Specification E-649

Feb. 10, 2009

Page 13 of 18

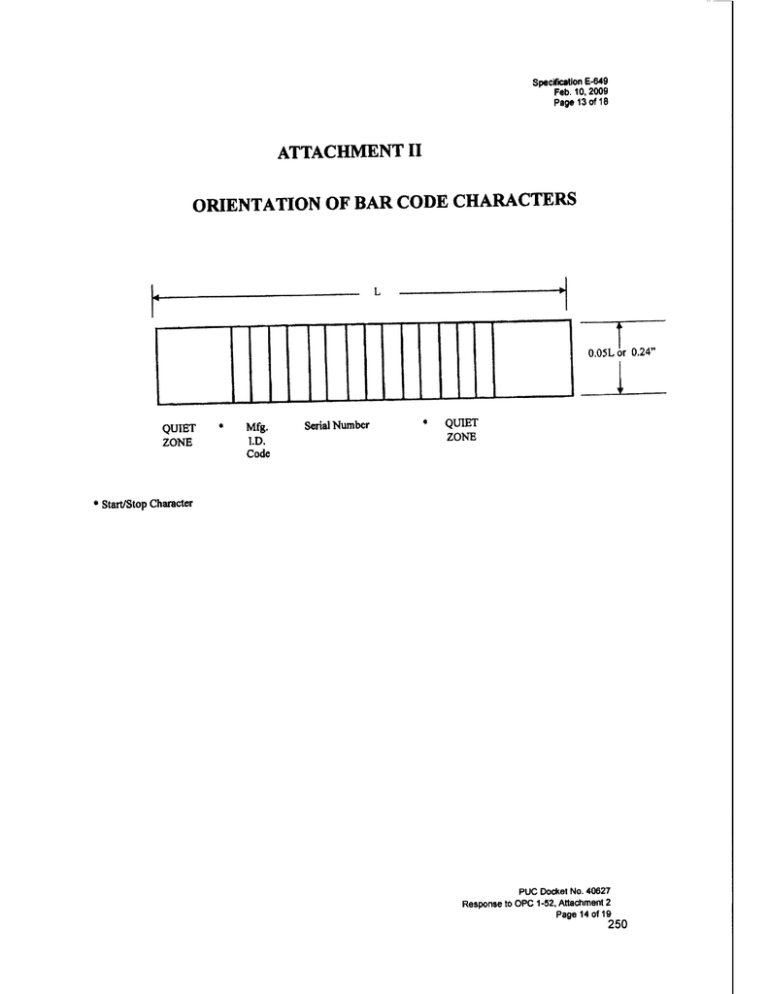

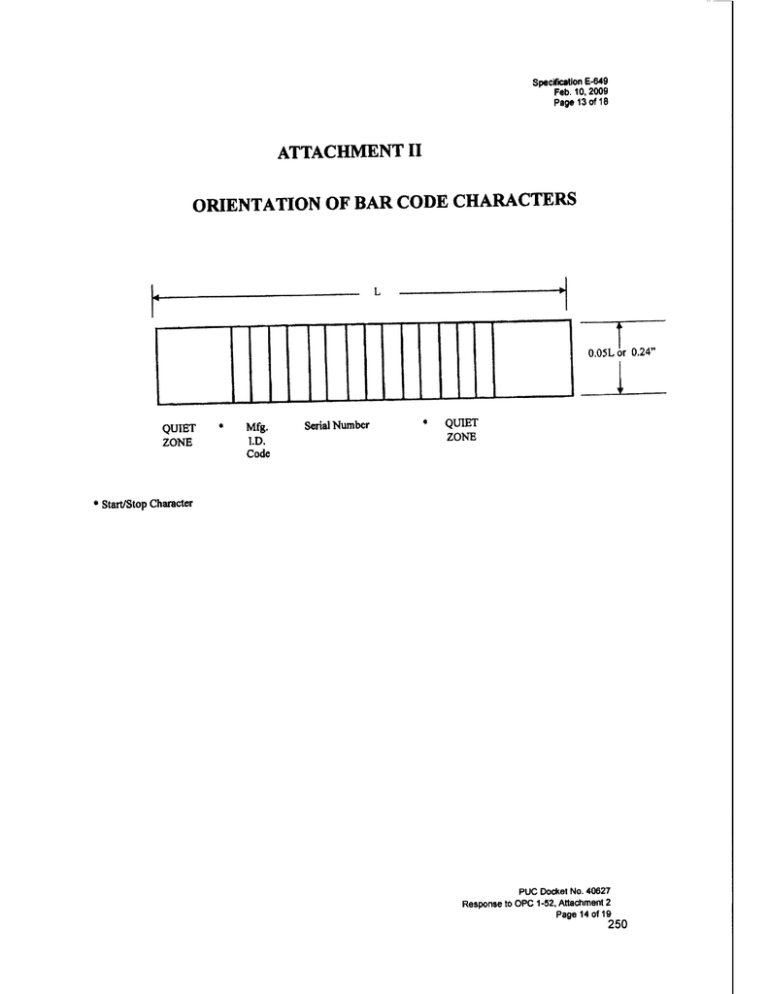

ATTACHMENT II

ORIENTATION OF BAR CODE CHARACTERS

L

0,05L or O24"

QUIET

ZONE

*

Mfg.

I.D.

Code

Serial Number

*

QUIET

ZONE

* Start/Stop Character

PUC Docket No. 40627

Response to OPC 1-52, Attachment 2

Page 14 of 19

250

Specification E-849

Feb.10, 2009

Page 14 of 18

ATTACHMENT III

TRANSFORMER SPADE SUPPORTS DRAWING

SttPl'C7R"f ANOLT~"`, ,,

,.-°"°

3

FLAT WASHER

FLAT a'ASIM

ChTSt.'Ti.(s"VC_.

'``^... ..:.

TiARRTBR STMMAT

`^.

^

"A, NIX NUT

LCICIC WASHER

TlARRTER ST?tKtAT CAPSCRBW

STAR WASHER

t^)

^?

^^

T!'C)sHrTlfi Sf..Arx';

ba..-,.v,..-.w..^

_.^--

PUC Docket No. 40627

Response to OPC 1-52, Attachment 2

Page 15 of 19251

SpecNication E-649

Feb. 10, 2009

Page 15 of 18

ATTACHMENT IV

GENERAL INF0RI4fATIC3N

1

SIGNACL

a

b00.1i «t t

st,a,^.r

SIGNAGE-PAD MOUNT 3 PF3

.,_^^..r.^.^ ^.. .. .

1000-14A SIGNAGE-PAD MOUNT 3PH

TYPICAL SIGNAGE PLACEMENT FOR 3 PHASE TRANSFORMER

T :^iC xiBER .Y °^ T^

^ IktC`l`i_

'^`

61'^[7R\S'R ` t lffttK

THREE IN ONE

NA xkIN f„ Ss<..N

r _^

c>R^^,^^

^

3 KA+tS F()FR'

KU 1: Et. IS SET

TO NORMAL r,t'r N

s:.ST'k' Yl.? `:Y.AItlc2:R

\

It

4

NO rc:ss

^

^f,•^

^ ^^^

EAULT INDICATOR

T.*t.^T,T C:Y^FT4ATOR

.

^

.. ,,,..,,.. „..

...^:..

... .,.

....... .....,..

^

j3^^T.A9£, PAD 11_,f.y!C`."rL[3

"^'21:A^...,,:^ cix i^^'9.^3^n_:_.

ri^ca„5^.

a CITY OF AUSTC.V DB.+. AUaTtN BMERi;iV ?(h73

PUC Docket No. 40627

Response to OPC 1-52, Attachment 2

Page 16 of 19252

Specification E-649

Feb. 10, 2009

Page 16 of 18

ATTACHMENT Wa

TYPICAL EXTERNAL SIGNAGE MATERIAL

REQUIREMENTS OF 3-PHASE PAD-MOUNTED

TRANSFORMERS

"No PCBS" ecal; 6 inch X 6 inch, blue, Base Film: 0.0035-inch cast polyvinyl chloride, with UV inhibitors as

per MqL-]v1-22106A, Cyasorb tJV-9 light absorber C14H1203, Gloss SOUL 94 rated. Over lamination: 002PVF

(pnlyvlnyltyouride) tedlar UV screening film from E.I. Dupont. Cold-seal bonded. Adhesive: 0.002-inch permanent

acrylic hi-tack, with high-temperature-resistant Elasticisors for adhesion at 40 deg. F, PSTC test method: #1

modified for a 15 minute dwell time, with 2 mils of adhesive, 56 oz/inch width rating. Ink: Silkscreen type 4, with

automotive grade pigments and binders, 0.0004-inch thick + 0.0001, inch high pigment volume concentration total

PVC 40-50 (copper phthalocyanines). Liner: 0.0007-inch ± 0.001-inch Kraft, coated one side chemical resistant.

Salt spray 240 hours 5%, at 100 degrees, with no blistering, color change, or other material degradation. No effect

when immersed in diesel fuel, motor oil, anti-freeze, detergent 2 °fa, ammonium hydroxide (12% and 391A),

kerosene, acetic acid, acetone and water. Service temperature range: -+30 to 4 170 deg. F. Minimum lifetime exterior

durability of 15 years from installation date with proper surface preparation.

Approved Manufacture or equal: Mitrographers, catalog number COA-001

"SIZE KVA" decal: width as required, 2 7/8 inches tall, Engineer Grade, adhesive reflective vinyl. Yellow

numbers, black background.

