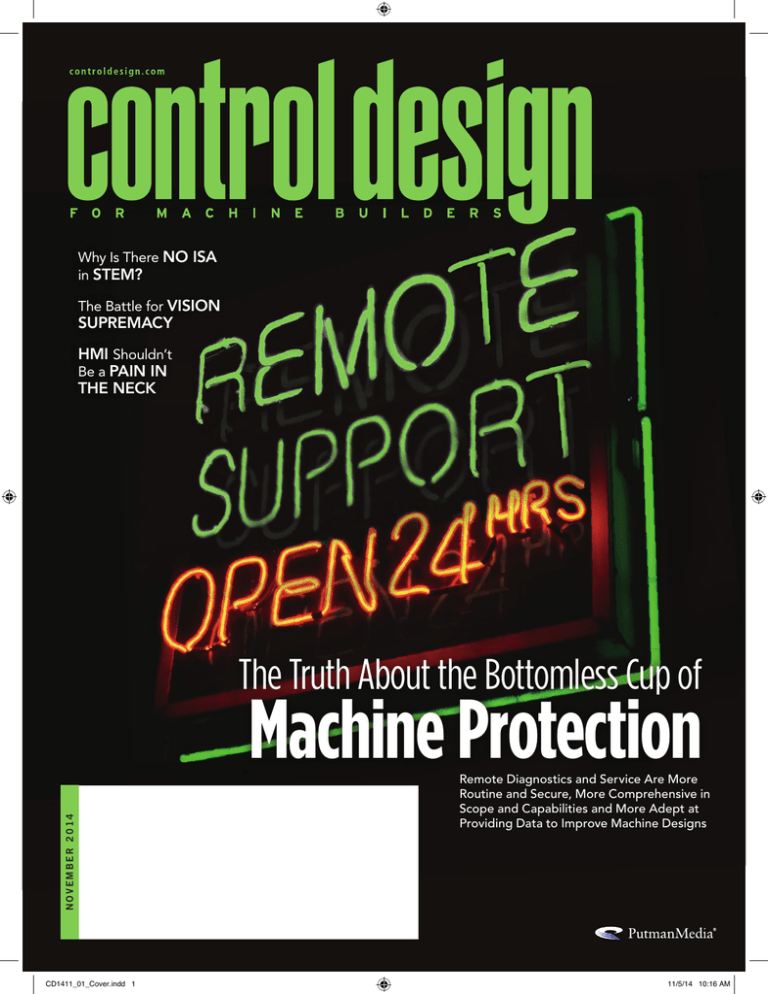

Why Is There NO ISA

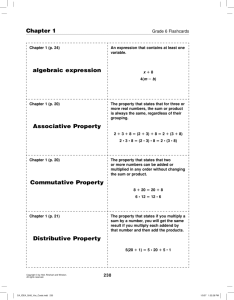

in STEM?

The Battle for VISION

SUPREMACY

HMI Shouldn’t

Be a PAIN IN

THE NECK

The Truth About the Bottomless Cup of

NOVEMBER 2014

Machine Protection

CD1411_01_Cover.indd 1

Remote Diagnostics and Service Are More

Routine and Secure, More Comprehensive in

Scope and Capabilities and More Adept at

Providing Data to Improve Machine Designs

11/5/14 10:16 AM

CD1411_FPA.indd 2

11/4/14 10:53 AM

Missed your connection again?

Support your customers—from anywhere—with the

free mGuard Secure Cloud service from Phoenix Contact.

Tired of hopping on a plane every time

your customers need support? Connect

to industrial equipment from anywhere

in the world with mGuard Secure Cloud:

fast, secure and reliable. With this

next-generation Tech-to-Machine (T2M)

connectivity, you can support from the

office, your home or wherever you are

all at no cost.

• Utilize widely accepted, highly secure

IPsec Virtual Private Network (VPN).

• mGuard hardware and software

configuration is provided via web,

email or SD card.

• In just a few clicks, resolve complex

problems, update programs and

commission new equipment with ease.

To learn more about mGuard Secure

Cloud, call 1-800-322-3225 or visit

www.phoenixcontact.com/msc

© 2014 PHOENIX CONTACT

14-1689_mGuardSecureCloud7.875x10.5_m.indd

1

CD1411_FPA.indd 3

10/10/2014

11/4/14 1:54:57

10:53PM

AM

CD1411_FPA.indd 4

11/4/14 10:53 AM

CONTENTS

Volume 18, No. 11

FEATURES

26

37

43

COVER STORY

The Truth About the Bottomless Cup

of Machine Protection

Remote Diagnostics and Service Are More Routine and

Secure, More Comprehensive in Scope and Capabilities and

More Adept at Providing Data to Improve Machine Designs

Jim Montague, executive editor

DRIVES & MOTION CONTROL

What’s ‘Pnew’ With Pneumatics?

With Alternative Solutions Available, Machine Builders and

End Users Still Find Plenty of Appeal in Pneumatic Systems

Mike Bacidore, editor in chief

PRODUCT ROUNDUP

Take Control of Control Software

Current Approaches Automate Automation

CONTROL DESIGN, (ISSN: 1094-3366) is published 12 times a year by Putman Media, 1501 E. Woodfield Rd., Suite 400N, Schaumburg, Illinois 60173. (Phone 630/467-1300; Fax 630/467-1124.) Periodical postage paid at Schaumburg, IL, and at additional mailing

offices. Address all correspondence to Editorial and Executive Offices, same address. Printed in the United States. ©Putman Media

2014. All rights reserved. The contents of this publication may not be reproduced in whole or part without consent of the copyright owner.

POSTMASTER: Send address changes to Control Design, Post Office Box 3430, Northbrook, Illinois 60065-3430. SUBSCRIPTIONS: To

apply for a free subscription, fill in the form at www.ControlDesign.com/subscribemag. To non-qualified subscribers in the Unites States

and its possessions, subscriptions are $96.00 per year. Single copies are $15. International subscriptions are accepted at $200 (Airmail

only.) Putman Media also publishes CHEMICAL PROCESSING, CONTROL, FOOD PROCESSING, INDUSTRIAL NETWORKING, PHARMACEUTICAL MANUFACTURING and PLANT SERVICES. CONTROL DESIGN assumes no responsibility for validity of claims in items

reported. Canada Post International Publications Mail Product Sales Agreement No. 40028661. Canadian Mail Distributor information:

World Distribution Services, Inc., Station A, PO Box 54, Windsor, Ontario, Canada N9A 6J5. Printed in the United States.

November 2014 Control Design

CD1411_05_07_TOC.indd 5

5

11/5/14 11:33 AM

NOV14 Catalog Ad (CD)_Control Design 10/9/14 1:47 PM Page 1

The Possibilities Are Endless

2015 Catalog

Over 120,000 products

|

Over 8,000 new products

Including seven new suppliers

|

|

Over 300 world-class suppliers

Order your catalog at alliedelec.com/2015Catalog

1.800.433.5700

© Allied Electronics, Inc 2014. ‘Allied Electronics’ and the Allied Electronics logo are trademarks of Allied Electronics, Inc.

CD1411_FPA.indd 6

An Electrocomponents Company.

11/4/14 10:53 AM

CONTENTS

COLUMNS

HOT BUTTONS

9 Editor’s Page

15 OEM Spotlight

Volume 18, No. 11

Go Small, Get Flexible

Everything That Rises

Mike Bacidore, editor in chief

18 InDiscrete

11 Live Wire

2 New Solution Factory Facilities in

the Mix; China Adopts EtherCAT as

National Technology Standard

Detour to Builder City

Jim Montague, executive editor

25 Embedded Intelligence

46 SpecMate

Make STEM Teachers ISA

Members

2 Views of Machine Vision

Jeremy Pollard, CET

48 Real Answers

Give Your HMI an Ergonomic

Tune-Up

42 TechFlash

ECAD: Simple or Complex?

Leslie Gordon, senior technical editor

50 Product Showcase

54 OEM Insight

Machinery Safety Labels Matter—

Part II

Geoffrey Peckham, chairman ANSI Z535 Committee

Take a picture of your product.

Tell the sensor what to verify in three quick steps.

Every product on your line is now

visually checked for quality.

NEW XUW Vision Sensor

Simply easy!

