware of the source of the data for the faceplate. Now, Yokogawa is blurring the boundaries of the two architectures with the integration of the STARDOM SCADA system with the CENTUM VP DCS. Using SIOS (System Integration OPC client Station), all STARDOM variables and function blocks are automatically mapped into the CENTUM DCS, providing seamless and transparent connection between the two systems. The STARDOM control family includes the FCN and FCJ high performance PLC type controllers and the FCN-RTU for remote applications. Programmed using the IEC 61131-3 suite of programming languages and supplied with a wide range of communication options, the STARDOM controllers are suitable for remote and PLC type applications. The FAST/TOOLS SCADA HMI provides a high performance user interface to the STARDOM controllers for a highly integrated SCADA system. Because of the transparent nature of the connection between the systems, full CENTUM connectivity can be realised, including peer-to-peer communication between controllers across the two systems, alarm monitoring, trending, monitoring and operation. The user can monitor and operate entirely through the CENTUM HIS operator station. However, the FAST/ TOOLS SCADA HMI can also be connected for local monitoring and operations of the STARDOM controllers in remote locations as required. The Yokogawa CENTUM VP DCS provides high integrity control of medium to large processing sites. Being a DCS, engineering is greatly reduced by the single The SIOS gateway provides seamless integration between STARDOM and CENTUM. Tags created in STARDOM are automatically recognised by the CENTUM Now the full benefits of both DCS and SCADA can be realised within a single system using the Yokogawa CENTUM and STARDOM technologies. Migrating to Centum using SIOS If you are considering upgrading your old DCS and it is not a Yokogawa system, then you may have a problem. One of Yokogawa’s basic design philosophies in developing latest technology DCS is to ensure full backwards compatibility with previous systems. This means that any generation of Yokogawa’s DCS will integrate seamlessly with any other generation, which protects your investment and ensures minimal downtime with each upgrade process. However, it’s a philosophy that is not typically adopted by other equipment providers. The good news is that Yokogawa is now applying its expertise in systems migration not only to legacy Yokogawa systems, but also to systems from just about any vendor, using a range of technologies. When replacing the field control hardware, downtime can be minimised by keeping the existing terminal boards.This saves a considerable amount of time in rewiring and testing and reduces errors in the changeover process. Yokogawa provides a range of cables and interposing boards for interfacing between Yokogawa I/O modules and a range of different vendors’ terminal boards. The operator monitors and operates through the standard Yokogawa faceplate without being aware of the fact that the associated functions are located in the other control system. Sometimes it is not feasible to change over the system in one go. It may be desirable to run the new system in parallel with the legacy system for a period of time. Yokogawa provides a range of integration options that allow the legacy system to be seamlessly integrated into the Yokogawa CENTUM system. By this method, SIOS seamlessly integrates variables and function blocks from the legacy system into the Yokogawa CENTUM system. As a result, standard Yokogawa functions such as peer-to-peer communication between controllers across the two systems, alarm detection, trending, operation and monitoring can be performed without regard for the source of the data. The SIOS (System Integration OPC client Station) is an OPC based gateway that interfaces to OPC servers and maps variables and function blocks from another system to the Yokogawa CENTUM VP system. For example, a PID function block in a Honeywell DCS can be mapped to a Yokogawa PID function block faceplate. The SIOS will read the parameters from the Honeywell PID function block and convert the variables into the correct format for the Yokogawa PID function block. 5 Product Releases century control systems technology onto older plant,” said John Hewitt, Managing Director of Yokogawa Australia. “Not only has the project increased the reliability of the electricity supply, it has done so while The Yokogawa DL9000/DL9700/9500 series and SB5000, simultaneously improving with the LXI compliant Ethernet option (/C9 or /C12) protection of the plant, installed, are now fully compliant with LXI Class C. LXI (Lan eXtensions for Instrumentation) is a reducing maintenance costs communication platform for test and measurementand optimising the use of instruments, built on LAN technology. It provides raw fuels.” steam range and a low pressure condensing turbine.This complex interactive configuration contrasts with most modern plants, where boilers and turbines are installed as unit plants in a much simpler one-to-one arrangement. LXI Support for Yokogawa Digital Oscilloscopes, MSOs and Serial Bus Analysers Yokogawa has been providimproved transfer speeds with enhanced ing control systems for power usability and lower cost than traditional plants for many years. However, instrument interfaces. It’s easy to migrate Energy Brix presented some over from traditional GPIB systems, because LXI utilises existing technologies such asunique challenges, particularly for Peter Morrow, General Manager of Yokogawa’s younger engineers. VXI-11 