113 In 1" decal: Dimensions will be approximately 10" wide X 10.5" tall. Sign shall be worded as followes:

WARNING To Report Problems Call (512) 322-9100 HIGH VOLTAGE Hazardous voltage inside. Can shock,

bum or cause death. Keep out if open or unlocked, immediately call electric power and light company.

ADVERTENCIA Para Reportar Problemas Llame al: (512) 322-9100 ALTA TENSION Contiene voltaje

peligroso. Puede producir descarga o sacudida el6ctrica, quemaduras o ausar muerte. Prohibida Is entrada. si esti

abierto o sin llave, inmediatamente flame a la central e1&trica. WARNING To Report Problems Call: (512) 3229100 Keep shrubs and structures at least 10 feet away from this side of equipment for safe utility maintenance and

operation. ADVERTENCIA Para Reportar Prob{emas Llame al: (512) 322-9100 Mantenga arbustos y

construccibn por lo menos a 10 pies de distancia de este lado del equipo para seguridad on el mantenimiento y

operacibn. ONE CALL SYSTEM of TEXAS 1-800-545-6005 CALL BEFORE YOU DIG IT'S THE LAW

UNA LLAMADA SISTEMA de TEXAS 1-500-545-6005 LLAME ANTES DE EXCAVAR ES LA LEY.

Base film; ,0035 cast palyvinylchloride with uv inhibitors mil-m-22106a. (cyasorb uv-9 light absorber cI4h1203).

Gloss 80 ul 94 rated. Overiamination: ,002pvf (polyvinyttlouride). Tedlar uv screening film from e.i. dupont. Cold

seal bonded. Adhesive .002 permanent acrylic hi-tack with high temperature resistant elasticisors for adhesion at 40

degrees f. Pstc test method: #1 modified for a 15 min dwell time with 2 mils of adhesive 56 oz/inch width rating,

Ink: silkscreen type 4 with automotive grade pigments and binders .0004" thick dry +/- .0001" high pigment volume

concentration total pvc 40-50 (copper phthalocyanines). Liner: .0007" +!- .001" kraft coated one side. Chemical

resistance: salt spray 240 hours 5% at 100 degrees f if no blistering, color change, or other material degradation. No

effect when immersed in diesel fuel, motor oil, anti-freeze, detergent 2%, ammonium hydroxide (12% and 39°/u),

kerosene, acetic acid, acetone and water. Service temperature range: -40 to + 170 degrees f. Labels shall have a two

year shelf life and a minimum lifetime exterior durability of 15 years from installation date with proper surface

preparation. All stick on signs will have a written guarentee of no fading or pealing for 15 years or they will be

replaced in the field free of charge.

Approved Manufacturer or equal:

Uticom, no catalog number

Electromark, no catalog number

Mitrographers, no catalog number

PUC Docket No. 40627

Response to OPC 1-52, Attachment 2

Page 17 of 19253

Specification E-649

Feb. 10, 2009

Page 17 of 18

ATTACHMENT IV B

GENERAL INFORMATION

SIGNAGE

^^art a+s

_ _

1000-14B

SPECIFICATION-PAD MOUNT JPH

...._...

..._,^

,_,__...._...-.-........

SPECIFICATION-PAD MOUNT3PH

^^....s» a...^

1'f'PICAL SIGNAGE PLACEMENT FOR J PHASE TRANSFORMER

NOTE, COVER FOR

19164" SMALL HAVE A

STUD THAT FITS

THROUGH THE HOLE

WITH A DOLT TO

HOLD COVER IN

PLACE.

T HR E E: IN (> N I:

S4`a.RN INc: sI A; -1

1

^

1

1

NO PC'BS

^

SIZE K%'A

10164" COVERED

i)LE FOR FAA+LT

H

ltiIDICATOIi 1.iGHT

FALTLT ^„^,

I '^',BICA'COR.

0 CITY OF AUSTIN DBA AUSTIN ENERGY :002

PUC Docket No. 40627

Response to OPC 1-52. Attachment 2

Page 18 of 19254

Specification E-849

Feb. 10, 2009

Page 18 o118

ATTACHMENT V

AUSTIN ENERGY TRANSFORMER TEST REPORT FORM

fnsert name of manufacturer)

CERTIFIED TRANSFORMER TEST REPORT

VENDOR NAME

VENDOR PURCHASE ORDER NUMBER:

AUSTIN ENERGY PURCHASE ORDER NUMBER:2;

AUSTIN ENERGY STOCK NUMBER-

12F.

ANSI I

SE$I8,4.

NUMBER

PERCENT

IMPEDANCE

PHAS

3PH

EXCITING

CURRENT

MANUFACTURER ORDER NUMBER

MFO CATALOGUE NUMBER:

-^ MANUFACTURER INVOICE NUMBER

^

MFG DRAWING NUMBER.

TEST DATE

SHIP DATE:

FR Q i NCY

60 Hz

K66

LOSSES

_ASV_IRFQ

ME&WEDry_ ^

Nn•LOAD LOSS LOAD LOSS

{ i11VWA61;,

HIGH VOLTAGE

- - ----.•. 1/d3EGULAT4sjN AT

MF.E1W=

TOTAL LOSfi

DOE

^ ^^ ^Y9

t ^^pNTEED LC^SSES;

NOTES:

to 96°C.

1 ► Lomas are measured at 100% of rated voltage, No-load loss data corrected to 20° C Load Loadd data corrected

2) All uwtsfom»rs were manufactured using rtisulalmg huid containing less than 1 PPM PCB. ASTM D4059 Test

Certficatfon avadaaeL

3)'t'tte winding tanspaer:au,re rise ^b ^ rs .^ Cvart tanVerattre does not exceed 65'C

d) E^ Gng t^ent is rr^^rrs ;red at i C1i?%rated ioa+3,

5) All xenefomrowtt titled hwe recciveti and pissed the krlvNmg test in accordance with ANStAEEE C57.12.00 West

edmon Csntnwy. Rato, Lou, Pdw.ruy and Phase Rebikwi", Routine impulse. induced Voltage, Applied Voltage

THE MANUFACTURER CERTIFIES THAT THIS TEST REPORT 19 A TRUE AND ACCURATE RECORD OF FINAL PRODUCT IOWLINE

TEST THAT WERE CONDUCTED IN ACCORDANCE WITH CURRENT ANSI TRANSFORMER TEST STANDARDS, AND THAT THE

ABOVE TRANSFORMERS WITHSTOOD THESE TESTS

NAME OF CERTIFYINV INDMDUAL:

PUC Docket No. 40627

Response to OPC 1-52, Attachment 2

Page 19 o11255

PUC Docket No. 40627

Response to OPC 1-52, Attachment 3

Page 1 of 7

Specification E-708

CITY OF AUSTIN - AUSTIN ENERGY (AE)

PURCHASE SPECIFICATION

FOR

TRANSFORMER, NETWORK, THREE-PHASE, 12.47 KV

APPROVAL

PROCESS MANAGERIM&ESS MANAGER

DATE

PREPARED BY

ISSUANCEIREVISION

05/29/97

Steve Booher

Revision

George Martinez / Peter Soosay_m _

03/10/99

George Martinez

Revision

George Martinez ! David Sloan

03/22199

George Martinez

Revision

George Martinez I David Sloan

07/16/99

George Martinez

Revision

Carl Nance / George Martinez

03/04/05

Steven Booher

Revision

t18/27/11

Steven Booher

Revision

REASON FOR REVISION

03/10/99 - Change to 12.47 KV

AFFECTED PARAGRAPHS

Title change, remove 1.1.3, change ratings 1,2.2,

Change BIL 1.2.4, remove contacts 3.3, add contacts

3.4, bushing 4.1, changed 4.3, added 4.9, changed

losses and evaluation 7.1.

3122l99 -Change LV throat requirements. Move General

Requirements to Supplemental Terms and Conditions

07116199 - Network Transformer to Include

2500 KVA, 4801277V

Revised transformer ratings, Added sudden pressure

Relay, Revised Evaluation

6/27/11 Add DOE requirement and revised loss

requirements

Section 4.2, 6.0, 8.0, 9.0

1 2 2, 42, 4.8

1.2.2, 3.7, 6.1

3,8 and 6.1

This specification, until rescinded, shall apply to each future purchase and contract for the commodity described herein.

Retain for future reference.

256

PUC Docket No. 40827

Response to OPC 1-52, Attachment 3

Page 2 of 7

Specification E-708

June 27, 2011

Page I of 5

CITY OF AUSTIN- AUSTIN ENERGY (AE)

PURCHASE SPECIFICATION

FOR

TRANSFORMER, NETWORK, THREE-PHASE, 12.47 KV

1.0

SCOPE AND CLASSIFICATION

1.1

1.2

2.0

Scope

1.1.1

This specification covers three-phase oil filled network type transformers.

1.1.2

No deviations from this specification will be permitted.

Classification

1.2.1

Voltage shall be 12,470 Volts delta, 480Y/277, or 216Y/125 Volts.

1.2.2

Transformer rating shall be 500, 750, and 1000for 2l6Y/125 and 500, 750,

1000, 1500, and 2000 kVA for 480Y/277 as specified on bid request.

1.2.3

No-load high voltage taps shall be 5% below, 2 1/2% below, rated 2 1/2%

above, and 5% above.

1.2.4

Basic Insulation Level (BIL) shall be 125 kV for windings, 95 kV for bushings.

APPLICABLE STANDARDS

Network transformers furnished under these specifications shall meet all applicable, ASTM,

EEl-NEMA, ANSI, AND IEEE Standards, latest revision.

2.1

ANSI C57.12.40 - Subway and Vault Types (Liquid Immersed) Requirements.