Quick, 3 step configuration

Up to 32 simultaneous checks

www.tesensors.com/vision

CD201411.indd 1

CD1411_05_07_TOC.indd 7

Booth #4749

10/20/2014 10:41:26 AM

11/5/14 9:52 AM

Control

Design-PFC200-Nov2014

Outlined.indd 1

CD1411_FPA.indd

8

10/21/1410:54

1:53AM

PM

11/4/14

Mike Bacidore

In Memory of Julie Cappelletti-Lange,

Vice President 1984-2012

•

editor in chief

•

mbacidore@putman.net

EDITOR’S PAGE

Everything That Rises

1501 E. Woodfield Rd., Suite 400N

Schaumburg, Illinois 60173

630/467-1300

Fax: 630/467-1124

WHEN YOUNG MEN and women

After all, service agreements are

leave home to make lives of their

lucrative add-ons to machinery

EDITORIAL TEAM

own, parents shed some tears

sales. If you’re not watching and

editor in chief

and hope they’ve equipped them

maintaining that machine, some-

to take on the challenges they’ll

one else surely will.

MIKE BACIDORE

mbacidore@putman.net

executive editor

JIM MONTAGUE

jmontague@putman.net

face. Sometimes, they end up back

And it would be really simple to

home for a spell, but for the most

use that existing control system

managing editor

part they’re out there, doing what

to measure almost anything with

NANCY BARTELS

nbartels@putman.net

they were born to do. And parents

the proper sensing device. Most

do their best to let them, secretly

world-class manufacturers have

wishing they still could watch over

recognized the financial benefits

them and protect them.

of avoiding equipment failures and

managing editor, digital media

KATHERINE BONFANTE

kbonfante@putman.net

associate editor, digital media

ERIN MASSEY

emassey@putman.net

senior technical editor

DAN HEBERT

dhebert@putman.net

senior technical editor

LESLIE GORDON

lgordon@putman.net

contributing editor

HANK HOGAN

hank@hankhogan.com

editorial assistant

LORI GOLDBERG

lgoldberg@putman.net

columnist

JEREMY POLLARD

jpollard@tsuonline.com

DESIGN/PRODUCTION

senior production manager

Machines emerge similarly.

profitability. Most of these plants

equip them with appropriate

also have software—it might be

controls, motion components, con-

CMMS, EAM or ERP—that’s used to

nections and safety elements, and

schedule maintenance on equip-

then they’re released to industrial

ment. And that software doesn’t

facilities, where they do what they

talk with control systems. “Oh,

were built to do.

but you can use a data historian,”

One of the big differences

advantage of monitoring is the

aside from the fact that machines

real-time, in-context analytics

won’t ever marry that loser son-

that are available.

in-law who can’t hold a job, is we

can’t monitor the health of our

sons and daughters on a real-time

assoc. art director

basis, but that is in fact possible

SUBSCRIPTIONS

customer service

888/644-1803

CIRCULATION

audited June 2014

Air & Gas Compressors

1,020

Engineering & Systems

Integration Services

6,989

Engines & Turbines

1,812

Food Products Machinery

1,990

Industrial Fans, Blowers

& Air Purification Equipment

759

Industrial Heating, Refrigeration

& Air Conditioning Equipment

1,383

Industrial Process Furnaces & Ovens

672

Machine Tools

3,415

Materials Handling, Conveyors

& Conveying Equipment

1,884

Metalworking Machinery

3,867

Mining Machinery & Equipment

539

Oil & Gas Field Machinery & Equipment 1,358

Packaging Machinery

1,072

Paper Industries Machinery

368

Printing Trades Machinery & Equipment 484

Pumps & Pumping Equipment

752

Rolling Mill Machinery & Equipment

161

Semiconductor Manufacturing

Machinery

1,170

Textile Machinery

225

Woodworking Machinery

284

Other Industries & Special Industrial

Machinery & Equipment NEC

9,816

TOTAL

40,020

CD1411_09_EDIT.indd 9

you say. That’s true, but the big

between machines and progeny,

ANETTA GAUTHIER

ANGELA LABATE

optimizing system capacity. That’s

They’re created by engineers who

with machines. Sensors allow

us to keep watchful eyes on any

number of conditions. And the

If you’re not watching

and maintaining that

machine, someone else

surely will.

Call it convergence or integra-

opportunities to equip machinery

tion, but the ability to use control-

with them keep increasing.

system sensors to monitor ma-

Seven years ago, Contribut-

chines remotely in real time and

ing Editor Dan Hebert wrote

schedule planned maintenance is

about how far remote monitor-

coming. And machine builders will

ing capabilities had come (www.

be able to care for their children in

controldesign.com/machinemoni-

unforeseen ways.

toring), and that technology curve

continues to steepen.

One of the more interesting

On a final note, let me take a

moment to salute Joe Feeley, who

has retired. You all remember him

recent developments has been the

as chief editor of Control Design. I

quest to use the existing control

will always remember him as one

system to facilitate condition

of my greatest publishing mentors.

monitoring and plan for main-

Here’s to you, Joe.

tenance of these machines. “Oh

yeah,” you say, “we’ve been doing

that for years.” It’s quite possible

that you have, on a limited scope.

controldesign.com

November 2014 Control Design

9

11/3/14 11:09 AM

Ultra Fast aUtomation

1µs rEsPonsE timE

www.br-automation.com/reACTION

<

<

<

<

<

Replaces dedicated hardware

Freely programmable

IEC 61131, Function Block Diagram

Reduces CPU load

Reduces machine cycle time

Find out more.

reACTION

TECHNOLOGY

CD1411_FPA.indd 10

11/4/14 10:54 AM

Jim Montague

•

executive editor

•

jmontague@putman.net

LIVEWIRE

Detour to Builder City

I REALLY NEED to be more careful driving because

and park district all have a hand in supporting the

I can’t help seeing interesting stuff. And my smart-

village’s business community. “Beyond Business

phone doesn’t help because now I can take pictures

Friendly” is its recent motto.

of everything. Well, at least I stop before snapping—

most of the time.

Anyway, I was driving to work a couple of years

“It’s essential for Elk Grove to support our businesses because the industrial park contributes

about 80% of the village’s revenue,” says Josh

ago, when I had to take a detour due to a freight

Grodzin, Elk Grove’s business development market-

train taking a long nap across an intersection up

ing director. “About five years ago, the park’s vacan-

ahead. So I was forced to venture more deeply than

cy rate was 14 to 15%, and so we started some of our

ever before into the huge industrial park just west

more recent efforts, including Made in Elk Grove, to

of O’Hare International Airport and located in the

assist our manufacturers with the challenges they

municipality of Elk Grove Village, Illinois.

face. More recently, we’ve driven the vacancy rate

Now I’ve been all over this area before, or so

I thought, because I came upon a strange sight.

back down to just 7%.”

Ironically, even though the expo featured dozens

One of the big warehouses on Pratt Avenue had its

of machine and equipment builders, end users and

equally big, garage-style doors open, and inside was

product manufacturers, and related suppliers and

an army of old press brakes, machining centers and

service providers, Grodzin adds many more haven’t

other industrial equipment.

attended the event yet.

I’m pretty sure many of the machines were in

various stages of refurbishment, rebuilding or decommissioning, but my glance and mental snapshot

made it look like someone had sealed up an IMTS

exhibit hall about 30 years ago and just let the dust

and cobwebs take over.

I felt a little like one of those anthropologists who

I felt a little like one of those

anthropologists who discovers

an ancient, buried city, except

it’s still up and running like

Rome or Paris.

discovers an ancient, buried city, except it’s still up

and running like Rome or Paris.

This was the first of several wakeup calls alerting

Consequently, because the park is so big, many of

its occupants don’t know what their neighbors are

me to the fact that I’ve been sitting on a hotbed of

building and producing that could be useful to them

machine builders and end users. How convenient for

and are buying products and paying to transport

me covering this field, but not very surprising, given

items they could get in their own town.

the Chicago area’s long and varied industrial history.

Some of the show’s other organizers report one

Even so, after many years covering industrial

of their main aims is to get the park’s residents to

tradeshows nationwide and internationally, I was

realize and use the supply chain that’s all around

startled again when I ran across the Made in Elk

them. Apparently, I’m not the only one who’s un-

Grove Manufacturing & Technology Expo (www.

aware of the hotbed he’s sitting on.

madeinelkgroveexpo.com) on Oct. 21. The one-day

As for me, I now have another rich vein of poten-

event is now two years old and, with 90 exhibiting

tial content and contributors to mine, and I don’t

companies and 1,000 visitors, is as at least as big as

have to get on an airplane to reach them. I’ll inves-

some similar tradeshows covering far larger regions.

tigate and report on as many as I can.

