exolit op 1230

advertisement

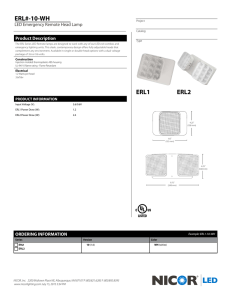

If safety and environmental compatibility is precious to you EXOLIT® FLAME RETARDANTS FOR THERMOPLASTICS 2 exolit® Flame retardants for thermoplastics Quick performance matters – and without a doubt, especially in areas where the protection of life and property is key. In that context, modern flame retardants have to fulfill additional demanding material requirements in addition to their most prominent role as an additive to slow down or even fully prevent starting fires. Contents 3 Introduction 2 Profile of modern flame retardants 4 Standard polyamides (6 and 66) 8 High performance polyamides 12 Polyesters 14 Thermoplastic elastomers 18 Polyolefins 20 Clariant development and costumer support 22 Profile of modern Flame Retardants Influence on compound properties The influence on mechanical and electrical properties, a good melt flow behavior and a robust processing window are critical points, especially in the electronics industry where miniaturization plays a vital role. For electrical properties like comparative tracking index (CTI), Exolit grades offer the best solution available. Compared to other flame retardants, Exolit products often have a smaller impact on mechanical properties due to their comparably low dosage. An additional feature is the low density which can be a convincing reason for their usage e.g. in the transport industry where weight reduction is becoming more and more important. glow wire test 4 exolit® Flame retardants for thermoplastics Influence on the surroundings in case of a fire Already a small, starting fire develops smoke and it is the toxic smoke that kills by far most fire victims. In addition, dense smoke can make visual orientation impossible and people may not be able to escape from e.g. a building, ship or train. If the smoke contains corrosive substances (e.g. from halogen containing polymers or flame retardants), equipment not effected by the fire itself can also be damaged. Exolit flame retardants show less toxic smoke development compared to other solutions. 5 Profile of modern Flame Retardants Environmental and legislative criteria The topic of sustainability is receiving more and more attention when deciding about new materials or designs. Aspects like use of hazardous materials, carbon footprint, recycling behavior, and life cycle analysis gain importance throughout the value chain and even for the end consumer. Clariant’s Exolit range is a good answer to these environmental concerns: ·Exolit flame retardants do not contain restricted heavy metals, bromine or chlorine as regulated e.g. in Europe by the Directive on the Restriction of certain Hazardous Substances in EEE (RoHS, 2011/65/EU). ·Other regions of the world are coming up with similar legislation. Hence, Exolit OP flame retardants are a preferred choice for electric and electronic equipment (EEE). ·Most commercial Exolit grades are globally registered in chemical inventories and all of the sales products are preregistered or fully registered under the European legislation on the Registration, Evaluation, Authorisation and Restriction of Chemicals (EC 1907/2006, REACH). ·Exolit products have shown in practice that they meet the performance levels expected and needed in modern applications. 6 In addition, Exolit flame retardants have been extensively tested in studies by independent researchers and public authorities. For example, the EU-funded collaborative research project ENFIRO (www.enfiro.eu) which ran from 2009 to 2012 studied the properties of various non halogenated flame retardants as alternatives to established brominated products. Furthermore, the material and fire performance as well as life cycle aspects were compared. Exolit OP (designated as »Alpi« in the project) was amongst the best rated products and a good environmental and health profile was confirmed. Another example are the »Design for Environment« projects of the United States Environmental Protection Agency (US-EPA) some of which studied alternatives to major brominated