Standard - LearnEASY.info

advertisement

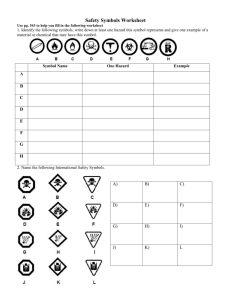

Section 7:

Feature representations - recognition

PURPOSE

This section aims to enable the student to extend their knowledge of Drawing

Interpretation from Engineering Drawings produced to AS1100 standard.

Objectives

At the end of this section you should be able to:

o

IdentifY symbols used in Engineering Drawing.

General

Electrical

Welding

Fluid power

Mechanical

•

•

•

•

•

Completion guidance

This section provide an outline of the symbols used in drawings in the objectives stated above.

It is expected all students will be able to identifY 'general drawing symbols' and those from one

of the bulleted list in the objectives. The remaining types of symbols should be covered briefly,

so that a student can recognise a drawing or sketch with symbols as being from one of the

three remaining areas.

:MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

", a:o

94

MEC076 -7-1

To be effective and competent in the reading of and interpretation of engineering drawings, it is

critical that we have a sound awareness of the names given to common features and their

function. A lot of these features are designated using abbreviations and symbols in order to

save time when producing a drawing, that is CSK - countersink or countersunk, c'bore counterbore, PCD - pitch circle diameter.

R

Diameter

050

Radius

R30

Slope and its

direction

(

)

Centre line

FL

Flat (material)

50 x 20 FL

PL

Plate (material)

10 PL

o

To indicate square

075

c:::=-

A taper and its direction

b

1.

Indicate corresponding dimensions on Section A-A

+0.1

Hole D12

0

012

.0.5

0

010 LJ012 :];10

06V012x90°

M10

012 LJ025

I::::::::,.. 1:1 0

A reference

dimension

1'

Dimension not

drawn t scale

1'

(620),1

60

V

Countersink (csk)

V03

LJ

Counter bore

(cbore)

LJ010

Depth of a

feature

~5

·1

Section A-A

2.

Fill in the missing details on the table below.

3:100

countersink

Counterbore

Spotface

o

Drill 010

Drill 010

U015 J 10

V900020

Depth offeature

40 x 10 FL

5 mm thick plate

Exercise 7-1

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

k" iI J

95

MEC076 - 7 -2

I

Block diagrams

These are simple diagrams intended to aid the understanding of the principle of operation of a

circuit or system. A block diagram on its own is of little use as it displays limited information.

Electrical symbols

Power

input

Electrical symbols are a graphical representation of a component or item to be used in a

diagram. Symbols are seen as a convenient means of representing items in a diagram as they

allow:

•

A symbol to replace the actual drawing of the item.

•

Items with similar appearances, but difft<rent functions, to be easily shown.

Power

supply

AC supply ____- I

Standard symbols in Australia comply with ISO (International Standards Organisation). They

are shown in Australian Standard 1102 (AS1102) Parts 1 to 15. Some symbols from Parts 1 to

15 are included in this workbook to assist you to identify them on a drawing. SAA HB3 - 1986

is also a useful reference.

Electrical

Regulator

Line

load

Starting

resistors

contactor

'----I Accelerating 1---1

contactor

Electrical diagrams

There are four basic types of electrical diagrams included in this workbook and used in

industry. They are:

•

•

•

•

Block diagrams

Circuit diagrams

Wiring diagrams

Architectural diagrams

' - - - - - - - 1 riming and

control

Circuit diagrams

These are detailed diagrams which should describe the operation of a circuit. Circuit diagrams

are sometimes called 'schematic diagrams'. Circuit diagrams do not necessarily represent

the actual physical layout of the equipment and wiring. Typical circuit diagrams are shown.

Competence in using electrical diagrams is essential for all electrical/electronic students. For

detailed knowledge students should complete NE31 Electrical Drawing, Interpretation and

Connection.

0

AO

The work included here is intended to provide a brief overview and some understanding of the

0

L1

T

L2

application of electrical symbols. Within this module you are expected to be able to explain

why standard symbols are used to represent components on electrical diagrams and identify

some common electrical symbols.