This shouldn’t be too surprising because the expo

You too may find neighbors with capabilities you

draws its exhibitors from the Elk Grove Business

thought you had to cross time zones to get. It hap-

Park, which covers more than 5 sq miles and is the

pens all the time with builders, integrators and us-

largest industrial park in North America. It’s home

ers. Even long-time business associates frequently

to more than 3,600 businesses, which are staffed by

say to each other, “I didn’t know you did this.”

about 100,000 employees.

These companies and their workers are served by

So keep you eyes on road, but also slow down,

stop sometimes and look around. More than likely,

Elk Grove’s municipal services, but its high school,

you’ll glimpse something cool and find some useful

local community colleges and even the library

resources hiding in plain sight.

controldesign.com

CD1411_11_LIVEWIRE.indd 11

November 2014 Control Design

11

11/3/14 11:11 AM

The Pulse of AuTomATion

World’s Largest Selection of Ultrasonic Sensors

A product of world-class acoustic engineering

expertise, Pepperl+Fuchs ultrasonic sensors are

completely unaffected by dust, color variations,

gloss, or transparency.

With sub-millimeter precision, software

configurability, and detection ranges from

½ inch to over 30 feet, ultrasonics are ideal for

both switch-point and analog control of

objects as diverse as bottles, refuse containers,

wooden pallets, steel coils, and foods.

Pepperl+Fuchs, Inc.

330.486.0001

www.pepperl-fuchs.us

CD1411_FPA.indd 12

Download four

application reports

that show you how to

easily use ultrasonic

technology.

www.sensing.net/pulse

Scan. Learn More.

11/4/14 10:54 AM

ADVERTISEMENT

Another option:

Retroreflective

ultrasonic sensors

Now you have a choice:

There or Where

The options when specifying sensors for long-range object

detection or positioning usually boil down to two alternatives:

optical sensors using either infrared or visible-red light and

ultrasonic sensors. Optical sensing is often the first choice

because it has excellent long-range detection capabilities and

relatively low cost. Direct-detecting ultrasonics are a reliable

second option when dust, dirt, color variance, or ambient-light

contamination limit optical effectiveness.

However, there are times when neither sensor will work.

Fortunately, a third option does exist: the retroreflective

ultrasonic sensor.

Traditional ultrasonic sensor designs determine sensor-to-target

distances by timing the propagation delay of high-frequency

sound pulses as they travel from the sensor to the target and

return. But problems occur when the target reflects the sound

pulses away from the sensor, making the target acoustically

invisible. Retroreflective ultrasonic sensors compare the echo

return time from a known, fixed acoustic reflector, such as a

wall or ceiling. If that time changes, or the echo disappears, the

sensor knows there’s a target present.

Vehicle detection, such as counting cars entering a parking garage,

provides an excellent example of the benefits in using retroreflective

technology. Optical technologies can demonstrate the problems

caused by varying paint colors and transparent glass windshields.

On the other hand, the smooth, sloped contour of a car body and

windshield deflect ultrasonic echoes away from the transducer,

rendering the target ultrasonically invisible.

An ultrasonic sensor mounted overhead learns the distance to the

floor below. Anytime the sensor detects a change in that distance

or loses the echo entirely, it signals the presence of a vehicle.

Beyond vehicle detection, retroreflective ultrasonic sensors

can also detect humans, whose soft clothing is both randomly

colored and acoustically absorbent. Colors, along with dusty,

fiber-laden environments such as those found in textile and

carpet manufacturing can also quickly defeat a standard optical

or ultrasonic sensor, giving the retroreflective ultrasonic sensor

an advantage in those environments as well.

Distance-based photo sensors address more challenging

applications by not just determining if an object is

THERE, but also WHERE it is located. Three methods

have emerged as front runners to show you Where:

Background Suppression

n Multi-Pixel Array

n Pulse Ranging Technology

n

Download our e-book that explains how

these technologies will work for you.

www.sensing.net/where

Scan. Learn More.

Distance-based photo sensors will have your standard

photo sensor nervously looking over its shoulder.

Pepperl+Fuchs, Inc. • 330.486.0001 • www.pepperl-fuchs.us

CD1411_FPA.indd 13

11/4/14 10:54 AM

High Quality – Great Value – Easy to Select

Purchase select Endress+Hauser

products online with E-direct

E-direct complements the traditional range of products from

Endress+Hauser. Certain instruments do not require a vast amount

of consultation in terms of application and price – that’s where

E-direct can help, as a fast, effective direct purchase channel.

Anwendung in

Broschüren

• High quality - E-direct products are 100% Endress+Hauser

quality, with sophisticated, state-of-the-art technology

• Great value - Attractive prices with tiered quantity discounts

Anwendung in

• Easy to select - The products are largely preconfisw-Publikationen

gured.

You can select the appropriate device quickly and easily

Anwendung in Magazinen

Shop now!

www.endressdirect.us

Endress+Hauser, Inc

2350 Endress Place

Greenwood, IN 46143

info@us.endress.com

www.us.endress.com

CD1411_FPA.indd 14

• Free shipping - Prompt delivery with easy order tracking

• Resource library - Access to educational material

Sales: 888-ENDRESS

Service: 800-642-8737

Fax:

317-535-8498

11/4/14 10:54 AM

OEM SPOTLIGHT

Go Small, Get Flexible

Emag Migrates From Large, Custom-Built Equipment

BIGGER ISN’T ALWAYS better, more features aren’t

always helpful, and many bells and whistles are just

noise. All the capabilities a useful machine requires

are no more than what each end user needs to produce its products with the greatest speed, accuracy,

efficiency, safety and quality. And this directive is

even truer for the many small users with shallow

pockets who are just beginning to approach using

automated machines and production for the first time.

These are the customers that Emag (www.emag.

com) has been reinventing several of its machines to

reach. Located in Salish, Germany, and Farmington

JIM MONTAGUE

Hills, Michigan, Emag traditionally builds big, vertical

turning, milling and drilling machines with customized control and operations for manufacturing precision metal parts, mainly for the automotive industry.

However, to expand into new markets, Emag also

began developing smaller, more flexible versions of its

larger machines to serve more Tier 1 and 2 parts suppliers and many mom-and-pop machine shops too.

“We wanted to get into new market segments with

new customers, and so we developed a new modular,

standardized concept and introduced it in Europe

CONCENTRATED CAPABILITY

The VLC 200 H gear-hobbing machine is one of a series of

machining centers that Emag has shrunk to one-half to onethird the size of its traditional vertical machines, but which

retains the Plus, numerical controls, G-code and capabilities of

the company’s larger devices.

three years ago and in North America two years ago,”

says Marius Mazur, Emag’s product line manager.

One especially important milestone arrived in 1992,

“Our traditional machines are two or three times

when Emag introduced its VSC, which it reports was the

larger than our new modular machines.”

world’s first vertical turning center with pickup spindle.

How did Emag pack the capabilities of its older, big

Over time, the VSCs developed into multifunctional,

machines into its new, small ones? Very carefully,

multitasking production centers. For instance, about 10

especially when integrating its PLC, numerical control

years ago, Emag also got into machining threaded parts

(NC), G-code and other essential components into its

for oil and gas piping applications and developed its VL

new half- or one-third-sized footprints. Amazingly,

3, VL 5 and VL 7 vertical centers. Designed to handle

the new, smaller machines still retain the capability

the unique material characteristics and requirements

of the older and larger cousins, employing Siemens’

of process industry components, the VL series are

840 DSL hybrid PLC and NC controller or Fanuc’s 32i

typically managed by Fanuc’s 32i controller and can be

and 33i CNC controllers.

monitored and diagnosed via Emag’s Internet protocol

“Our new modular machines are the same as our

larger ones,” says Mazur. “We just put all our knowledge into smaller spaces.”

Founded in 1867 in Bautzen, Saxony, as an iron

(IP)-based, Ethernet network.

