H-106_MARKING OF PIPE MATERIAL

advertisement

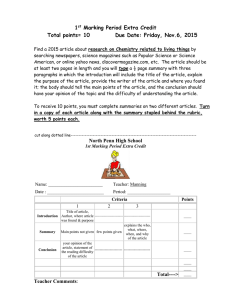

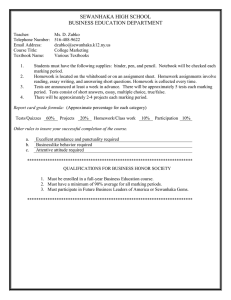

< Security Level 2 > Sheet 1 of 19 CONSTRUCTION SPECIFICATION MARKING OF PIPING MATERIALS FOR NITROGEN PACKAGE FOR HINDUSTAN PETROLEUM CORPORATION LTD. VISAKH REFINERY DHT PROJECT TEIL JOB NO. : 6261 DOCUMENT NO.: H-106 A 16.04.09 For Bid Enquiry Rev. no. Issue Date Description UCM PRK Prepared by Checked by Approved by TOYO ENGINEERING INDIA LIMITED MUMBAI SSV INDIA < Security Level 2 > Sheet 2 of 19 Revision History Rev. Date A 16.04.2009 Description For Bid Enquiry < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 3 of 19 CONTENTS PAGE 1. GENERAL 1.1 Intent 1.2 Scope 1.3 Specific Job Requirements 2. MARKING GENERAL 2.1 Marking of Items 2.2 Material Discrimination Color 3. 7 8 VALVES 5.1 Marking of Valves 5.2 Marking Items and Marking Location 6. 5 5 6 FITTINGS 4.1 Marking of Pipe Fittings 4.2 Material Discrimination Color 5. 4 4 PIPES 3.1 Marking of Pipes 3.2 Marking Location 3.3 Material Discrimination Color 4. 4 4 4 10 11 FLANGES (Including Spacers/Spades, 8-Fig Flanges and Stub Ends) 6.1 Marking of Flanges, Spacers/Spades, 8-Fig Flanges and Stub Ends 13 6.2 Marking Location 14 6.3 Material Discrimination Color 14 7. BOLTS AND NUTS 7.1 Marking of Bolts and Nuts 7.2 Material Discrimination Color 8. 15 15 GASKETS 8.1 Marking of Gaskets 8.2 Marking Location 16 16 Table 1 Table 2 18 18 Table 3 Discrimination Colors for Piping Materials Identification Marks and Discrimination Colors for Casting and Forging Materials Identification Marks and Discrimination Colors for Materials of Bolts and Nuts 19 < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 1. GENERAL 1.1 Intent JOB NO. : 6261 DHT PROJECT Sheet 4 of 19 This specification covers the procedure of markings for the identification of piping materials which shall be included in the Nitrogen Package for Diesel Hydrotreater Project (DHT) at M/s. Hindustan Petroleum Corporation Limited (HPCL) Visakh Andhra Pradesh, India has appointed Toyo Engineering India Ltd as “Project Management Consultant “(PMC). 1.2 Scope This specification shall be applied to piping materials such as pipes, fittings, valves, flanges, gaskets, bolts and nuts. 1.3 Specific Job Requirements Specific Job Requirements shall be attached to this specification, if applicable. 2. MARKING GENERAL 2.1 Marking of Items 2.1.1 Marking shall generally be accomplished by either one or a combination of casting-out, forging-out, punching, stenciling, tagging, labeling, and taping. 2.1.2 Punching depth shall not exceed 1 mm. 2.1.3 Stenciling color shall be black, however for piping components whose surfaces are black or dark, it shall be white. 2.1.4 Paint or ink for marking shall not contain any harmful metal or metal salts which can cause corrosive attack either ordinarily or in service. 2.1.5 Special items/smaller items shall have attached corrosion resistant tag providing salient features. 2.1.6 Color coding on broad material basis. 2.2 Material Discrimination Color 2.2.1 Basic colors to be used for material discrimination shall be as indicated below: Color Name Munsell Notation Color Name Munsell Notation White N 9.5 Yellow 2.5Y 8/12 Black` N 1.0 Light green 7.5GY 7/4.5 Silver - Green 5G 5.5/6 < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 5 of 19 Pink 5R 7/5 Sky blue 10B 6/7 Red 5R 4/13 Blue 2.5PB 5/6 Orange 2.5YR 6/13 Purple 2.5RP 4.5/12 Brown 7.5YR 5/6 2.2.2 Brands of paint used for material discrimination shall be selected by manufacturer of piping materials. For stainless steels, paints containing materials which adversely affect the quality of the steel shall not be used. 2.2.3 Discrimination color shall be painted in one line, and in case of two discrimination colors, in parallel two lines. 