SIMULATION AND IMPLEMENTATION OF BUCK CONVERTER

advertisement

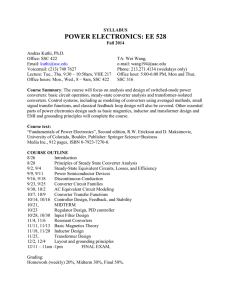

International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 SIMULATION AND IMPLEMENTATION OF BUCK CONVERTER WITH TAPPED INDUCTOR S.Veeramani #1, S.K.Subramanian #2, Mr.Nirmalraj M.E #1 Bachelor of Engineering, #2 Bachelor of Engineering #3 Assistant Professor Department of Electrical & Electronics Engineering, Sathyabama University,Chennai Tamil Nadu,India veera_om82@yahoo.co.in, subbu.race@gmail.com ABSTRACT Tapped-inductor buck converters allow great improvements in the performance of 12V-input voltage regulator modules (VRMs). A novel digital adaptive voltage positioning (digital AVP) technique with dual-voltage-loop was proposed. Good transient performance had been achieved without using complicated control. The stepping inductance method is implemented by replacing the conventional inductor in a buck converter by two inductors between in series. One has large inductance and the other has small inductance. The inductor with small inductance will take over the output inductor during transient load change and speed up dynamic response. Tapped-inductor buck converters can provide large step-down ratios at high efficiency and are well suited in support power supplies for modular multilevel converter cells supplying gate drive units etc. The output inductor of the conventional buck converter is replaced by a tapped inductor and an auxiliary switch to achieve fast transient response. Usually, the proposed converter works as a conservative buck converter with very large output inductance during the steady state to reduce the output current ripple. Once the transient load change appears, the auxiliary switch is turned ON in order to speed up the dynamic process by plummeting the equivalent output inductance.A10-V output voltage buck converter with maximum 30-A output current has been built and tested. The experimental results demonstrated the effectiveness of the proposed converter, which also means that the proposed arrangement shows great possible for fast fleeting comeback voltage regulator applications. Keywords: Buck converter, fast transient, tapped inductor, voltage regulator converters share the load current equally and INTRODUCTION stably. Parallel modules are usually Generally, the paralleling of power nonidentical due to finite tolerances in the converter modules offers a number of power stage and control parameters. If advantages over a single, high-power, special provisions are not made to distribute centralized power supply. Paralleling of the load current equally among paralleling standardized converter modules is an modules, then it is possible that one or more approach that is used widely in distributed units may have an excessive load current. power systems for both front-end and load This causes higher thermal stress on specific converters. A desirable characteristic of a units and reduces the system reliability. parallel supply system is that individual International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 Advance in electronic systems demand corresponding advances in power supply technology. Power supplies must be increasingly reliable and efficient, and power density requirements are increasing as well. In particular, advances in computer technology require increasing currents at lower voltages. Single high-current converters have problems such as heat dissipation, expensive high-power components and failure protection circuits. A better method of meeting these demands is to employ several individual converters that share the load requirements; hence, the topic of multiple module power supply (MMPS) systems is currently of great interest. Modular power systems have many desirable properties. First, the thermal design of high-current, low-voltage systems is simplified, since one may use multiple low-power converters in parallel to meet the total power requirements of a given system. Second, changes in power specification can be met with changes in the number of modules, rather than the design of a new converter. Third, MMPSs can be useful in high reliability systems. The redundancy possible with multiple converter modules provides greater system reliability, since an individual module failure does not mean a system failure. The repair of such systems is simplified since on-line replacement of faulty modules is possible. Also, since individual converters handle low-power levels, component stresses are low and converter life is lengthened. RELETED WORKS In [1] Zhihong Ye, Ray-Lee Lin and Fred C. Lee et al presents, Paralleling of standardized converter modules is an approach that is used widely in distributed power systems for both front-end and load converters. A desirable characteristic of a parallel supply system is that individual converters share the load current equally and stably. Parallel modules are usually nonidentical due to finite tolerances in the power stage and control parameters. If