Emag’s equipment covers the entire spectrum of

machining processes in metalworking. In fact, besides Emag’s turning, milling and drilling machines,

foundry and engineering works, Emag was reestab-

the larger Emag Group’s companies manufacture

lished in 1952 in Esslingen, Baden-Württemberg, where

chucked, shaft-type and cubic components. Founded,

it manufactured lathes and special-purpose machines.

organized or acquired mostly since 2000, these

In 1969, it moved to Salish, where it introduced pro-

divisions include Karstens, which makes external,

gram-controlled, automatic turning machines, which it

cylindrical grinding equipment; Naxos-Union, which

began distributing worldwide in 1977, including open-

specializes in crankshaft grinding; Emag Automa-

ing its Michigan-based subsidiary in 1980.

tion, which provides automation for all applications;

controldesign.com

CD1411_15_16_OEMSPOTLIGHT.indd 15

November 2014 Control Design

15

11/5/14 10:15 AM

OEM SPOTLIGHT

“Our new modular machines are the same as our larger

ones. We just put all our knowledge into smaller spaces.”

for electrochemical machining.

Reinecker for internal, precision

While its recent modular

grinding; Kopp for camshaft

grinding; Koepfer for gear hob-

program started with just one

bing; Emag Laser Tec for assembly

scaled-down machine three years

and laser welding; and Emag ECM

ago, Emag reports its new vertical

The MAQ®20 Industrial

Data Acquisition & Control System

JIM MONTAGUE

Rugged Precision

PARTS FOR PROCESS

Emag’s VL 5i vertical machining center is

designed to manufacture parts taking into

account the unique characteristics and

requirements of oil and gas piping applications

line includes VL 2, which produces

parts up to 100-mm diameter; VL

4, which makes parts up to 200mm diameter; VL 6, which makes

parts up to 600-mm diameter; and

VL 8, which makes parts up to

800-mm diameter.

“VL 2 makes small, round gear

and chuck parts, while our VT 2 and

VT 4 have two spindles, so they’re

really two machines in one,” adds

Mazur. “We also typically add our

automated part conveyors to the

Signal Integrity, Compact Design

2 Software Packages for DAQ or T&M

outside of our machines. They’re

controlled by small Fanuc servo

motors and can be on both sides of

a machine to move work pieces in

• $17 per Channel Possible –

Lowest Cost in Industry

and move completed parts out.”

To maintain these controls

• Up to 384 Channels in 19”

Instrumentation Rack

for its users, Emag operates its

• Application Software from $250

remotely monitors clients’ ma-

• ±0.035% Accuracy

chines via a password-protected

• 1500Vrms Channel-to-Bus

Isolation

machines on our Emag network,

Service Plus program, which

network. “Our users can put their

and we can see everything,” says

• PID Software Control

- Up to 32 Loops with ReDAQ® Shape

- Unlimited Loops with IPEmotion

• –40°C to +85°C Operating

Temperature

CD1411_15_16_OEMSPOTLIGHT.indd 16

Mazur. “Our PLC guys can view

the performance of machines on

their individual Web pages via our

Ethernet-based network.”

Instrument Class® Signal Solutions

dataforth.com • 800-444-7644

11/5/14 10:15 AM

This changes everything.

Limited Time Offer!

$399

Software, cable, and power supply.

All included!

www.IDEC.com/touch

New HMI+PLC with Extensive Analog Capabilities!

Introducing the new, better than ever, FT1A Touch 14 I/O.

It takes a lot to be the next best thing, but with a host of new

features, these combo 14 I/O PLC/3.8-inch HMI units make it

look easy. Perfect for advanced analog monitoring and control,

FT1A Touch 14 I/O combines an operator interface and control

in a single compact package, all programmable with IDEC’s

• PID Control

user-friendly software. The only question is, are you ready?

• 65K TFT Color

• Modbus TCP and RTU

• Ethernet connectivity

• 2 built-in Analog inputs (0-10V DC, 4-20mA)

• 2 built-in Analog outputs (0-10V DC, 4-20mA)

www.IDEC.com/usa

800.262.IDEC

CD1411_FPA.indd 17

11/4/14 10:54 AM

INDISCRETE

2 New Solution Factory Facilities in the Mix

MOSS DOES NOT grow on Tom

Johnstone or Poul Jeppesen. On

Oct. 19, Johnstone, president

and CEO of SKF, and Jeppesen,

president and CEO of SKF North

America, attended the Geico 500

at Talladega Superspeedway in

Alabama to watch Team Penske’s

Brad Keselowski win the NASCAR

Sprint Cup Series race in the SKFsponsored No. 2 car.

Two days later, they were at the

United Center in Chicago, watching the BlackHawks defeat the

Philadelphia Flyers, 4-0.

INNOVATION AND KNOWLEDGE

The Solution Factory that will be included in the GTCA will be the 29th Solution Factory.

In between the two sporting

events, all they did was open

the company’s 28th SKF Solution Factory near Birmingham,

Alabama, and break ground for the

Global Technical Center—Americas (GTCA), which will include the

29th Solution Factory, in Naperville, Illinois.

The Alabama facility is designed to provide customers

with industry knowledge and

value-added solutions. With Solution Factory facilities already in

Houston and Cleveland this is the

third to open in the United States

and joins the growing network of

five others in North America. “The

SKF Solution Factory is another

BREAKING GROUND

Paol Jeppesen, president of SKF North America, A. George Pradel, mayor of

Naperville, Illinois, and Tom Johnstone, president and CEO of SKF, make way for the

Global Technical Center—Americas.

way for us to provide customers

application support, custom-

Netherlands and Sweden. You can

with the resources they need to

ized machined sealing solutions,

even track the progress of the new

meet machinery performance and

mechanical equipment services,

GTCA in Naperville at www.skf.

operating efficiency goals,” said

engineering consultancy and re-

com/gtca. When it opens, it will

Jeppesen. “We’re pleased to bring

mote diagnostics and monitoring.

combine technical resources with

this state-of-the-art facility and

It also includes training courses

knowledge experts in an effort to

its unique portfolio of services to

and seminars.

create a culture of collaboration

this region.”

The GTCA is part of SKF’s plans

and innovation. Over the next two

for a global network of technical

years, SKF will recruit a technical

tory, which focuses on pulp and

centers, including ones built in

staff of 40 employees to work at

paper, food and beverage, mining

China in 2013 and in India in 2011.

the facility, which is being built

and metals industries, offers ac-

Two more are currently under

to LEED Gold standards. SKF also

cess to SKF’s technical resources

construction, adjacent to the exist-

is pursuing ISO 50001 for all of its

for machine productivity solutions

ing technology and manufacturing

manufacturing facilities.

and services, including bearing

process research centers in the

The Birmingham Solution Fac-

18

Control Design November 2014

CD1411_18_23_INDISCRETE.indd 18

The GTCA will be an open

controldesign.com

11/3/14 11:20 AM

VALVES

WHEN

YOU’RE IN

A PINCH

•

•

•

•

•

•

•

NEW Versagrip® electric-solenoid models

Ideal for preventing inline fluid/media contamination

Fast actuation speeds for opening or shutoff

Compact, panel-mount ready design

No maintenance required

Seals support full wash-down procedures

Corrosion resistant

PNE

PNEUMA

MORE OPTIONS, MORE FLEXIBILITY,

MORE ELECTRIC AND PNEUMATIC PINCH VALVE SOLUTIONS

To learn how Bimba can help your applications go with the flow, or to learn more about the

NEW Versagrip® Solenoid Pinch valves, visit acroassociates.com

BIMBA BRANDS I ACRO I MEAD I MFD I PNEUMADYNE I TRD

© Copyright 2014 Bimba Manufacturing Company. All Rights Reserved.

BIM-752

Bimba Resizes_Control

Deign_New_Acro_Ad_090114.indd 1

CD1411_FPA.indd

19

8/18/1410:54

4:32AM

PM

11/4/14

INDISCRETE

reduction through better energy

and resource efficiency.”

Driving project development

and technical recruitment for the

GTCA is Cengiz Shevket, director,

engineering and emerging segments, renewable energy business

unit, at SKF. “I’m confident that

this will be a great facility, not only

in which to work, but to collaborate

through open visits and workshops

with customers, our distributors

ROOMS WITH A VIEW

When the GTCA opens, it will include a mezzanine viewing balcony and a high-bay

workspace with up to 25-ton lift capacity.

and university researchers,” said

Shekvet. The facility will include

approximately 130,000 ft 2 of space,

laboratory for idea generation,

ich, vice president of communica-

open workspaces, an exhibit hall,

leveraging a modular building

tions at SKF North America. “This

testing capabilities for special-

structure that’s adaptive, open and

new facility will be an eye-opener

ized industries such as aerospace,

informal. “A common refrain from

for our North American customers

energy and automotive, training

even long-standing customers is

and a great opportunity for SKF

classrooms, a mezzanine viewing

‘I didn’t know,’ when they see the

to put its best technology forward

balcony, a wellness center and a

full range of SKF offerings across

to solve today’s most pressing

high-bay workspace with up to 25-

all our platforms,” said Walt Delev-

engineering challenges, like CO2

ton lift capacity.