3. PIPES 3.1 Marking of Pipes The following items or the like shall be indicated on all pipes. Marking shall normally be accomplished by stenciling and/or punching, in the following order. (1) Manufacturer's name or trade mark (2) Codes or standards (ASTM, API, IS ... etc.) (3) Material specification (4) Manufacturing method (5) Date of manufacture (1) (6) Dimension (2) (7) Manufacturing No. or mark (charge No. or lot No.) (8) Heat No. (9) Test Pressure Notes : (1) For lined pipes, the date of lining work shall also be indicated. (2) Dimensions shall be indicated in "Nominal size x Schedule No. x Length". When nominal sizes and schedules No. cannot be applied, actual outside or inside diameter and wall thickness in millimeter may be indicated. Nominal Pipe Size (NPS) shall be in accordance with inch system. 3.2 Marking Location < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 6 of 19 3.2.1 For pipes of Nominal Pipe Size (NPS) 1 1/2 and under, a stiff tag on which all items in Par. 3.1 are indicated, shall be attached to each bundle of pipes. However, material specification shall be marked on the outer surface of individual pipe. 3.2.2 For pipes of NPS 2 and over, all items in Par. 3.1 shall be marked on the outer surface of each pipe. 3.2.3 For pipes of NPS 16 and over, all items in Par. 3.1 shall be marked on the inner surface of one end of each pipe. However, for seamless pipes, marking shall be made on the outer surface. 3.2.4 For coated pipes of NPS 3 and under, all items indicated in Par. 3.1 shall be marked on the outer surface of each pipe. 3.2.5 For coated pipes of NPS 4 and over, all items in Par. 3.1 shall be marked on the inner surface of one end of each pipe. Any item which cannot be marked on the inner surface, shall be indicated on a tag, which shall be attached to the pipe. 3.3 Material Discrimination Color 3.3.1 Discrimination colors indicated in Table 1 shall be painted on the outer surface of all pipes, except for coated pipes and galvanized pipes. 3.3.2 Discrimination color shall be painted all through the longitudinal length of pipe. 3.3.3 Painting shall generally be as shown in Fig. 1.2. For NPS 1.1/2 and smaller, pipes may be painted as shown in Fig.1.1 at the mill, and such pipes shall be painted through the longitudinal length after being receipt at site as specified in Fig.1.2. (a) One color Discrimination color NPS 1 and under NPS 1 1/2 2 mm or over 3 mm or over (b) Two colors 3 mm Discrimination color Same as in case of one color. Fig.1.1 Painting of Discrimination Color (NPS 11/2 and smaller only) < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 7 of 19 (a) One color Discrimination color NPS 1 and under NPS 1 1/4 - 2 1/2 NPS 3 and over 15 mm or over 15 mm or over 25 mm or over (b) Two colors Discrimination color NPS 1 and under NPS 1 1/4 - 2 1/2 NPS 3 and over 15 mm or over 15 mm or over 25 mm or over Same as in case of one color Fig.1.2 Painting of Discrimination Color 4. FITTINGS 4.1 Marking of Pipe Fittings The following items shall be indicated on all fittings. Marking for pipe fittings shall generally be accomplished by stenciling and/or punching, or labeling. Butt (7) Socket (8) Welding Welding No. Items 1 Manufacturer's name or trade mark 2 Material Specification & Dimensional Std. (1) (5) 3 Nominal size (2) (4) 4 Schedule No. (2) 5 Pressure Class 6 Manufacturing No. or mark (3) (Charge No. or lot No.) Screwed Type (9) (Malleable Iron Casting) (6) For fittings of the type other than those indicated above, marking shall be made in the same manner as shown for the similar type among the three. Notes : (1) Discrimination/Identification marks in Table 1 or Table 2 may be used as material specification. < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 8 of 19 Austenitic stainless steel socket and fittings need carry only grade identification symbol. (2) When nominal sizes and schedule No. cannot be applied, actual outside or inside diameter, and wall thickness in millimeter may be indicated. Nominal sizes shall conform to inch system (NPS). (3) Manufacturing No. or Mark may be omitted for materials of group 1A in Table 1, and of group 10 in Table 2. (4) In case of elbows, symbols indicating long radius or short radius type shall be included. (5) ASTM specification A234, A403 and A420 shall use marking symbols