Levitation of Pyrolytic Graphite and Neodymium Magnets

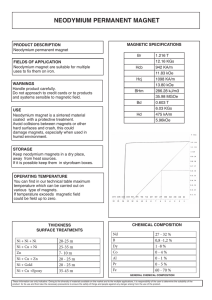

advertisement

Levitation of Pyrolytic Graphite and Neodymium Magnets through the Utilization of Magnetic and Electromagnetic Fields Introduction Levitation is not possible using only ferromagnetic material. Therefore, our levitation research was conducted using diamagnetic material in which a magnetic field is induced in opposition to an externally applied magnetic field causing a repulsive force and thus making levitation possible (see Figure 1). Many materials considered to be non-magnetic actually have diamagnetic properties and because of this, it was possible for example to levitate a living frog in a high magnetic field as seen in the figure directly above. Also, a magnet was able to be suspended between diamagnetic fingers (see picture in the top right) by use of a strong lifting magnet. In our investigation, three experiments were conducted. Conclusion: In experiment one, several correlations were determined to exist. The size of the magnet affected the levitating distance of the pyrolytic graphite. The larger the magnet, the greater the distance between the magnet’s surface and the pyrolytic graphite. The strength of the magnet also affected the levitating distance of the pyrolytic graphite. The stronger grade of the magnet, the greater the levitating distance. However, there was no correlation between the thickness of the pyrolytic graphite and it’s levitating distance over the magnets. Figure 1 Levitation of a neodymium magnet between diamagnetic plates In Experiment two, the distance between the levitated Neodymium magnet and mounted lifting magnet was able to be increased using larger lifting magnets (figure 14). Figure 9 Schematic diagram of circuit Figure 10 Constructed circuit Experiment 3: Levitation of neodymium magnet using an electromagnet Figure 2 Levitating Pyrolytic graphite plate over 12. 7 mm³ Neodymium magnets In experiment three, the researchers constructed an apparatus for dynamic levitation between a permanent magnet by use of an electromagnet. The researchers were are to levitate up to a mass of 9.45g. Mounted lifting magnets A circuit was constructed (Figure 9 schematic arrangement and Figure 10: actual circuitry) that utilized a Hall sensor that had an output proportional to the magnetic field experienced. The closer the levitating magnet got to the Hall sensor the stronger the signal produced. This way, the circuitry drove the electromagnet with a Pulse Width Modulated (PWM) signal. A voltage of 14.0V and current of 0.10amp was used. The electromagnetic had a ferrous core and so the levitated magnet would be attracted. If the Hall sensor detected the magnet close then the PWM signal would turn the electromagnet off and the levitated magnet would begin to fall. The Hall sensor would detect the falling magnet and a signal would then turn the electromagnet back on and would attract the falling magnet. A stable dynamic levitation could then be achieved (see figures 11 and 12). The levitating magnet mass was too small to levitate by itself and mass was added to achieve dynamic equilibrium. The levitation equilibrium point has a very narrow margin and a systematic technique of the reduction of the levitating mass by half was utilized to achieve the electromagnetic force and gravitation force balance. Figure 3 Orientation of the Neodymium magnets Levitating magnet Pyrolytic graphite plates The data for the different size of magnets showed that the size of the magnet did affect the levitating distance. In figure 2, the levitating plate gap is greater than the distance for the smaller 6.35mm³ magnets (figure 4) using the same sized levitating plate (both sets of magnets N52 strength). The actual measured distance between the center of the plate and the top edge of the magnet was 1.16mm for the 12.7 mm³ magnet and 0.649mm for the 6.35mm³ magnet. Figure 4 Levitating Pyrolytic graphite plate over 6.35mm³ Neodymium magnets Figure 11 (right) and Figure 12 (left) Levitation of a neodymium magnet by an electromagnet receiving a PWM signal Figure 5 Levitating Pyrolytic graphite plate over N35 magnet) Notable diamagnetic materials Appendix A Magnetic susceptibilities of notable diamagnetic materials at 20ºC The data for the strength of the magnets showed that the levitating distance was dependent on the strength. The N52 magnet in figure 2 had a levitating distance of 1.16mm. The N35 magnet had a levitating distance of 0.480 mm (figure 5). Figure 6 Two different masses of Pyrolytic graphite