7200 Series Radar Tank Gauges

Smart Transmitter for continuous and non-contact level

measurement. Cost-effective 4…20 mA 2-wire

technology. Suitable for hazardous locations.

Highlights

•

2‐wire technology, low price: A real alternative to differential pressure, floats and displacersentity. 2‐wire technology reduces wiring costs and allows easy implementation into existing systems.

•

Non‐contact measurement: Measurement is almost independent from product properties.

•

Easy on‐site operation via menu‐driven alphanumeric display.

•

Easy commissioning, documentation and diagnostics via operating software (ToF Tool).

•

2 frequency ranges ‐ 7230/7231 RTG in the C‐band and 7240/7245 RTG in the K‐band: No compromises, the right frequency for every application.

•

HART or PROFIBUS PA respectively FOUNDATION Fieldbus protocol.

•

High temperatures: Suitable for process temperatures up to 200 °C (392 °F), up to 400 °C (752 °F) with high‐temperature antenna.

•

Application in safety related systems (overspill protection) with requirements for functional safety up to SIL 2 in accordance to IEC 61508/IEC 61511‐1.

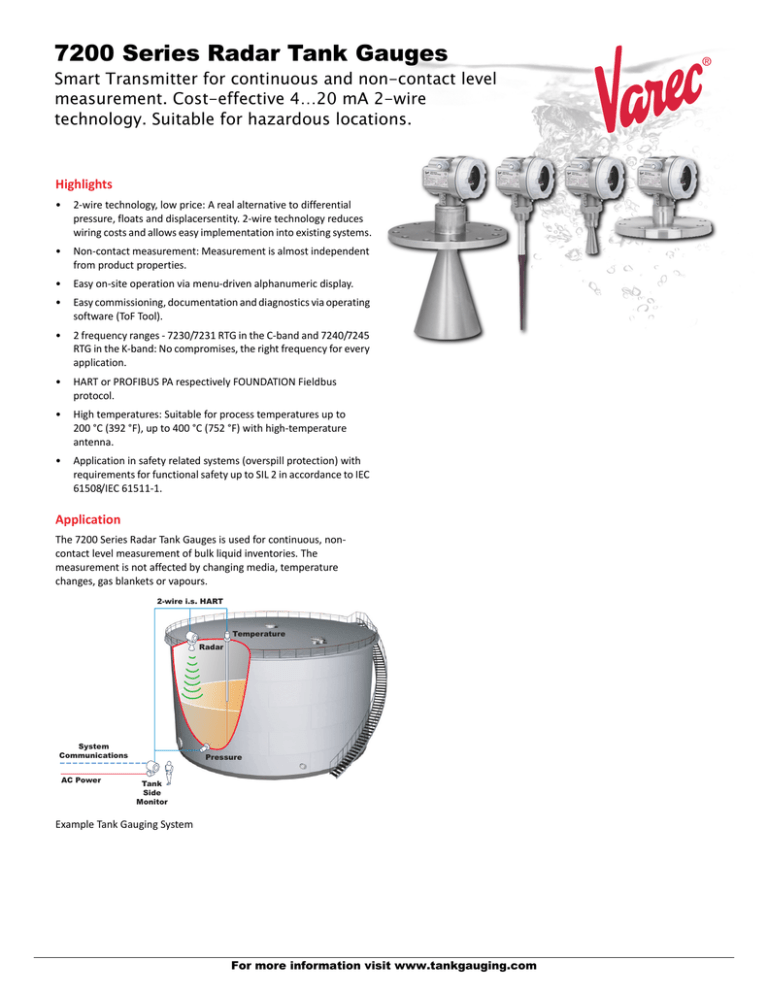

Application

The 7200 Series Radar Tank Gauges is used for continuous, non‐

contact level measurement of bulk liquid inventories. The measurement is not affected by changing media, temperature changes, gas blankets or vapours.

2-wire i.s. HART

Temperature

Radar

System

Communications

AC Power

Pressure

Tank

Side

Monitor

Example Tank Gauging System

For more information visit www.tankgauging.com

7200 RTG

Function and system design

Measuring Principle

The Radar Tank Gauge is a "downward‐looking" measuring system, operating based on the time‐of‐flight method. It measures the distance from the reference point (process connection) to the product surface. Radar impulses are emitted by an antenna, reflected off the product surface and received again by the radar system.

Antenna Selection

It is essential for each and every application and installation to evaluate the right antenna type. The antenna selection depends on the following criteria:

Tank Gauging System

The Varec 4590 Tank Side Monitor provides integrated communications for sites with multiple tanks, each with one or more sensors on the tank, such as radar, spot or average temperature, capacitive probe for water detection and/or pressure sensors. Multiple protocols out of the Tank Side Monitor guarantee connectivity to nearly any of the existing industry standard tank gauging protocols. Optional connectivity of analogue 4...20 mA sensors, digital I/O and analogue output simplify full tank sensor integration. Use of the proven concept of the intrinsically safe HART bus (HART multidrop) for all on‐tank sensors yields extremely low wiring costs, while at the same time providing maximum safety, reliability and data availability.

•

Type of application (i.e. free space vs. stilling well)

•

Installation possibilities (size, location and height of nozzle)

Configuration

•

Properties of the product stored in the tank (radar reflectivity, vapor pressure, temperature, etc.)

•

Accuracy requirements

The 7200 Radar Tank Gauge is commissioned by entering an empty distance E (=zero) and a full distance F (=span) that correspond with 4mA and 20mA current output. Horn antenna

The 7230 with horn antenna is suitable for free space applications that disallow the use of a parabolic antenna due to tank/

nozzle geometry. It is essential that the horn extends below the nozzle. The general rule for diameter selection is "the larger, the better," as a larger aperture of the antenna generates a narrower beam and has a better gain – signal to noise (S/N) ratio.

Rod antenna

The 7231 with rod antenna is used for measurements where only small diameter nozzles are available and tanks containing condensing products (or heavy water condensation) or corrosive products, such as sulphur, as the rod is easy to clean and has good "drip‐off" properties. The "inactive" length of the antenna should extend below the nozzle.

Small horn antenna

The 7240 with the small (1½") horn antenna is ideally suited for small vessels. Additionally, it provides an accuracy of ±3 mm.

Process antennas

The 7245 combines the advantages of the horn antenna with high chemical resistance while being easy to clean.

On‐site operation and configuration is performed using:

•

The built in display and operating module VU331

•

A Personal Computer, Commubox (FXA195) and "Fieldcare" operating software.

Remote operation and configuration can be performed using:

•

A Personal Computer, Commubox (FXA195) and "Fieldcare" operating software.

•

A Personal Computer, 4590 TSM and the operating software FuelsManager.

ToF Tool

FieldTool

Package

Commubox

FXA195

HART

2 wire

Level

Pressure

Fieldbus Protocol

+24V

+5V

+15V

-15V

CPU

COMM

I/O

ERROR

8130 RTU

or

8300 TGI

68 Temperature

Supply voltage:

16…253 VAC

FuelsManager

Software

Varec, Inc.

