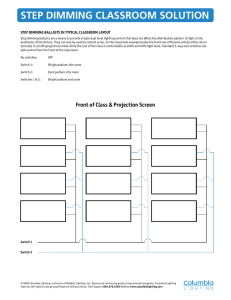

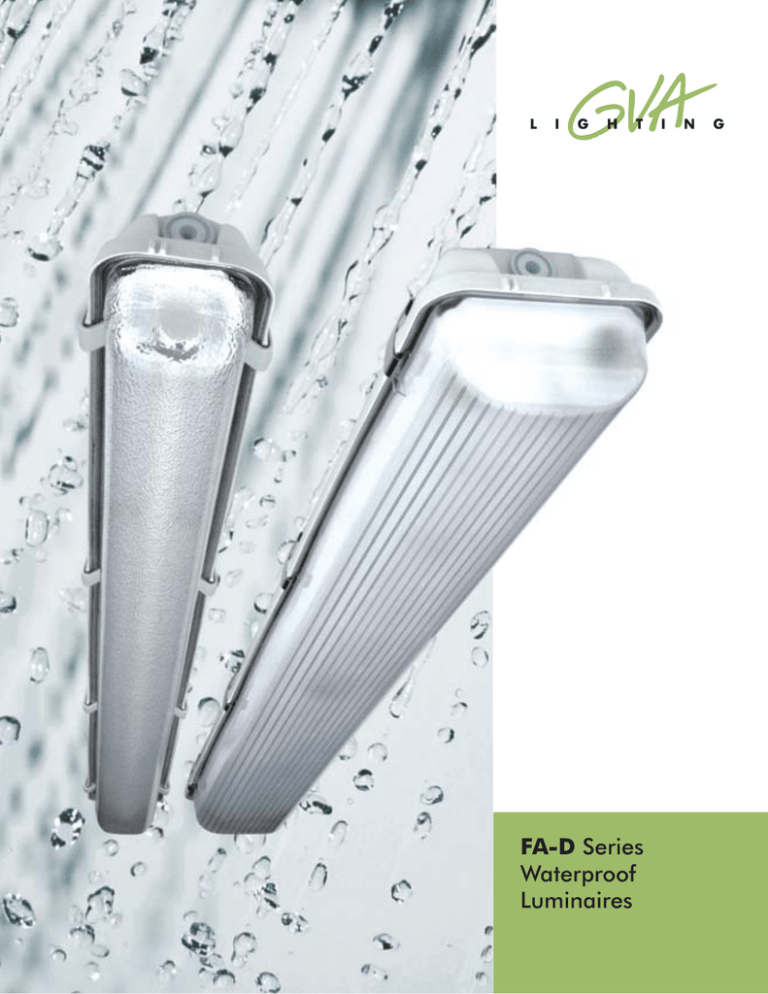

FA-D Series Waterproof Luminaires

advertisement

FA-D Series Waterproof Luminaires FA-D Series Waterproof Luminaires gvalighting.com File: 208502 IP65 IP66 Ip67 GRP Body FA-D is an IP65, IP66 and IP67 rated, dimensionally stable, lightweight fixture for use in damp or wet locations and for areas with high concentrations of dust, fumes and diluted acids. It is an energy efficient surface or suspension mount waterproof luminare for use with T8, T5 or T5HO lamps. Standard Features GRP (Glass Reinforced Polyester) body, corrosion-moisture-acid resistant IP65, IP66 and IP67 rated cCSAus certified for wet locations in Canada and the USA High performance Electronic Ballast, Instant Start, 120/277V, THD<10% Available in single, two or three T8, T5 or T5HO lamps Available in 2 ft, 4 ft and 5 ft lengths Diffuser available in PM (Pearled Acrylic), CA (Clear Acrylic) and PC (Polycarbonate) Non-ageing robot formed continuous polyurethane gasket Captive, highly resistant clips made of polyamide (PA) 6 clips per 2 ft, 8 clips per 4 ft and 10 clips per 5 ft fixture Snap-in 22 gauge steel reflector tray, painted high-reflective white after fabrication Highest quality lampholders (BJB) Quick disconnect for screwless power and ground connection Suitable for end to end installation without gaps Trouble-free installation and maintenance Rubber washers, end plugs and mounting screws supplied with the fixture Luminaire lenses are recyclable Optional Features Program Start electronic ballasts Cold Weather electronic ballasts (-30°C) Dimmable (digital or analog) electronic ballasts Emergency electronic ballasts Stainless Steel clips with optional Tamper Resistant Screws Specular aluminum reflector Suspension set Through Wiring Harness (3 or 5 conductors AWG 14) Master/Slave wiring option 220V-240V ballasts Diffusers PM lens is made of UV-resistant acrylic with a pearl structure. This thermoformed diffuser provides a highly translucent, durable lens that is resistant to weathering and aging and provides outstanding resistance to chemical influences. CA diffuser is also made of UV-resistant acrylic and available for 4 ft fixtures. PC lens is made of highly transparent UV stabilized polycarbonate with internal longitudinal prisms and an etched surface structure. This injectionmolded diffuser has outstanding impact resistance and dimensional stability. PM PC CA 1 PG FAD 21.11.11 Mechanical Drawing W H L D W H Dimensions Size Lamps L, mm (inch) W, mm (inch) H, mm (inch) D, mm (inch) Weight, kg (lb) 1 673 (26.49,,) 111 (4.37,,) 110 (4.33,,) 450 (17.72,,) 1.50 (3.30) 2/3 673 (26.49,,) 168 (6.69,,) 114 (4.49,,) 450 (17.72,,) 1.90 (4.18) 1 1283 (50.51,,) 111 (4.37,,) 110 (4.33,,) 660 (26.00,,) 2.40 (5.28) 2/3 1283 (50.51,,) 168 (6.69,,) 114 (4.49,,) 660 (26.00,,) 3.40 (7.48) 1 1583 (62.32,,) 111 (4.37,,) 110 (4.33,,) 900 (35.43,,) 2.50 (5.50) 2/3 1583 (62.32,,) 168 (6.69,,) 114 (4.49,,) 900 (35.43,,) 4.30 (9.46) 2’ 4’ 5’ FA-D fixtures are approved for protected outdoor installation. Normal ambient temperature range: -20 °C (0°F) to +25°C (77°F) Chemical Resistance No material is resistant to all chemical influences. Chemical resistance is an important consideration given the number of chemical environments in which this fixture may be used. Our chemical resistance table gives only a brief overview of some frequently occurring chemical influences. This table