Spectra Temperature Sense

advertisement

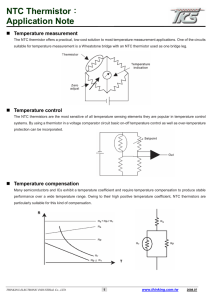

Application Note 2 Spectra Temperature Sense Introduction Spectra LED Driver is an Intelligent LED Driver Designed for Colour Mixing Applications. This Application Note “AN2_Spectra Temperature Sense” provides technical information useful to realize an efficient and cost effective Over Temperature Protection of the LED Board driven by Spectra. Spectra has four independent output channels; the Driver integrates the Device Over Temperature protection. Moreover, besides this built-in Thermal Protection, Spectra includes dedicated inputs to realize LEDs Over Temperature protection, as explained in this document. It is possible to protect each channel separately by realizing a thermal feedback for each channel. In this way each string of LEDs of the same color (usually connected to the same channel) is protected against Over Temperature that may occur due to abnormal operating conditions. The Thermal protection described in this Application Note is simply to be realized; basically it consists in adopting a Negative Temperature Coefficient sensor (NTC) for the channel we intend to protect. Nevertheless if this protection is not possible or not necessary to be adopted, please consider that each Spectra Channel includes an internal pull up, therefore if no connection is made to the Temperature Sense Input, the Driver operates at the nominal set point and the LED’s temperature does not influence the output current. Number of Temperature Sensors to adopt and NTC Master function This section explains which is the right number of thermal feedbacks to realize depending on the final application characteristics. All Spectra models have 4 dedicated inputs for connecting Thermal Sensors. So it is possible to protect each channel independently by adopting one Negative Temperature Coefficient sensor (NTC) for each channel, as showed in the Figures 1 and 2. In color Mixing Applications, LEDs with the same colour are connected to the same Output Channel. For example one of the possible choices could be Red LEDs connected to Channel 1, Green LEDs connected to Channel 2, Blue LEDs connected to Channel 3 and White LEDs connected to Channel 4. If LEDs of the same colour are mounted on the same LED Board, then it is possible to monitorize the Temperature of each channel, by measuring the Temperature of the respective PCB. In this case each channel can be protected independently by adopting 4 NTCs, one for each channel as showed in the figures 1 (Boxed Models) and 2 (Open Frame Model). In case there are one or more channels that do not require the LED Over Temperature protection, their Temperature Sense inputs can be left open (not connected). Application Note 2 Spectra Temperature Sense CHANNEL 1 LEDn .....LED1 NTC1 CHANNEL 4 LEDn .....LED1 NTC4 Temp. Sense CH1 Temp. Sense CH2 Temp. Sense CH3 Temp. Sense CH4 Figure 1: Output Wiring (Boxed Models RSPT190-BWOD and RSPT190-BWD) by 1 NTC for each channel CHANNEL 1 LEDn .....LED1 NTC1 CHANNEL 4 LEDn ....LED1 NTC4 Temp. Sense CH1 Temp. Sense CH2 (NTC2) Temp. Sense CH3 (NTC3) Temp. Sense CH4 (NTC4) Figure 2: Output Wiring (Open Frame Model RSPT190-OPEN) by using 1 NTC for each channel In some cases the monitoring of the temperature of each channel is not possible; this is the case when LEDs of various colors are mounted in the same LED Board or when each LED is a multicolor device itself; in these cases thanks to the NTC Master function, the use of only 1 NTC is enough; the thermistor is adopted to measure the LED Board Temperature and it works as reference for all channels. With the NTC Master Function, in LEDs Over Temperature Condition, the current reduction is applied in the same way to all output channels (CH1, CH2, CH3, CH4). Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 2/9 Application Note 2 Spectra Temperature Sense To activate the “NTC Master” function it is necessary to set “NTC Master=ON” using the Spectra display, within the Settings menu (See also Appl. Note 3 ”AN3_Spectra Display & Keypad”). When only 1 NTC is mounted on the LED Board and the NTC Master function is selected, the thermistor has to be connected to the Channel 1 Temperature Sense Input; all Temp. Sense inputs of the other channels (CH2, CH3, CH4) have to be left open (not connected), as showed in the figures 3 and 4. CHANNEL 4 LEDn .....LED1 CHANNEL 1 LEDn .....LED1 NTC1 Temp. Sense CH1 Temp. Sense CH2 (NOT Connected) Temp. Sense CH3 (NOT Connected) Temp. Sense CH4 (NOT Connected) Figure 3: Output Wiring (Boxed Models RSPT190-BWOD and RSPT190-BWD), by using 1 NTC (NTC Master function) CHANNEL 4 LEDn ....LED1 CHANNEL 1 LEDn .....LED1 NTC1 Temp. Sense CH1 Temp. Sense CH2 (NOT Connected) Temp. Sense CH3 (NOT Connected) Temp. Sense CH4 (NOT Connected) Figure 4: Output Wiring (Open Frame Model RSPT190-OPEN), by using 1 NTC (NTC Master function) Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 3/9 Application Note 2 Spectra Temperature Sense SMD e non-SMD NTC Thermistors There are many thermistors with various technologies/case size available in the market and produced by several manufacturers (Epcos, Vishay, Murata, AVX and others). Thanks to Spectra design a Negative Temperature Coefficient (NTC) thermistor can be used to reduce the output current in case of LED Board Over Temperature Condition. The most common NTCs used in LED Lighting are SMD devices (see Figure 5). This kind of NTC can be quickly mounted during the SMD assembling phase and it is available with different sizes (0805, 1206, 0603 and others). Of course if LEDs are placed into the LED Board through the SMD process (e.g. LEDs produced by Lumileds, CREE, Osram, Seoul, Nichia etc.), then the right choice for the NTC is a SMD Thermal Sensor. Figure 5: SMD NTC thermistor Figure 6: Ring lug NTC thermistor Nevertheless some LEDs (e.g. Multichip LEDs) produced by Manufactures like Bridgelux, Citizen, Xicato etc. , are designed to be mounted directly on the heatsink fixing them by the use of screws. In this case the SMD assembling phase is not present in the LED Board production process and a LUG NTC (see Figure 6) can be easily adopted because it is equipped with a probe easy to be assembled on the LED’s heatsink by using a screw. For best performance, the NTC sensing thermistor should be located close to LEDs or in the hot spot of the LED Board, if any. Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 4/9 Application Note 2 Spectra Temperature Sense Current reduction versus the resistance value When the temperature increases over a certain limit, the NTC mounted on the LED Board measures the Temperature of the mounting surface (PCB or heatsink) and the Temperature Sense feature allows to reduce the output current of the Driver. The following graph shows the relationship between the resistance connected to the Temperature Sense input and the corresponding reduction in the output current. Figure 7: Output Current (%) along Thermistor Resistance Value, (NTC Value set to 10kOhm) The diagram represented in the Figure 7 is valid provided that the NTC Value set through the display is 10kOhm (Settings menu, submenu NTC Value setting); please note that other NTC value options settable by the display are factory reserved. For the display use see also the Appl. Note 3 “AN3_Spectra Display & Keypad”. At normal operating condition (where NTC’s resistor is more than 3.5 kΩ), the temperature sense input has no effect on the driver output current. This means that the Output Current is equal to the Current Set (Iout=100%Iset). As the temperature rises determining a NTC resistor value below 3.5 k Ω, the output current of the driver begins to drop resulting in a reduction in the temperature at the LEDs. In this graphic the current reduction is exclusively due to the Over Temperature Condition and the effect of the Dimming is NOT considered (Dimming=100%), to avoid to mix the two different current reduction causes. When the current is reduced due to LED Board Over Temperature condition, many factors, predominately the thermal impedance of the LED heatsink, play a role in determining the ultimate thermal equalization. According to Figure 7, when the Over Temperature Condition is removed, the Output current comes back gradually to its original Value (Iout=100% Iset). Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 5/9 Application Note 2 Spectra Temperature Sense Current Reduction examples with and without the NTC Master function As explained in the section “Number of Temperature Sensors to adopt and NTC Master function”, in case of using only 1 NTC through the NTC Master function, Spectra will manage all the Output Channels according only to the Temperature Measured by the NTC1. Here below there are 2 examples of current reduction due to Over Temperature Condition, with and without the NTC Master function. Example 1 (with the NTC Master function): Let us assume that the Output Current values are set to I1=350mA, I2=500mA, I3=750mA, I4=1000mA ; if due to temperature increasing the resistance of the NTC is 2500 Ohm, according to the Figure 7, Spectra will reduce the output current values to 78% of the initial values. In this case, thanks to the NTC Master Function, the reduction will effect all current values in the same way, as showed in the Table 1. Parameter Only one NTC connected, with NTC Master function (NTC Master = ON) Normal Operating Condition Over Temperature Condition R > 3500 Ω = 2500 Ω Absent (Iout=100% Iset) I1 set = 350 mA I2 set = 500 mA I3 set = 750 mA I4 set = 1000 mA Iout= 78% Iset for all channels I1 Over Temp= 78% I1set = 273mA I2 Over Temp= 78% I2 set = 390mA I3 Over Temp= 78% I3 set = 585mA I4 Over Temp= 78% I4 set = 780mA NTC1 Current Reduction Ioutput CH1 Ioutput CH2 Ioutput CH3 Ioutput CH4 Table 1: Current Reduction due to Over Temperature Condition, with NTC Master function Example 2 (without the NTC Master function): Let us assume now that we use 4 NTCs, one for each output channels (so the NTC master function is OFF); in this case each output channels current is reduced independently, according to the temperature measured by each channel Temp Sense. If the Output Current values are set to I1set=I2 set=I3 set=I4 set=1000mA and if due to temperature increasing the resistance of the NTCs are the values written in the Table 2, Spectra will adjust the output current values independently for each channel as shown below. Parameter R NTC1 R NTC2 R NTC3 R NTC4 Current Reduction Four NTCs connected (NTC Master = OFF) Normal Operating Condition Over Temperature Condition > 3500 Ω = 4000 Ω (See Note 1) > 3500 Ω = 3000 Ω > 3500 Ω = 2500 Ω > 3500 Ω = 2000 Ω According to the Resistor (Temperature) of the Absent (Iout=100% Iset) NTC of each channel Ioutput CH1 I1 set = 1000 mA I1 Over Temp= 100% I1 set = 1000mA (See Note 