LP1

LP2

L3

A3

N

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

,,196iI:O

MEC076 -7 - 3

Wiring diagrams

Architectural diagrams (layout diagrams)

These are detailed diagrams showing the way in which a circuit or system is actually wired and

assembled. Components are often drawn in a simplified way in which the outline and external

These show various features related to the construction of a building. A typical diagram is

shown. They are also called 'layout or site diagrams'.

connections (terminals) are shown. All 'terminal to terminal' connections showing the

necessary conductors (wiring) required to connect the circuit are shown.

r----- ---------------------- - - --,

A

I

I

I

N

I

I

E

®

I

I

I

I

I

S1

L___

i

@

I

I

I

i

I

I

I

Bed 1

I

I

I

I

I _____ _

L

I

I

:

:

___ ,

" ,

I

___~----L---*----J

--,-

I

Wiring diagram - basic lighting circuit

Dining

I

I

I

Bed 2

I

I

I

[J51

Bed 3

I

I

I

: :

:

I

I

,

I

I

I

I

I

I

I

~---:-_®_--l---+---_®

:I

___ J

I

I

Living

I

TV

I

_...J

UJ

I

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

h", iI ill

97

I

MEC076 - 7 -4

I

Electrical/Electronic symbols

This short table has been assembled from SAA HB3 - 1986 - Electrical & Electronic Drawing

Practice for students. For detailed information students should refer to that book or parts 1

to 15 of AS 1102.

Terminal strip

Junction of

steady voltage

Mechanical coupling

General6ymbol

Negative polarity

_ -' L_

or hydraulic connection

General 6ymbol

--V--

Mechanical interlock

E---

Operated by pushing

5---

Operated by turning

I;

Fault. The same symbol

Boundary line

Discharge lamp, gas

filled

General 6ymbol

----

-<

----.........

is used on equipment to

indicate a dangerous

voltage

e)- Signal lamp

Electric bell

+

alternating current

-0-

Manually operated

General symbol

Emergency switch

Battery of

accumulators or

primary cells

Earth (ground)

11111111~

voltage should then be

indicated

~ 1-----11-

Frame or chassis

connection

Part 3 - Resistors, capacitors and inductors

/-----I I I I

Heater

(1---.

Filament lamp

Indicator

-6-

Wiring or cabling in

8

Letter symbols for

coding cables

--1~

Example of nominal

voltage in a battery

~ h----il50V

Example:

E = Electrical

power

L = Lighting

SL=Street

lighting

COM=comm-

Jm

IC

MB

MCC

MK

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

Two-conductor cable

-

Method of cable

installation

Example: Electric power

cable on wall

Fixed resistor

General symbol

I-

-l

e

Overhead line

•

- E OW

Wiring or cabling joint

D

SWitchboard,

distribution board,

frame, panel or cubicle

1

Main switchboard

Emergency lighting

luminaire

I

MSB

=

0

-l 7 / I -

Underground line

Example letter symbols for coding of boards are as follows:

CP

Control panel

CN

= Control station

DBL

= Distribution board light

DSB

= Distribution board

Conductor or group

emphasised by

increasing its

thickness

/'

Variable resistor

General symbol

unication

of conductors. A

Cable

General symbol

I-

0

conduit, pipe or duct

Part 2 - Conductors and connecting devices

line for a particular

path may be

Plug (male) or one pole

of a plug

+lorl

(male and female)

- - --

Example: tee joint

The primary symbol may

be used to indicate a

battery. The nominal

Y or '(

Socket (female) or one

pole of a socket

-'-r-

Part 8 - Symbols for location diagrams

Primary cell or

accumulator. The long

line represents the

positive pole, the short

line the negative pole

Electric buzzer

-1,-

Junction of conductors

using terminals

Plug and socket

Mechanical, pneumatic

+

P06itive polarity

either direct or

Double junction (either

used)

Conductors,

crossing without

electrical connection

Suitable for use on

Alternating current

General6ymbol

32

-0--

method shown may be

conductors

Direct current or

Terminals or tags may

be numbered as shown

0

:::: Instrument cubicle

= Meter board

:::: Motor control centre

I

I

MSB

PBS

RCP

RP

SAS

TB

TP

= Main switchboard

= Push-button station

Remote control panel

= Relay panel

= Security and alarm systems

= Terminal box

= Terminal panel

=

= Marshalling kiosk

Luminaire or 5ignal

lamp

fi " iI 'II

98

I

®

Luminaire fixed to a wall

~

Emergency lighting

luminaire

~

MEC076 - 7 -5

I

Fluorescent lumina ire

Floodlight

c:::J

Electrical appliance General symbol

Example letter symbols for coding of electrical appliances are as

follows:

AC

Air conditioner

BWU = Boiling water unit

FH

Fan heater

GDU

Garbage disposal unit

=

=

=

1--1

Contactor - N/C

contact

Example: Luminaire

with three lamps

Example: Air conditioner

On-load isolator

H

HD

R

SDU

= Heater

= Hand dryer

= Range

= Sanitary disposal unit

fuse switch

Alternative

3x4OW

1-+-1

Two-way switch

Socket outlet

General symbol

Antenna (aerial).

General symbol

Television receivingJ

set

Lig hting outlet position

e.g. batten holder

Dimmer switch

~

Socket outlet for

telecommunications

X

t

~

r

Loudspeaker

oj

[0]

Microphone

0-

Electric buzzer

y

Horn

Generating station,

planned

D

Equipped wall telephone

outlet

:::n=='>

One way switches,

single-pole and twopole

lei

Push-button switch

©

r

~

,

Circuit breaker

Limit switch, make

contact

Manually-operated

switch

General symbol

~

~

I

I--~

Isolator

Fuse

Push-button SWitch,

(non-latching)

~

~

I

E--~

Example: Television

Radio receiving set

Electric bell

Clock

~

Part 11: Switching and protective devices

Make contact

Make contact early

to operate

Make contact

without spring

return (stay put)

~

~

~

MEC076 Engineering Drawing Interpretation 1

Resource Package

December. 1998

Break contact

Make contact late to

operate

Switch

General symbol

r

~

~

Changeover contact

Make contact with

spring return

Contactor - N/O

contact

~

~

~

, "it:O

99

MEC076 -7 - 6

Exercise 7-2

5.

IdentiiY and complete the table showing the symbols used on the diagram.

IdentiiY and complete the questions and statements

1.

--tl

power _ _

input

•

2.

,----- ---------------------- -

What type of diagram is this?

~

I

,---'===1

Power

supply

- --,

II

0

I

I

i

I

I

What type of diagram is this?

__ ~.,

1

1L __ _ .

CP

:I

:I

t

I

-.I

I

I

I

I

:

:

:

I

I

I

I

I

I

I

I

I

I

I

I

I

L---:--®---,---+----0

,

,

I

I

LP2

DI

F=rr~~·----~----L---1f----J

I

LPl

II

, I

AO>-----T----,

N~------

-

' :

____ .1

1

I

\D=====~7===~~====~~~~~==3E===c~~

L______

_________________________

__------~

I

_~

3.

IdentiiY these symbols used in the above diagram.

I

f~

4.

A

0--

Luminaire

How many are

required?

IdentiiY the symbols listed below from the supplied diagram.

O~----L~;~

~>----..~

L2

I

TOL

L5~

One way switch single

pole

o

A2

O-+-~~L~3~rA3~~~~

Luminaire fixed to a wall

How many are required?

-y ------------

P",,,h button switch

Socket outlet for

television

I

I

E---\

---------i~

Circuit diagram - motor starter

MEC076 Engineering Drawing Interpretation I

Resource Package

December. 1998

",ilj

100

I

MEC076-7-7

I

Application of welding symbols

Symbolic representation of weld positions

Drawings showing weld positions as a picture.

Note:

II

I

Il

I

Each symbol should be used only once on a real drawing not repeated on views.

(Three possible positions shown)

I

~

g

I

~

I

~

"

f'.

v

v

4

I

I

~

(Two possible positions shown)

/I

I

I

(~:t1:t1~~

I

/~

I

I

-

t>

I

l

1'I1l'1l"'!"'lIIl

I

!

I

I

I

I' !

I

I

I' !

I

I

MEC076 Engineering Drawing Interpretation 1

Resource Package

December. 1998

\

-

"

,..--...

v

( Two possible positions fO~

each weld symbol shown

~

I

~s

t

I

I

I

!

I

I

'-

'-

I

'-

~

I

[7

[7

I

/

v

~

v

(Correct application of symbols)

,,1 it:o

102

MEC076 -7 - 9

Welding Symbols

Welding symbols on drawings are shown in:

AS1101 - Graphical Symbols for General Engineering - Part 3 Welding and Non Destructive Examination.