special provisions are not made to distribute the load current equally among paralleling modules, then it is possible that one or more units may have an excessive load current. In [2] Xunwei Zhou, PengXu, and Fred C. Lee et al presents, Voltage Regulator Module will need a large amount of extra decoupling and output filter capacitors to meet future requirements, which will basically make the existing VRM topologies impractical. As a candidate topology, the interleaved quasi square-wave VRM exhibits very good performance, such as a fast transient response and a very high power density. The difficulty with the application of the interleaved parallel technology is the current-sharing control. In this paper, a novel current-sensing and current-sharing technique is proposed. With this technique, current sharing can be controlled simply in parallel converters without a current transformer and currentsensing resistors. In [3] John S. Glaser, and Arthur F. Witulski et al presents, The origin of the dc current International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 sharing problem of parallel-converter systems and the dual problem of voltage sharing in series-converter systems. Both problems may be studied by examining the output plane (output current versus output voltage) of a particular converter. It is shown that strict current source behavior is unnecessary for good current sharing in parallel-converter systems. Furthermore, broad classes of converters whose output voltage is load-dependent, i.e., those that have a moderate value of output resistance, all exhibit good voltage- and current-sharing characteristics. Such converters are often suitable for ax b arrays of converters that can meet a large range of power-conversion requirements. In [5] Michael T. Zhang, Milan M. Jovanovi´c,,and Fred C. Y. Lee et al presents, Analysis, design, and evaluation of different interleaving techniques for the forward converter are presented. Specifically, the performance of the onechoke interleaving approach is compared with the two-choke interleaving approach. The results of the analysis are verified experimentally on two 5-V/20-A interleaved dc/dc converters. In addition to physically distributing the magnetics and their power losses and thermal stresses, paralleling also distributes power losses and thermal stresses of the semiconductors due to a smaller power processed through the individual paralleled power stages. In [4] Oun Lee, Shin-Young Cho, and GunWoo Moon et al presents, A new interleaved buck converter having low switching losses and improved step-down conversion ratio, which is suitable for the applications where the input voltage is high and the operating duty is below 50%. It is similar to the conventional IBC, but two active switches are connected in series and a coupling capacitor is employed in the power path, such as C´uk, Sepic, and Zeta converters. The proposed IBC shows that since the voltage stress across all the active switches is half of the input voltage before turn-on or after turn-off when the operating duty is below 50%, the capacitive discharging and switching losses can be reduced considerably. This allows the proposed IBC to have higher efficiency and operate with higher switching frequency. Interleaved multiple buck converters The interleaved multiple buck converters are very popular in high-current fast transient applications. The interleaved operation mode reduces the equivalent output inductor of the dc–dc converters; hence, it shows good dynamic performance during the transient state. However, some issues still remained such as the high conduction losses and stresses causing by the large peak current in each branch of the interleaved multiple converter. A buck converter with stepping inductance for fast transient response can be found. With two extra small MOSFETs and diodes added, the stepping inductor converter is very suitable for fast transient application. During the transient state, the stepping inductor circuit works to short circuit the output inductor by a hysteresis controller. However, the control International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 strategies are relatively complicated comparing with the one in the conventional buck converter. Buck converter with tapped converter A buck converter with stepping inductance for fast transient response can be found. With two extra small MOSFETs and diodes added, the stepping inductor converter is very suitable for fast transient application. During the transient state, the stepping inductor circuit works to short circuit the output inductor by a hysteresis controller. However, the control strategies are relatively complicated comparing with the one in the conventional buck converter. The voltage regulator buck converter with a tapped inductor for fast transient response applications is proposed in this letter. The extra auxiliary switch was added to change the equivalent output inductance. The proposed converter was able to