CAST STAINLESS STEEL

NE

W

XCESX

ENCLOSURES

Ideal for offshore applications in oil & gas industry

5 standard sizes available up to 24”W x 36”H x 10”D

Rated for Division 1 and Zone 1 Hazardous Areas

Corrosion resistant, cast stainless steel 316L

UL, cUL, ATEX, and IECEx Certifications

Flat plate cover design

BUILT TO LAST

IN HIGHLY

CORROSIVE AREAS

Call for a Free Application Evaluation!

TM

OWN YOUR ENVIRONMENT.

adalet.com • info@adalet.com • TEL 216.267.9000 • FAX 216.267.1681

CD1411_18_23_INDISCRETE.indd 20

11/3/14 11:20 AM

Yourvision.

vision.

Your

Yourpick.

pick.

Your

New Matrox

Design

Assistant

4 flowchart-based

New Matrox

Design

Assistant

4 flowchart-based

visionvision

software

is

so

easy

to

learn,

anyone

can

use

it.

Because

software is so easy to learn, anyone can use it. Because it’s it’s

hardware

independent,

youchoose

can choose

any computer

hardware

independent,

you can

any computer

with with

®

™

®

™

GigE

Vision

or

USB3

Vision

cameras

and

get

the

processing

GigE Vision or USB3 Vision cameras and get the processing

you need.

Thisproven

field proven

software

a perfect

powerpower

you need.

This field

software

is alsoisaalso

perfect

the Matrox

GPm vision

the Matrox

matchmatch

for thefor

Matrox

4Sight4Sight

GPm vision

systemsystem

or the or

Matrox

GT smart

camera.

Assistant

gives

you

the freedom

Iris GTIris

smart

camera.

DesignDesign

Assistant

gives you

the

freedom

to

choose

the

ideal

platform

for

your

inspection

projects.

to choose the ideal platform for your inspection projects.

Try Design

Assistant

4 today

and watch

Try Design

Assistant

4 today

and watch

your your

applications

grow:

www.matrox.com/da4/cd

applications grow: www.matrox.com/da4/cd

1-800-804-6243

1-800-804-6243

+1-514-822-6020

+1-514-822-6020

imaging.info@matrox.com

imaging.info@matrox.com

CD1411_FPA.indd

21

ContDesign_DA_ad_full_US_final_0514.indd

1

ContDesign_DA_ad_full_US_final_0514.indd

1

11/4/14 10:55

AM

2014-05-15

2014-05-15

09:57:27 09:57:27

INDISCRETE

China Adopts EtherCAT as

National Technology Standard

ON OCT. 21, Dr. Wei Sun, repre-

Technology Group (ETG) at a

sentative of the Standardization

ceremony in Beijing. He informed

Administration of China (SAC),

the crowd that EtherCAT, which

made an announcement about

has seen strong global use for

a milestone and the EtherCAT

more than 10 years, is now a

What will you

control tomorrow?

national technology standard in

China.

The ceremony in Beijing was

hosted by ITEI president, Prof.

Jinsong Ouyang in the official

guest house of the Chinese government and brought together

numerous experts from a wide

range of industries. There, SAC

Director, Dr. Wei Sun announced

EtherCAT as National Standard

GB/T 31230.

When pigs fly!

Until then, Maple Systems

controller with display

provides an affordable

control solution.

For over 30 years, we’ve

provided both HMI and

Programmable Controller

solutions to companies

around the world.

How can we help you?

In close cooperation with ITEI,

several ETG member companies

from China, as well as the local

EtherCAT Competence Center at

Beihang University in Beijing,

contributed significantly to the

completion of the standard.

As a special highlight to the

ceremony, Chinese company

representatives shared some

experiences about their numerous EtherCAT systems and

applications with the audience

members, and they explained

the benefits realized through

implementation.

The ceremony closed with live

demonstrations of various EtherCAT systems featuring a variety

of Chinese and international

EtherCAT products.

CD1411_18_23_INDISCRETE.indd 22

11/5/14 10:52 AM

MERGERS,ACQUISITIONS & ALLIANCES

Zebra Technologies (www.zebra.com) has completed the

acquisition of Motorola Solutions’ (www.motorolasolutions.

com) Enterprise business for $3.45 billion in cash. The

transaction was funded with $200 million of cash on hand

and $3.25 billion in new debt. As part of the sale, 4,500

Motorola Solutions employees from locations throughout

the world will transfer to Zebra.

Rockwell Automation (www.rockwellautomation.

com) has purchased the assets of ESC Services, (www.

escservices.com), a hazardous energy control provider of

lockout-tagout services and solutions. ESC Services, based

in Franklin, Wisconsin, will be integrated into Rockwell

Automation’s Control Products & Solutions segment as part

of its customer support and maintenance business unit.

Terms were not disclosed.

Turck (www.turck.com) has acquired a 50% interest in its

long-term Canadian sales partner, Chartwell Automation

(http://chartwell.ca/). The new company name is now Turck

Chartwell Canada, Inc. On Oct. 1, 2017, Turck will acquire

the remaining shares and thus be 100% owner of the new

subsidiary, Turck Canada.

TE Connectivity (www.te.com) has completed the

previously announced acquisition of Measurement

Specialties. For reporting purposes, Measurement

Specialties will be included as part of TE’s Transportation

Solutions segment.

Mitsubishi Electric (www.meau.com) and Kemper Storatec

(www.kemper-storatec.eu ) have collaborated to introduce

a new, fully automated system that loads and unloads any

existing cutting equipment, regardless of the manufacturer.

In a fully automated laser line, the StoreAutomation

loading and unloading unit takes the raw material from

the raw sheet stack and loads the cutting machine’s table.

After processing, a rack in the machine removes the cut

blank automatically.

Kepware Technologies (www.kepware.com), developer of

software solutions for industrial automation and controls,

has made available its Industrial Data Forwarder for Splunk.

(www.splunk.com). The forwarder, a plug-in for the widely

deployed KEPServerEX platform, enables customers to send

industrial data from sensors, devices and control systems to

Splunk Enterprise and Splunk Cloud.

Monitor and control your HMI on a Smart Phone or a Tablet.

ON

W

SALE NO

$ 19.99

Y

L

ON

/25/14

ENDS 12

Pro-face Remote HMI

Check machines

and equipment

for alarms,

operating status,

and other information using

a tablet or smartphone

(Apple or Android) from

anywhere in the world!

For more information,

Watch the Video, then

check out the Remote HMI

by visiting the link below.

profaceamerica.com/RemoteHMI | 800-289-9266

CD1411_18_23_INDISCRETE.indd 23

11/3/14 11:20 AM

TRUE STORY

Every day, IceStation enclosures are washed down

with harsh chemicals and water. And every day, the

electronics inside remain dry and clean.

Food-processing and pharmaceutical plants are harsh environments for electronics. Your critical systems must

withstand water and chemicals used during wash-down – including the electronics inside every computer

enclosure. The NEMA 4X Titan from ITSENCLOSURES is made specifically for these extreme conditions. The Titan

is constructed of 14-gauge Type 304 stainless steel to handle corrosive cleaners and chemicals that would break

down a lesser enclosure. The Titan features a 24-inch (16:9) viewing window and a generously sized work surface.

Should a Titan ever fail due to manufacturer defect, ITSENCLOSURES will replace it immediately so your business

does not skip a beat. To learn more about IceStation TITAN, call 1.800.423.9911 or visit ITSENCLOSURES.com.

25

CD1411_FPA.indd 24

11/4/14 10:55 AM

Jeremy Pollard, CET

•

jpollard@tsuonline.com

EMBEDDED INTELLIGENCE

Make STEM Teachers ISA Members

WHAT DO WE need to do with our industry—dis-

This local robotics revolution now boasts 50 teams

crete and process—to engage youngsters who don’t

over two days. The grade school’s gifted program stu-

yet realize they’re really engineers?

dents have had more exposure to science, technology,

I challenged the International Society of Automation (www.isa.org) to “do it differently” (DiD) many

years ago during a conversation with Dick Morley. He’d

engineering and math (STEM) programs. A full day of

the competition is dedicated to them.