Students should refer to the standard for more detailed information.

Welds - Fillet

Elements of a weld symbol

The symbol

The arrow

Type of weld

Sketch of weld

Examg-

The line

Symbol

Example

/

/

This is a reference line drawn parrallel

to the base line of a particular view. The

position of the symbol above or beneath this

line determines the location of the weld.

Fillet

The arrow pOints to the position of

the welded jOint.

Location of weld symbols

Symbol above the line weld

joint opposite side to arrow.

/

Sketch of weld

Indication on

drawing

Symbol beneath the line

weld joint, the same side

as the arrow.

Indication on

drawing

MEC076 Engineering Drawing Interpretation 1

Resource Package

December. 1998

r

Weld all round

Symbol beneath the line

Weld

both

sides

Sketch of weld

The symbol

To be welded on site

or

site weld.

Sketch of weld

Indication on

drawing

Supplementary symbols

~

~

h"

Combination of site weld

and weld all round.

it:n

Symbol

r

Indication on

drawing

Indication on

drawing

~

101

Indication on

drawing

Symbol

0

Sketch of weld

Sketch of weld

Symbol above the line

v

I

MEC076 - 7 - 8

Exercise 7 - 3,"

identify and complete the following table of symbols taken from drawing 02 -MF1 - MY82

Sheet MEC076 - 7 - 11

~

/

~

~

Fillet weld size 6mm both sides of the web

C3

~

/

C3

C3

~3V

C3

Fillet weld size 6mm both sides of the web

C5

UNO

D2

M,S,

D5

@.Ej

A1

I

<&1fVA

B5

0

B4

Radius 35

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

B3

6,1;':0

103

MEC076 - 7 - 10

I

Page 104

MEC076 - 7 - 11

I

1

I

2

r

; -03 oil hole

I

/

,I

'-41-"

I

I

A

2 -

(B-

\

I

Ii

I

I

I

I

I

I

I

I

I

I

5

4

6

DO NOT SCALE

ALL DIMENSIONS IN MILLIMETRES

.012-4 holes

,

(®'

1

I :I:

,

3

,_

\

,

,

I

',.'

A

--------,+-----+-;--------- --

-

--'----+-

/~,-'

'.

,

,

\

!

'

'"

'I'

"

,I,,

"

t

!

I

',.'

80

/--A

B

B

R35

-L

3

~

1 ' / / /, / /

,

I,

.,.-------- - - - f-- - - ,

f-j-

. - - - - - _1, ____ _

-

I

I

2

V///I////

~!

I

~

C

/

a

!~

,I

L

;I,,

!

l '

I:I.

c

,I

3V

tyP

I

l '

PARTS liST

1

: I ,, ,

I

'140

!200

.1

I ...

A

All welds 6mm fillet UNO

o

r--T--~r-_r-----------T_-~~~ UNLESS

NOTED OTHERWISE

TOLERANCES ARE:

LINEAR:

A

ISSUE

FIRST ISSUE

7/3/98

DATE

ZONE

1

CHANGE

AMENDMENTS

I

ECN

2

LZ

BB

BY

CKD

I

±O.5

3

ROUND BAR

.025x6

MS

4

MINOR WEBS

7Ox8x56

MS

3

ROUND BAR

.06Ox80

MS

2

MAIN WEB

20Ox8x135

MS

1

BASE PLATE

20Ox10x120

MS

ITEM

I-C:-:HE-:-:C.,,-KE.,,-D,----,:J,::B--lTITLE

APPROVED

BB

ISSUED

7 - 3 - 98

RECORD OF ISSUE

MATERIAL:

M.s.