Radar Tank Gauge

Installation Guidelines

Media group

DC (r)

Examples

The usable measuring range depends on the size of the antenna, the reflectivity of the medium, the mounting location and eventual interference reflections.

A

1.4...1.

9

non‐conducting liquids, e.g. liquefied gas (LPG). For more information please contact your Varec representative.

The maximum configurable range is:

B

1.9...4

non‐conducting liquids, e.g. benzene, oil, toluene, white products, black products, crudes, bitumen/

asphalts, …

C

4...10

e.g. concentrated acids, organic solvents, esters, aniline, alcohol, acetone, …

D

> 10

conducting liquids, e.g. aqueous solutions, dilute acids and alkalis

Measuring Range

•

20 m (65 ft) for 723x RTG

•

40 m (131 ft) for 724x RTG (basic version)

•

70 M (229 ft) for 724x RTG (with Advanced Dynamics)

The following tables describe the groups of media as well as the achievable measuring range as a function of application and media group. If the dielectric constant of a medium is unknown, it is recommended to assume media group B to ensure a reliable measurement.

:

Measuring range depending on vessel type, conditions and product for 7230/7231 RTG

Product class

Storage tank Calm product Buffer tank Moving surfaces surface (e.g. intermittent filling, (e.g. continuous filling, from filling from bottom,

above, mixing jets).

immersion tubes).

Process tank with agitator

Turbulent surface.

Single stage agitator <60 RPM.

Stilling well

Bypass

Measuring range

7230

150 mm (6")

200 mm (8")

250 mm (10")

150 mm (6")

200 mm (8")

250 mm (10")

150 mm (6")

200 mm (8")

250 mm (10")

80...250 mm (3"...10")

7231

Rod

‐

Rod

‐

Rod

‐

‐

‐

A

Use a stilling well 20 m/65 ft

20 m/65 ft

B

10 m/33 ft

15 m/49 ft

5 m/16 ft

7.5 m/24 ft

4 m/13 ft

6 m/20 ft

20 m/65 ft

possible, i.e. with stilling well in bypass.

C

15 m/49 ft

20 m/65 ft

7.5 m/24 ft

10 m/33 ft

6 m/20 ft

8 m/27 ft

20 m/65 ft

20 m/65 ft

D

20 m/65 ft

20 m/65 ft

10 m/33 ft

12.5 m/41 ft

8 m/27 ft

10 m/33 ft

20 m/65 ft

20 m/65 ft

Technical Information

69

7200 RTG

Measuring range depending on vessel type, conditions, and product for the 7240 & 7245 RTGs:

Product class

Storage tank Calm product surface (e.g. intermittent filling, filling from bottom, immersion tubes).

Dimensions

Measuring range

7240

40 mm (1½" )

7245

—

A

3 m/10 ft

(5 m/16 ft)

4 m/13 ft

(8 m/26 ft)

3 m/10 ft

(8 m/26 ft)

C

D

B

Basic Version

(Advanced Dynamics)

50 mm (2")

80 mm (3")

Buffer tank Moving surfaces (e.g. continuous filling, from above, mixing jets).

100mm (4")

40 mm (1½")

50 mm (2")

80 mm (3")

100mm (4")

—

—

8 m/26 ft

(10 m/32 ft)

10 m/32 ft

(15 m/49 ft)

—

—

2.5 m/8 ft

(5 m/16 ft)

5 m/16 ft

(7.5 m/24 ft)

5 m/16 ft

(12 m/39 ft)

10 m/33 ft

(20 m/65 ft)

25 m/82 ft

(30 m/99 ft)

2 m/7 ft

3 m/10 ft

(5 m/16 ft)

5 m/16 ft

(10 m/32 ft)

10 m/32 ft

(15 m/49 ft)

6 m/20 ft

(15 m/49 ft)

10 m/33 ft

(25 m/82 ft)

15 m/49 ft

(40 m/131 ft)

40 m/131 ft

(45 m/148 ft)

4 m/13 ft

(5 m/16 ft)

7.5 m/24 ft

(10 m/32 ft)

10 m/32 ft

(15 m/49 ft)

15 m/49 ft

(25 m/82 ft)

9 m/30 ft

(25 m/82 ft)

15 m/49 ft

(40 m/131 ft)

20 m/65 ft

(60 m/197 ft)

40 m/131 ft

(70 m/229 ft)

7.5 m/24 ft

(10 m/32 ft)

10 m/32 ft

(15 m/49 ft)

15 m/49 ft

(25 m/82 ft)

25 m/82 ft

(35 m/110 ft)

—

Measuring range depending on vessel type, conditions, and product for the 7240 & 7245 RTGs:

Product class

Process tank with agitator Turbulent surface.Single stage agitator <60 RPM.

Stilling well

Bypass

Dimensions

Measuring range

Measuring range

Measuring range

7240

40 mm (1½")

100mm (4")

40...100mm (1½...4")

50...100mm (2...4")

7245 —

—

50...80mm (2...3")

50...80mm (2...3")

A

—

—

—

—

20 m / 65 ft

Contact Factory

1 m/3 ft

2 m/7 ft

2.5 m/8.2 ft

4 m/13 ft

(5 m/16 ft)

C

2 m/7 ft

3 m/10 ft

(7.5 m/24 ft)

5 m/16 ft

(12 m/39 ft)

8 m/26 ft

(15 m/49 ft)

D

3 m/10 ft

(5 m/16 ft)

5 m/16 ft

(10 m/32 ft)

8 m/26 ft

(15 m/49 ft)

10 m/32 ft

(20 m/65 ft)

B

70 Basic Version

(Advanced Dynamics)

50 mm (2")

80 mm (3")

20 m / 65 ft

Varec, Inc.

Radar Tank Gauge

Measuring Conditions in Liquids

Note! Please refer to the specific instrument’s Installation & Oper‐

ation Manual for complete installation instructions

•

In case of boiling surfaces, bubbling or tendency for foaming, use 7230 or 7231 RTG. Depending on its consistence, foam can either absorb microwaves or reflect them off the foam surface. Measurement is possible under certain conditions.

•

In case of heavy steam development or condensate the max. measuring range of 7240 RTG may decrease depending on density, temperature and composition of the steam use 7230 or 7231 RTG.

•

For the measurement of absorbing gases such as ammonia or some fluorocarbons* please use 7230 RTG in a stilling well.

Gauge orientation (refer to diagram on pg. 8)

• Recommended distance (1) wall – outer edge of nozzle: ~1/6 of tank diameter. Nevertheless the device should not be installed closer than 30 cm/12“ (7230/7231) resp. 15 cm/6“ (7240/7245) to the tankwall.

•

Not in the centre (3), interference can cause signal loss.

•

Not above the fill stream (4).

•

It is recommended to use a weather protection cover (2) in order to protect the transmitter from direct sun or rain. Assembly and disassembly is simply done by means of a tension clamp.