Ready says that solutions tend to be more creative

been asked to help guide the society to make it more

coming from the gifted program students, but not

relevant and have a bigger appeal. I sent him a picture

always. He believes that the ability to be unshackled

of its executives and told him this has to change.

from the expected is what leads to solutions that can

There were more white shirts and ties than one

sees at a funeral. And no one was under 50 years old.

We’re paying engineers more now than before,

be unexpected.

There have also been For Inspiration and Recognition of Science and Technology (FIRST, www.usfirst.

which tells me that the resource pool is shrinking,

org) events run at a local college that Ready has

but that isn’t new.

been involved with. Again, where have I been? These

ISA has held YAPFest, which was strictly for the

young automation professional (YAP), during its Automation Week. Nice job, Tracy! It was well attended and

teams have competed in the United States on behalf

of Canada.

So, here’s where the rubber meets the road. I asked

provided attendees an insight into their future with a

Ready if he is a member of ISA, and he said, “Never

conference and tradeshow. But how can we continue

heard of it.”

the YAPFest movement, and how can ISA help?

Since I am a member of ISA and over 50, I get in

the mail a brochure that suggests I can have a voice

in choosing the ISA leadership for 2014.

There are 10 white shirts and nine ties on the 16

candidates. Hopefully, we can DiD somehow.

I recently discovered that my area has a Lego

robotics lab at the central board of education for the

county of Simcoe. All kids from grades four to eight

at a local public school can participate in the standard curriculum involving the techs.

So I tracked down Mike Ready, teacher at Mountain

I then asked him how an international organization

could help grassroots programs such as those he has

been dealing with. In a nutshell—resources.

He tends to believe that the ability

to be unshackled from the expected

is what leads to solutions that can

be unexpected.

Budget restrictions, as well as time resources, tend

to throttle the programs’ efforts. But Ready volunteers his time and is all about the experience for the

View Elementary School in Simcoe County, Ontario.

students. It is teachers like him who care who can

He organized the local “robotics revolution” competi-

make a positive impact.

tion, where more than 20 challenges are presented

The reason I scoped out Ready was to provide

to be solved using Lego robotics. More than 150 stu-

some feedback to the ISA process. Vote you must, but

dents participated this year. Where have I been?

vote for those who can be progressive and have some

Ready was generous with his time and guidance,

for which I’m grateful. I asked him some pointed

questions but remembered that he heads up an au-

determination to make a difference. Who are they? I

don’t know, but find out.

I would then implore the ISA to launch a grass-

tomation program for local grade school kids, where

roots program to encourage educational profession-

budding engineers can be found. So here we go.

als to register for a full membership free of charge.

He refers to specific projects as purpose-driven,

Get resource materials into teachers’ hands to help

which defines the exercise’s end goal. He says the

them to develop those engineers who don’t know

out-of-the-box thinking that results generally makes

they’re engineers yet. It’s time for real innovation.

spotting young engineering minds easier. And he

refers to an additional project, the WonderCoaster

JEREMY POLLARD, CET, has been writing about technology

Contest, where students build scale-model, gravity-

and software issues for many years. Pollard has been

powered coasters. He suggests that unless a project

involved in control system programming and training for

is fun, students’ enthusiasm wanes.

more than 25 years.

controldesign.com

CD1411_25_EMBEDDEDINTEL.indd 25

November 2014 Control Design

25

11/3/14 11:22 AM

The Truth About the Bottomless Cup of

Machine Protection

Remote Diagnostics and Service Are More Routine and Secure,

More Comprehensive in Scope and Capabilities and More

Adept at Providing Data to Improve Machine Designs

by Jim Montague, executive editor

26

Control Design November 2014

CD1411_26_34_COVERSTORY.indd 26

controldesign.com

11/5/14 10:07 AM

CAN’T WORK EVERYPLACE AT ONCE?

Better find a way.

Manufacturers demand 24/7 uptime and system

pneumatic lines for grippers and other functions.”

However, because Tornos deployments to users like

Rolex and other watchmakers are growing along with

availability, but that means machine builders and sup-

the recent resurgence of the industry, it needed a better

port technicians must be ready at a moment’s notice

way to keep tabs on its machines in the field. So about

to maintain, troubleshoot and repair practically every

a year ago, Tornos launched its Tisis machine com-

machine they’ve ever sold in hundreds if not thousands

munication system, which transfers 2D and 3D CAD/

of locations scattered worldwide.

CAM designs to its machines, selects tools and checks

While human cloning isn’t practical yet, and machine

on their programs and operating status. Tisis uses a

builders and other stressed-out professionals can’t make

small, password-protected web server integrated into

all the copies they need of themselves, there are other

its machines, communicates via VPN, Internet protocol

helpful tools they can employ to get in front of all the

(IP) and even Wi-Fi, and delivers HTML-based displays to

equipment they must maintain. Remote monitoring,

PCs and tablets.

support and even control are offering more varied and

“Users can remotely organize parts databases, set

sophisticated capabilities for accessing machines and

production rates to run machines overnight, monitor

production lines from a distance and then examining,

their machines from home and receive preset alerts and

troubleshooting, repairing and upgrading them so users

alarms,” says Cassella. “Besides using passwords, we

need not go to each physical location.

also rely on Wi-Fi’s native encryption for added security.

More recently, rather than communicating via old-

Though it’s not part of Tisis, we also use TeamServer

fashioned modems or asking for permission to access

software to access users’ VPNs with their permission,

virtual private networks (VPNs), the newest remote-sup-

take control of our remote machines and go into their

port methods enable builders and technicians to service

CNC controls to solve most problems.”

protected versions of a machine’s operating data and

A few years ago, remote access was just about

software, which are delivered to virtual, cloud-based

monitoring machines, says Sal Conti, remote monitor-

services that don’t require users and their IT staffs to

ing product manager in Rockwell Automation’s (www.

permit access to their internal networks.

rockwellautomation.com) Remote Support Services di-

For instance, Tornos (www.tornos.com) in Moutier,

vision. “Now it’s allowing machine builders and users

Switzerland, builds Swiss-type lathes and other equip-

to deploy their best engineers anywhere at any time,

ment, such as its six-axis SwissNano CNC machine. It

doing it a lot less expensively, gaining data for much

uses bar stock to manufacture wristwatch, medical and

better proactive maintenance and letting technicians

dental device parts up to just 4-mm wide and 28-mm

know what they’ll be facing and what they need before

long with a precision of ±1 micron. Where watchmakers

going into the field,” he explains. “We do more remote

traditionally used several cam-driven lathes to make

monitoring and troubleshooting and less remote con-

their tiny parts, two-year-old SwissNano can make 85%

trol. However, we tell users how to fix their machines,

of typical watch parts in a footprint that’s only 600-mm

or we can fix them by putting machines into program

wide, but contains a multi-spindle lathe with two rotat-

mode and making needed changes.”

ing tool positions and 12 total positions (Figure 1). Tornos

One of Rockwell Automation’s primary remote moni-

also has a subsidiary company, Almac, which builds

toring and assistance tools is its two-year-old Virtual

milling machines based on SwissNano’s frame.

Support Engineer (VSE), which can be scaled to fit the

“Companies were not making the old cam-operated

size and risk threshold of each user’s application, use

machines anymore because they were so costly to

store-and-forward functions to preserve data, display

build, and so the watch industry wanted a new, differ-

operating trends following alerts and alarms and

ent type of machine with counter-spindles mounted

maintain access via cellular links if an IP connection

on three axes, so they could get better centering and

isn’t available.

alignments. Watchmakers also wanted more tools,

easier access and simple presets to switch out worn

Simpler Security? Sweet!

tools,” says Paul Cassella, applied technology manager

Of course, the dark undercurrent and persistent ques-

for Tornos Technologies US in Lombard, Illinois. “The

tion that goes with all this remote access is how to

watch industry previously used some CNCs, so we

maintain its security. One instructive solution comes

developed SwissNano with Fanuc Oi-TD CNC controls,

from Big Drum Engineering (www.bigdrum-engineering.

chucks from Rohm, vacuum parts recovery and six

com) in Edertal-Giflitz, Germany, which designs, builds,

controldesign.com

CD1411_26_34_COVERSTORY.indd 27

November 2014 Control Design

27

11/5/14 10:07 AM

installs and supports filling machines for the ice cream

and other food industries worldwide. Its machines fill

liquid products in 50-ml to 5-l containers with an output

of up to 50,000 units/hr (Figure 2). The machine builder

reports its end users are increasingly demanding continuous system availability because any downtime can

quickly lead to production and financial losses. Consequently, Big Drum views “demand-oriented maintenance” and fast troubleshooting via safe, secure remote

services as critical for keeping its users up and running.