FINISH

UNO

10/

DESCRIPTION

SIZE

MATL

MANUFACTURING AND ENGINEERING

FDI Jr:ATlnNAL SERVIr:ES DIVISION

@-ct-

ANGULAR: ±O" - 30'

DRAWING PRACTICE

AS 1100

5

A

4

SCALE

1:2

SHAFT SUPPORT BEARING

SIZE DRG N°

A3

5

02 - MF 1 -- MY 98

I

6

SHT

1 OF 1

0

Fluid power symbols

Crossing lines NOT

CONNECTED

(no dot at the

intersection of the

Fluid power symbols are standardised in:

AS1101 • Graphic Symbols for General Engineering Part1 • Hydraulic and Pneumatic Systems

Fluid power is the umbrella term for both hydraulic and pneumatic systems.

lines)

Atmospheric reservoir

LJ

Header line

y

being shown. They also normally show a return to an external reservoir. L.J

C>- being

Pressure gauge

Fluid flow symbols

Heat engine (internal

combustion engine)

-I>

Hydraulic

2/2

2 ports/2 positions

Outlet pneumatic

U

EJ

Uni-directional hydraulic

pump

Mechanical connection

0

Electric motor

5/2

5 ports/2 pOSitions

0

4/3 4 ports/3 pOSitions

with a float centre

--

5/3 5 ports/3

positions with a closed

Flow generator symbols examples

U==0

Power supply

Line ending below the fluid

level

L1

~

Line ending above the

fluid level

~

cp

Temperature gauge

Flowmeter

-0-

3/2

3 ports/2 positions

[ nXI

Directional control valves

Flow generator symbols

Un i-directional

compressor

(pneumatic)

+

Gauge symbols

shown. They also normally show a return to an exhaustport.!>

Pneumatic

--v-

Hydraulic and Pneumatic

Fluid storage unit symbols

In most cases hydraulic circuits can be identified by the simplified general symbol ~

Pneumatic circuits can usually be identified by the simplified general symbol

+

CrOSSing lines not

connected

(the arc does not

indicate a flexible line)

~

IIlil

I~lllirl

[TIHXI

3/2

3 ports/2 positions

lGGSJ

[ n:;;lxl

4/3 4 ports/3 positions

with a closed centre

II n~lxl

4/3 4 ports/3 positions

with a tandem centre

4/34 ports/3 positions

with a open centre

5/35 ports/3 positions

with

I:;;IHXI

l~lllIllllrl

a float centre

Il\Uhmll

centre

C)===EJ

Manual actuation methods

General manual

8

operation

1=

(j=

Push button operation

Lever operation

=f

Fluid conductor symbols

Working line (feed &

return lines)

Flexible working line (a

pilot or drain flexible

line could also be

drawn)

Drain line (short dashes)

Pilot line (long dashes)

A teed connection (the

dot at the join indicates

the connection)

A croGsed connection

(the dot at the join

indicates the crossed

connection)

+

Air service unit symbols

Detailed symbol

,._._._.-.-.

~Q,

'YIA:

i. /!'-.

:,

!.

~

!

MEC076 Engineering Drawing Interpretation I

Resource Package

December. 1998

", it:o

105

L•• J

Simplified symbol

I

MEC076 -7

-121

Examples of pneumatic circuits

Shut-off valve

-I><J-wr<:)-

Spring loaded check

Basic check (non-return

valve)

¢§t

Shuttle valve

~---.

Pilot pressure te close

check (non-return valve)

Pilot pressure te Open

check (non-return valve)

--c)Pneumatic circuit

~---.

Pressure control valve actuation methods

1+

I

Actuator symbols

Single acting load or gravity

return pisten type cylinder

Single action spring return

pisten type cylinder

Double acting pisten type

cylinder

Single acting load or return

ram type cylinder

Double acting ram type

cylinder

Hydraulic mater

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

Pneumatic motor

Meter-out

Exhaust throttle

-0-

-0-

h..,ilJ

106

MEC076 - 7 - 13

Examples of hydraulic circuits

Exercise 7-4

Identify and complete the following questions and statements.

Hydraulic circuit

1.

What type of circuit is this?

2.

What type of circuit is this?

taken from the circuits shown in this section.

+1I----11 I 1

Lever operation

Push button operation

Ii\illli

Atmospheric reservoir

Bleed off

Meter out

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

Meter in

[ TIiilXI

" , ;tj

107

I

MEC076 - 7 - 14

I

Mechanical symbols

Mechanical symbols are featured in this art of the section. For more detailed information, students should refer to AS1100 - Part 201 - Mechanical Drawing.

Physical features

Tap

s:

a

~

s:

The cutting tool used to produce internal

screw threads

Blind hole

Through hole

Drill

A hole which is partly drilled through an

object.

To make a cylindrical hole with a cutting tool

called a twist drill.

