Measurement Solutions Product Guide

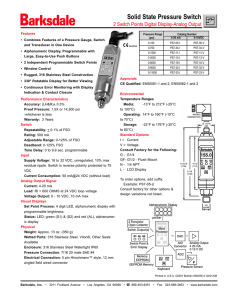

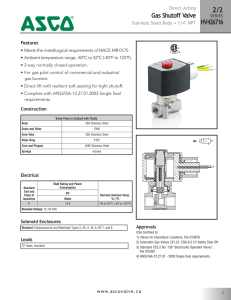

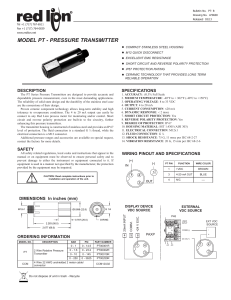

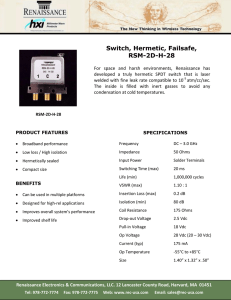

advertisement