can be found on the following pages. The information in the table is applicable under the following conditions. The chemical substance listed in the table is a basic material and not part of a chemical compound. The ambient temperature is 22°C To be used as a guide only Chemical reactions will occur more or less rapidly and intensively at higher or lower temperatures depending on the type and composition of the substances involved. We will be happy to assist you, should you have any questions or concerns about the resistance of any materials. Specification Logic FAMILY DIFFUSER # OF LAMPS LAMP WATTAGE VOLTAGE BALLAST CLIPS OPTIONS FAD PC (Polycarbonate) PM (Pearled Acrylic) CA (Clear Acrylic)* 1 2 3 17 W T8 (2’) 32 W T8 (4’) 40 W T8 (5’) 120 277 120/277 347 IR (Instant Start, THD < 20%) IH (Instant Start, THD < 10%) PH (Program Start, THD < 10% PH-CW (Programmed Start Cold Weather, -30C, THD < 10% DDIM (Digital Dimming) ADIM (Analog Dimming 0-10V DC) SB (Specified Ballast) PL (Plastic) SS (Stainless Steel) EM (Emergency Ballast) ALR (Aluminum Reflector) TWH3 (Through Wiring Harness 3 conductors) TWH5 (Through Wiring Harness 5 conductors) TRS (Tamper Resistant Screws) 14 W T5 (2’) 28 W T5 (4’) 35 W T5 (5’) 24 W T5HO (2’) 54 W T5HO (4’) 80 W T5HO (5’)** * Note only available in four foot fixtures ** Note: only available in two lamp cross section Sample catalog number: FAD-PM-254-120/277-PH-SS 2 PG FAD 21.11.11 FA-D Series Waterproof Luminaires gvalighting.com Optional Features 3 PG FAD 21.11.11 1. Acrylic (PM), Clear Acrylic (CA) or Polycarbonate (PC) diffuser (interchangeable) 2. Glass Reinforced Polyester (GRP) body 3. Plastic clips (6 pcs for 2' units, 8 pcs for 4' units, 10 pcs for 5' units) 4. Snap lock for holding gear tray 5. Robot formed polyurethane gasket without joint 6. Alignment pins 7. Niches allow installing fixtures with waterproof fittings end to end without gaps 8. Through wiring harness (optional) 9. Cable holder for through wiring harness (optional) 10. Formed 22 gauge steel gear tray painted white 11. Quick disconnect 12. Wire support clips 13. Label with cCSAus logo 14. Electronic ballast 15. Mounting holes 16. Holes on each side for hanging gear tray for easy connection and maintenance 17. Grounding screw terminal for grounding continuity with Master/Slave installations 18. Lampholders 19. Tandem liquid-tight connector FAD (optional) 20. Stainless Steel clips (optional) 21. Mirrored aluminum reflector (optional) 22. Rubber plug for sealing unused opening (use CSA/ UL approved fittings for wiring) 23. Suspension set (two plastic hooks with rubber washers and screws) (optional) 24. Surface-mount installation of the body 25. Snap-in mounting kit (NEW) 4 PG FAD 21.11.11 MASTER-SLAVE Tandem Wiring of FA-D series fixtures gvalighting.com For illumination of large facilities the luminaires are often arranged in continuous rows. Master-Slave/Tandem wiring configurations can be used for long runs of FAD fixtures and remote ballast applications. Master-Slave Wiring is connecting the electrical power to one fixture (Master) and the ballast of that one fixture controls the lamps inside the Master and other nearby similar fixture (Slave). Unlike magnetic ballasts, electronic ballasts are limited in remote mounting distance from the lamp they operate. The factors limiting the distance from the electronic ballasts to the lamps are: open circuit voltage as opposed to operating voltage, operating frequency