2.2

ANSI/ASTM D3487 - Mineral Insulating Oil Used in Electrical Apparatus.

2.3.

ASTM D2300 - Standard Test Method for Gassing of Insulating Oils under Electrical

Stress and Ionizing. Modified Pirelli Method R (1991)

2.4

ASTM D1816 - Standard Test Method for Dielectric Breakdown Voltage of Insulating

Oils of Petroleum Origin Using VED Electrodes.

2.5

ASTM D877 - Standard Practices for Sampling Water-Formed Deposits. R (1994)

2.6

ASTM D971 - Standard Test Method for Interfacial Tension of Oil against Water by the

Ring Method.

2.7

ASTM/D1500 - Standard Test Method for ASTM Color of Petroleum Products.

(ASTM Color Scale) (1P Designation: 196/91)

2.8

ASTM D1524 - Standard Test Method for Visual Examination of Used Electrical

Insulating Oils of Petroleum Origin in the field.

2.9

ASTM D1533 - Standard Test Method for Water in Insulating Liquids. (Karl Fisher

Method)

2.10 ASTM D924 - Standard Test Method for Dissipation Factor and Relative Permittivity of

Electric Insulating Liquids.

257

PUC Docket No. 40627

Response to OPC 1-52, Attachment 3

Page 3 of 7

3.0

4.0

Specification E-708

June 27, 2011

Page 2 of 5

FUNCTIONAL REQUIREMENTS

3.1

Transformers shall be self-cooled, 65 degrees (°) Centigrade (C) temperature rise above

ambient, vault type construction, suitable for occasional submerged operation

3.2

Marking of terminals, winding connections, and vector relationships of windings shall be

as shown on the attached drawing (Attachment I).

3.3

The transformer shall be equipped with a glass or magnetic type liquid level indicator on

all oil filled compartments. The liquid level gauge shalt have a dark dial face with light

markings and a light indicating hand, The dial markings shall show the 25 degrees O

centigrade (C) level and the minimum and maximum levels. The words "Liquid Level"

shall be on the dial or on a suitable nameplate mounted adjacent to the indicator.

3.4

The transformer shall be equipped with a dial type thermometer on the main tank for

indicating liquid temperature. The thermometer shall have a black indicating hand and a

red maximum indicating hand. The main tank thermometer shall be provided with

electric alarm contacts.

3.5

A three pole, three position switch for disconnecting and grounding the high voltage

feeder shall be provided on the transformer. The switch shall remain it alignment under

normal installation and operating conditions. The switch shall have a continuous rating

of 200 amperes at 60 cycles. The switch shall be provided with three operating

positions: "OPEN," "CLOSED," and "GROUND," and shall be marked as such. In the

closed position, the switch shall be capable of withstanding the full short circuit duty of

the transformer. In the ground position, the switch shall be capable of withstanding

15,000 amperes short circuit current. An electrical interlock slid] prevent movement of

the switch from any position when the transformer is energized. The sequence of

operation shall be open, closed and ground, and the switch shall be designed so that

when it is moved from open to ground, or ground to open. The operSor shall pause in

the closed position to give the electrical interlock time to engage if the transformer is

energized. The operating handle shall be equipped for padlocking the switch in each

direction.

3.6

Alarm contacts shall be suitable for interrupting:

a.

0.02 ampere direct-current inductive load

b.

0.02 ampere direct-current noninductive load

c.

2.5 ampere alternating-current noninductive or inductive load

d.

250 volts maximum in all cases

3.7

A sudden pressure relay shall be mounted on the main tank to respond to sudden

increases in internal gas pressure. A seal-in relay with contacts for alarm and tripping

and a reset switch shall be externally mounted. Normal operating voltage of the sealin

relay shall be 125VAC. Adequate surge suppression to prevent false operations due to

transient voltages on control leads shall be provided. The sudden pressure relay shall be

designed such that external vibration or mechanical shocks shall not cause false

operations. All mechanical provisions and equipment for testing shall be provided. In

addition, the seal -in relay and wiring shall be rated for in-circuit testing with remote

lockout relay.

3.8

All transformers supplied to AE shall meet or exceed the efficiency values in accordance

with Department of Energy 10 CFR 431 part III - Energy Conservation program for

Commercial Equipment: Distribution Transformers Energy Conservation Standards

table 1. 1. Certified test data by serial number shall be provided with each transformer.

PHYSICAL REQUIREMENTS

258

PUC Docket No. 40627

Response to OPC 1-52, Attachment 3

Page 4 of 7

4.1

The transformer shall have 600 ampere minimum sidamounted apparatus bushings on

the high side. The bushings shall be bolted to the tank for ease in replacement. Welded

bushings are not acceptable. Bushings provided shall be Elastimold K650•S 1(copper)

or AE approved equivalent.

4.2

The low voltage throat and bushings shall be in accordance with ANSI C57.12.40,

Figure 3 for 216Y/125V transformers rated 500 kVA and 480Y/277V transformers rated

500, 750, and 1000 kVA. Figure 4 for 216Y/125V transformers rated 750, 1000, and

1500 kVA; and 480Y/277V transformers rated 1500, and 2000 kVA.

4.3

The neutral bushing shall be insulated from the transformer tank. The ground to tank

shall be made by a flexible copper braid bolted between the transformer tank and the

neutral bushing of the transformer, Copper braid size shall be equal to 500 MCM bare

copper. The neutral bushing shall have a four hole NEMA pad for 1000 kVA and

smaller and a six-hole NEMA pad for 1500 and 2000 kVA transformers.

4.4

The high voltage compartment shall be completely sealed and filled with insulating oil

prior to shipping.

4.5

The tap changer shall be designed for de-energized operation. An indicator shall clearly

show the position of the tap changer.

4.6

The transformer tank shall be of a sealed construction, consisting of a welded main

cover equipped with lifting lugs and hand-hole cover(s) with gasket.

4.7

Jack pads or bars shall be provided so that there is three inches (3") of clearance up from

the bottom of the transformer for lifting jacks.

4.8

Transformer sizes listed below are maximums and shall not be exceeded.

KVA

500

750

1000

1500

2000

4.9

5.0

Specification E-708

June 27, 2011

Page 3 of 5

EiGI

ETh

7'0"

7'0"

7'6"

8'0"

8'6"

6'0"

6'2"

6'2"

6'6"

61"

3'6"

4'0"

4'0"

4'6"

510„

All high voltage windings shall be made of copper.

INSULATING OIL REQUIREMENTS

5.1

The insulating oil shall be non polychlorinated biphenyl (PCB), defined as containing

less than one part per million (ppm) PCB. Certification of the non-PCB oil shall be

furnished and shall include the method of testing used.

5.2

The transformer nameplate shall be marked "non-PCB." In addition, a blue "non-PCB"

label of a minimum 1"X 2" size shall be installed directly below the nameplate.

5.3

The oil shall conform to the latest revision of ANSI/ASTM D3487, Type [l. The

gassing coefficient shall be negative when tested in accordance with ASTM D2300,

Section 2.0.

5.4

The Contractor shall supply test reports, which verify compliance with the oil

performance requirements given below:

Test and Method

Dielectric Strength,

ASTM D-18S6, kV

minimum,

0.04 inch gap:

0.08 inch gap:

20 kV

40 kV

259

PUC Docket No. 40627

Response to OPC 1-52, Attachment 3

Page 5 of 7

Dielectric Strength,

ASTM D-877, kV

minimum

30 kV

Power Factor, ASTM D-924,

% maximum; 25°C

0.15

% maximum; 100 ° C

1.50

Interfacial Tension,

ASTM D-971, mN/m

minimum:

35

Color, ASTM D-1500,

ASTM Units:

Visual Examination,

ASTM D-1524

Specification E-708

June 27, 2011

Page 4 of 5

1.0

Bright and Clear

Water Content,

ATSM D-1533,

ppm, maximum:

5.5

25

The Contractor shall be subject upon request, to furnish laboratory test data for the

insulating oil. Oil furnished under these specifications shall be subject to tests and any

insulating oil failing these tests will be returned to the Contractor at the Contractor's

expense.

6.0

COST EVALUATION

6.1

All network transformer bids will be evaluatedand awarded based on purchase price,

guaranteed no load losses, and guaranteed winding losses. The founula and cost of

losses are as follows:

Total Evaluated Bid (owning cost) = Bid Price + ( cost of no load losses) x (quoted

guaranteed no load losses) + (Cost of winding losses) x (quoted guaranteed winding

losses)

Cost of no load losses =$5,239.00/kW

Cost of winding losses = $3,123.00/kW

6.2

Each Bidder shall quote the guaranteed no load losses and guaranteed winding losses at

the time of bid opening.

6.3

Before or upon delivery, Contractor's certified factory test reports shall be provided to

AE for final review.

6.4

Losses shall be the actual tested losses corrected to 20°C no load and 85°C for load,

reported by serial number and City of Austin purchase order number for each

6.5

The actual losses of any one transformer on an ordershall not exceed the quoted

guaranteed losses by more than the following percentages:

transformer delivered.

No load losses

Network Transformer

6.6

10%

T t 1 osses

6%

Penalty

260

PUC Docket No. 40627

Response to OPC 1-52, Attachment 3

Page e of 7

Specification E-708

June 27, 2011

Page 5 of 5

For each transformer where the actual losses exceed the quoted guaranteed losses, a

penalty will be assessed through a price reduction for each transformer.