consisting of the prefix “WP” added to the ASTM specified grade identification symbol. (6) Symbols indicating straight type or reducing type, shall be included. (7) For small fittings on which all marking items cannot be fully indicated, the following items, in whole or a part, may be omitted in the following order. (8) (9) (a) Symbols indicating long radius or short radius type. (b) Nominal sizes (c) Schedule No. For small fittings on which all marking items cannot be fully indicated, the following items may be omitted in the following order. (a) Symbols indicating straight type or reducing type. (b) Nominal sizes (c) Schedule No. Where marking items cannot be fully indicated, marking for each fitting may be omitted, but, in this case, a stiff tag on which all items are indicated shall be attached to each package of fittings. 4.2 Material Discrimination Color 4.2.1 Material Discrimination Colors in Table 1 and Table 2 shall be painted on the outer surface of each fitting. 4.2.2 Discrimination color paint shall be accomplished as indicated in Fig. 2. < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 9 of 19 B A Dimension A NPS 1 and under NPS 1 1/4 - 2 1/2 NPS 3 and over 2 mm or over 3 mm or over 5 mm or over Dimension B NPS 1 and under NPS 1 1/4 - 2 1/2 NPS 3 and over 2 mm or over 3 mm or over 4 mm or over Fig. 2 Painting of Discrimination Color < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 5. VALVES 5.1 Marking of Valves JOB NO. : 6261 DHT PROJECT Sheet 10 of 19 5.1.1 All items indicated in Par. 5.2 shall be marked on all valves. 5.1.2 Marking of valves shall be made on valve body, hand wheel, name plate and bolt & nut. 5.1.3 Marking on valve body shall be made on body or bonnet by casting-out, forging-out or punching. 5.1.4 Marking on hand wheel shall be made by casting-out, forging-out or punching. When marking items cannot be fully indicated on handwheels, marking may be made adequately by alternative method. 5.1.5 Name plates which shall be generally attached on the upper side of handwheels, shall have marking by etching, press or punching. 5.1.6 Marking on bolt & nut shall be made on the end face (bolt), or on the upper or side face (nut) by punching. 5.1.7 For small or special valves on which marking items can not be fully indicated on the body, markings may be omitted with Purchaser’s approval in the following order: a) Nominal size b) Thread Identification c) Melt Identification d) Rating Identification e) Material Identification f) Valve Trim Identification Vendor shall inform the item to purchaser in case vendor wishes to omit markings because of small space. 5.1.8 The identification plate of valves (with stem extension) which will be insulated at site, shall be, if possible, fixed in a place located out of the insulated surfaces. This plate in stainless steel shall be fixed securely on the valve. The fasteners used for fixing shall resist to marine corrosion. < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 5.1.9 JOB NO. : 6261 DHT PROJECT Sheet 11 of 19 For cryogenic valves : in order to ensure that the valve is mounted to the correct side of the line pipe, the word “vent” must be stamped, at the same side of the cavity relief device, on the corresponding flange or BW end. 5.1.10 Valve no. shall be specified on the valve name plate. 5.1.11 Valve name plate shall be attached on the valve body or on the top of handwheel. Attaching the name plate to handwheel by wire or clip is not acceptable. 