or IVI. EBAC (left) and Philip Nicholson, MoreEngineer than 20 of test and measurement Some of them were working for the Principal Yokogawa manufacturers provide LXI first time with a power plant equipped Australia (centre) accepted thecompliant products, PACE Award fromof Jeremy andZenith the total number supported products withissteam ranges and pass-out turbines Needham Mitsubishi Electric, alreadyof above 1100. As a new communication — where all boilers feed a common sponsors of the Transport, Power platform for applications requiring high transfer steam range supplying multiple turbines, and Infrastructure category. speed, low cost and usability, LXI will become some of which then supply a process more widespread in the future and Yokogawa will be including this feature on many more new products. One significant achievement of the project was the automated optimisation of energy used for total plant operation, replacing what had been a much more manual approach.This was made possible by the installation of digital controllers on the turbines and load sharing controllers on the boilers. The PACE Zenith Awards were established in 2004 by Process Control and Engineering (PACE) magazine to publicly recognise companies that show leadership in engineering and technological excellence and innovation. The awards are presented annually, with a record number of entries received in 2009. Yokogawa projects have previously won awards in 2005, 2007 and 2008. The Foundation in Australia The Fieldbus Foundation visited Australia within the region and the rest of the Main Benefits of Foundation in August to meet with local equipment world. of liquids Fieldbus Technology suppliers, with a view to establishing an Mr Hisashi Sasajima, Vice President for reduced wiring and installation Yokogawa has developed a retractable fitting available electrodes with PG 13.5mm Australian Marketing Committee to pro- sensor Asia Pacific, and Mr Shane Parr,pH Chairman costs that the offersfeatures a flexibleand approach to online analytical or DIN connections, as well as mote benefits of liquid of the Asia Pacific thread Executive Advisory measurements in a wide range of process industries. reduced control/equipment room Yokogawa’s SC4A conductivity and ISC40 Foundation Fieldbus to the local market. Council, visited Australia to share the space (no marshalling) inductive conductivity sensors (with a The Yokogawa PR10 has been designed for online The Foundation has been championed Foundation’s vision. built-in protection cage for the latter). process applications where the sensor has to be easy integration with asset in Australia for many years by the All delegates to the meeting were management systems removed safely without interrupting process continuity For dissolved oxygen measurements, Foundation Fieldbus End Users’ Council, enthusiastic and agreed to the formation – in anaerobic, toxic orfeels pressurised environments, for the Yokogawa-Hamilton Visiferm, saving in operations and however the Foundation that a sepof a Marketing Committee. Mr Tom Rolton example. The PR10 is suited to pH, ORP, conductivity, maintenance through superior Oxyferm and Oxygold sensors can be arate Marketing Committee would pro- of Emerson was elected Chairman of the diagnostic availability inductive conductivity and dissolved oxygen installed. These sensors are vide a supplementary function and more Committee. He will be assisted by measurements. in nitrogen focussed approach to promotion of the Committee memberstypically Shaun used Loesch of blanketing applications, The unit is available with a wide range of adaptors, technology. Such a structure is similar to ABB, Lindsay Hadland of Yokogawa, and where the optional flush valves and flanges, and the insertion Andrew depth can thatball existing in many other countries Siabe of Rockwell. port will allow regular adjusted to achieve optimum measurement conditions. moisturising of the sensor to Total disassembly without interruption to the process is Local suppliers meet with prevent the membrane from Fieldbus Foundation executives. possible when the ball valve is closed, and safe drying out. retraction is possible at pressures up to 5barG. Retractable sensor fitting for analytical measurement For ease of maintenance, a scraper is built in, and maintenance time is further reduced because fewer O-rings are needed for a good process seal. An optional flush port makes it easy to keep pH and dissolved oxygen sensors moist and clean, and also provides access for calibration. The PR10 will accommodate most commercially 2 6 Applications for the Yokogawa PR10 include the chemical industry, power plants, pulp and paper manufacture, water and effluent treatment, pharmaceuticals and the semiconductor industry. Automation State of the replacement art analysis completed at Western Europe’s largest onshore oilfield Delta Electricity has ordered two Yokogawa generator analyser panels for installation at its Munmorah Power Station Yokogawa UK has successfully completed on the NSW Central Coast. a full replacement of the control and At thissystems plant, hydrogen to 2) is used safety for BP’s(HWytch Farm cool the generators. The merits of H as a 2 oilfield project in Dorset. coolant are its capacity to cool while Developed by BP,Wytch Farm is Western causing only minimal drag or friction Europe’s largest onshore oil field, with between the generators’ moving parts, estimated recoverable reserves of 480 thus increasing efficiency. The potential million barrels. It is located in one of the downside, however, is