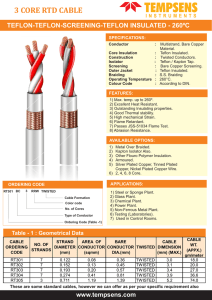

Cable Product Guide - Tempsens Instruments

advertisement