Turn housing

The housing can be tur

ned 350° in order to simplify access to the

display and the terminal compartment

T12 housing

F12/F23 housing

*Affected compounds are e.g. R134a, R227, Dymel 152a.

•

•

•

The measuring range begins, where the beam hits the tank bottom. Particularly with dish bottoms or conical outlets the level cannot be detected below this point. (refer to diagram on pg. 8)

2

2

In case of media with a low dielectric constant (groups A and B), the tank bottom can be visible through the medium at low levels (low height C). Reduced accuracy has to be expected in this range. If this is not acceptable, we recommend positioning the zero point at a distance C above the tank bottom in these applications.(refer to diagram on pg. 8)

3

In principle it is possible to measure up to the tip of the antenna with 7230/7231/7240 RGGs. However, due to considerations regarding corrosion and build‐up, the end of the measuring range should not be chosen any closer than A to the tip of the antenna.(refer to diagram on pg. 8)

1

3

1

Allen key 4 mm / 0.1"

FMR 244: max. torque 0.5 Nm

•

For 7245 RTG, the end of measuring range should not be chosen closer than A to the tip of the antenna, especially if there is development of condensate. (refer to diagram on pg. 8)

Mounting in a stilling well (7230/7240/7245)

• The stilling well should be constructed from metal (no enamel coating, plastic on request) with a constant diameter.

•

The smallest possible measuring range B depends on the antenna version. (refer to diagram on pg. 8)

•

Diameter of stilling well not larger than antenna diameter.

The tank diameter should be greater than D, the tank height at least H. (refer to diagram on pg. 8)

•

Any rectangular increase of the pipe diameter has to be avoided.

•

Welding seam as smooth as possible and on the same axis as the slots.

•

Slots offset 180° (not 90°).

•

Slot width respectively diameter of holes max. 1/10 of pipe diameter, de‐burred. Length and number do not have any influence on the measurement.

Symmetrical installations (2), i.e. vacuum rings, heating coils, baffles, etc., can also interfere with the measurement.

•

At any transition (e.g. when using a ball valve or mending pipe segments), no gap may be created exceeding 1 mm (0.04").

Optimization options

•

The stilling well must be smooth on the inside (average roughness Rz 6.3 m). Use extruded or parallel welded stainless steel pipe. An extension of the pipe is possible with welded flanges or pipe sleeves. Flange and pipe have to be properly aligned at the inside.

•

Do not weld through the pipe wall. The inside of the stilling well must remain smooth. In case of unintentional welding through the pipe, the weld seam and any unevenness on the inside need to be carefully removed and smoothed. Otherwise, strong interference echoes will be generated and material build‐up will be promoted.

•

Tank Installations

Avoid any installations (1), like limit switches, temperature sensors, etc., inside the signal beam (see Beam angle on Page 22).

•

Antenna size: the bigger the antenna, the smaller the beam angle, the less interference echoes.

•

Mapping: the measurement can be optimized by means of electronic suppression of interference echoes.

•

Antenna alignment: refer to "optimum mounting position"

•

Stilling well: a stilling well respectively a Wave Guide antenna can always be used to avoid interference.

•

Metallic screens (3) mounted at a slope spread the radar signals and can, therefore, reduce interference echoes.

Technical Information

71

7200 RTG

•

Slot width respectively diameter of holes max. 1/10 of pipe diameter, de‐burred. Length and number do not have any influence on the measurement.

•

Select horn antenna as big as possible. For intermediate sizes (i.e. 180 mm) select next larger antenna and adapt it mechanically (7230/7240 only).

•

Particularly on smaller nominal widths it needs to be observed that flanges are welded to the pipe such that they allow for a correct orientation (marker aligned toward slots).

Recommendations for the bypass pipe (7230/7240/7245)

• Metal (no plastic or enamel coating)

•

Constant diameter

•

Select horn antenna as big as possible. For intermediate sizes (i.e. 95 mm) select next larger antenna and adapt it mechanically (7230/7240 only).

•

At any transition (i.e. when using a ball valve or mending pipe segments), no gap may be created exceeding 1 mm (0.04").

•

In the area of the tank connections (~ ±20 cm / 8“) a reduced accuracy of the measurement has to be expected. (refer to diagram on pg. 8)

Enamelled antenna

Do not hit or chip the enamelled antenna as the coating may be damaged and effect the measurement accuracy.

Antenna extensions

•

An antenna extension needs to be selected to allow the antenna to extend below the nozzle ‐ See FAR10 Accessory

•

If the antenna has to be mounted on a sloping or vertical vessel wall, an extension with a 45° respectively 90° bend is available. The smallest possible radius R for the bend is 300 mm (12”).

Installation with heat insulation

The 7200 RTG can be installed on a tank with heat insulation. Please contact Varec for further information about all special installations.

The beam angle is defined as the angle a where the energy density of the radar waves reaches half the value of the maximum energy density (3dB‐width). Microwaves are also emitted outside the signal beam and can be reflected off interfering installations. Beam diameter W as function of antenna type (beam angle α) and measuring distance D. (See page 9)

Effect of gas phase

High pressures reduce the propagation velocity of the measuring signals in the gas/vapour above the fluid. This effect depends on the gas/vapour and is particularly large for low temperatures. This results in a measuring error that gets bigger as the distance increases between the device zero point (flange) and product surface. The following table illustrates this measured error for a few typical gases/

vapours (with regard to the distance; a positive value means that too large a distance is being measured).

Special Installations

Note! When the pressure is known and constant, this measured error can, for example, be compensated by means of linearization.

Beam Angle

Measurement through plastic tank walls

It is also possible to measure the contents of a tank by installing the gauge on the outside of the tank and measuring through the wall of the tank.

Gas phase

Air

Nitrogen

Hydrogen

72 Measurement in plastic tanks

If the outer wall of the tank is made of a non‐conductive material (e.g. Plastic or GRP), microwaves can also be reflected off objects outside the tank (e.g. metallic pipes, ladders, grates, etc.). Therefore, these objects should be considered as interfering installations if they are within the signal beam.

Gas Phase Information

Temperature

Pressure

°C

°F

1 bar/14.5 psi

10 bar/145 psi

50 bar/725 psi

100 bar/1450 psi

160 bar/2320 psi

20

68

0.00 %

0.22 %

1.2 %

2.4 %

3.89 %

200

392

‐0.01 %

0.13 %

0.74 %

1.5 %

2.42 %

400

752

‐0.02 %

0.08 %

0.52 %

1.1 %

1.70 %

20

68

‐0.01 %

0.10 %

0.61 %

1.2 %

2.00 %

200

392

‐0.02 %

0.05 %

0.37 %

0.76 %

1.23 %

400

752

‐0.02 %

0.03 %

0.25 %

0.53 %

0.86 %

Varec, Inc.