that if the H2 most environmentally sensitive areas of becomes mixed with oxygen, it can the UK. become explosive, and thus a significant The Wytch Farm oilfield comprises safety hazard. three separate oil reservoirs that lie under In normal operation, the gas blanket Poole Harbour and Poole Bay in Dorset inside the generator is monitored to on the south coast of England. The ensure that the H2 is pure. When the operation, comprising a central oil generator needs to be shut down for gathering station and a number of remote maintenance, the hydrogen is removed by well sites, was established in the early flushing it out with carbon dioxide (CO2); 1980s, and the recently completed the CO2, in turn, is flushed out with automation replacement project was part breathable air so that access to the of a development plan that will enable its generator is safe. When the generator is operational life to be extended. put back into service, the process is Yokogawa was selected by BP as the reversed: air is flushed out with CO2, main automation contractor (MAC) for then the CO2 is swept away with H2.The the project, and the Yokogawa project process is referred to as the Generator team worked closely with the BP team Purge Cycle. during the project implementation. The major challenges were the initial definition of the project scope and requirements in a front-end engineering and (FEED) It included Rotadesign Yokogawa will study. be celebrating 100a site survey, document verification, years of production of high quality changeover and interface with flowmeters planning for industrial applications existing infrastructure. This was followed next month. Founded as Deutsche by the implementation of a smooth hot cutover to the new integrated control An RAMC02 and safety system Rotameter during the from Rota commissioning phase. Using traditional gas analysis techniques, three separate analysers would be needed to monitor all stages During the FEED phase, the Yokogawa of operation and the purge cycle. FEED team was resident at Wytch Farm for But, using state of the art site survey work, liaising with the BP technology from Yokogawa, only a engineers and collecting the engineering single GD402 GastoDensity Analyser data necessary complete the is FEED required. Delta however chose use before commencement of theto detailed two analysers for operational reasons. design. A one-team approach by BP The GD402 is exceptionally stable and by and Yokogawa was achieved reliable andthe is becoming the choice ofin an managing business relationship the power generation industry for and open, performance-focused these applications. collaborative manner. In conjunction with Delta,with “Yokogawa worked collaboratively Yokogawa has designed, the on-site BP team through the many manufactured, commissioned and and challenges of the FEED phase documented a complete process subsequent design, build and test phases, analyser that on enables deliveringsystem the system time,” the said Ian operation and purge cycle for the Bennett, project manager, Automation two Munmorah 350 Excellence, at BP Wytch Farm.MW “Lessons generators to be measured. Thethose have been learned, especially system waswith designed so that it associated the preparation of the minimises the effects of oil and moisture in the sample stream. Pressure measurement was included to provide compensation for changes in operating pressure in the generator cooling hydrogen; such compensation loop diagrams and subsequent commissioning phase, which will benefit the management and planning of future retrofit projects. We commend Yokogawa for the open and honest way they have accepted responsibility in taking the lessons process forward.” BP confirmed its satisfaction in the way Yokogawa completed the Wytch Farm distributed control system (DCS) and safety instrumented system (SIS) upgrade project. Key project performance achievements included: 100% health, safety, security, and environment performance; no plant shutdown as a result of the project; on-time delivery; a smooth and safe changeover to the new system; a ‘one team’ approach with the client project team; and a high The analyser system installed at the level of customer satisfaction. Munmorah Power Station. Wytch Farm is Western can be performed by the GD402 Analyser. Europe’s largest The first system was installed and comonshore oil field. missioned in June and a second identical system has now been delivered. Celebrating a century of excellence The integrated controlYokogawa. and safety system is based on the Yokogawa CENTUM CS 3000-Vnet/IP distributed control system, the ProSafe-RS safety system for emergency shutdown and burner management, and STARDOM networkbased controllers for use as remote terminal units. This project replaced the existing control system, safety system, dual redundant PLC system, process automation controllers, and SCADA/RTU previously used to monitor and control the gathering and processing operations. Rotawerke in the German town of Aachen in 1909, Rota Yokogawa became part of theYokogawa Electric Corporation in 1995. Wytch Farm The early years of the business were focussed on production of the recentlyinvented Rotameter, a float-based flowmeter. The company was so successful that ‘Rotameter’ is often used as a generic term for any flowmeter of this kind, not just Yokogawa’s. Today, Rota Yokogawa continues as the company’s worldwide centre of excellence for flowmeters, which now include mass flow measurement using the Coriolis principle as well as Rotameters. Manufacturing floor space has