“With the exception of the Sahara Desert, our

systems are used in almost every region of the world,”

says Andreas Itter, Big Drum’s sales and marketing

manager. “To ensure 100% availability, we’ve developed

an effective and secure remote service infrastructure.

Large customers such as Nestlé and Unilever expect us

to deliver services in accordance with total productive

maintenance (TPM), and similar demands from other

companies have also increased strongly in this area.”

JIM MONTAGUE

Big Drum has provided remote machine support

for about 10 years, constantly monitors its machines

and transmits key parameters to its headquarters,

which allows its technicians to maintain ongoing data

control. Its service department is staffed 24/7 and can

WATCHING WATCH PARTS PRODUCTION

immediately react to any machine disturbances. This

Figure 1: To monitor and service it Swiss-type lathes, Tornos uses its Tisis

machine communication system, which integrates a password-protected

web server into its machines, communicates via VPN, Internet protocol

(IP) and Wi-Fi and delivers HTML-based displays to PCs and tablets. The

builder also uses TeamServer software to access VPNs with permission,

take control of machines remotely and access CNCs to solve problems.

always-on availability typically means users need and

expect a permanent, online connection to Big Drum as a

prerequisite for better service, preventive maintenance

and higher security. All its filling machines with PLCs

from Rockwell Automation are routinely equipped with

remote service modules. The builder reports it presently

accelerated encryption with 3DES (168 bits) or AES (128,

operates more than 100 of these remote systems with

192, 256 bits) and the IP Security Protocol (IPsec). An

different end users.

integrated firewall also helps seal off Big Drum’s system

To achieve secure, online connectivity, Big Drum also

from users’ production networks, and a configurable,

employs mGuard security routers from Innominate

stateful, packet-inspecting firewall protects against

Security Technologies, a division of Phoenix Contact.

unauthorized access. Also, a dynamic packet filter scans

These switches protect IP data connections with a VPN-

for new connection attempts based on their addresses,

enabled Ethernet router and a configurable firewall with

ports of origin and destination, and it blocks any un-

dynamic packet filtering. Technicians connect to users’

wanted traffic.

plant operators via a VPN, and mGuard serves as VPN

These security measures are needed because Big

gateway, connecting the technicians to the plant net-

Drum increasingly performs needs-based maintenance

work via the Internet. These secure, broadband IP and

of devices that can wear out faster and require closer

VPN connections for online monitoring are more reliable

monitoring, such as servo motors and drives. Increased

and stable than former modem connections, and they

temperatures in these components can indicate prob-

can handle increasing data volumes and other services.

lems due to wear. If predefined tolerance values are ex-

In practice, Internet connections to Big Drum only mate-

ceeded, an automatic email warning can be sent to the

rialize when a VPN key is manually switched on.

service team, which conducts indicated inspections and

To safeguard confidentiality and authenticity,

can prevent previously unavoidable interruptions. Like-

mGuard uses cryptographic protocols and hardware28

Control Design November 2014

CD1411_26_34_COVERSTORY.indd 28

wise, its continuous, online connection also allows Big

controldesign.com

11/5/14 10:07 AM

CD1411_FPA.indd 29

11/4/14 10:55 AM

Drum’s technicians to assess and verify new equipment

performance during startups, introduce optimizations

during the warranty period and monitor deviations in

filling volume or compliance with predefined opening

and closing times of the valves or machine-specific

cycle times during the final service phase.

“Our remote services increase users’ system availability, and we’ve reduced fault-clearance times by 70%,”

says Itter. “With access to remote data, not only can

we troubleshoot faster, but we’re less expensive for our

customers due to the elimination of travel costs.”

Unusual Users

BIG DRUM

Logically, once remote support shows it can be used

securely and gains wider acceptance, all kinds of new,

nontraditional and unexpected applications want to

ALWAYS AVAILABLE—SECURELY

Figure 2: Big Drum’s ice cream filling machines, such as its

Choice Filler, can be continually monitored and serviced by

technicians and maintain 100% availability via VPN network

connections enabled by security routers, which serve as

secure, encrypted gateways and firewalls.

try it, too.

For example, VRTX Technologies (www.vrtxtech.

com) in San Antonio, Texas, uses a high-pressure flow

technique called “dynamic cavitation technology” to

clean cooling water in its users’ HVAC, refrigeration

and process cooling systems. However, as its skidbased systems multiplied worldwide, VRTX’s staff

realized it needed access to its PLCs on the skids, even

though accessing them through most customers’ IT

TM

infrastructures was often difficult. In fact, only 5% of

VRTX’s users allow them to access data about their

Modular, All-In-One, PLC + HMI

systems. After talking to several users, VRTX decided

it needed a cellular monitoring system for its water

treatment skids, which would enable it to monitor the

Now

available

with

15.6”

PLC+HMI

Panel

equipment and give users access to their data without

having to pass through IT systems.

“With direct access to our PLCs, we felt we could

monitor the operation of our systems,” says Carl Steffen,

VRTX’s engineering services manager. “We’d be able to

get alarms, see detrimental system operation and offer

better and more informed technical support.” Following

a lengthy investigation, VRTX selected Netbiter EC220

gateways and Netbiter Argos Web-based, remote monitoring systems from HMS Industrial Networks.

“The initial reason we chose the Netbiter solution was the Netbiter EC220 gateway offered RS-485

interfaces in a small, well-built device,” says Steffen.

“It also offered preprogrammed GSM cards that would

Up to 2,000 I/Os I External memory: microSD, USB Flash I Audio Support:

mp3/wave, via internal speaker or stereo audio-out jack I Ports: 2 Ethernet, 1 RS485,

1 CANbus, 2 USB host, 1 USB programming port I Environment: IP66/IP65/NEMA4X

immediately work in many of our desired countries

without the need to negotiate with local cellular carriers. Although the EC220 offered many standard I/O

connections, we initially only interfaced with our PLC

Unitronics, Inc.

1 Batterymarch Park Quincy, MA 02169 USA

Tel: 617-657-6596, Toll Free: 866-666-6033

w w w. u n i t r o n i c s . c o m

CD1411_26_34_COVERSTORY.indd 30

usa.sales@unitronics.com

via the Modbus interface.”

30

Control Design November 2014

controldesign.com

11/5/14 10:08 AM

as our technicians arrive. It also

ral gas, wind and solar, and all of

VRTX wanted to capture system

gives us insight into the operations

these have a lot more equipment in

information only once or twice per

of our systems on a minute-by-min-

critical paths and need much more

day. However, when its staff learned

ute basis, whereas, in the past, we

remote monitoring.”

they could get information more

only saw changes over long periods.”

Also, based on its long experi-

frequently, they started finding

Remote support benefits upper

ence in helping users gain insight

Steffen explains that, at first,

benefits for its customers that they

levels, as well as end-user sites,

into the health of rotating machin-

hadn’t seen before. The ability to get

and it inspires machine builders

ery and making business decisions

more frequent information also led

because it affects how they do their

to successfully implement predic-

VRTX to change some of the treat-

jobs, explains Kamalina Srikant,

tive maintenance, National Instru-

ment system’s operations, which

product manager for condition

ments recently released its NI

also led to better treatment and a

monitoring solutions at National

InsightCM Enterprise ready-to-run

more consistent product.

Instruments (www.ni.com). “Many

software with tightly integrated

engineers and technicians don’t

and flexible hardware options for

creased the value of our treatment

have to make as many trips to us-

online condition monitoring ap-

skids,” adds Steffen. “It enabled us

ers’ locations, which is changing

plications. It’s used to acquire and

to change system settings without

their thinking and showing up on

analyze measurements, generate

needing to call the customer or send

their bottom lines,” says Srikant.

alarms, visualize and manage data

out a technician. It’s also enabled

“At the same time, traditional

and results and simplify remote

us to troubleshoot failures and have

power-generation applications like

management for large deployments

the appropriate repair parts on site

coal are being joined by more natu-

of monitoring systems.