and the lamp operating current. Maximum distance between Master and Slave units is based on the general rule that Instant Start fixed light-output ballasts can be remoted up to 18’-20’ using 18 AWG wire. There are a wide range and varying types of electronic ballast architectures that are capable of being remote mounted for an equally wide range of distances. If you are uncertain of the remote mounting restrictions for a particular electronic ballast please consult the ballast manufacturer or our factory. Niches Centering Locks Liquid-tight fitting Bodies of FA-D fixtures have special niches for liquid-tight fittings. These avoid overlapping and allow placement of FA-D fixtures end to end. Tandem or Continuous Row wiring is when two (or more) fixtures are attached together and the primary electrical connection is made into the first fixture but then internally wired to subsequent fixtures in the row. The fixtures act as a raceway for the power (usually described as “through wiring”). FA-D housings are equipped with centering locks for easy row mounting and row alignment. GVA offers as an option, a through wiring harness to simplify and reduce the on-site wiring requirement. Tandem liquid-tight connectors can be supplied by GVA (optional). Mounting Dimensions of Tandem FA-D fixtures Center to Center spacing of mounting holes Within each fixture 2’ FAD - 17.72’’ (450 mm) 4’ FAD - 26’’ (660 mm) 5’ FAD - 35.43” (900mm) Fixture to fixture 2’ FAD - 9’’ (227 mm) 4’ FAD - 24-11/16’’ (627 mm) 5’ FAD - 27” (686 mm) Optional Through Wiring Harness 3 or 5 conductor with 5 wire clips. 14, 16 or 18ga. 5 Optional Tandem Liquid-Tight Connector PG FAD 21.11.11 IP CODE Enclosure Type Designation Enclosures serve the dual purpose of protecting personnel from incidental contact with the enclosed electrical equipment and protecting the enclosed equipment against specified environmental conditions. Enclosures are rated for use in specific environmental conditions by international and national standards organizations. The major international rating system uses the IEC Enclosure Classification Designation. The IEC Founded in 1906, the International Electrotechnical Commission (IEC) is the global organization that prepares and publishes international standards for all electrical, electronic and related technologies. The membership consists of more than 60 participating countries, including Canada and the USA. The central office of IEC is located in Geneva, Switzerland. IEC web site www.iec.ch International Standard IEC 60529 IEC International Standard 60529 “Degrees of protection provided by enclosures (IP Code)” describes a system for classifying the degree of protection by the IP Code. IP Code IP (International Protection) Code is a coding system to indicate the degree of protection provided by an enclosure against access to hazardous parts, ingress of solid foreign objects, ingress of water and to give additional information in connection with such protection. IP code is arranged in the following way: IP Code letters (International Protection) 7 6 First characteristic numeral (numerals 0 to 6, or letter X) Second characteristic numeral (numerals 0 to 8, or letter X) Elements of the IP Code and their meaning The second digit The protection against ingress of water with harmful effects The first digit The protection class against the penetration of firm foreign Objects and hazardous touch by persons The first digit Protection of