flame retardants for printed circuit boards, polyurethane foams and thermoplastics (www.epa.gov/dfe). Exolit OP and Exolit AP were amongst the candidates studied – only minor hazards were identified. Together with other member companies of the Association for non-halogenated Phosphorus, Inorganic and Nitrogen Flame Retardants (pinfa.org), Clariant engaged in a pilot project for a »Green Screen« assessment of its flame retardants (www.cleanproduction.org/Greenscreen.php) with positive results. exolit® Flame retardants for thermoplastics Consequently, in 2012 Clariant doubled the capacity for Exolit OP phosphinates with another state of the art plant at the Knapsack site near Cologne, Germany, where we have over 100 years of experience with phosphorus and chemicals. 7 Standard polyamides (6 and 66) Exolit OP 1312 Exolit OP 1314 Exolit OP 1400 TP* ·UL 94 V-0 down to 0.4 mm ·CTI of up to 600 V ·Low material density ·Low impact on mechanical properties ·Good colorability ·Good contrast in laser marking ·Halogen free Plastics in general exhibit excellent insulation properties combined with low weight and high mechanical strength – an important feature for the electric and electronic (E&E), transportation and appliances industry. In these industries, glass fibre reinforced polyamides are increasingly used due to their well balanced properties. However, they can start a fire when exposed to an ignition source. In order to ensure the fire safety, flame retardants are added to meet the various fire classes. Exolit OP 1312, Exolit OP 1314 and Exolit OP 1400 TP* are blends containing an organic aluminium phosphinate and synergists. While Exolit OP 1312 and Exolit OP 1314 are fully established and globally used flame retardants, Exolit OP 1400 TP* contains a new substance which is currently under registration in various chemical inventories. For current registration status please contact Clariant’s corporate product stewardship. As a newly developed product, Exolit OP 1400 TP* is currently available from a semi-commercial production. Exolit OP 1400 TP* does not contain any hazardous substances. TECHNICAL DATA Delivery form Phosphorus content [ % ] UL 94 V-0 at 0.4 mm (PA 66 GF30) [ % ] Decomposition temperature [ °C ] EXOLIT OP 1312 White powder 18.7 - 19.7 18 - 20 > 330 EXOLIT OP 1314 White powder 20.5 - 21.5 20 > 330 EXOLIT OP 1400 TP* White powder 23.5 - 26.0 20 > 350 * Test Product 8 exolit® Flame retardants for thermoplastics Circuit breaker Advantages Clariant’s Exolit OP 1312, OP 1314 and the newly developed OP 1400 TP* offer many advantages compared to other types of flame retardants on the market: ·Compounds made with Exolit OP have a low density and combine good mechanical properties with high CTI values. ·Exolit OP 1312 is the most efficient grade regarding UL 94 and glow wire ignition temperature (GWIT) test performance. ·Exolit OP 1314 and OP 1400 TP* provide an enhanced thermal stability and are therefore especially suitable for high processing temperatures and compounds which are injection molded into complex cavities. ·Exolit OP 1400 TP* extends the application range with its better stability to hot and humid environments. Reinforced polyamides with UL 94 V-0 classification down to 0.4 mm thickness can be achieved with the Exolit OP products. Exolit OP 1312 can be used to obtain a glow wire ignition temperature (GWIT) of 775°C, optionally in combination with melamine polyphosphate. A glow wire flammability index (GWFI) of 960°C can be attained with Exolit OP 1312, 1314 and 1400 TP* within the range of typical UL 94 V-0 dosages. PA 66GF 30: Dielectric strength** PA 66GF 30: Density** PA 66GF 30: CTI** [ kV/mm ] [ g/cm ] [ V ] 40 2.0 3 600 35 500 1.8 30 25 400 1.6 20 300 1.4 15 10 200 1.2 100 5 0 1.0 PA without FR * Test Product ** dry as molded 9 with Exolit OP with Br/Ato 0 PA without FR with Exolit OP with Br/Ato PA without FR with Exolit OP with Br/Ato Standard polyamides (6 and 66) Exolit OP 1312 Exolit OP 1314 Exolit OP 1400 TP* Material Performance The main application of Exolit OP is in glass fibre reinforced