perform not only fast transient response during the transient state but also low current ripple at the steady state. The prototype of a 300-W buck converter is built and tested to verify the effectiveness of the proposed adjustable inductor and the corresponding fast transient response. Inductor prototypes A first prototype was made with the high and low voltage windings distributed in two layers as shown in Fig Fig 3 Tapped inductor winding layout, first prototype. High-voltage winding (Np) in red and low-voltage winding (Ns) in blue It was anticipated that the leakage inductance would be low as the radial displacement of the windings was small. A second prototype was made with high and low voltage windings of equal axial length. Also, a first order interleaving was utilized to minimize the leakage inductance. The insulation between the layers is made from three layers of 65 μm polyimide film tape which can withstand the electric field stress and has excellent resistance to partial discharge degradation. The film tape extends approximately 4mm on each side of the winding layers to provide sufficient creep age distance. Inductor characterization and testing Figure 1 Buck Converter with Tapped Inductor The inductor magnetizing inductances and leakage inductances were measured at 10 kHz and 1V using a WK TMPO 4230 LCRmeter. The leakage inductance was measured by short circuiting one part of the International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 winding and measuring the inductance of the other part. Fig. 4. Tapped inductor winding layout, second prototype. High-voltage winding (Np) in red and low-voltage winding (Ns) in blue BLOCK DIAGRAM Input Supply Step Down Transformer Rectifier Voltage Regulator Microcontroller Filter Driver Circuit Tapped Inductor Load Auxiliary Switch Buck Converter Unit Conventional unit Fig 2 Block Diagram that the conversion has a very wide range of variation as compared with before. The intented application for the inductor is tapped-inductor buck converters with current injection which allows soft switching of the main switch. The current injection is achieved by allowing the current in the synchronous rectifier reverse and reaches a negative value before turning off. At turn-off of the synchronous rectifier the energy stored in the inductor will charge the stray and snubber capacitors of the main switch and, if sufficient energy is stored, drive the voltage over the main switch to zero, which allows a soft turn on. In cases with non-negligible leakage inductance the voltage over the synchronous rectifier can reach destructive levels. The energy stored in the leakage inductance must thus be absorbed by the synchronous switch stray and snubber capacitance to clamp the voltage. The inductors were tested in a boost-configuration circuit to evaluate the effect of the leakage inductance. For the switching test it is not necessary to use a high voltage supply, instead only an appropriately sized (150 pF) snubber capacitor was connected between the inductor high voltage lead and the negative supply rail as shown in Fig Tapped converter The tapped converter of the classical switched-mode power converter is an extension of the conventional switched mode power converters. Using the tapped configuration, the control parameter of the converter can be using tapping. It is found Fig 5 Tapped Inductor Circuit International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 Basic buck topology The basic topology consists of 4 components which are active switching devices, diode, inductor and output capacitor. The nomenclature of transistor-tapped is referred to the tapping of the inductor is connected to the active devices. Similar definition is used for the diode tapped and rail tapped. For electronic and industrial equipment requiring non−isolated, offline, low power outputs, the simple buck converter appears ideal; however, the large differential input−to−output voltage can be problematic in terms of very low converter duty cycle, peak−to−average switching current ratios, and overall conversion efficiency. This application presents a solution that will overcome many of these issues without additional electronic circuitry. The solution involves a modification to the buck inductor in which a tap is added to the winding and the buck freewheeling diode is connected to the tap. Tapped inductor buck converter topology The dynamic response of the dc–dc converters is also required to maintain the output voltage constant at the presence of variations or fluctuations in the load current. To characterize this feature, we should investigate the closed-loop transfer function from the load current to output voltage (also named output impedance). As the output impedance becomes smaller, the dc– dc converter resembles an ideal voltage source more closely. The output impedance starts with a very small magnitude at low frequencies and gradually increases until it approaches a constant value at high frequencies determined