Radar Tank Gauge

Gas Phase Information

Gas phase

Temperature

Pressure

°C

°F

1 bar/14.5 psi

10 bar/145 psi

50 bar/725 psi

100 bar/1450 psi

160 bar/2320 psi

100

212

0.20 %

—

—

—

—

180

356

—

2.1 %

—

—

—

263

505.4

—

—

8.6 %

—

—

310

590

—

—

—

22 %

—

364

687.2

—

—

—

—

41.8 %

A [mm/inch]

B [m/inch]

C [mm/inch]

D [m/inch]

H [m/inch]

7230/7231

50 / 2

> 0,5 / > 20

150...300 / 6...12

> 1 / > 40

> 1,5 / > 60

7240

50 / 2

> 0,2 / > 8

50...150 / 2...6

> 0,2 / > 8

> 0,3 / > 12

7245

200 / 8

> 0,2 / > 8

50...150 / 2...6

> 0,2 / > 8

> 0,3 / > 12

Water

(saturated steam)

Installation Dimensions

Installation Considerations

3

4

5

100% A

E

2

6

B

H

1

0%

C

ØD

Installation in tank (free space):

Mark on process connector

facing the nearest tank wall!

Installation in bypass:

Mark on process connector 90° offset

from the tank connections!

°

90

Installation in stilling well:

Mark on process connector pointed to

towards the slots or vent holes!

90

°

°

°

90

90

90°

°

90

°

90

90

°

90

°

90

°

°

90

90

°

Technical Information

73

7200 RTG

Beam Angle Information

72 3 0

7 231

Antenna size

(horn diameter)

150 mm (6")

200 mm (8")

250 mm (10")

Beam angle ɲ

23°

19°

15°

Rod

30°

Beamwidth diameter (W)

Measuring

distance (D)

150 mm (6")

200 mm (8")

250 mm (10")

Rod

3 m (10 Ō)

1.22 m (4.07 Ō)

1.00 m (3.35 Ō)

0.79 m (2.63 Ō)

1.61 m (5.36 Ō)

6 m (20 Ō)

2.44 m (8.14 Ō)

2.01 m (6.70 Ō)

1.58 m (5.26 Ō)

3.22m (10.72 Ō)

9 m (30 Ō)

3.66 m (12.21 Ō)

3.01 m (10.05 Ō)

2.37 m (7.90 Ō)

4.82 m (16.08 Ō)

12 m (40 Ō)

4.88 m (16.28 Ō)

4.02 m (13.40 Ō)

3.16 m (10.53 Ō)

6.43 m (21.44 Ō)

15 m (49 Ō)

6.10 m (19.94 Ō)

5.02 m (16.40 Ō)

3.95 m (12.90 Ō)

8.04 m (26.26 Ō)

20 m (65 Ō)

8.14 m (26.45 Ō)

6.69 m (21.75 Ō)

5.27 m (17.11 Ō)

10.72 m (34.83 Ō)

7240

40 mm (1½")

50 mm (2")

80 mm (3")

100 mm (4")

7244

40 mm (1½")

—

80 mm (3")

—

7245

—

50 mm (2")

80 mm (3")

—

23°

18°

10°

8°

Antenna size

(horn diameter)

Beam angle ɲ

D

a

W

a

W = 2 . D . tan _

2

Beamwidth diameter (W)

Measuring distance (D)

74 40 mm (1½")

50 mm (2")

80 mm (3")

100 mm (4")

3 m (10 Ō)

1.22 m (4.07 Ō)

0.95 m (3.17 Ō)

0.53 m (1.75 Ō)

0.42 m (1.40 Ō)

6 m (20 Ō)

2.44 m (8.14 Ō)

1.90 m (6.34 Ō)

1.05 m (3.50 Ō)

0.84 m (2.80 Ō)

9 m (30 Ō)

3.66 m (12.21 Ō)

2.85 m (9.50 Ō)

1.58 m (5.25 Ō)

1.26 m (4.20 Ō)

12 m (40 Ō)

4.88 m (16.28 Ō)

3.80 m (12.67 Ō)

2.10 m (7.00 Ō)

1.68 m (5.59 Ō)

15 m (49 Ō)

6.10 m (19.94 Ō)

4.75 m (15.52 Ō)

2.63 m (8.57 Ō)

2.10 m (6.85 Ō)

20 m (65 Ō)

8.14 m (26.45 Ō)

6.34 m (20.59 Ō)

3.50 m (11.37 Ō)

2.80 m (9.09 Ō)

25 m (82 Ō)

10.17 m (33.37 Ō)

7.92 m (25.98 Ō)

4.37 m (14.35 Ō)

3.50 m (11.47 Ō)

30 m (98 Ō)

—

9.50 m (31.04 Ō)

5.25 m (17.15 Ō)

4.20 m (13.71 Ō)

35 m (114 Ō)

—

11.09 m (36.11 Ō)

6.12 m (19.95 Ō)

4.89 m (15.94 Ō)

40 m (131 Ō)

—

12.67 m (41.50 Ō)

7.00 m (22.92 Ō)

5.59 m (18.32 Ō)

45 m (147 Ō)

—

—

7.87 m (25.72 Ō)

6.29 m (20.56 Ō)

60 m (196 Ō)

—

—

10.50 m (34.30 Ō)

8.39 m (27.41 Ō)

70 m (229 Ō)

—

—

—

9.79 m (32.03 Ō)

Varec, Inc.

Radar Tank Gauge

Inputs & Outputs

4…20 mA with HART

Output Signal

The 2‐wire cable is connected to the screw terminals in the terminal compartment.

•

4…20 mA with HART protocol

•

PROFIBUS PA

•

FOUNDATION Fieldbus (FF)

Note! A standard installation cable is sufficient if only the analogue signal is used. Use a screened cable when working with a superim‐

posed communications signal (HART).

Note! Protective circuitry against reverse polarity, RFI, and over‐

voltage peaks is built into the device (refer to TI241F »basics for EMC‐tests«).

Terminal Compartment

Three housings are available:

•

Aluminium housing F12 with additionally sealed terminal compartment for:

power

–standard,

–EEx ia.

• Aluminium housing T12 with separate terminal compartment for:

–standard,

–EEx e,

–EEx d,

–EEx ia (with overvoltage protection).

• 316L housing F23 for:

alternatively

Commubox

FXA191/195

DXR375

communication

resistor

(> 250 W)

4...20 mA

–standard,

–EEx ia.

The electronics and current output are galvanically isolated from the antenna circuit.

test sockets for testing

of the signal current

1 2 3 4

L- L+ I+

1.

2.

US

HA

S+

ES

DR

ER

4.

1 2 3 4

Sealed terminal

compartment

Accessing the Terminal Compartment

Overvoltage Protector

The level transmitter 7200 Series Radar Tank Gauges with T12‐

housing (housing version "D", see ordering information on page 52‐

63) is equipped with an internal overvoltage protector (600 Vrms surge arrester) according to DIN EN 60079‐14 or IEC 60060‐1 (impulse current test 8/20 ms, Î = 10 kA, 10 pulses). Connect the metallic housing of the 7200 Series Radar Tank Gauges to the tank wall or screen directly with an electrically conductive lead to ensure reliable potential matching.