5.2 Marking Items and Marking Location Body (Forged) Hand- (1) Bonnet By By By By wheel Name Bolt/ Others Cast- Punchi Forg- Punchi Plate Nut ing-out ng ing-out ng Body (Cast) No. Marking Items 1 Manufacturer's O name or trade mark 2 Class 3 4 (6) O O O Nominal size O O Material specification (2) valve body O O flow O O of (3) O (3) O (3) O (3) O 5 Arrow of (7) direction 6 Melt No. 7 Material of trim O 8 Manufacturing No. O 9 Date manufacture O 10 Letters Symbols Arrowhead indicate “OPEN” (8) “SHUT” O(11) O (3) O(11) (4) (4) of or and to and O O < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 12 of 19 of 11 Material bonnet bolt and nut 12 Certificate inspection 13 Valve No. (9) (10) O of O (5) O Notes : (1) Marking on name plate is not necessary when the valve body and bonnet are made of gray cast iron, cast bronze or brass, black heart malleable cast iron, spheroidal graphite cast iron or carbon steel (excluding those for low temperature service). Marking of trim material shall be made on name plates, except for the following cases; (a) When valve body is of gray cast iron, black heart malleable, or spheroidal graphite cast iron and trim is of bronze, brass or 13Cr steel. (b) When valve body is of carbon steel (excluding those for low temperature service) and trim is of 13Cr Steel. (c) Plug valves whose body and plug are of the same material. (2) When the body material differs from the bonnet material, marking shall be individually made on each of them. If the body material is the same as bonnet, marking may be made on either one of them. In this case, material identification mark shall be in accordance with Table 2. (3) Except for Item 1 wherein approval is required, punching may be substituted for forging-out if forging-out is impossible. (4) Manufacturing number indicating the product history shall be marked on all cast and forged steel valves. These may be omitted, however, for carbon steel valves (excluding those for low temperature service, cast steel valves of class 600 or above, or forged steel valves of class 900 or above). Date of manufacture may be marked instead of the manufacturing number. (5) Each valve shall be accompanied by a test label or a quality guarantee letter indicating that the valve has been carefully made under the control of the manufacturer and that its quality is guaranteed. Instead of this, punch marking may be used for this purpose. (6) Class (Rating) shall generally be indicated by using the following abbreviations. < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Class (Rating) Class 150 Class 300 Class 600 Class 800 Class 900 Class 1500 Sheet 13 of 19 Abbreviations 150 300 600 800 900 1500 (7) Arrow of flow direction shall be indicated, only when required by the valve structure. (8) This item may be marked on valve body for butterfly valve. (9) Valve number shall be as indicated in the data sheet. Marking shall be made as large as possible, on the outer surface of valve body. (10) This is not applicable for valve without bonnet such as check valve. (11) Melt No. by punching is acceptable if it is not possible by casting out. Remark : Items desired by the manufacturer may be marked at the manufacture's discretion, such as symbols for special specification, catalogue number, type number and patent number. 6. FLANGES (Including Spacers/Blanks, 8-Fig Flanges, and Stub Ends) 6.1 Marking of Flanges , Spacers/Blanks, 8-Fig Flanges and Stub Ends, The following items shall be punched on the outer surface (rim) of flanges and stub ends. Items which cannot be indicated on the outer surface of stub end, may be marked on the outer surface of pipe by stenciling or painting. (1) (1) Nominal size (2) Schedule No. (1) (when required) (3) Rating (2) (4) Material specification and Applicable Std. (3) (5) Manufacturer's name or trade mark (6) Ring Groove No.(4) (7) Temperature (8) Charge No. and lot No. Notes : < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 6.2 JOB NO. : 6261 DHT PROJECT Sheet 14 of 19 (1) When nominal sizes and schedule no. cannot be applied, actual outside or inside diameter and wall thickness of pipes to which flanges will be provided, may be indicated in millimeter. (2) Refer to Note (6) in Par. 5.2. (3) Material specifications may be in accordance with Table 1 and Table 2. (4) Ring groove no. shall be applied to ring joint flange, and shall be marked with the letter “R” at the edge (periphery) of ring joint flange. Marking Location Marking location shall generally be as indicated in Fig. 3. 