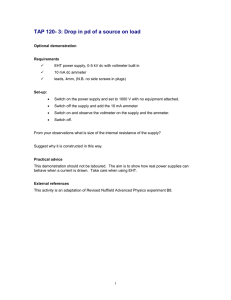

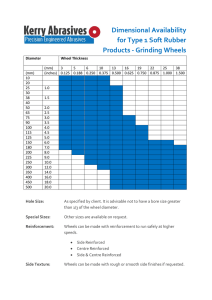

Grinding and Cut-Off Wheels

advertisement