equipment Protection of persons The second digit Protection of equipment 0 non-protected non-protected 0 non-protected 1 50 mm diameter back of hand 1 vertically dripping 2 12,5 diameter finger 2 dripping (150 tilted) 3 2,5 diameter tool 3 spraying 4 1,0 diameter wire 4 splashing 5 dust-protected wire 5 jetting 6 dust-tight wire 6 powerful jetting 7 temporary immersion 8 continuous immersion Example: an enclosure with IP 67 Code: Totally protects persons against access to hazardous parts (tested with a wire of 1.0 mm diameter) Dust-tight enclosure, totally protects the equipment inside the enclosure against dust ( tested by the talcum powder in suspension in a closed test chamber with underpressure) totally protects equipment inside the enclosure against water penetration ( tested by completely immersing the enclosure in water tank for 30 minutes 1 m deep) Waterproof enclosure, Note 1: The higher protection classification does not always takes precedence over the lower classification. For instance, IP67 rating does not mean that fixture is IP66 rated. Note 2: IP rating will ONLY apply for properly installed equipment! 6 PG FAD 21.11.11 CHEMICAL RESISTANCE gvalighting.com No material is resistant to all chemical influences. This is not really surprising because there are so many chemical influences. In fact, they fill whole volumes of resistance tables. Our chemical resistance table gives only a brief overview of some frequently occurring chemical influences. The information in the table applies subject to the following conditions. The chemical substance listed in the table is a basic material and not part of a chemical compound. The ambient temperature is 22°C To be used as a guide only Chemical reactions will occur more or less rapidly and intensively at higher or lower temperatures depending on the type and composition of the substances involved. We shall be happy to assist you if you have any questions or doubts about the resistance of any materials. Chemical Resistance PC (Polycarbonate) PMMA (Acrylic) Polyester Chemical Material Investigated Accumulator acid (Battery) Acetic acid up to 30% Acetic acid up to 5% Acetone Alcohol concentrated Alcohol up to 30% Alcoholic Drinks Aluminum Sulphate Ammonia 25% Ammonia 5% Aniline Arsenic acid 20% Beer Benzene Benzillic Alcohol Benzol Blood Bromine Calcium Chloride Calcium Nitrate Carbon dioxide Carbon monoxide Carbon tetrachloride Carbonic Acid Caustic Potash Caustic Soda solution 10% Caustic Soda solution 2% Cement Chloroform Chlorphenol Chromic Acid Citric Acid Common salt solution Cooper Sulfate Diesel oil, Crude oil Dioxane Ether (diethyl ether, ethyl ether) Ethyl Acetate Ethyl Alcohol Ethylene Chloride Food Oil and Fat Formic Acid 30% Gasoline Glycerine (Glycerol) Glycol (Ethylene Glycol) Glysantin ( BASF Engine Coolant) Hexane Hydrobromic acid (Hydrogen Bromide) Hydrocarbon Hydrocarbons Aliphatic 7 PG FAD 21.11.11 Chemical Resistance PC (Polycarbonate) PMMA (Acrylic) Polyester Chemical Material Investigated Hydrocarbons Aromatic Hydrochloric acid above 20% Hydrochloric acid up to 20% Hydrogen peroxide above 30% Hydrogen peroxide up to 30% Iodine Iron Chloride Isopropyl Alcohol Ketones Liquid Chlorine Vapours Lysol Manganese Sulphate Mercury Metal salts (Aqueous solution) Methanol (Methyl Alcohol, Wood Alcohol) Methlylene chloride Milk of lime (Calcium Hydrate) Mineral Oil Nitric acid above 20% Nitric acid up to 20% Nitric acid up to 10% Oxygen Ozone Perchloric