Technical Information

I-

4‐20 mA with HART Terminal Wiring Diagram

EN

3.

plant

ground

System integration via PROFIBUS PA

A maximum of 32 transmitters (8 if mounted in an explosion hazardous location EEx ia IIC according to FISCO‐

model) can be connected to the bus. The segment coupler provides the operating voltage to the bus. Both on‐site as well as remote operation are possible. The complete measuring system consists of:

1 2 3 4

– +

plant

ground

Right ‐ Profibus PA Wiring Diagram

The digital communication signal is transmitted to the bus via a 2‐

wire connection. The bus also provides the auxiliary energy.

Note! Use a twisted, screened two‐wire cable, preferably cable type A

75

7200 RTG

Foundation Fieldbus

Operation

A maximum of 32 transmitters (standard, EEx em or EEx d) can be connected to the bus. For protection class EEx ia IIC: the max. number of transmitters depends on the established rules and standards for intrinsically safe circuits (EN 60079‐14), proof of intrinsically safety. Both on‐site as well as remote operation are possible.

The display of the process value and the configuration of the Radar Tank Gauge occur locally by means of a large 4‐line alphanumeric display with plain text information. The guided menu system with integrated help texts ensures a quick and safe commissioning.

Display and operation can occur in one out of six languages (English, German, French, Italian, Dutch, and Spanish). During the first start‐

up, the instrument explicitly asks for the desired unit / language.

Remote commissioning, including documentation of the measuring point and in‐depth analysis functions, is supported via Fieldcare, the graphical operating software for Varec instruments.

Access to the electronics can be prevented by means of a custody locking switch that locks the device settings. The custody locking switch can be sealed for custody transfer applications.

Software Reliability

plant

ground

1 2 3 4

– +

Foundation Fieldbus Wiring Diagram

The software used in the 7200 Series Radar Tank Gauge fulfils the requirements of OIML R85. This particularly includes:

•

cyclical test of data consistency

•

non‐volatile memory

•

segmented data storage

The complete measuring system consists of the digital communication signal is transmitted to the bus via a 2‐wire connection. The bus also provides the auxiliary energy. For further information on the network structure and earthing and for further bus system components such as bus cables, contact Varec.

Radar Tank Gauges continuously monitor the compliance with accuracy requirements for custody transfer measurements according to OIML R85. If the accuracy cannot be maintained, a specific alarm is generated on the local display and via the digital communication.

Note! Use a twisted, screened two‐wire cable, preferably cable type A

On‐site Operation

Fieldbus Plug Connectors

For the versions with fieldbus plug connector (M12 or 7/8"), the signal line can be connected without opening the housing.

Pin assignment of the M12 plug connector (PROFIBUS PA plug)

1

3

2

+ 4

–

nc

Pin

Meaning

1

Ground

2

Signal +

3

Signal ‐

4

not connected

The LC‐Display VU331 (Four lines with 20 characters each.) allows configuration via 3 keys directly at the instrument. It can be removed to ease operation by simply pressing the snap‐fit. It is connected to the device by means of a 500 mm cable.

All device functions can be set through a menu system. The menu consists of function groups and functions. Within a function, application parameters can be read or adjusted. The user is guided through a complete configuration procedure.

LCD

(liquid crystal display)

symbols

Pin assignment of the 7/8" plug connector (FOUNDATION Fieldbus plug)

1

– 3

2

+ 4

nc

Pin

Meaning

1

Signal ‐

2

Signal +

3

not connected

4

ground

–

+

E

snap-fit

sealing pin

custody locking

switch

red LED

green LED

3 keys

LC‐Display VU331

To access the display, it is possible to open the cover of the electronics compartment even in an explosion hazardous area.

76 Varec, Inc.

Radar Tank Gauge

Remote Operation

Fieldcare is a graphical operation software for instruments from Varec that operate based on the time‐of‐flight principle. It is used to support commissioning, securing of data, signal analysis, and documentation of the instruments. Compatibility

It is compatible with the following operating systems: •

Microsoft Windows Vista Business, Enterprise, Ultimate (x32) Service Pack 1 or later.

•

Microsoft Windows 2003 R2 Service Pack 2 Standard Enterprise (x32) •

Microsoft Windows XP Service Pack 2 (x32) or later

•

Microsoft Windows 7 Professional, Ultimate Enterprise (x32, x64) as of Fieldcare Version 2.08.01

It supports the following functions:

•

Online configuration of transmitters

•

Signal analysis via envelope curve

•

Loading and saving of instrument data (Upload/Download))

•

Documentation of measuring point

Note! More information can be found on the DVD‐ROM which is supplied with the instrument.

Connection options:

• HART with Commubox FXA195

•

Service‐interface with adapter FXA291 and ToF Adapter FXA291 (USB)

Signal on Alarm

Maintenance

The 7200 series RTG is designed and manufactured to provide accurate and reliable operation without an intensive maintenance schedule. Varec can provide spare parts, preventive maintenance advice, training and warranties. Please consult your Installation and maintenance manual or a representative for more details.

Cleaning the Antenna

The antenna can get contaminated, depending on the application. The emission and reception of microwaves can thus eventually be hindered. The degree of contamination leading to an error depends on the medium and the reflectivity, mainly determined by the dielectric constant r. If the medium tends to cause contamination and deposits, cleaning on a regular basis is recommended. Care has to be taken not to damage the antenna in the process of a mechanical or hose‐down cleaning. The material compatibility has to be considered if cleaning agents are used! The maximum permitted temperature at the flange should not be exceeded

Accessories

Antenna Extension for 7230 RTG

The antenna extension has to be selected such that the horn extends below the nozzle.

If the horn diameter is greater than the nominal width of the nozzle, the antenna including the extension is mounted from inside the vessel. The bolts are tightened from outside, with the instrument lifted up. The extension has to be selected such that the instrument can be lifted by at least 100 mm (4”).

Error information can be accessed via the following interfaces:

•

Radar

Local display:

–Error symbol

–Plain text display

–LED’s: red LED continuously on = alarm, red LED

flashes = warning

• Current output

•

> 100 mm/4”

Digital interface

Linearization

The linearization function of the 7500 Series Radar Tank Gauge allows the conversion of the measured value into any unit of length or volume. Linearization tables for calculating the volume in cylindrical tanks are pre‐programmed. Other tables of up to 32 value pairs can be entered manually or semi‐automatically.

Antenna Extension

Antenna Extension Dimensions

Technical Information

77

7200 RTG

4400 Remote Display Unit

Weather Protection Cover

A weather protective cover made of stainless steel is available for outdoor mounting (order code: 543199‐0001). The shipment includes the protective cover and tension clamp.

Separate housing

4400 RDU (IP 65)

0

15

Wall-mounting

(without mounting bracket)

122

80

7200 RTG

Cable

6,

3

120

82

Made in Germany

Maulburg

AU

A

106

122

Weather Protection Cover

8,

5

Pipe-mounting

(mounting bracket and plate

supplied optionally,

s. product structure)

118

96

180

160

max. 80

min. 30

Roof Reflector

Measurements on floating roofs are not recommended for highly accurate measurements due to the unsteady movements of the floating roofs. A special reflector can be used for applications on floating roofs. Optimum mounting of the reflector on a floating roof:

•

The upper edges of the reflector have to be aligned horizontally.

