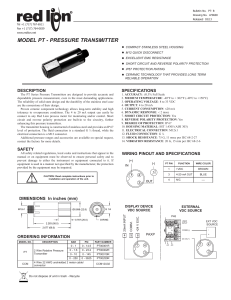

Pressure Transmitters and Transducers - Esi

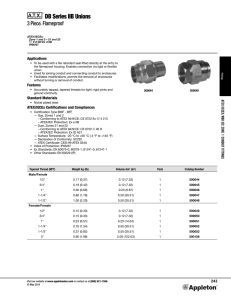

advertisement