Acid 10% Petrol Petrolium Petrolium ether Phenol (Carbonic Acid) Potasium Permanganate Potassium Nitrate Pottasium Bromide Pyridine Sea Climate Sea-water Silicone Acid Soap-suds Soda Sodium Chloride Sodium Hydrate Sodium Hydroxide Sodium Sulphate Sugar Sulphur Sulphuretted Hydrogen Sulphuric Acid above 70% Sulphuric Acid up to 70% Sulphuric Acid up to 50% Sulphuric Chloride Sulphurous Acid up to 5% Synthetic Detergents Toluene Trichloro-Ethylene Turpentine Water up to 60° C Xylene Zinc Sulphate - Resistant - Resistant Within Limits - Non Resistant 8 PG FAD 21.11.11 DIGITAL DIMMING Fluorescent Lighting System For Poultry gvalighting.com Proper lighting in poultry farming is a critical production factor. A good lighting schedule positively affects: feed consumption and digestion water consumption egg size, quality and production rate fertilization and hatchability eliminates pecking and cannibalism decreases mortality rate provides maximum energy savings boost farm profitability GVA Lighting has developed an innovative Digital Dimming Fluorescent Light System for the Poultry Industry consisting of: Digital Programmable Lighting Control Lux-D which automatically adjusts light duration and intensity during the bird's life cycle according to the pre-programmed lighting schedule. With ability to program up to 64 different daily lighting schedules and up to 99 groups of daily programs, Lux-D is very versatile and allows farmers to easily design a lighting program specific to their farm operation. FA-D series dust/water proof fixtures, designed to withstand harsh poultry environment. FA-D fixtures have digital electronic ballasts which create perfect light quality and save energy. Digital Photo Sensors for the daylight harvesting, allow users to reach energy savings up to 75%. The advantage of getting a complete lighting system (control+light fixtures+photo sensors) from one manufacturer, guarantees compatibility and reliability of the entire system. Control Lux-D features FA-D luminaire features Digital ballast features Programmable IP65, Continuous, automatic lighting operation to 16 intervals per daily program Up to 64 different daily lighting programs Up to 99 days per segment (group of days with the same daily program) Up to 99 segments per operating schedule crop Displays illumination values in % or lux One Lux-D controls 1 to 100+ ballasts 16-character, two line backlit LCD display Four-button keypad Real time clock (up to 10 years battery life) Power failure memory protection Supports up to 15 independent channels with Photo Sensors, which adjust the light output of the lamps dependent on changing ambient light levels in the barn Low input voltage 12-16VDC Quick wire connection terminals in separate compartment IP 65 enclosure guarantees protection of the electronic components from aggressive barn atmosphere Up IP66, IP67 protection against dust (Dust-tight) and water (Water-tight) Robotically formed gasket without joints Can be hosed down with pressure of up to 1200 psi Body (Glass Reinforced Polyester) and lens (Acrylic) are corrosion-moisture-acidammonia-hydrogen sulfide, carbon monoxide- and carbon dioxide resistant Light weight, dimensionally stable Extremely easy installation and maintenance Through-wiring harness with push-in terminal blocks for quick power and control wiring connections One or two lamp models Plastic (standard) or stainless steel clips Plastic suspension set (optional) GVA can supply 