•

For slanted locations (e.g. dome‐shaped floating roof), the feet must be extended accordingly.

pipe

88

Technical data (cable and housing)

Max. cable length

20 m (65 ft)

Temperature range

‐30 °C...+70 °C (‐22 °F...158 °F)

Degree of protection

IP65 acc. to EN 60529 (NEMA 4)

Materials

Housing: AlSi12; cable glands: nickle plated brass

Dimensions [mm] 122x150x80 (HxWxD) / 4.8x5.9x3.2

/ [inch]

For connection of the remote display 4400 use the cable which fits the communication version of the respective instrument.

78 75xx/72xx RTG

roof reflector

horizontal top edge

e.g.floatingroof

e.g. tank

The construction serves as retroreflector such that a tank roof incline does not influence the measured value.

Top View Of Reflector

The cross‐sectional area shouldn‘t be smaller than specified in the figure above to receive and transmit enough energy. The construction should be open in the bottom part to allow rainwater to drop out. Thin stainless steel sheets should be used, to prevent the construction from becoming too heavy.

Varec, Inc.

Radar Tank Gauge

Technical Specifications

Note! The following specifications apply to the following 7230, 7231, 7240 and 7245 RTG over the following reference operating conditions:

•

Temperature = +20 °C (68 °F) ±5 °C (9 °F)

•

Pressure = 1013 mbar abs. (14.7 psia) ±20 mbar (0.3 psi)

•

Relative humidity (air) = 65 % ±20%

•

Ideal reflector

•

With no major interference reflections inside the signal beam

Physical

Weight for F12 or T12 housing

(weight of flange additional)

7230 Approx. 6 kg

7231 Approx. 4 kg

7240 Approx. 4 kg 7245 Approx. 4 kg

Weight for F23 housing (weight of flange additional)

7230 Approx. 9.4 kg

7231 Approx. 7.4 kg

7240 Approx. 7.4 kg

7245 Approx. 7.4 kg

Enclosure

IP 65, NEMA 4X (open housing and removed liquid crystal display: IP20, NEMA 1

housing F23: 316L, corrosion‐resistant steel

Housing F12/T12: separate terminal compartment for increased safety respectively explosion proof.

Material: aluminium, seawater repellent, chromate, powder coated

Sight window: glass (all Housings)

Antenna

IP 68 (NEMA 6P)

Conduit entries

Cable gland: M20x1,5 (for EEx d: cable entry)

Cable entry: G ½ or ½ NPT

PROFIBUS PA M12 plug

Fieldbus Foundation 7/8" plug

Cable gland

Type

Clamping area

Standard, EEx ia, IS

Plastic M20x1.5

5...10 mm

EEx em, EEx nA

Metal M20x1.5

7...10.5 mm

Performance

Reaction time

The reaction time depends on the parameter settings (min. 1 s). In case of fast level changes, the instrument needs the reaction time to indicate the new value.

Resolution

Digital / analogue in % 4…20 mA

0.03 % of measuring range (1mm) Maximum Measured Error

Type of device

to 10 m

ex 10 m

7230/7231

± 10 mm

± 0.1 % of measuring range

7240

± 3 mm

± 0.03 % of measuring range

7245

± 3 mm

± 0.03 % of measuring range

HART Field Communications

Min Load

250

Cable

Two (2) wire, twisted pair (wire diameter 0.5…2.5 mm)

Ripple HART

47...125 Hz: Uss = 200 mV (at 500 )

Max. Noise HART

500 Hz...10 kHz: Ueff = 2.2 mV (at 500 )

Supply voltage

The following values are the voltages across the terminals directly at the instrument:

Communication

HART

Current

Consumption

Terminal voltage

min

max

4 mA

16 V

36 V

20 mA

7.5 V

36 V

4 mA

16 V

30 V

20 mA

7.5 V

30 V

4 mA

16 V

30 V

20 mA

11 V

30 V

11 mA

10 V*

36 V

11 mA

10 V*

30 V

standard

4 mA**

16 V

36 V

EEx ia

4 mA**

16 V

30 V

standard

EEx ia

EEx em

EEx d

Power Consumption

min. 60 mW, max. 900 mW

Current Consumption

Communication

Current consumption

HART

3,6...22 mA for HART Multidrop: start up current is 11 mA.

PROFIBUS PA

max. 13 mA

FOUNDATION Fieldbus

max. 15 mA

standard

Fixed current, adjustable e.g. for EEx ia

solar power operation (measured value transferred at HART)

Fixed current for HART Multidrop mode

*Short‐term min. start‐up voltage: 11.4 V

**Start‐up current 11 mA.

Technical Information

79

7200 RTG

Process Temperature/Pressure Limits

Type of antenna

7230

7240

7245

Seal

Temperature

a)

Pressure

Wetted parts

‐1 ... 64 bar

(... 928 psi)

PTFE, seal,

316L/1.4435 resp.

Alloy C4

Ceramic (Al2O3: 99,7%),

Graphite, 316L/1.4435

V

Standard

FKM Viton

GLT

‐40 °C ... +200 °C (‐40 °F ... ‐392 °F)

E

Standard

EPDM

‐40 °C ... +150 °C

(‐40 °F ... +302 °F)

K

Standard

Kalrez

(Spectrum 6375)

‐20 °C ... +200 °C )

(‐4 °F ... +392 °F)

L

Extended temperature

Graphite

‐60 °C ... +280 °C

(‐76 °F ... +536 °F)

‐1 ... 100 bar

(... 1450 psi)

M

High temperature

Graphite

‐60 °C ... +400 °C

(‐76 °F ... +752 °F)

‐1 ... 160 bar

(... 2320 psi)

H

Enamel

PTFE

‐40 °C ... +200 °C

(‐40 °F ... +392 °F)

‐1 ... 16 bar

(... 232 psi)

PTFE, Enamel

V

Standard

FKM Viton

‐20 °C ... +150 °C

(‐4 °F ... +302 °F)

‐1 ... 40 bar

(... 580 psi)

E

Standard

FKM Viton

GLT

‐40 °C ... +150 °C

(‐40 °F ... +302 °F)

PTFE, seal,

316L/1.4435 resp.