1) Ioutput CH2 I2 set = 1000 mA I2 Over Temp= 90% I2 set = 900mA Ioutput CH3 I3 set = 1000 mA I3 Over Temp= 78% I3 set = 780mA Ioutput CH4 I4 set = 1000 mA I4 Over Temp= 65% I4 set = 650mA Note 1: in this case the Channel 1 is still working in normal condition and all the others Channels are in Over Temperature Condition Table 2: Current Reduction due to Over Temperature Condition, without NTC Master Function Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 6/9 Application Note 2 Spectra Temperature Sense NTC selection Figure 7 shows that the Output Current reduction starts when the Resistor measured by Spectra is around 3.5 kΩ. This is the key parameter to take in consideration to choose the more appropriate NTC to realize the required Current Reduction behavior. For example if the Current Reduction has to start from around 80°C, a NTC with 3.5kΩ @ 80°C has to be chosen. Here below you can find some examples that use SMD NTC devices produced by Epcos; of course Epcos Codes mentioned are only for a design reference. In fact different Epcos codes or NTC produced by other manufacturers can be used and the diagram of the Current Reduction Vs Temperature (see Figures 8 and 9) is always obtained starting form the Figure 7 and considering the R(T) characteristic of the chosen thermistor. Spectra design produces a knee in the output current regulation at approximately 50°C when it operates with the Epcos Code B57421V2103J062 (10 kΩ @ 25°C) as showed in Figure 8. At temperatures less than 50°C, the temperature sense input has no effect on the driver output current; as the temperature rises above 50°C, the output current of the driver begins to drop resulting in a reduction in the temperature at the LED. Figure 8: Output Current (%) along Temperature The graphic represented in the Figure 8 refers to the current reduction caused only by the LED Over Temperature protection. The effect of the current reduction due to dimming is excluded (Dimming=100%). Of course the changing of the nominal value of the NTC @25°C (typically this parameter is indicated as R25 in the NTC datasheets) generates a different current reduction behavior in particular with a different derating starting point (knee). The following section clears up how to do it. Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 7/9 Application Note 2 Spectra Temperature Sense Changing the Current Reduction behaviour by using a different NTC If a current reduction with a different knee is required, it can be easily obtained by choosing a NTC with a different nominal resistance value @ 25° C (R25) The graph of Figure 7 can be used to determine the required resistance characteristics of alternate NTC resistors; the general rule that comes from it is that if a knee at lower temperature is required, then the resistance value @25°C has to be reduced, whereas if a knee with a higher temperature is admitted then the R25 value has to be increased. For example the Figure 9 shows the different curves depending on different NTC used. Starting from the NTC used in the Figure 8 (B57421V2103J062 (10 kΩ @ 25°C), if a higher PCB temperature is admitted, a NTC with higher R25 has to be used. For example, the Epcos NTC code B57471V2223J062 (22 kΩ @25°C) produces a curve with a knee at around 68°C; the device code B57471V2333J062 (33 kΩ @25°C) produces a curve with a knee at around 79°C and so on, as showed in the Figure 9 below. Figure 9: Output Current (%) along Temperature, by using different NTC Thermistors (Epcos) Generally moving from one code to another to change the R25 value, the size case of the NTC can remain the same (in this case a 0805 size has been selected), so that the LED Board layout is not required to be modified. The graphics showed in the Figure 9 refer to the current reduction caused only by the LED Over Temperature protection. The effect of the current reduction due to dimming is excluded (Dimming=100%). Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 8/9 Application Note 2 Spectra Temperature Sense All the examples mentioned above use Surface-mount NTC thermistors (Epcos, Series B574**V2). Alternatively, Epcos offers a similar thermistors (Series B57703M), specifically designed for Surface temperature measurement, e.g. on housings and heat sinks, with a probe assembly (see Figure 6), useful to measure the temperature close to LEDs in non-SMD applications. The method explained above that allows to obtain the Current Reduction Vs Temperature diagram (see Figures 8 and 9) is valid regardless of the NTC used. Roal Electronics, S.p.A. may change product specifications and accordingly the information presented in this document. Customers are responsible for their products and applications using Roal Electronics, S.p.A. products. Roal Electronics, S.p.A. assumes no liability from the use of its products outside of specifications. No license is granted to any intellectual property rights by this document. ROAL ELECTRONICS, S.P.A. DISCLAIMS ALL REPRESENTATIONS AND WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF NONINFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Eu and RoW ROAL Electronics S.p.A Via Jesina 56/A 60022 – Castelfidardo (AN) - Italy Tel:+39 071 721461 Fax:+ 39 071 72146 480 North America www.roallivingenergy.com ROAL Electronics USA, Inc. 701, Main St. Suite 405 Stroudsburg, PA18360 Phone: + 1 570 421 5750 Fax: +1 570 421 5687 Rev. 00 – 28 Sept.2010 - Pag. 9/9