Penalty =

2I($5,239.00/kW) (actual no load losses - quoted guaranteed no load

losses) +(53,123.00/kW) (actual winding losses - quoted guaranteed

winding losses)]

261

PUC Docket No. 40627

Response to OPC 1-52, Attachment 3

Page 7 of 7

Specification E-0709

CITY OF AUSTIN - AUSTIN ENERGY (AE)

PURCHASE SPECIFICATION

FOR

k

TRANSFORMER, NETWORK, THREE-PHASE, 34.5 KV

ISSUANCElREVISION

APPROVAL

PROCESS SUPV. I MATERIALS SUPV.

DATE

PREPARED BY

05/29/97

Steve Booher

Revision

George Martinez / Peter Soosay

03/10/99

George Martinez

Revision

George Martinez 1 Peter Soosay

03/22/99

George Martinez

Revision

George Martinez / David Sloan

07/16199

George Martinez

Revision

Peter Soosay / George Martinez

03/04/05

Steven Booher

Revision

06/29/11

Steven Booher

Revision

REASON FOR REVISION

Network Transformetr to Include

AFFECTED PARAGRAPHS

Sections: 1.2.2.4.2,4.8

2500 KVA, 480/277VAdd sudden pressure device,

revised evaluation, Revised transformer size ratings,

added Warranty, and drawing with test reports.

Section 3.7, 8.1

8/27/11 Added DOE requirements and revised loss

requirements

Section 7.0 - 7.6

Section 3.8 and 8.1

6/27111 Added 2500 KVA 4160/2400 requirements

Section 1.2.2 and 4.3

Section 1.2.2

This specification, until rescinded, shal apply to eaoh future purchase and contract for the commodity described herein,

Retain for future reference.

262

specification E-709

June 29, 2011

Page 1 of 6

CITY OF AUSTIN- AUSTIN ENERGY

PURCHASE SPECIFICATION

FOR

TRANSFORMER, NETWORK, THREE-PHASE, 34.5 KV

1.0

SCOPE AND CLASSIFICATION

1.1

1.2

Scope

1,1.1

This specification covers three-phase oil filled network type transformers.

1.1.2

No deviations from this specification will be permitted.

Classification

1.2.1

Voltage shall be 34,500 Volts delta, 480Y/277 or 216Y/l25 Volts.

1.2.2

Transformer rating shall be as specified on bid sheet.

a. 500, 750, and 1000 for 216Y/125

b. 500, 750, 1000, 2000 and 2500 kVA for 480Y/277

c. 2500 kVA for 4160/2400 '

1.2.3

1.2.4

2.0

No-load high voltage taps shall be 5% below, 2 1/2% below, rated 2 1/2% above, and 5%

above,

windings, 150 kV for bushings.

Basic Insulation Level ( BIL) shall be 200 kV for

APPLICABLE STANDARDS

ASTM, EEI-NEMA,

Network transformers furnished under these specifications shall meet all applicable,

ANSI, AND IEEE Standards, latest revision.

Liquid Immersed) Requirements.

ANSI C57.12.40 • Subway and Vault Types (

2.1

in Electrical Apparatus.

ANSI/ASTM D3487 - Mineral Insulating Oil Used

2.2

Electrical Stress and

Standard Test Method for Gassing of Insulating Oils Under

2.3. ASTM D2300 Ionizing. Modified Pirelli Method R (1991)

2.4

ASTM D1816 -

Standard Test Method for Dielectric Breakdown Voltage of Insulating Oils of

Petroleum Origin Using VED Electrodes.

2.5

ASTM D877 -

2.6

ASTM D971 -

2.7

ASTMID 1500 -

Standard Practices for Sampling Water-Formed Deposits. R(1994)

Standard Test Method for Interfacial Tension of Oil Against Water by the Ring Method.

(ASTM Color Scale)

Standard Test Method for ASTM Color of Petroleum Products.

( 1P Designation: 196/91)

18

ASTM D1524 -

Examination of Used Electrical Insulating Oils

Standard Test Method for Visual

of Petroleum Origin in the field.

PUC Docket No. 40627

Response to OPC 1-52, Attachment 4

Page 1 of

h3

Specification E-709

June 29, 2011

Page 2 of 6

2.9

ASTM D1533 -

Standard Test Method for Water in Insulating Liquids. (Karl Fisher Method)

2.10

ASTM D924 -

Standard Test Method for Dissipation Factor and Relative Permittivity of Electric Insulating

Liquids.

3.0

FUNCTIONAL REQUIREMENTS

3.1

Transformers shall be self-cooled, 65 degrees (°) Centigrade (C) temperature rise above ambient, vault

type construction, suitable for occasional submerged operation.

3.2

Marking of terminals, winding connections, and vector relationships of windings shall be as shown on

the attached drawing (Attachment I).

3.3

The transformer shall be equipped with a glass or magnetic type liquid level indicator on all oil filled

compartments. The liquid level gauge shall have a dark dial face with light markings and a light

indicating hand. The dial markings shall show the 25 degrees (°) centigrade (C) level and the

minimum and maximum levels. The words "Liquid Level" shall be on the dial or on a suitable

nameplate mounted adjacent to the indicator.

3.4

The transformer shall be equipped with a dial type thermometer on the main tank for indicating liquid

temperature. The thermometer shall have a black indicating hand and a red maximum indicating hand.

The main tank thermometer shall be provided with electric alarm contacts.

3.5

A three pole, three position switch for disconnecting and grounding the high voltage feeder shall be

provided on the transformer. The switch shall remain in alignment under normal installation and

operating conditions. The switch shall have a continuous rating of 200 amperes at 60 cycles. The

switch shall be provided with three operating positions: "OPEN,', "CLOSED", and "GROUND", and

shall be marked as such. In the closed position, the switch shall be capable of withstanding the full

short circuit duty of the transformer. In the ground position, the switch shall be capable of

withstanding 15,000 amperes short circuit current. An electrical interlock shall prevent movement of

the switch from any position when the transformer is energized. The sequence of operation shall be

open, closed and ground, and the switch shall be designed so that when it is moved from open to

ground, or ground to open. The operator shall pause in the closed position to give the electrical

interlock time to engage if the transformer is energized. The operating handle shall be equipped for

padlocking the switch in each direction.

3.6

Alarm contacts shall be suitable for interrupting:

3.7

3.8

a.

0.02 ampere direct-current inductive load

b.

0.02 ampere direct-current noninductive load

c.

2.5 ampere alternating-current noninductive or inductive load

d. 250 volts maximum in all cases

A sudden pressure relay shall be mounted on the main tank to respond to sudden increases in internal

gas pressure. A seal-in relay with contacts for alarm and tripping and a reset switch shall be externally

mounted. Normal operating voltage of the seal-in relay shall be I2SVAC. Adequate surge suppression

to prevent false operations due to transient voltages on control leads shall be provided. The sudden

pressure relay shall be designed such that external vibration or mechanical shocks shall not cause false

operations. All mechanical provisions and equipment for testing shall be provided. In addition, the seal

-in relay and wiring shall be rated for in-circuit testing with remote lockout relay.

All transformers supplied to AE shall meet or exceed the efficiency values in accordance with

Department of Energy 10 CFR 431 part I11- Energy Conservation program for Commercial

Equipment: Distribution Transformers Energy Conservation Standards table 1.1. Certified test data

by serial number shall be provided with each transformer.

PUC Docket No. 40627

Response to OPC 1-52, Attachment 4

Page 2 of 6264

Specification E-709

June 29, 2011

Page 3 of 8

4.0

PHYSICAL REQUIREMENTS

4.1

The transformer shall have 600 ampere minimum side-mounted apparatus bushings on the high side.

The bushings shall be bolted to the tank for ease in replacement. Welzled bushingI are not accefst;ablc.

Bushings provided shall be Elastimold 750-S1 (copper) or AB approved equivalent.

4.2

The low voltage throat and bushings shall be in accordance with ANSI C57.12.40, Figure 3 for

216Y/125V transformers rated 500 kVA and 480Y/277V transformers rated 500, 750, and 1000 kVA.

Figure 4 for 216Y/125V transformers rated 750, 1000, and 1500 kVA; and 480Y/277V transformers

rated 1500, 2000 and 2500 kVA.

4.3

On the 2500 kVA 4160/2400 transformer the low side bushings shall be bolted to the tank for ease in

provided shall be Elastimold 750-S1

replacement. Welded bushings are not ai;gotable. Bushings

(copper) or AE approved equivalent. The network protector throat is not required on the 2500 kVA

4160/2400 volt transformer.

4.4

The neutral bushing shall be insulated from the transformer tarik. The ground to tank shall be made by

a flexible copper braid bolted between the transformer tank and the neutral bushing of the transformer.

Copper braid size shall be equal to 500 MCM bare copper. The neutral bushing shall have a four hole

NEMA pad for 1000 kVA and smaller and a six hole NEMA pad for 1500, 2000 and 2500 kVA

transformers.

4.5

The high voltage compartment shall be completely sealed and filled with insulating oil prior to

shipping.

4.6

The tap changer shall be designed for de-energized operation, An indicator shall clearly show the

position of the tap changer.

4.7

The transformer tank shall be of a sealed construction, consisting of a welded main cover equipped

with lifting lugs and gasketed hand hole cover(s).

Jack pads or bars shall be provided so that there is three inches (3") of clearance up from the bottom of

4.8

the transformer for lifting jacks.

4.9

Transformer sizes listed below are maximum and shall not be exceeded.

500

750

1000

1500

2000

2500

6'0"

6'21'

6'2"

6'6"

6187'0"

7'0„

7, 01,

7,V

81011

8'6"

9'010

3,6»

4:09.

