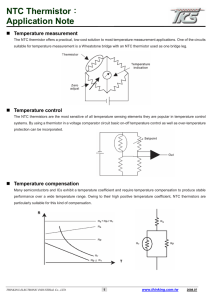

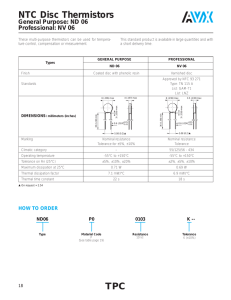

AVX TPC Thermistors NTC

advertisement