“Remote monitoring has in-

CFW500 Machinery Drives

One VFD, endless possibilities

Developed for fast commissioning, the CFW500 VFD is perfect for machines. Extremely compact and

cost-effective, it meets the needs of machine manufacturers, system integrators, panel installers and users.

g

g

g

Efficient - provides optimal speed for production

Reliable - 100% are tested with rated load at the factory

Integrable - Multiple Fieldbus networks options

Transforming energy into solutions.

CD1411_26_34_COVERSTORY.indd 31

g

g

g

Compatible - wide range of accessories

Flexible - application functions with integral PLC

Robust - 150% overload for one minute in an

ambient temperature of 50°C

www.weg.net

11/5/14 10:08 AM

REMOTE SUPPORT TO-DO LIST

Every application has its own unique characteristics and requirements, but there are some common requirements, methods and tools

that machine builders, integrators and others can use to establish

remote support, monitoring, troubleshooting and even control.

• Reexamine end users’ business performance goals; evaluate

machines, production lines and other equipment for achieving

them; and evaluate how and where report monitoring and support could help.

• Analyze existing network infrastructure, including ports, other

physical and wireless connections, communication protocols,

hardware components and software used.

• Determine if network upgrade from dial-up modems to VPN and

IP-based communications would improve remote support to end

users and establish permissions and policies for granting access.

• Coordinate deployment of remote monitoring components with

existing machines and equipment, especially to make sure remote support devices don’t affect production operations.

• Implement appropriate level of security functions in remote support devices and networks, including secure IP and VPN links, configurable firewalls, packet inspections and dynamic data filtering.

If you have not been able to

find the ideal PLC for the OEM

machines that you build, we

now make it easy for you to

create your own.

Reduce cost, product

development time/effort,

maintenance pains for future

projects with your own

SmartTILE-driven PLC.

IT’S EASIER THAN YOU THINK.

www.triplc.com/STILE_CD

Tel : 1 877 874-7527

Web : www.triplc.com/cd.htm

TRIANGLE

RESEARCH

Really Far Out Support

for the installation and spooling of

Naturally, once remote machine

flexible flowlines, umbilicals, cables,

support is established between

wire ropes and coil tubing,” says

builders and users, it’s tempting to

Brian McRitchie, electrical manager

see just how remote that support

at Aquatic’s marine workshop in

can be. Strong IP connections, VPNs

Peterhead, Scotland. “Installed on

and communication signals can go

marine vessels, this equipment can

anywhere, way beyond land-based

include anything from small ten-

shops and factories, but they’d bet-

sioners to dual-tensioner systems,

ter have stellar support.

powered reel-drive systems or a

For instance, Aquatic Engi-

fully modular carousel system with

neering & Construction (www.

built-in tensioner,” he explains. “Our

aquaticsubsea.com) in Aberdeen,

customers hire this service and ex-

Scotland, recently worked with

pect the equipment and the person-

system integrator MAC Solutions

nel that operate it to perform reli-

in Redditch, England, to improve

ably with minimal downtime. These

monitoring of its ship-based ten-

ships can be located anywhere in

sioning machines, which lay down,

the world, so if there’s an uncom-

install, transpool, recover and

mon problem with our machine, we

decommission flexible and semi-

need to resolve it quickly.”

rigid cables and other products

VPN router that Aquatic could inte-

oil and gas, telecommunications

grate with its 85Te dual-tensioner

and energy industries. Though it

system, and found MAC Solutions

strives to make its equipment reli-

and eWon’s 2005CD VPN routers

able and can resolve many issues

and Talk2M Internet-based, remote-

with a phone call, Aquatic wanted

access, support and diagnostics

to quiz its tensioners remotely and

software and service. Aquatic

reduce service engineer call-outs

installed three 2005CD routers with

to vessels.

dual local area network (LAN) and

“Aquatic provides equipment

INTERNATIONAL

32

CD1411_26_34_COVERSTORY.indd 32

McRitchie researched a suitable

on the seabed for clients in the

Control Design November 2014

modem connectivity on the 85Te,

controldesign.com

11/5/14 10:09 AM

OFFSHORE PERFORMANCE ONSHORE

and it monitors the tensioner via

to maximize their efficiency and

VSAT global, satellite-based Internet

identify any potential problems

links or 3G cellular Internet connec-

before they affect production. This

tions. Besides having an Ethernet

integrated, condition-based mainte-

port, two of the three routers also

nance system provides machinery

have SIM cards, so if a VSAT link

protection, prediction and perfor-

is unavailable, Aquatic’s engineers

mance monitoring of all critical

can access their equipment via 3G.

and essential assets, and includes

“To test and fully understand the

Emerson Process Management’s CSI

VPN router and Talk2M, we trialed

6500 machinery health monitor and

the system on one of our 50Te ten-

AMS Suite predictive maintenance

sioners in the workshop at Peter-

software, which is built on Merid-

head,” explains McRitchie. “Every-

ium’s Asset Performance Manage-

thing worked well, and if we didn’t

ment (APM) software.

understand something, the team at

STATOIL AND EMERSON

Figure 3: Statoil is implementing a $2.7-million, condition-based, performance

monitoring and maintenance system on its Gina Krog oil and gas platform in the

North Sea, so onshore personnel can monitor its pumps, compressors and other

mechanical equipment to maximize their effi ciency and identify problems

before they affect production.

These software and hardware

downs and maintain production

MAC Solutions quickly provided us

components will allow Gina Krog

while reducing maintenance costs.

with the necessary technical sup-

to deliver equipment health alerts

In addition, AMS Suite will ag-

port. With Talk2M, it’s as if the ser-

and predictive diagnostics, which

gregate all asset data to present a

vice engineer is physically onboard

will enable the platform’s staff to

clear picture of overall asset health

the ship, next to the machine or

perform corrective maintenance

and performance, so work notifica-

control cabinet, accessing the HMI

actions to avoid unplanned shut-

tions can be created and fed back

display or PLC with a laptop.”

McRitchie adds that eWon and

Talk2M give Aquatic a differentiator in the dual-tensioners it rents

to marine vessel operators. “Some

of our tensioner systems also have

cameras installed, so local opera-

Dream big in small sizes

HARTING har-flexicon®

tors can see what’s happening from

their control rooms or booths,” says

McRitchie. “Talk2M also enables me

to access this same web-camera

view. I can also screen-share with

a user to remotely instruct them

on the operational idiosyncrasies

of the systems or how to navigate

through the more isolated control

and monitoring screens.”

Likewise, Statoil (www.statoil.

com) in Stavanger, Norway, is

HARTING har-flex

har-flexicon

har

-flexicon®

1.27/2.54mm

implementing a $2.7-million condition and performance monitoring

system on its Gina Krog oil and gas

platform in the North Sea (Figure

3), which will allows its onshore

Deliver superior PCB performance with compact and robust connectivity

personnel to continuously moni-

The har-flexicon® series offers:

tor the new fixed platform’s critical

and essential pumps, compressors

and other mechanical equipment

■

■

■

■

Robust Connectivity – Ideal for rugged industrial environments

Compact Solutions - Pitches from 1.27mm and 2.54mm through 5.08mm

Easy Processing – Surface mount compatibility / Full SMT termination to PCB

Fast wire installation – Push in / IDC termination

www.HARTING-usa.com

HRT-10.2014-CD-4.625x4.875-har-flexicon®.indd 1

CD1411_26_34_COVERSTORY.indd 33

10/21/2014 1:24:12 PM

11/5/14 10:09 AM

connect to their operations data.”

to Statoil’s SAP enterprise asset

new for many machine builders

management system for immedi-

and unknown to many others,”

ate attention. The platform also

says Mariam Gallegos, product

mSC is presently supported on PCs

includes a wireless communication

marketing specialists for network

and Android devices, and will be

infrastructure based on Wire-

security at Phoenix Contact (www.

available on Apple iOS in 2015. It

lessHART (IEC 62591), which will

phoenixcontact.com). “Even those

uses IPsec security protocol and

support future enhancements to

who were connected probably had

performs high-level AES 256 en-

capture added equipment data on

remote desktops or public IP links

cryption with hashing algorithm,

the platform at less cost than wired

that weren’t very secure,” says Gal-

says Gallegos. “Remote support

communications.

legos. “Now, VPNs are tied to hubs

used to require dial-up or old-style

and servers and then go straight to

VPNs that users had to maintain,”

Forecast: Mostly Cloudy

cloud-based infrastructures, such as

explains Gallegos. “Now, we host

Beyond routine monitoring and