A hole drilled through the entire thickness of

an object.

i5

D

Twist

drill

~M10tap

Drill.010

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

i

"it:a

108

MEC076 - 7 - 15

Physical features

fitch circle diameter

The diameter of a circle centre line on which

holes or other features are located.

Pitch circle

diameter

Clearance

Web

Spotface

A thin flat member acting as a brace or

support. It increases strength without

greatly increasing weight.

A circular machined area around a hole at

right angles to the axis of the hole.

Spotface

8 holes

On 150 PCD

That space provided between parts or a

mechanical assembly to ensure easy

separation of the parts.

12

Drillf212

Uf2 20:r:1

I

I

I

I

I

I

I

..L-

B------1

SectB-B

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

i" i!:O

109

-

Clearance not shown

unless excessive

Front view

I

MEC076 - 7 - 16

I

Physical features

Spigot

A protruding cylinder or plug which fits into a

mating hole so that parts can be fitted

together.

Shaft

Taper

Spoke

1.

2.

Anyone of the bars which connect the rim

and hub of a wheel.

An incline plane surface.

The conical form given to a pin or shaft

(like the end of a pencil) or hole.

A cylindrical p'iece of metal used to carry

rotating machine parts such as pulleys or

gears, to transmit power or motion.

Spoke

Inclined plane

Spigot

Pin 15haft

1~

Rim

--=_

L.-_ _ _

1: 4

f!l20

E::::=-h

Inclined plane

Top view

Front

view_--------l

Pin I shaft

Front view

I

Spoke

Front view

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

h" iI ill

110

I

MEC076 - 7 - 17

I

Physical features

Boss

Pad

Bush

Rivet

A hollow cylindrical lining inserted in a hole in

machinery to act as a bearing for a shaft or

spindle.

A cylindrical rod of soft metal with one head

formed when manufactured. A head is

formed on the other end after the rivet has

been inserted in the drilled or punched hole of

mating parts

A slight irregular shaped projection above

the surrounding surface of a casting or

forging, usually to provide a bearing surface.

A cylindrical projection on a casting or

forging which provides extra thickness for

tapping, or a seat for the head of a bolt or

screw.

Bush

Pad

Rivet

n

05 Rnd Hd rivet

5.1 I.

32

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

.1

0151H

I

R3

020

k"

it:o

III

I

MEC076 - 7 - 18

I

Physical features

Radius

An external rounded corner formed to enable

better fits between parts and to reduce risk

of injury.

Eccentric

Stepped

The position of a shaft whose axis does not

coincide with the position of the axis of the

main part of the shaft (off-centre).

Having increases in height or diameter

shaped like steps.

Shoulder

A raised section of a shaft or surface which

prevents movement along the surface or

permits bearing against.

'-',,_ _---,Shoulder

Stepped

block -shaft

-&---B---i-,------ +---\-----

+----15

MEC076 Engineering Drawing Interpretation 1

Resource Package

December. 1998

hl1i1J

112

MEC076 -7 -19[

Physical features

Collar

Chamfer

Recess

Fillet

<:

o

~

<:

i5

A circular flange or ring secured on a shaft to A flat surface cut on the intersection of two

prevent sliding.

surfaces usually cut at 45°.

The mating hole into which a spigot fits.

An internal rounded intersection of two

surfaces which prevents the forming of

weakness planes in castings or forgings.

D

Recess

Chamfer

,.--_ _'""'\.I

060

I'

050

12 x 45 °

R5

030

f\..iEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

k " iiI:O

113

I MEC076 - 7 - 20 I

Physical features

Setscrew

Key

Jig

Key:

s::

a

:es::

~

D

A headed fastener usually screwed along its

complete length and screwed into a tapped

hole rather thanoa nut, for the purpose of

locking or setting.

A holding device that holds work and guides

the cutting tool during a machining

operation.

Keyseat:

Keyway:

Keyway

Split lug

Keyseat

A small piece of metal fitted axially

partly in hub and shaft to prevent

rotation.

The slot in a shaft into which the key is

fitted.

A slot in the hub or portion surrounding

a shaft to receive a key.

A lug usually projecting from a boss or hub both of

which are sawn tnrough to produce a clamping effect

when the lugs are clamped together.

Key~

Split Iug,.......:::::::==;:::::-...