4.0„

4'6"

5,0"

5.6„

4.10 All high voltage windings shall be made of copper.

5.0

INSULATING OIL REQUIREMENTS

5.1

The insulating oil shall be non-PCB (polychlorinated biphenyl), defined as containing less than one

part per million (ppm) PCB. Certification of the non-PCB oil shall be furnished and shall include the

method of testing used.

5.2

The transformer nameplate shall be marked "non-PCB". In addition, a blue "non-PCB" label of a

minimum 1"X 2" size shall be installed directly below the nameplate.

5.3

The oil shall conform to the latest revision of ANSI/ASTM D3487, Type ll. The gassing coefficient

shall be negative when tested in accordance with ASTM D2300, Section 2.0.

PUC Docket No. 40627

Response to OPC 1-52, Attachment 4

Page 3 of 6

265

Specification E-709

June 29, 2011

Page 4of6

5.4

The Contractor shall supply test reports, which verify compliance with the oil performance

requirements given below:

est and Method

Dielectric Strength,

ASTM D-1816, kV

minimum,

0.04 inch gap:

0.08 inch gap:

Dielectric Strength,

ASTM D-877, kV

minimum

20 kV

40 kV

30 kV

Power Factor, ASTM D-924,

% maximum; 25° C

% maximum; 100 ° C

0.15

1.50

Interfacial Tension,

ASTM D-97 1, rnNlm

minimum:

Color, ASTM D-1500,

ASTM Units:

35

Visual Examination,

ASTM D-1524

Bright and Clear

Water Content,

ATSM D-1533,

ppm, maximum:

5.5

6.0

1.0

25

The Contractor shall be subject upon request, to furnish laboratory test data for the insulating oil. Oil

fumished under these specifications shall be subject to tests and any insulating oil failing these tests

will be returned to the Contractor at the Contractor's expense.

COST EVALUATION

All network transformer bids will be evaluated based on purchase price, guaranteed no load losses, and

6.1

guaranteed winding losses. The formula and cost of losses are as follows:

Total Evaluated Bid (owning cost) = Bid Price + (cost of no load losses) x (quoted guaranteed no load

losses) + (Cost of winding losses) x(quoted guaranteed winding losses)

Cost of no load losses = 55,239.00/kW

Cost of winding losses = 53.123.00/kW

6.2

Each Bidder shall quote the guaranteed no load losses and guaranteed winding losses at the time of bid

opening.

6.3

Before or upon delivery, Contractor's certified factory test reports shall be provided to AE (Section

6.3) for final review.

6.4

Losses shall be the actual tested losses corrected to 20°C no load and 85°C for load, reported by serial

see section 6.2).

number and City of Austin purchase order number for each transformer delivered (

6.5

The actual losses of any one transformer on an order shall not exceed the quoted guaranteed losses by

more than the following percentages:

PUC Docket No. 40627

Response to OPC 1-52, Attachment 4

Page 4 of ^66

Specftation E-709

June 29, 2011

Page 5of8

No load losses

Network Transformer

6.6

10%

Loldhim

6%

Penalty

For each transformer where the actual losses exceed the quoted guaranteed losses, a penalty will be

assessed through a price reduction for each ttansfotmer.

Penalty =

2[(55,239.O0/kW) (actual no load losses - quoted guaranteed no load lossas) +

($3.123.00/kW) (actual winding losses - quoted guaranteed winding losses

PUC Docket No. 40627

Response to OPC 1-52, Attachment 4

Page 5 of $67

Specification E•709

June 29, 2011

Page 6018

ATTACHMENT I

X0 tKU^►T^^►^m

iJIIIII I IL

xa

k2

HI

O

K

xa

X2

X1

IIIII

TERMINAL DESIGNATIONS

X2

H2

xl

Mt

^

xo

X3

DELTA - WYE

VECTOR RELATIONSHIPS

TERMINAL DESIGNATIONS AND VECTOR RELATIONSHIPS

FOR NETWORK TRANSFORMERS

ATTAdIMENT I

PUC Docket No. 40627

Response to OPC 1-52, Attachment 4

Page 6 of 6

68

Specification E-1579

February 11, 2009

Page 1 of 14

CITY OF AUSTIN ELECTRIC UTILITY DEPARTMENT

PURCHASE SPECIFICATION

FOR

TRANSFORMER, SINGLE-PHASE OVERHEAD-TYPE DISTRIBUTION

(3 kVA through 167 kVA)

DATE

PREPARED BY ISSUANCEIREVISION

07/08/99

Gary Noble

issuance

01/01/03

Steve Booher

Revision

05/30/03

Steve Booher

Revision

06/06/03

Steve Booher

Revision

09/05/03

02/18/04

Steve Booher

Leonard Hough

Revision

Revision

04/28/05

Dennis Patrick

Revision

2/11/09

Arthur Gonzalez

Revision

APPROVAL

PROCESS SUPV. /MATERIALS SUPV.

AFFECTED PARAGRAPHS

REASON FOR REVISION

01l01/03: Referred to part not used on this transformer.

3.6.7

01/01103: changed the ground requirement from 1 lug to

2 lugs

3.7.7

01/01/03: Added ground requirement for two-bushing

transformer. Added bushing ground length requirement

3•7,7

05/30/03: changed arrester rating requirements and

added Arrester style number

3.8.2

Attachment il

08/08/03: Updated attachment II

3.8 & 4.0

09/05/03: Added arrester connection & animal guard

02/18/04: Added labeling instructions

3.7.8

05/04/05: Added verbage and chart

3.5.1

05/04105:

Added grounding for 4 bushing Xfmr

^_

12/28/05: Added arrestor wire details

^... .-. _

3.7.7

3.8.1

04/28/05: Changed Mfg Part No. Added new Mfg with

part number.

3.8.2

04/28J05: Changed approved Mfg and Mfg Part No's.

4.0

04/26/05: Restructured Data Requirements

7•0

04126/05: Added Warranty Requirements

11.4

04/26/05: Changed Sticker Requirements.

Attachment VI

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 1 of 14269

Specification E-1579

February 11, 2009

Page 2 of 14

This specification, until rescinded, shall apply to each future purchase and contract for the commodity described herein.

Retain for future reference.

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 2 of 1470

Specification E-1 579

February 11, 2009

Page 3 of 14

CITY OF AUSTIN ELECTRIC UTILITY DEPARTMENT

PURCHASE SPECIFICATION FOR

TRANSFORMER, SINGLE-PHASE OVERHEAD-TYPE DISTRIBUTION

(3 kVA through 167 kVA)

1.0

SCOPE AND CLASSIFICATION

1.1

Scope

The City of Austin Electric Utility Department, hereinafter referred to as Austin Energy (AE), requires

a qualified Vendor, to provide, single phase, 60 hertz, dual HV bushings with tank-mounted surge

arrester, oil-filled, conventional distribution transformers rated 3 kVA through 167 kVA.

1.2

2.0

Classification

1.2.1

No deviation from these specifications on the part of the Vendor shall be allowed. Any item

supplied under these specifications which is not in complete compliance with these

specifications will not be accepted and will be returned to the Manufacturer.

1.2.2

All Manufacturers furnishing transformers under these specifications shall have at least ten

(10) years experience in the manufacture and sale of distribution transformers.

APPLICABLE SPECIFICATIONS

All Characteristics, definitions and terminology, except specifically covered in this specification shall be in

accordance with the latest revision of ANSI/IEEE C57.12.20 and C57.12.31.

3.0

FUNCTIONAL REQUIREMENTS

3.1

Voltage and kVA Ratings

The voltage ratings shall be in accordance with the table in Attachment I.

3.2

Maximum Guaranteed Transformer Losses

The single phase distribution transformer maximum guaranteed losses (both No Load and Load Loss)

shall be in accordance with Attachment II. All units, exceeding the maximum guaranteed losses will

be rejected. There is no additional tolerance allowed on these values.

3.3

High Voltage (HV) Taps

Manufacturer shall not provide taps for the transformers described herein.

3.4

3.5

High Voltage Bushings and Terminals

3.4.1

The High Voltage Terminals shall be in accordance with ANSI C57.12.20.

3.4.2

High voltage bushing shall be in accordance with ANSI C57.12.20, IEEE C57.19.00 and

IEEE C57.19.01.

Low Voltage (LV) Bushings and Terminals

3.5.1

The low-voltage bushings and terminals shall be 2-hole spades for 3 kVA - 15 kVA

transformers. 25 kVA - 167 kVA transformers shall have 4-hole spades. All secondary

bushings shall have captive, compression limited, fully shielded conductor and flange seals.

Bushings shall be certified to withstand the following cantilever loading without leaking. The

bushings for the 100 kva and the 167 kva pole mounted transformers shall be Central

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 3 of 1 427,i

Specification E-1579

February 11, 2009

Page 4 of 14

Moloney Intermediate Speedmount NPA0010I8. Terminal designation and markings shall be

in accordance with ANSI C57.12.70.

. . . . . _..

3.5.2

3.6

SECONDARY VOLTAGE

__._......_.._..,_.._. .._. .,..^,...^._..._._._..u......

277

240/480

_

KVA

120/240

10-50

100FTLBS

100FTLBS

100FTLBS

75

300 FT LBS

100 FT LBS

100 FT LBS

100

300 FT LBS

100 FT LBS

100 FT LBS

167

300 FT LBS

300 FT LBS

300 FT LBS

250

400 FT LBS

360 FT LBS

400 FT LBS

333

400 FT LBS

300 FT LBS

400 FT LBS

500

400 FT LBS

400 FT LBS

400 FT LBS

_ ...-....

The terminals shall be finished on both sides to enable a complete connection to either side.