100 hrs burned in lamps (recommended for dimming application for long lamp life) Available in non-dimmamble version certified cCSAus (approved for both Canadian and U.S. markets) Perfect Light Quality DALI Digital Dimming Value (Intervals) DSI Typical Linear Dimming flicker free dimming from 1%100% Starts lamps at any dimming level without initial flash to higher level Eye sensitivity optimized logarithmic dimming curve Programmed Rapid Start High operating frequency 40-100 kHz Digital bi-directional Control-Ballast communication Polarity free control wiring (two wires) can be run in the same conduit as power wires DSI (Digital Serial Interface) or DALI (Digital Addressable Lighting Interface) Digital On/Off (no relays needed) Universal input voltage 120V/277V AC, including 220 and 240VAC, 50/60 Hz Available for one or two 32W T8, 36W T8, 28W T5 or 54W T5HO lamps End-of-lamp-life protection and inrush current limiting circuitry THD < 10% Ballast factor - 1.0 Standby mode Ultra-quiet operation Minimum starting temperature 0°F/-18°C Minimum dimming temperature 50°F/10°C 3 year warranty Bird and human eyes are extremely sensitive to light level changes between 0% and 10%. Irregular or sudden change is a distraction and is clearly visible to the eye. Digital ballasts used in FA-D fixtures have a logarithmic dimming curve, specifically developed to match the eye sensitivity. Digital ballasts assign almost 70% (up to 175 intervals from 256 available) of the dimming range to the first 10% of the light. It allows for very smooth, gentle, flicker-free continuous dimming at low light levels compared to traditional linear dimming. Relative lighting level (%) 9 PG FAD 21.11.11 Daylight Harvesting Lighting System The idea is clear: the sun provides free light that can be used to reduce your energy consumption. Photo sensors monitor the ambient light levels and send a command to the digital dimming ballasts to reduce lamp light output proportional to the amount of daylight that enters the barn. The more usable daylight entering the space, the more the electric lights can be dimmed, resulting in significant energy savings—as much as 75% of the connected lighting load to the space. The addition of daylight control with photo sensors is a key factor in achieving such high energy savings. Large barns that have sufficient daylight are the most cost-effective areas for daylight harvesting. GVA’s Digital Ambient Light Photo Sensor PR 734 is the industry’s first light sensor that reads the light intensity directly in Lux. It manages the digital ballasts of it’s channel according to the lighting schedule preprogrammed in LUX-D. 1 PM: there is enough daylight to sufficiently light the barn - photo sensors turned the lights off. 5 PM: dusking - photo sensors turned two rows of the lights on at minimum level. The left side of the barn is still receiving enough light from the windows photo sensor of the third row is keeping the lights off. 8 PM: no light from outside - all three rows of the lights are on and photo sensors adjust the light output according to preprogrammed lighting schedule. GVA Lighting is recognized and honoured by the Canadian Society for Bioengineering with the 2009 Industrial Award. The award is presented for the significant contribution which GVA’s daylight harvesting lighting system has made to the agriculture industry. 10 PG FAD 21.11.11 CREATING NEW BEAUTY FOR OUR HOME PLANET™ Copyright GVA Lighting, Inc. 2009