polyamides. The glass fiber content will typically be varied from 10 to 50 %. Exolit OP can also be used in non-reinforced polyamides, resulting in a non-dripping V-0. The loadings required for UL 94 V-0 ratings are in the same range as for reinforced grades. Exolit OP 1312/1314/1400 TP* are suitable for polyamides based on renewable raw materials as well, e.g. PA 6.10. Compared to polyamides flame retarded with brominated polystyrene (polystyrene/antimony trioxide) polyamides with Exolit OP achieve higher CTI values up to 600 V. Compared to compounds with red phosphorus, polyamides with Exolit OP obtain UL 94 V-0 classifications down to 0.4 mm and are suitable for color matching and laser marking. Furthermore, no specific workplace precautions against potential phosphine formation and emissions are necessary. Flame retarded polyamides with Exolit OP can be used for laser marking on light and dark colors and show good contrasts. The compounds are suitable for laser welding. Polyamides with Exolit OP provide a lower smoke density than compounds with brominated flame retardants combined with antimony trioxide or compounds with red phosphorus. Lasermarking: PA 66 GF 30 with 20 % Exolit OP 1400 TP*, 0.3 % Lazerflair 835 and 1 % Renol black MB (Nd:YAG - Laser; wavelength 1064 nm) PA 66GF 30: E-Modulus** PA 66GF 30: Tensile strength at break** PA 66GF 30: Elongation at break** [ Mpa ] [ N/mm ] [ % ] 12,000 200 4.0 2 11,000 10,000 9,000 8,000 7,000 6,000 175 3.5 150 3.0 125 2.5 100 2.0 75 1.5 50 1.0 25 0.5 0 5,000 PA without FR with Exolit OP with Br/Ato 0 PA without FR with Exolit OP with Br/Ato PA without FR with Exolit OP with Br/Ato * Test Product ** dry as molded 10 exolit® Flame retardants for thermoplastics Mechanical Properties 100 80 Smoke GWIT 60 polyamide 66-GF: Spider web diagram 40 n Exolit OP n Red Phosphorus n Br-PS 20 UL 94 Performance CTI Processing/ handling Safety PA 66GF 30: Impact strengt** PA 66GF 30: Notched impact strength** [ kJ/m ] [ kJ/m2 ] 100 12 2 90 10 80 70 8 60 6 50 40 4 30 20 2 10 0 0 PA without FR * Test Product ** dry as molded 11 with Exolit OP with Br/Ato Color 0 PA without FR with Exolit OP with Br/Ato High performance polyamides Exolit OP 1230 ·UL 94 V-0 down to 0.4 mm ·High thermal stability ·Excellent electrical properties ·Good colorability ·Halogen free Properties of Exolit OP 1230 EXOLIT OP 1230 Delivery form Decomposition temperature [ °C ] Typical UL 94 V-0 at 0.4 mm White powder > 350 °C 12 - 15 % Within the last years, high performance polyamides (HPPA) have experienced a tremendous growth. The use of aromatic monomers like terephthalic acid or isophthalic acid increases their mechanical strength as well as temperature and chemical resistance. They are used wherever a standard polyamide or polyester is not stable enough. Due to their high thermal stability as well as their easy processing, HPPAs are a very competitive choice versus liquid crystal polymers (LCP). 12 Most of these HPPA compounds need to be flame retarded according to UL 94 rating in order to fulfill the requirements in their specific applications. HPPAs used as insulating materials have to be stable against tracking (high comparative tracking index (CTI) is often required). High processing temperatures and the trend towards miniaturization challenge the performance of flame retardants in HPPAs. Additionally, when applied in the SMT process (surface mounting technology) used for printed circuit boards, HPPAs have to resist high temperatures in lead-free reflow soldering. Exolit OP 1230 is the first non-halogenated flame retardant which can withstand the demanding requirements of this high end segment of engineering plastics. Exolit OP 1230 has proven to be effective in bio based HPPAs as well. exolit® Flame retardants for thermoplastics CTI 100 80 Elasticity Water uptake 60 40 Spider web diagram of HPPA with Exolit OP 1230 vs. LCP 20 UL 94 n HPPA with Exolit OP 1230 n LCP Flowability 0 Flashing Weld line strength Surface Stiffness Blistering test of HPPA with Exolit OP 1230 HPPA compound with Exolit OP 1230 pass