CORE AND COIL

3.6.1

The transformer coils shall be designed to maintain their nameplate kVA rating throughout

the temperature range. The continuous kVA ratings shall be based on an average winding

temperature rise by resistance of 65°C as per ASNSI/IEEE C57.12.00.

3.6.2

All materials used shall be of the 65°C (85° C Hot Spot) Class and be thoroughly tested for

compatibility with all transformer components.

3.6.3

Oil ducts shall be strong enough to withstand full short circuit forces.

3.6.4

The windings shall be a mechanically rigid assembly to resist axial and radial short circuit

forces.

3.6.5

The primary coil shall be wound in such a manner, that when properly cured, will have an

effective bond both turn to turn and layer to layer.

3.6.6

The primary coil shall be wound with continuous conductor without splices, joints or welds

inside the windings.

3.6.7

High Voltage (HV) leads shall be trained and appropriately insulated to avoid dielectric

breakdown between adjacent cables. Spacers, permanently held in place, shall be used to

prevent a phase-to-ground short.

3.6.8

The secondary coils shall be wound with a roctangular or strip conductor. Each secondary coil

shall be wound with a continuous conductor without splices, joints or welds inside the

windings.

3.6.9

LV bushing leads shall be cold or thermally welded, where joined to the winding material

3.6.10

Aluminum low voltage leads shall be connected to their bushings, with hardened aluminum

connectors which have been cold or thermally welded to the leads.

Pl1C Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 4 of 14272

specification E-1579

February 11, 2009

Page 5 of 14

3.6.11

3.7

The core and coil assembly shall be rigidly held together as a unit with a core clamp whose

design shall maintain reasonable pressure on the assembly throughout the life of the unit.

Tank

3.7.1

Leak Resistant

The transformer tank shall be leak resistant throughout the operational life of the transformer.

3.7.2

Covers

The transformer cover shall be insulated. The transformer shall have removable cover with

nitrile rubber gaskets. The cover, when secured in place, shall prevent any moisture from

entering the tank.

3.7.3

Pressure

The transformer tank and cover shall be designed to withstand pressure in accordance with

ANSI C57.12.20.

3.7.4

Pressure Relief Valve

An automatic pressure-relief valve shall be furnished on all transformers. The location of the

valve shall be in accordance with ANSI C57.12.20, Figures 1, above the oil and in segments 2

or 4 of these figures.

3.7.5

Hand Holes

The transformers shall not have hand holes.

3.7.6

Support Lugs (Hangers)

All transformers shall have support lugs for one (1) position mounting. The support lugs shall

be in accordance with ANSI C57.12.20, Section 7.5.2 (Figure 1 and Figure 111).

3.7.7

Grounding

The transformer shall have two tank ground provisions as per ANSI C57.12.20, Section

7.5.4.1, Figure 11.

Transformers with three LV bushings shall be externally grounded to the tank with a ground

strap of sufficient length to attach to the adjacent bushings.

Transformers with two LV bushings shall have a grounding strap attached from the X2

bushing to a grounding lug on the tank centered between X1 and X2.

Transformers with four LV bushings shall have a grounding strap attached from the X2

bushing to a gounding lug on the tank centered between the X2 and X3.

3.7.8

Labels

The Vendor shall place all labels required by AE Distribution Construction Standard #1000-17,

and shown in Attachments V and VI, on the tank of each transformer. This includes the "SIZE

KVA" and the "NO PCBS" labels.

3.8

Arresters

3.8.1

An arrester shall be mounted on the transformer adjacent to the Hi bushing. The arrester shall

be connected from the top of the arrester the H I transformer bushing. The arrester wire shall

be 24 inches long; #6 compressed soft stranded copper transformer riser wire, polyethylene

covered. A single hole tin plated compression connector shall be utilized to connect the wire

PUC Docket No. 40627

Response to OPC 1-52. Attachment 5

Page 5 of 14273

Specification E-1579

February 11, 2009

Page 6 of 14

to the H1 bushing to the arrester. The connection from the bottom of the arrester shall be solid

copper strap rated for l OKA and bolted to the bottom of the transformer tank. All connections

to the arrester shall be properly installed as per arrester manufacturer instructions

3.8.2

4.0

The arrester supplied shall have a rating of 10 kV, 8.4 kV MCOV, polymer, metal- oxide

type, with wire nut and wire clamp on top terminal. The transformers shall be delivered with

one of the arresters listed:

a.

Cooper catalog number UHS 10050A I A I A 1 A

b.

Ohio Brass catalog number 213709-7214

c.

Maclean catalog number ZH^,-0000000

WILDLIFE GUARDS

All transformers shall be delivered with the below listed animal guard properly installed on the HV bushing

and arrestor:

a.

5.0

Howard Industries 0060-0021634Q5

TRANSFORMER DIELECTRIC OIL

The dielectric fluid shall be bio-based biodegradable electric insulating and cooling liquid. The coolant shall

be a list less-flammable fluid meeting the requirements of National Electric Code Section 450-23 and the

National Electric Safety Code, Section 15. The fluid shall be Factory Mutual Approved and be UL Classified.

The dielectric fluid supplied with all transformers shall be in accordance with IEEE C57.147. The

manufacturer shall provide batch test reports of the oil characteristics to the AE Standards Engineer.

The PCB content in the dielectric fluid shall be less than 1 ppm. The vendor shall provide written certification

to the City that all dielectric fluid contains less than I ppm. The PCB content shall be shown on the

nameplate of the transformer.

6.0

PAINT REQUIREMENTS

The unit shall be painted ANSI 70 Light Gray, Munsell Notation 5BG 7.0/0.4.

7.0

DATA REQUIREMENTS

The Vendor shall provide for the AE Specifications Engineer, upon receiving a new shipment of transformers

to Vendor's receiving site, including but not limited to the following information on each transformer:

7.1

The tol{crwi^tgil;ern^ sl^ i^ prir^ i!<<1 t<>rReacll ir^nsfa^,c^ ^..n..:^V.^r^...slll:p^^

7.1.1

Serial Number

7.1.2

kVA Ratina

7.1.3.1

Voltage Rating

7.1.4

Core aron) losses at rated load , corrected to 85°C

7.1.5

Copper losses at rated load, corrected to 85°C

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 6 of 14

Specification E-1579

February 11, 2009

page 7 of 14

7,2

8.0

7.1.6

percentage (%@ impedance

7.1.7

Exciting curre

7.1.8

Pereentare f°!o1 rezu)P-Ocat,8il°^powcr ta4 ar ^nc#^r ted L(NW

7,1.9

^ltat:e ("^a) rggr^la^sn^t 100"l^w^ 8S or and^t^djpid

i'erco

7.1.10

^iicle4l.ct (lt^i used in he tr^ns(ormer

i

Gailc^ttc,^..l^l^gr^tiabi^

7.1.11

Percentage (%) efficienc,y(gDOE efficiency criteri

100% rated v

The followin}^ t^nts shall be tsrovid^ ^! ►?^ yearly repo^ with evt*ry ti^ tihiy,^_^^^lt oF evcr

7.2.1

Drawings

7.2.2

Total transformer weig)Ilz #I}^5^ widt t1i1 and with arrester maunted

7,2.3

Windina, Material

7.2.4

9211 mm"

7.2.5

Conductor temperature at rated load (Design Test)

7.2.6

Hot Soot tenanerature at rated load (Design Test)

7.2.7

Top Oil temperature at rated load (Design Test)

7.2.8

Thermal time constant ( Design Test)

7.2.9

^hort-Circuit Withstand Caoability ( Design Test)

7.2.10

Exciting current at I In/ rated vQlta^e (Desien Test)

7.2.11

Ftadio Influence Volta^e (R_l_V) at110N raeAvolta >a, (.I7^^ T_est

ez^r:

NAMEPLATE

The nameplate of the transformer shall be in accordance with ANSI/IEEE C57.12.00, Table 10 (Nameplate

A). The following additional information shall be provided on the nameplate:

9.0

8.1

Bar Code (Section 9.0)

8.2

PCB content (No-PCB or Less than I PPM)

PERMANENT BAR CODE

The bar code shall be in accordance Attachment IV and with the latest revision of the following standards:

ANSI X3.17, ANSI X3.182, ANSI X3.4, ANSI X3.49, and ANSI MH10.8M

PUC Docket No. 40827

Response to OPC 1-52, Attachment 5

Page 7 of 14 275

specification E-1 579

February 11, 2009

page 8 of 14

10.0 AUSTIN ENERGY REQUIREMENTS

Austin Energy or its designated representative reserves the right to inspect and test transformers and materials

in all stages of manufacturing and testing, at whatever location the manufacturing is performed, at no charge

to Austin Energy.

11.0 OTHER REQUIREMENTS

All transformers supplied to AE shall meet or exceed the efficiency values in accordance with

11.1

III - Energy Conservation program for Commercial

Department of Energy 10 CFR 431 part

Energy

Conservation Standards table I.1. Certified test data by

Equipment: Distribution Transformers

with

each

transformer.

be

provided

serial number shall

11.2

A decal shall be placed on the transformer in accordance with Attachments V and VI, The decal shall

be colored blue with white lettering. The decal shall be 6" tall by 6" wide and shall have the precise

wording, in capital letters, "NO PCBS".

11.3

The Vendor shall provide the information in Section 7 (numerical values and/or pass/fail, as

applicable) to the AE Distribution Standards Engineer:

AE Distribution Standards Engineer

4411-B Meinardus Drive

Austin, TX 78744

The test reports shall clearly state Austin Energy's specification number E-1579 and the type of

transformer (Polemount).