recently been enlarged by 40% with the opening of one of the most modern and innovative production lines of its kind. Production has also been increasingly automated with sizeable investment in production equipment, robots and automated test rigs. Further investment of tens of millions of Euros is planned in buildings and plant in the next few years. Today, Rota Yokogawa develops and manufactures high-quality flowmeters based on five measuring principles: floats, magnetic-inductive, vortex flowmeters, Coriolis and differential head. Calibrations are carried out in the company’s own DKD-certified facility, which also provides a calibration service to other companies. With outstanding products and an excellent business performance in recent years, Rota Yokogawa is in good shape for the future. The continuous development of new and existing measuring devices will ensure that customers around the world are supplied with top quality Yokogawa flowmeters. Photo courtesy of BP Zenith Award for Energy Brix and Yokogawa cont'd 7 3 Expert Safety Training to reapply to TÜV Rheinland for revalidation. Suitable evidence of continuing experience and education must be submitted. Did you know that Yokogawa has been authorised by TÜV Rheinland to conduct Safety Training, and at the end of the training, subject to successfully passing an examination, attendees receive a certificate from TÜV Reinland certifying them as a TÜV Functional Safety Engineer? Yokogawa has three TÜV certified Functional Safety Expert trainers who are able to conduct the training course on a world-wide basis, and to date, over 10 courses have been completed and many others scheduled. Successful students also have the right to use the TÜV logo on their business cards and correspondence, and will be listed on the TÜV website as FS Engineers. equivalent engineering experience. The cumulative pass rate to date has been just under 70% of students attempting the examination. Any student who does not pass may re-sit it within one year of their first attempt. The course comprises three and a Yokogawa is planning to run a course half days of training lectures, followed in Australia within the next six months. by a four hour examination. Prerequisites Readers may submit expressions of To celebrate the release of FieldMate R1.03, Yokogawa is offering readers include three years’ functional safety interest in attending the course to of Connections a special price on FieldMate and Yokogawa hand-held experience and a bachelor degree or inquiries@au.yokogawa.com communication products on orders placed by August 31, 2008. Each certificate is valid for five years, after which time the FS Engineer needs News Tid Bits Yokogawa New Zealand has been selected by Environment Canterbury (ECan) as an ol systems and ntract to supply contr co a n wo s ha a gaw nt Yoko nt in Vietnam. The pla Vung Ang 1 power pla l na instrumentation for the tio era ed to be op its, with the first plann un W 0M 60 o tw ve ha built will ce, the plant is being in the Ha Tihn provin a by mid-2012. Situated gaw tnam). The Yoko d Gas Group (Petrovie for the Vietnam Oil an million. ated value of US$16.6 contract has an estim This month marks the 10th anniversary of the introduction of Yokogawa’s DAQstation, which replaced paper chart recorders with digital data acquisition and display stations in control rooms around the world. Revolutionary at the time, the DAQstation was a stepping stone to a full-blown DCS; it visually mimicked what chart recorders had provided but added a lot more functionality. The DAQstation has evolved to provide additional functionality, with the latest model, the DXAdvanced R3, offering user-customisable display screens and an intelligent annunciator system with data display and recording functions that can replace common annunciator lamp panels. Yokogawa’s WT3000-2A and WT210 digital power meters are now certified to carry out the standby power tests specified in the new IEC 62301 standard. Key parameters whose limits are specified in IEC 62301 are total harmonic distortion (THD), crest factor, accuracy, resolution and stability at different power levels, and the ability to record true average power over a period of more than five minutes Authorised Water Meter Equipment Supplier for the Rakaia Selwyn Groundwater Zone. The two Yokogawa flowmeters that have been approved by ECan meet the needs of farmers who are now required as part of their water consent to install approved water meters to measure their irrigation water take. report Yokogawa has published its annual 31, for the financial year ended March the ded inclu 2009. Highlights of the year strengthening of product lineup in launch response to market needs, with the system of a new manufacturing execution d rove imp platform that contributes to ase of production efficiency, and the rele ption sum highly durable, low power con e control and monitoring modules. Mor l stria than 60% of sales in the indu e automation and control business wer made outside Japan. YOKOGAWA AUSTRALASIAN NETWORK National toll free number: 1300 558 965 Sydney: 02 8870 1100, Adelaide: 08 8415 2600, Brisbane: 07 3902 6600, Melbourne: 03 8804 8800 Newcastle: 02 4016 2100, Perth: 08 6465 6600, Gladstone: 07 4972 6044, Townsville: 07 4779 9155 Auckland: 09 255 0496, Christchurch: 03 348 0066, New Plymouth: 027 667 7226 Internet: www.yokogawa.com/au Email inquiries: inquiries@au.yokogawa.com 8 Contributors to this issue: Megan Fisher, John Kemp, Simon Lillie, Philip Nicholson, Paul Twigg, David Walker, Mike Wallis Editor: Lindsay Hadland