by the ESR of the output capacitor. A vital component in this converter is the tapped inductor itself. From circuit simulations and preliminary experiments it was found that the leakage inductance of the tapped inductor should be minimized in order to optimize the efficiency of the converter. As will be shown below, design of such an inductor is not trivial. It is the intention of this paper to describe the design process of such an inductor and to build and evaluate a first series of prototypes. Both the design process and the evaluation focus on the minimization of the leakage inductance, and it is experimentally verified that leakage inductances of the order of 0.8 percent are achievable. Tapped-inductor buck converter Fig 6 Tapped Inductor buck converter topology The tapped-inductor buck converter is one of the simplest topologies with an extended duty cycle. The biggest advantage of the tapped inductor buck converter over other International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 proposed topologies is the fact that it only involves a slight modification of the original buck converter. minimize the leakage inductance, in other cases extensive interleaving must be used to obtain low leakage. CONCLUSION REFERENCE A novel voltage regulator buck converter with a tapped inductor for fast transient response applications is proposed. Analysis, design, and performance evaluations of two interleaved forward converters with common output-filter inductor (one-choke approach) and separate output-filter inductors (two-choke approach) are presented. Several attempts were pursued earlier to model the self-oscillating converters, and being able to accurately capture only the low-frequency behavior without the effect of switching delay. It was shown that the system is of the second order, and the effect of switching delay in smallsignal sense is minimal justifying the use of rather simple models in predicting accurately the dynamics of the associated converter. [1] X. W. Zhou, P. Xu, and F. C. Lee, “A novel current-sharing control technique for low-voltage high-current voltage regulator module applications,” IEEE Trans. Power Electron., vol. 15, no. 6, pp. 1153–1162, Nov. 2000. With the tapped inductor and auxiliary switch, the proposed converter is able to achieve faster transient response comparing to the conventional buck converter. Meanwhile, the control circuit and method of the auxiliary switch are simple and low cost. The detailed simulated analysis and experimental results demonstrated the effectiveness of the proposed converter. It has been shown that such a tapped-inductor fast transient method is very suitable for all types of the dc–dc converter with basic LC output filter. If cost and size restrictions allow, a large core should be used in order to [2] R. Erickson and D. Maksimovic, Fundamentals of Power Electronics, 2nd ed. Norwell, MA, USA: Kluwer, 2001, pp. 42– 45. [3] S. Maniktala, Switching Power Supplies A to Z. Amsterdam, The Netherlands: Elsevier, 2006, pp. 51–54. [4] S. Luo, Z. Ye, R. L. Lin, and F. C. Lee, “A classification and evaluation of paralleling methods for power supply modules,” in Proc. IEEE Power Electron. Spec. Conf., Jul. 1999, vol. 2, pp. 901–908. [5] F. C. Lee, “Voltage regulator module for future generation of processors,” in Proc. 16th VPEC Power Electron. Sem., Blacksburg, VA, USA, Sep. 1998, pp. 1– 115. [6] X. W. Zhou, P. Xu, and F. C. Lee, “A novel current-sharing control technique for low-voltage high-current voltage regulator module applications,” IEEE Trans. Power Electron., vol. 15, no. 6, pp. 1153–1162, Nov. 2000. International Journal of Research Science and Engineering (ISSN: 2212 4012) Volume 4 –Issue.9, September 2015 [7] J. S. Glaser and A. F. Witulski, “Output plane analysis of load-sharing in multiplemodule converter systems,” IEEE Trans. Power Electron., vol. 9, no. 1, pp. 43–50, Jan. 1994. [8] I. O. Lee, S. Y. Cho, and G.W. Moon, “Interleaved buck converter having low switching losses and improved step-down conversion ratio,” IEEE Trans. Power Electron., vol. 27, no. 8, pp. 3664–3675, Aug. 2012. [9] M. T. Zhang, M. M. Jovanovic, and F. C. Lee, “Analysis and evaluation of interleaving techniques in forward converters,” IEEE Trans. Power Electron., vol. 13, no. 4, pp. 690–698, Jul. 1998. [10] A. Soto, P. Alou, and J. A. Cobos, “Design concepts and guidelines for VRMs from a power stage perspective,” in Proc. IEEE Power Electron. Spec. Conf., Jun. 2004, pp. 2218–2224. [11] B. Choi and D. Han, “Control of parallel-module boost converter with twostage output filter,” Electron. Lett., vol. 34, no. 24, pp. 2295–2296, 1998. [12] N. K. Poon, J. C. P. Liu, and M. H. Pong, “A low cost DC-DC stepping inductance voltage regulator with fast transient loading response,” in Proc. IEEE Appl. Power Electron. Conf., 2001, pp. 268– 272. [13] N. K. Poon, M. H. Pong, and C. P. Liu, “Stepping inductor for fast transient response of switching converter,” U.S. Patent 6 188 209, Feb. 13, 2001.