11.4

If any defect in the equipment supplied, or failure to comply with this specification, shall appear

within the period of 18 months from date of final acceptance of the equipment, the Contractor shall be

notified, and the Contractor shall thereupon correct without delay and at Contractor's own expense the

defect or failure of compliance by repairing the defective part or parts, by supplying a non-defective

replacement or replacements, and/ or by correcting a deficient design as required. The Contractor

shall further replace or repair all other similar equipment if such defect may reasonable be expected to

develop or occur in said similar equipment. Removal and installation cost of the defective parts or

equipment shall be at Contractors expense. In the event the Contractor shall correct any defectts) or

failure of compliance by repair, replacement, or correction as required above, then with respect to the

equipment corrected, the aforesaid warranty period shall begin from the date of completion of

installation of such correction and acceptable therefore, provided same is not unreasonably delayed by

Austin Energy.

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 8 of 14276

Speclficatbn E-1579

February 11, 2009

Pape9of14

ATTACHMENT I

TRANSFORMER VOLTAGE RATINGS

FOR

SINGLE-PHASE DISTRIBUTION TRANSFORMER

_._. ^^...

.^^ ^.........^..

HIGH VOLTAGE

HV BIL kV

LOW VOLTAGE

LV BIL kV

7200/12470Y

95

120/240

30

7200/12470Y

95

240/480

30

7200/12470Y

95

277

30

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 9 of 14277

Specification E•1579

February It 2009

Page 10 of 14

ATTACHMENT H

MAXIMUM GUARANTEED TRANSFORMER LOSSES

._.__

^edance (%)

Transformer (kVA)

No-Load Losses Watts

Load Losses (Watts)

3

14

43

2.0

10

31

141

2.0

15

47

164

2.0

25

70

178

2.0

50

11 ]

409

2.0

75

135

652

2.0

100

192

730

2.0

167

250

1295

3.0

85° C

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 10 of 14 27$

Specification E-1579

February 11, 2009

Page 11 of 14

ATTACHMENT III

TANK-MOUNTED SURGE ARRESTERS FOR

SINGLE-PHASE DISTRIBUTION TRANSFORMER

Nominal

System Voltage

BIL*

(L-L) kV RMS

*

(kV)

Manufacturer

(W)

anufacturer

PM art Number

12.47

95

Cooper

8.4

UHS10050A1A1A1A

12.47

95

Ohio Brass

8.4

213709-7214

12.47

95

Maclean

8.4

ZHPOIO-0000000

MCOV Rating**

Minimum BIL of Surge Arrester Housing with Metal Oxide Blocks

** MCOV - Maximum Continuous Operating Voltage

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 11 of 14279

Speckicatfon E•1579

February 11, 2009

Page 12 of 14

ATTACHMENT IV

BAR CODING AND MANUFACTURING CODES

FOR

SINGLE-PHASE DISTRIBUTION TRANSFORMER

1.0

ORIENTATION OF BAR CODE CHARACTERS

L

0.15L

QUIET

ZONE

MFG

SERIAL NUMBER

CODE

QUIET

ZONE

*Start/Stop Character

2.0

MANUFACTURER IDENTIFICATION CODES

The Manufacturer Identification Codes suggested below represent, in part, codes which are utilized for bar coding

distribution transformers. The above listing does not represent an inclusive list of distribution transformer

manufacturers.

AB

-

Asea Brown Boveri

CM

-

Central Moloney

CP

-

Cooper

GE

-

General Electric

HI

-

Howard Industries

KU

-

Kuhlman

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 12 of 1 4_80

Specification E-1579

February 11, 2009

Page 13 of 14

ATTACHMENT V

SIGNAGE FOR SINGLE-PHASE POLE-MOUNTED

TRANSFORMERS

(AE DISTRIBUTION CONSTRUCTION STANDARD #1000-17)

c;BNERAL INFORMATION

p0t7

8IClYACE414LE MOU.'T1' TRANSF'ORMER

eev. DKC 0vi 5+04 _ ;

^....._,,^..^...__-.---.--.,••....-w..^--^....._

^....._

91G.NACE POI.E MOUNT TRANSFORMER

1Ug(1-]7

a^'"^«..

'''l

F 1 ^m1

t

1,y^ l•s^

t^

^ --...,.^

>AJ

^^....... ;^

^

..^.

^.^=

J

N4

f

rI7Y w

1,11,1170 'IT 10,1 TOP Of

l71! TR.AN91"()RM ER ON

TIM RIQIIT•ITABTD SIDE

Wwf:RL' IT is YtSmix FR0N

THE RT'RP.FTIYARI).

- SIZE AY .4

LOl'A7HD IN 17lB

vrNTUR ABOVE

-rut-. PCs.-, 110 MR

WHIM. LT IS YI9TTIT E

k12OM T8E S'fRkETIYAkD.

NO 1'C83

i.('W.xAV D 1.14 THE

CENTER OF TIM

Ilk AW3100114 FR UN 111R

THE SIZE K VA STICKER

FVITP,kE ITLSVTSTnLE

MOW ML STRLTL^TIYAKU,

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 13 o114281

Specifloation E-1579

February 11, 2009

Page 14 of 14

ATTACHMENT VI

TYPICAL EXTERNAL SIGNAGE MATERIAL

REQUIREMENTS POLE-MOUNTED TRANSFORMERS

"NO PCBS" decal. 6 inch X 6 inch, blue. Base Film: 0.0035-inch cast polyvinyl chloride, with UV inhibitors as

per M[L-M-22106A. Cyasorb UV-9 light absorber C14H1203. Gloss 80 UL 94 rated. Over lamination: 002PVF

(polyvinyltlouride) tedlar UV screening film from E.I. Dupont. Cold-seal bonded. Adhesive: 0.002-inch permanent

acrylic hi-tack, with high-ternperatura-resistant Elasticisors for adhesion at 40 deg. F. PSTC test method: #1

modified for a 15 minute dwell time, with 2 mils of adhesive, 56 ozlinch width rating. Ink: Silkscreen type 4, with

automotive grade pigments and binders, 0,0004-inch thick j- 0.0001, inch high pigment volume concentration total

PVC 40-50 (copper phthalocyanines). Liner: 0.0007-inch t 0.001-inch Kraft, coated one side chemical resistant.

Salt spray 240 hours 5%, at 100 degrees, with no blistering, color change, or other material degradation. No effect

when immersed in diesel fuel, motor oil, anti-freeze, detergent 2°fo, ammonium hydroxide (1211/6 and 39%),

kerosene, acetic acid, acetone and water, Service temperature range: -40 to + 170 deg. F. Minimum lifetime exterior

durability of 15 years from installation date with proper surface preparation.

Approved Manufacture or equal: Mitrographers, catalog number COA-001

"SIZE KVA" decal: width as required, 2 7/8 inches tall, Engineer Grade, adhesive reflective vinyl. Yellow

numbers, black back ground.

"City lp Number" decal: width as required, 2 7/8 inches tall, Engineer Grade, adhesive reflective vinyl. black

numbers, Yellow back ground.

PUC Docket No. 40627

Response to OPC 1-52, Attachment 5

Page 14 of 14282

PUC Docket No. 40627

Response to OPC 1-52, Attachment 6

Page 1 of 1

Specification E-0815

4.4,

Losses

4.4.1.

The transformer losses will be used in the evaluation of the offers. No-load and load

loss values at the I raise OLTC position at the self cooled (18 MVA, 24MVA, 30

MVA or 40 MVA) rating shall be supplied with the Offer and will be used in the

evaluation. If the transformer has an OLTC, which uses variable volts per turn

design, the no-load losses shall be guaranteed on the OLTC position having the

highest no-load losses.

The Offeror shall state in the Offer the DETC and OLTC positions with the highest

no-load losses as the guaranteed losses in the case of variable volts per turn design.

The Offeror shall also submit with the Offer the auxiliary load at the maximum

forced cooled rating for use in the evaluation.

The following life cycle costs will be used.

Cost of no-load losses

Cost of load losses

Auxiliary losses

4.4.2.

- $ 5,300/kW

- $ 3,970/k W

- $ 1,250/kW

The Offeror shall submit with the Offer the maximum percent total measurement

error for the no-load loss measurement and the load loss measurement systems. The

errors must contain all components of the error including probable calibration errors

and other uncertainties in the measurement system. Certified data for the loss

measurement errors shall be submitted with the Offer. The data shall be traceable to

the United States National Institute of Standards and Technology or other equivalent

standardization organization. Equivalency will be determined by AE using

supporting documentation provided by the Offeror as part of the Offer. A system

check to insure that all errors have been properly applied may be required. Failure to

submit a loss measurement system error or the submission of an error that is

obviously erroneous will result in the rejection of the offer. The maximum loss

measurement error that is acceptable is ± three (3) percent as per ANSI/IEEE

C57.12.00. Loss measurement errors greater than ± three (3) percent will result in

the rejection of the Offer.

4.4.3. The no-load losses and excitation current at room temperature after impulse tests

shall be used as the guaranteed values and shall not deviate from the no-load losses

and excitation current values measured before impulse tests by more than five (5)

percent. If the difference between the before and alter values are greater than five

(5) percent, AE shall be contacted and a course of action determined. It is expected

that the manufacturer shall determine the cause and correct any problems that result

in deviations in no-load losses and excitation current that are greater than five (5)

percent. AE reserves the right to reject the transformer if satisfactory explanations or

corrections are not made.