Alloy C22

K

Standard

Kalrez

(Spectrum 6375)

‐20 °C ... +150 °C

(‐4 °F ... +302 °F)

B, C

Standard,

PTFE clad

none

‐40 °C ... +200 °C

(‐40 °F ... +392 °F)

‐1 ... 16 bar

(...232 psi)

PTFE (TFM1600,

FDA‐listed) b)C

a.max. +150 °C (+302 °F) for conductive media

b.3A‐, EHEDG approval for Tri‐Clamp process connection.

c. Meets USP Class VI conformity

7231

Type of antenna

Connection

Temperature

Pressure

Wetted parts

A, B

PPS

‐

‐20 °C ... +120 °C

(‐4 °F ... +248 °F)

‐1 ... 16 bar

(... 232 psi)

316L/1.4435, Viton, PPS

E, F

PTFE (TFM1600)

PVDF threaded

connection

‐40 °C ... +80 °C

(‐40 °F ... +176 °F)

‐1 ... 3 bar

(... 43.5 psi)

PVDF, PTFE

Metal threaded

connection

‐40 °C ... +150 °C

(‐40 °F ... +302 °F)

‐1 ... 40 bar

(... 580 psi)

316L/1.4435, PTFE

(TFM1600)

Flange clad

‐1 ... 16 bar

(... 232 psi)

PTFE (TFM1600)

Tri‐Clamp 2"

‐1 ... 16 bar

(... 232 psi)

316L/1.4435, PTFE

(TFM1600) *

Tri‐Clamp 3"

‐1 ... 10 bar

(... 145 psi)

Aseptic,

Dairy

‐1 ... 25 bar

(... 362 psi)

Flange unclad

H, J

PTFE antistatic

(TFM4220, 2%

conductive

additives)

Metal threaded

connection

‐40 °C ... +150 °C

(‐40 °F ... +302 °F)

‐1 ... 40 bar

(... 580 psi)

316L/1.4435, PTFE

(TFM4220)

‐1 ... 16 bar

(... 232 psi)

PTFE (TFM4220)

Flange unclad

Flange clad**

* FDA-listed material meets USP Class VI conformity

** on DN150, 6" ANSI, JIS 150A the disc is made of antistatic PTFE (=black)

80 Varec, Inc.

Radar Tank Gauge

Viscosity

7240 : 500 cst. (Max. Allowable)

Climate class

DIN EN 60068‐2‐38 (test Z/AD)

Electromagnetic compatibility (EMC)

Interference Emission to EN 61326, Electrical Equipment Class B.

Interference Immunity to EN 61326, Annex A (Industrial) and NAMUR Recommendation NE 21 (EMC)

A standard installation cable is sufficient if only the analogue signal is used. Use a screened cable when working with a superimposed communications signal (HART).

Vibration shock DIN EN 60068‐2‐64 / IEC 68‐2‐64: 20…2000 Hz, 1 (m/s2)2/Hz

This value can be reduced for Wave Guide antennas, depending on the length. In the event of horizontal stress, mechanical support is required or provide the Wave Guide antenna with a protective pipe.

Operating frequency

7230/7231: C‐band

7240/7245: K‐band

Up to 8 7200 Series Radar Tank Gauges transmitters can be installed in the same tank because the transmitter pulses are statistically coded.

External standards and guidelines

EN 60529 ‐ Protection class of housing (IP‐code)

EN 61010 ‐ Safety regulations for electrical devices for measurement, control, regulation and laboratory use.

EN 61326 ‐ Emissions (equipment class B), compatibility (appendix A – industrial area)

NAMUR ‐ Standards committee for measurement and control in the chemical industry

Overspill protection ‐ SIL 2, for 4...20 mA output signal

RF approvals ‐ R&TTE, FCC

Marine certificate ‐ GL (Germanisch Lloyd), ABS, NK

HART, PROFIBUS PA, not HT antenna

Factory Mutual ‐ IS Class I,II,III, Div 1 Groups A‐G T*

Class 1, Zone 0, AEx ia IIC T*

DIP Class II,III, Div 1 Groups E,F,G T*

NI Class I, Div 2 Groups A‐D T*

XP‐IS Class 1, Div. 1 Groups A‐D T*

XP Class 1, Zone 0, IIC T*

Antenna Class 1, Zone 0, AEx ia IIC T*

CSA ‐ ExnC IIC Class 1 Zone 2, Exd [ia] IIC Zone 1/0, Ex ia IIC Class 1 Zone 0

ATEX ‐ ATEX II 2 (1) G Resp. II 2 G, EEx ia IIC T6, EEx em [ia] IIC T6, EExd [ia] IIC T6

Product Dimensions

65

max.110

78

Influence of Ambient Temperature

85

max.94

104

Zero point (4 mA) ‐ average TK: 0,03 %/10 K, max. 0,45 % over the entire temperature range ‐40 °C...+80 °C

Span (20 mA)

Ø 129

Current output (additional error, in reference to the span of 16 mA)

F12 housing

(Aluminium)

7240 ‐ average TK: 2 mm/10 K, max. 5 mm over the entire temperature range ‐40 °C...+80 °C

7230 ‐ average TK: 3 mm/10 K, max. 10 mm over the entire temperature range ‐40 °C...+80 °C

7231 ‐ average TK: 5 mm/10 K, max. 15 mm over the entire temperature

range ‐40 °C...+80 °C

40

Digital output (HART, PROFIBUS PA, FOUNDATION Fieldbus)

150

‐40 °F and +176 °F (‐40 °C and +88 °C)

‐50 °C (‐58 °F) on request.

Sanitary compatibility

7231 with PTFE‐antenna made of FDA‐listed TFM 1600.

7245 with flange cladding made of FDA‐listed TFM 1600

3A/EHEDG approval with Tri‐clamp process connection

Ø 129

Storage Temperature

CE approval 150

‐40 °F and +185 °F (‐40 °C and +85 °C)

‐50 °C (‐58 °F) on request.

For calibration to regulatory standards: ‐25 °C ... +55 °C (‐30 °F…+140 °F)

With Tu<‐20 °C and Tu>+60 °C the operability of the LC‐display is reduced. A weather protection cover should be used for outdoor operation if the instrument is exposed to direct sunlight.

162

Ambient Temperature

Certifications & Approvals

Ø 129

Environmental

F23 housing

(316L)

max.100

65

94

78

T12 housing

(Aluminium)

85

F12, F23, & T12 Housing dimensions

Technical Information

81

7200 RTG

7230 RTG antenna dimensions

F12 / T12 / F23 housing

R = reference point of measurement

Group 30 / Code L

Ext. temperature version

Group 30 / Co d e M

High temperature version

Gr o u p 30 / Code H

Enamel antenna

Ø 60

277

346

Ø 60

b

b

b

114

86

Ø 70

114

Ø 70

C

L

L

R

Ød

Ød

ØD

ØD

ØA

ØB

Standard antenna

Antenna extension

Enamel antenna

b

b

86

86

Antenna size

A [mm]

B [mm]

C [mm]

R

212

222

268

272

3" Tri-Clamp

ISO 2852

Ø 78

86

L

L1

Ø 45

150mm/6” 200mm/8”

145

163

L

33

R

Ød

30

ØD

Ø 130

Ød

Antenna extension:

standard length

L1 = 100 mm / 200 mm /

300 mm / 400 mm

Note!

material proces connection = material horn antenna,

resp. wetted parts of the process connection

ØD

Flange to ANSI B 16.5

Horn antenna

Antenna size

316L

L [mm]

Alloy4C

80mm/3”