Drill jig

M12 x 1.

setscrew

Locknut

~ -1--4I

_

~

_

RJ30

06.10

06.05

<:II

s::

III

OJ

a

~

-e

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

I

I

-

I

I

I

I

I

I

I

I

RJll

....! _ c

I

I

I

I

III

R15

I

I

.s::

o

I

I

I

I

I

I

I

I

1____________ _

R10

fit'U)

114

I

MEC076 - 7 - 21

I

Physical features

Dovetail

Knurl

A wedge-like section which slides in a slot of

the same shape preventing lift.

Dowel pin

To impress a pattern of dents or lines in a

turned surface to provide a better grid.

A cylindrical pin partly located in each of two

contacting surfaces to prevent sliding

between the surfaces.

Fillet runout

A line of intersection formed by the junction

of a fillet and another fillet.

Fillet

run out

Dovetail

slides

Dowel pin

Knurling tool

Lathe chuck

r-.025

n

----~----

med kn uri

60°

I

IV

V

1---

Drill 011.5, ream 012

for 012 dowel

-~---

R6

typ

50

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

i ,'iI)

115

I MEC076-7-22I

Metric screw threads

Drawing proportions for metric hexagon bolts, screws, nuts and washers

ISO

COARSE PITCH SERIES

PREFERRED SIZES

-6--3----~-0_--

Designation

(dia in mm)

I

External

M1,6

M2

M2,5

M3

M4

M5

M6

M8

MlO

M12

M14

M16

M20

M24

M30

M36

M42

D~

EB--F--+

Hexagon

bolt

Pitch

(mm)

Lentlth

D

$A

0,35

0,4

0,45

0,5

0,7

0,8

1

1,25

1, 5

1,75

2

2

2,5

3

3,5

4

4,5

BE

- - ~-L i - - - - -

..L.

:y

J

A

1.70£1

c

B

.5A

E

1.5£1

,

G

F

D

.7£1

'---- Bolt dia (0)

{I~

-® Q--fi

Q JKL

to

--g--l--l

G

F

C

Bolt

dia

rl

H

K.5£1

J

2£1+

.8£1

+

rJL

L

2£1

N

£1+1

P

6

M5

10

5

5

4

8

1

16

3

4

3

10

6

1

M6

12

6

6

5

9

1

18

4

5

3

12

7

1

M8

14

7

8

6

12

1

22

5

6

4

16

9

1

M10

18

9

10

7

15

1

26

5

7

5

20

11

1

Specifications

M12

20

10

12

8

18

1

30

6

8

6

24

13

1

For general purposes in engineering the coarse thread series should be used. The thread is

identified by the letter 'M' followed by the thread diameter in millimetres. The pitch of the

thread and the length of the thread are only shown in special cases. Where critical control of

the thread form is required a tolerance should be specified.

M14

24

12

14

10

21

2

34

7

10

7

28

15

2

M16

28

14

16

12

24

2

38

8

11

8

32

17

2

M20

34

17

20

14

30

2

46

9

13

10

40

21

2

M24

42

21

24

17

36

2

54

11

16

12

48

25

2

ES6cntial-

10mm nominal diameter thread

· h f h

d

P ItC 0 t rea

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

_

J

T

f

See bolt drawing

M10 x 1.5 x length x tOler~ecial only)

Not required if ISO

coarse thread used

Examples:

eg: 6H internal

6

t

I

g ex erna

Ml0'25~

(Simple sizing)

""B

116

.

."M"".lO'6H

(Tolerance sizing)

I

MEC076 -7 - 23

1

2.

Exercise 7-5

What does fCD mean? _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ __

Complete the following questions and statements.

8 holes M10

On 150 peD

1.

Identify by description the hole types shown.

@E--3

;0.1

Hole D12

.012

0

.012 J10

.012 LJ.025

,0.5

0

.010 LJ.012 J10

M10

.06 v.012 x 90°

Pictorial

--&r--

3.

Orthogonal

Identify and name the part marked by the arrow A.

B---l

II

A

12

A

~

/

Hole 1

Hole2

-

Hole 3

Sect B-B

Hole4

Front view

Hole 5

Hole 6

Hole7

MEC076 Engineering Drawing Interpretation 1

Resource Package

December, 1998

5 '1 iii J

117

! MEC076-7-24!