4.4.4. A transformer which, after factory testing, has losses exceeding the guaranteed losses

as stated in the Offer shall have its selling price reduced. The amount of reduction

will be calculated by the kW difference ( actual tested minus calculated guaranteed)

multiplied by the evaluated cost per kW

283

SOAH Docket No. 473-13-0935

PUC Docket No. 40627

City of Austin's Response to OPC's lst RFI

OPC 1-53

Please state the value of energy and capacity used when making economic

comparisons among bidders when purchasing transformers; provide the source of

those figures; and provide the date when the figures were developed.

RESPONSE:

Responsive information for distribution transformers is found in Austin Energy's response to

OPC 1-52. For Substation class transformers, see section 4.4.1 of the excerpt from the City of

Austin Electric Utility Department Purchase Specification E-0815, revision 07/24/2012, for 13812.47 kV, 30, 40, 50, 67 MVA three phase power transformers states the life cycle costs used to

make economic comparisons when purchasing substation size transformers. Section 4.4.1 was

implemented September 8, 2005. This excerpt was provided in the response to OPC 1-52.

Prepared by:

Sponsored by:

David Wood

David Wood

284

SOAH Docket No. 473-13-0935

PUC Docket No. 40627

to OPC's 1st RFI

Response

City of Austin's

OPC 1-54

Please estimate the average price premium that Austin Energy currently pays over

the transformer with the lowest capital costs in each size range in order to avoid

losses.

RESPONSE:

Austin Energy does not have any information responsive to this request.

Prepared by:

Sponsored by:

David Wood

David Wood

285

SOAH Docket No. 473-13-0935

PUC Docket No. 40627

City of Austin's Response to OPC's 1st RFI

OPC 1-55

Please identify gross and net plant for capacitors and indicate in which account

costs are included.

RESPONSE:

See Attachment I for the requested information.

Attachment 1- Summary for Capacitors at 09-30-2009, 1 page.

Prepared by:

Sponsored by:

Ann Little

Ann Little

286

t^

kA

0.,a_

4

H

'

^

19'

C

O

8 ^

m ^

O

^

14 9

888l

o

4

8

1

0

= cr

c ^

..a W . a ..a

jpp!^

^Oco 4

00 IM O`Jt^!

ONNG ► t^

IV

^ ^PA 00 ^A co

T' .ts tl^ ^D '"a W

t,

j

(e y

^^

^

"1k V W 'J

4CA ► tO 9 0

:6.

Z

CA "W'

l► IVtD

V a ^► Wt;J

.`^t+W

Oh)C)7 C

A ^a co w9

NtoD{J0^

^0

2

0 0

0

n

^ -^ V

287

SOAH Docket No. 473-13-0935

PUC Docket No. 40627

City of Austin's Response to OPC's 1st RFI

OPC 1-56

Please provide workpapers supporting the customer weighting and allocation

factors for meters.

RESPONSE:

Customer weighting and allocation factors for meters is described on pages 55-56 and in shown

in Table 14 of Mr. Mancinelli's Direct Testimony. Additionally, this information is show in

WP/F-2.3 of the RFP.

Prepared by:

Sponsored by:

Joe Mancinelli

Joe Mancinelli and Beverly Bonevac

288

SOAH Docket No. 473-13-0935

PUC Docket No. 40627

to OPC's 1st RFI

Response

City of Austin's

OPC 1-57

Which types of meters or sizes of customers use (a) Current Transformers (CTs)

and/or (b) Potential Transformers (PTs).

RESPONSE:

Residential customers up to 400 amps do not require CTs. However, 200 amp to 400 amp

(residential) service have the option of CTs. All other customers over 200 amps (commercial or

industrial) use CTs. Additionally, service voltages above 600V, require PTs and CTs regardless

of amps.

The typical types of meters that are CT-rated include:

-Form 9S for 3-phase

-Form 3S (2 wire) or Form 4S (3 wire 120/240V) for single phase

-Form 5S (or Form 45S) for 3 wire 120/208V

Prepared by:

Sponsored by:

David Wood

David Wood

289

SOAH Docket No. 473-13-0935

PUC Docket No. 40627

City of Austin's Response to OPC's 1st RFI

OPC 1-58

Please provide any studies or analyses prepared on the cost of service drops by

customer class and/or by single-phase versus three-phase service.

RESPONSE:

Austin Energy does not have any documents responsive to this request.

Prepared by:

Sponsored by:

David Wood

David Wood

290

SOAH Docket No. 473-13-0935

PUC Docket No. 40627

City of Austin's Response to OPC's 1st RFI

OPC 1-59

Please provide all available information on the length of service drops by

customer class.

RESPONSE:

Austin Energy has no statistics on its system as built. Please refer to Austin Energy's Design

Criteria Sections 1.5.2.1.G and 1.5.2.3.B for criteria governing service drops.

Attachment 1- Austin Energy's Design Criteria, 168 pages.

Prepared by:

Sponsored by:

David Wood

David Wood

291

PUC Docket No. 40627

Response to OPC 1-59, Attachment 1

Page 1 of 168

City of Austin Electric Utility

Austin Energy

Design Criteria

Effective January 1, 2010

Cost: $15.00

292

PUC Docket No. 40627

Response to OPC 1-59, Attachment 1

Page 2 of 168

293

PUC Docket No. 40627

Response to OPC 1-59, Attachment 1

Page 3 of 168

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................................................1

1.1.0

INTRODUCTION ..............................................................................................................7

1.2.0

RELEVANT CITY OF AUSTIN BUSINESS OFFICES .............................................................7

1.3.0

CHARACTERISTICS/ BASIC REQUIREMENTS OF ELECTRIC SERVICE ................................9

1.3.1

AE Electric Distribution Service Voltages and Maximum Demand Ampacities ...................................... 9

1.3.2

Availability of AE Facilities ............ ............................................................................................... 9

1.3.3

One Service Point and One Service Voltage ................................................................................... 9

1.3.4

Service Point (Point of Delivery) ................................................................................................... 9

1,3.5

Electrical Facility Ownership ......................................................................................................... 9

1.3.6

Easements ...............................................................................................................................10

1.3.7

Color Coding of Customer's Service Conductors .............................................................................10

1.3.8

Customer Electrical Facilities that Cross Property Lines ................. .................................................12

1.3.9

Single-Phase/Three-Phase Service ...............................................................................................12

1.3.10

Voltage Stability and Continuity ..................................................................................................13

1.3.11

Electric Service Reliability ...........................................................................................................13

1.3.12

AE Line Extension Policy .............................................................................................................13

1.3.13

AE Excess Facilities/Excess Cost Policy .........................................................................................13

1.3.14

Front Lot Line Construction Requirement ......................................................................................15

1.3.15

Customer Switchover Policy ........................................................................................................15

1.3.16

Three Mega-Watt Demand and Larger Customer Requirements .......................................................15

1.3.17

Underground Only Service Areas ( Non Network Areas) . .................................................................15

1.3.18

Americans with Disabilities Act ....................................................................................................15

1.4.0

REQUESTING/OBTAINING ELECTRIC SERVICE . ............................................................16

1.4.1

Applying for Electric Service .......................................................................................................16

1.4.2

AE Service Area Questions ..........................................................................................................16

1.4.3

Electric Service Requests ............................................................................................................16

1.4.3.1

Service Only Requests ......................................................................................................16

1.4.3.2

All Other Information, Cost, or Service Requests ..................................................................16

1.4.3.3

Submittal of Customer Drawings Required with Electric Service Requests ...............................17

1.4.4

ESPA Approval ..........................................................................................................................18

1.4.5

Electric Permits for AE Electric Service within COA .........................................................................19

1.4.6

Electric Permits for AE Electric Service Outside of COA ...................................................................19

1.4.7

COA Electric Inspection ..............................................................................................................19

1.4.8

'Service Only' Service Drop and Service Lateral Installations ...........................................................19

1.4.9

Service to Residential, Commercial, and Other Types in Non-Network Area .......................................21

1.4.10

Service Requests in the AE Network Area .....................................................................................23

1.4.11

Truck Access to AE Construction and Existing Facility Sites .............................................................23

1.4.12

Customer Demand Load Determination ........................................................................................23

1.5.0

TYPES OF PERMANENT ELECTRIC SERVICE ...................................................................24

July 31, 2009

Austin Energy Design Criteria

m Austin Energy 2009 - All Rights Reserved

294

PUC Docket No. 40627

Response to OPC 1-59, Attachment I

Page 4 of 168

1.5.1

1.5.2

1.5.3

1.6.0

1.6.1

Network Service ....................................................................................................................... 24

1.5.1.1

Underground and Vault Service Only ................................................................................. 24

1.5.1.2

Available Network Service ................................................................................................ 24

1.5.1.3

Existing Overhead Service - RESIDENTIAL AND COMMERCIAL .............................................. 25

1.5.1.4

Underground 216Y/125V Service - RESIDENTIAL ................................................................ 25

1.5.1.5

Underground 216Y/125V Service - COMMERCIAL ................................................................ 26

1.5.1.6

Network Transformer Vault Service ................................................................................... 27

1.5.1.7

Inspections of Customer Installed Civil Work in the Network Area ......................................... 28

COMMERCIAL Service in Non Network Areas ................................................................................ 28

1.5.2.1

General Conditions and Requirements - Commercial ............................................................ 28

1.5.2.2

Available Commercial Electric Service ................................................................................ 31

1.5.2.3

Overhead Secondary Voltage Service - Commercial ............................................................. 32

1.5.2.4

Customer-installed Underground Services and Civil Work for AE Infrastructure ....................... 36

1.5.2.5

Underground Secondary Voltage Service From Secondary Riser - Commercial ........................ 40