GF Series – Complete Manual

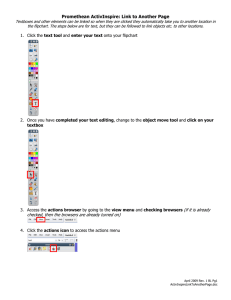

advertisement