6.3 Material Discrimination Color 6.3.1 Material discrimination colors in Table 1 and Table 2 shall be painted on the outer surface of flanges, spacers/blanks, 8-Fig Flanges, and stub ends. 6.3.2 Discrimination colors shall be painted on the outer surface of flanges and stub ends, but not on the punched portion. Painting shall generally be accomplished as indicated in Fig. 3. Flange Discrimination color Punching location < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 15 of 19 Stub End Discrimination color Marking location for items which cannot be indicated on the punching location Punching location Remark : Dimensions for painting of discrimination color shall be in accordance with Par. 3.3.3. Fig. 3 Punching and Painting Locations of Flanges, Spacers/Blanks, 8-Fig. Flanges, and Stub Ends 7. BOLTS AND NUTS 7.1 Marking of Bolts and Nuts Material identification marks shown in Table 3 shall be punched on bolts and nuts separately. Marking location shall be as indicated in Fig. 4. 7.2 Material Discrimination Color Material discrimination colors shown in Table 3 which indicate the combinations of bolt and nut materials, shall be painted on bolts and nuts. < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 16 of 19 Machine Bolt Identification mark Discrimination color Discrimination color Stub Bolt Identification mark Discrimination color Discrimination color Fig. 4 Marking Location of Bolts and Nuts 8. GASKETS 8.1 Marking of Gaskets The following items shall be indicated on gaskets. Marking shall generally be made by one or combination of punching, stenciling, tags or tapes. (1) Manufacturer's name or trade mark (2) Product's name (Manufacturing No. and material) (3) TS No. (4) Dimension (Nominal size and ring No.) (5) Code (rating)* Note : * Ratings shall be as indicated in Note (6) in Par. 5.2. 8.2 Marking Location 8.2.1 For asbestos sheet gaskets and non-asbestos gaskets, a stiff tag on which all items specified in Par.8.1 are indicated shall be attached to each package. < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 17 of 19 8.2.2 For spiral wound gaskets of basic type and those with inner ring, tags or tapes on which all items specified in Par.8.1 are indicated shall be attached. 8.2.3 For spiral wound gaskets with outer guide ring, and those with outer guide ring and inner ring, all items specified in Par.8.1 shall be indicated on surface of outer guide ring by punching or stenciling. 8.2.4 For ring joint gaskets, all items specified in Par.8.1 shall be marked on the circumference of ring by punching. A tag on which all items specified in Par.8.1 are indicated shall also be attached. 8.2.5 For other types of gaskets, all items specified in Par.8.1 shall be adequately indicated with the above methods. < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 18 of 19 Table 1 Identification Marks and Discrimination Colors for Piping Materials Grou Material p Discrimination 1A - - - A53 Gr.B – Galv. - API5LGr.B SAW A283Gr.C Blue API5LGr.B ERW Pink API5LGr.B SMLS Orange - Silver A312Gr.TP304 SMLS Orange A312Gr.TP304 WELD Carbon Steel 1C 4 18Cr-8Ni Equivalent ASTM Material(1) REMARK S Color A358 CL.1 A234Gr.WP B A240 304 TYPE A403Gr.WP 304 TP304 Notes: (1) To be equivalent does not mean to be identical, but to be similar. Table 2 Identification Marks and Discrimination Colors for Forging and Casting Materials Grou Material p Forging ASTM Material 10 Bronze 1 Carbon Steel 4A 18Cr-12Ni- A182 Mo Gr.F316 Casting Identifica ASTM tion Mark Material Identific Discriminati Remark a-tion on Color s Mark BRZ A105 Yellow A105 A216Gr.W WCB CB - F316 A351Gr.CF CF8M 8M Brown < Security Level 2 > MARKING OF PIPING MATERIALS TOYO ENGINEERING INDIA LTD. HPCL, Visakh ISSUED : 29.12.2008 DOC.No. H - 106 JOB NO. : 6261 DHT PROJECT Sheet 19 of 19 18Cr-8Ni A182Gr.F30 F304 4 A351Gr.CF CF8 8 Orange 18Cr-8NiMo L A182Gr.F31 F316L 6L A351Gr.CF CF3M 3M White Table 3 - Identification Marks and Discrimination Colors for Materials of Bolts and Nuts Material and Combination Identification Mark Bolt Discriminatio n Color Bolt Nut Nut A193 Gr.B7 A194 Gr.2H B7 2H - A193 Gr.B7 – Cadmium plated A194 Gr.2H B7 2H - A320 Gr.B8M(CL.2) A194 Gr.8A B8M 8A Orange