levitating over 4.72mm³ Neodymium magnets The data for the different masses of Levitating plates was that although the gap was larger for the small mass plate, the actual distance between the center of plate and magnet surface was the same (Figure 6). Two electromagnets were constructed (see figure 13) using 22 and 26 gauge copper wire. Figure 14 shows the theoretical and actual data for the electromagnets. After initial testing, the constructed electromagnets did not provide satisfactory strength to levitate the magnet. Therefore, a purchased electromagnet was used in the experimentation. Figure 13 Construction of the electromagnets Table 1 Data table of theoretical and actual data of the constructed electromagnets Experiment 2: Levitation of neodymium magnet A kit was purchased that demonstrated the levitation of a neodymium magnet between two pyrolytic graphite sheets using a neodymium lifting magnet mounted above them (see figure 7). Because of size limitations with the kit, a larger apparatus was designed and constructed to increase the distance between the suspended magnet and the levitated magnet (see figure 8). Larger magnets were added to the constructed apparatus and the distance between the levitating magnet and mounted lifting magnet was measured. In figure 1, the levitated magnet can be seen between the two pyrolytic graphite plates. Figure 7 Neodymium magnet levitated between two pyrolytic plates (purchased kit) Figure 8 Neodymium magnet levitated between two pyrolytic plates (constructed kit) The purchased kit had a distance of 40mm between the bottom of the suspended Neodymium magnet and the Levitating magnet (see figure 7) The constructed apparatus had a distance of 68mm between the suspended Neodymium magnet and the Levitating magnet (see figure 8). Wire Size /AWG Actual Resistance (Ω) % Error of Resistance (Ω) 22 Calculated # of turns 1449 Calculated Resistance (Ω) 14.1 Actual # of turns 1322 12.0 15 26 568 2.2 638 2.0 9 Research was conducted to determine the ratio of the mass of the Neodymium magnet to the total mass that was in dynamic equilibrium and the surface area of the magnet to the total levitating mass. Two levitating masses were analyzed. One magnet was 6.35mm³ the other 8.001mm x 5.982mm x 1.486mm. The results for the total mass levitated divided by the mass of the magnet were that the 6.35mm³ had a ratio of 4.92 (total mass levitated = 9.45g) and the 8.001mm x 5.982mm x 1.486mm had a ratio of 12.89 (total mass levitated = 6.96g). When the surface area was compared to the levitated mass of each magnet, the results were that the 6.35mm³ had a ratio of 0.234 (surface area = 40.3225mm²) and the 8.001mm x 5.982mm x 1.486mm magnet had a ratio of 0.146 (surface area = 47.86mm²) Figure 14 Levitating magnet between two Pyrolytic graphite plates using mounted lifting magnets Magnetic susceptibility (χm) χm=Km-1 (x 10-5) Ammonia ‐0.26 Density @ 20°C ( g/cm3 ) 0.88 Bismuth ‐16.6 9.78 Mercury ‐2.9 13.534 Silver ‐2.6 Carbon (diamond) ‐2.1 3.53 Carbon (graphite) ‐1.6 2.09–2.23 10.5 Lead ‐1.8 11.34 PyrolyKc Graphite ‐40.0 2.3 Sodium chloride ‐1.4 2.16 Copper ‐1 8.94 Water ‐0.91 0.9982 Acknowledgments We would like to give thanks and recognition for our research experience . We would like to thank Dr. Alexey Souslov who served as our mentor scientist, James Maddox and Vaughn Williams for helping us in the design and construction process of the apparatus in experiment 2, and Lee Marks for helping construct the two electromagnets. Much appreciation is given to the National Science Foundation and the National High Magnetic Field laboratory at Florida State University for making the Research Experience Program for Teachers possible. Special thanks goes to Dr. Pat Dixon and Jose Sanchez for supervision in the RET process. References: 1. http://www.trifieldmeter.com/DCMagnetometer_instructions.html 2. Nave, Carl L.. "Magnetic Properties of Solids". HyperPhysics. http:// hyperphysics.phy-astr.gsu.edu/Hbase/tables/magprop.html. Retrieved on 2008-11-09. 3. http://www.hfml.ru.nl/nature-july22v400.pdf 4. http://www.dougdelamatter.com/website/science/physics/magnets04.pdf 5. Wixforth, A., Kothaus, J.P., and Weimann, G. “Quantum Oscillations in the Surface-Acoustic Wave Attenuation Caused by a Two-Dimensional Electron System”. 1986 6. Geim, A.K, and Simon, M.D.. Diamagnetic Levitation: Flying Frogs and floating magnets (invited)”. Journal of Applied Physics. 1 May 2000. 7. Souslav, A. “Resonances of piezoelectric plate embedded 2D electron system. NHMFL 8. Marsden, G. “Levitation!”. Nuts and Volts . Sept. 2003