68

74

100mm/4” 150mm/6” 200mm/8” 250mm/10”

105

185

268

360

119

204

289

379

75

d [mm]

95

145

190

DN 150

22

DN 200

24

DN 250

26

D [mm]

DN 80

20 (24)

DN 100

20 (24)

200 (200) 220 (235)

285

340

405

for PN 16 (for PN 40)

6”

25.4

8”

28.4

10”

30.2

D [mm] 190.5 (209.5) 228.6 (254) 279.4

342.9

406.4

3”

23.9 (28.4)

4”

23.9 (31.8)

for 150 lbs (for 300 lbs)

Flange to JIS B 2220

Flange to EN 1092-1 (agreeable to DIN 2527)

Flange

b [mm]

240

Flange

b [mm]

Flange

b [mm]

D [mm]

DN 80 DN 100 DN 150 DN 200 DN 250

18

22

22

24

18

185

210

280

330

400

for 10K

7230 RTG process connection and type of antenna

82 Varec, Inc.

Radar Tank Gauge

7231 RTG antenna dimensions

F12 / T12 / F23 housing

DN 50 dairy coupling

DIN 11851

2”/3” Tri-Clamp

ISO 2852

b

a

a

DN 50 aseptic

DIN 11864-1 form A

with O-ring for tubes

according to DIN 11850

a

Flange DN 50…150

or equivalent

b

a

43

Threaded connection

1 ½” BSPT (R 1 ½”)

or 1 ½ NPT

a

R = reference point of measurement

23

R

ØD

4

Flange

cladded version

R

L2

L2

L2

Ø 25

Ø 33

390 / 540

390 / 540

360 / 510

PPS, antistatic

165

200 (200)

PTFE

(in conjunction with

DN50 aseptic/dairy coupling

respectively Tri-clamp

FDA-listed TFM 1600)

PTFE, antistatic

Flange to EN 1092-1 (agreeable to DIN 2527)

Flange

DN 50

DN 80

DN 100

DN 150

22

20

20 (24)

20

b [mm]

D [mm]

Ø 33

Inactive length, equivalent

to max. nozzle height

L2 = 100 mm / 250 mm

285

220

for PN 16 (for PN 40)

Flange to ANSI B 16.5

Flange

b [mm]

D [mm]

2”

19.1

3”

23.9 (28.4)

4”

6”

23.9 (31.8) 25.4

152.4 190.5 (209.5) 228.6 (254) 279.4

for 150 lbs (for 300 lbs)

Process

Flange

DN 50 aseptic DN 50 diary

2”/ 3”

connection DN 50…150

coupling

coupling Tri-Clamp

a [mm]

without gastight

feedthrough

a [mm]

with gastight

feedthrough

41

44.5

41

41

77

80.5

77

77

Flange to JIS B 2220

Flange

b [mm]

DN 50

16

DN 80

18

DN 100

18

DN 150

22

D [mm]

155

185

210

280

for 10K

Technical Information

83

7200 RTG

7240 RTG antenna dimensions

F12 / T12 / F23 housing

R = reference point of measurement

Screw-in adapter, compact

Flange plated

R 1½” or 1½” NPT

DN 50 ... 150

or equivalent

flange DN 50 ... 150

or equivalent

2” + 3”

Tri-Clamp

ISO 2852

b

5

b

61

61

64

SW55

5

L

L

L

2

3

R

Ød

Ød

Ød

ØD

ØD

ØA

Screw-in adapter

R 1½” or 1½” NPT

2” + 3”

Tri-Clamp

ISO 2852

flange DN 50 ... 150

or equivalent

b

64

61

SW55

R

L

L

5

5

L1

L1

With tube extension:

L1 = 100 mm

Ød

ØD

ØA

Ød

Horn antenna

Antenna size

40 mm / 1”

50 mm / 2”

80 mm / 3”

100 mm / 4”

L [ mm ]

86

115

211

282

d [ mm ]

40

48

75

95

Note!

material proces connection = material horn antenna,

resp. wetted parts of the process connection

Flange to JIS B 2220

Flange to EN 1092-1 (agreeable to DIN 2527)

Flange

DN 50

DN 80

DN 100

DN 150

Flange

DN 50

DN 80

DN 100

DN 150

b [ mm ]

18 (20)

20 (24)

20 (24)

22

b [ mm ]

16

18

18

22

285

D [ mm ]

155

185

210

280

D [ mm ]

165 (165)

200 (200)

220 (235)

for 10K

for PN 16 ( für PN 40 )

Flange to ANSI B 16.5

Tri - Clamp to ISO 2852

Flange

2”

3”

b [ mm ]

19.1 (22.4)

23.9 (28.4)

D [ mm ]

152.4 (165.1)

190.5 (209.5)

6”

Clamp

2”

3”

23.9 (31.8)

25.4

A

64

91

228.6 (254)

279.4

4”

for 150 lbs ( for 300 lbs )

7240 RTG process connection and type of antenna

84 Varec, Inc.

Radar Tank Gauge

7245 RTG antenna dimensions

F12 / T12 / F23 h ousing

R = reference point of measurement

Group 20 / Code B

Group 20 / Code C

Var. DN 50

Var. DN 80

flange DN 50

or equivalent

b

b

88

115

flange DN 80 ... 150

or equivalent

Ø48

ØA

4”

Tri - Clamp

ISO 2852

ØD

88

ØD

Ø 75

ØA

115

2” + 3”

Tri-Clamp

ISO 2852

28.6

13.8

4

4

R

2.6

2.6

13.8

R

28.6

Ø 48

ØA

Ø 75

ØA

plating from PTFE (FDA - listed TFM 1600, meets USP Class VI conformity):

3A/EHEDG approval with Tri-Clamp process connection

F lange to EN 1092-1 (agreeable to DIN

F lange

DN 50

b [ mm]

DN 80

F langes to ANSI B

2572)

DN 100

Tri-Clamp and dairy coupling

16.5

2”

3”

4”

6”

22

19.1

23.9

23.9

25.4

DN 150

20

20

20

D [ mm ]

165

200

220

285

152.4

190.5

228.6

279.4

A [ mm ]

102

138

158

212

92

127

158

212

for PN 16

Tri-clamp

A [ mm ]

dairy coupling

A [ mm ]

2”

3”

4”

64

9

119

DN 50

DN 80

68.5

100

for 150 lbs

7245 RTG process connection and type of antenna

Order Codes

Please consult your local sales representative for product options.

Technical Information

85

7200 Radar Tank Gauge

Varec, Inc., 5834 Peachtree Corners East, Peachtree Corners (Atlanta), GA 30092 USA

Tel: +1 (770) 447‐9202 | Toll Free: +1 (866) 698‐2732 | Fax: +1 (770) 662‐8939 | www.varec.com

2013 © Varec, Inc. All Rights Reserved. This document is for information purposes only. Varec, Inc. makes no warranties, express or implied, in this summary. The names of actual companies and products mentioned herein may be the trademarks of their respective owners.

Document Code: TEC027GVAE4013