the blistering test. The plates were pretreated according to JDEC-J-STD 020C (MSL 2) and did not show any changes after exposing them three times to the reflow soldering temperature profile with a peak temperature of 260 °C. Plates of the same HPPA containing a competitive flame retardant showed heavy blistering under these conditions. HPPA GF 30 HPPA GF 30 HPPA GF 30 without flame retardant 13 with competitive flame retardant with 15 % Exolit OP 1230 Polyesters Exolit OP 1240 ·UL 94 V-0 down to 0.4 mm ·For reinforced and unfilled polyesters ·Excellent electrical properties ·Good colorability ·Versatile use with synergists ·Halogen free Exolit OP 1240 is a flame retardant based on an organic aluminium phosphinate which is a thermally stable white solid without any hazard classification or labeling. It can be easily compounded into polyesters and subsequently processed again to manufacture flame retarded parts used in consumer or industrial products. One of the most widely used engineering polymers is polybutylene terephthalate (PBT) and to a lower extent the related polyethylene terephthalate (PET). These thermoplastic polyesters feature excellent dimensional stability due to low moisture absorption, a good resistance against solvents and high insulating capacity making them preferred polymers for many applications in the automotive, E&E- and appliances industry. Many of these PBT or PET materials, especially glass fiber reinforced grades, need to be flame retarded to fulfill international safety requirements like the classifications of the UL 94 standard. TECHNICAL DATA Key properties of Exolit OP 1240 EXOLIT OP 1240 14 Delivery form Phosphorus content [ % ] UL 94 V-0 at 0.4 mm (PBT GF30) [ % ] Decomposition temperature [ °C ] White powder 23.3 - 24.0 20 > 350 exolit® Flame retardants for thermoplastics Melamine Polyphosphate Increased efficiency nanometric metal oxide Increased efficiency Melamine cyanurate Synergistic components Cost reduction Exolit OP 1240 POLYPHOSPHONATE Phosphinate Increased GWIT organic phosphazene Improved elongation boehmite Cost reduction By showing an outstanding flame retardant efficiency (see LOI increase in PBT compound) Exolit OP 1240 meets the demand for halogen free flame retardants in polyester applications. It works as a very good flame extinguisher by interrupting the chemical process of burning in the gas phase, comparable to the mechanism of halogen containing flame retardants. In addition, it forms a thin char barrier on the surface of the polyester. [ % ] 55 50 Limiting oxygen index Improved elongation Exolit OP 1240 can be used at relatively low loadings on its own but can be combined with many synergistic components as well. Optimised ratios of components can be provided by our technical service on request. This helps to match a variety of flame retardant and other requirements specified by equipment manufacturers. Depending on the application the focus of design engineers will be on certain electrical or mechanical properties of the PBT material. PBT compound – LOI increase by addition of Exolit OP 1240** 45 40 35 30 25 20 0 5 10 Dosage FR [ % ] ** dry as molded 15 Aryl Phosphates 15 20 Apart from the technical profile required for the application recipe costs and other criteria will be considered as well. Compared to a PBT containing a brominated flame retardant combined with antimony oxide, the halogen free materials based on Exolit OP 1240 in general have a lower density. The values are typically in the range of 1.5 versus 1.7 kg/l, depending on the synergists and the ratios applied. This allows a more lightweight construction and production of more molded parts per weight unit of compounded PBT. Polyesters Exolit OP 1240 Exolit OP 1260 TP* Material performance Exolit OP 1260 TP* is a new synergistic blend achieving UL 94 V-0 at 0.8 mm thickness with 18 wt % loading only, while enhancing melt flow and mechanical properties of polyester compounds as well. The table below summarizes the performance of a few other synergistic combinations based on Exolit OP 1240 compared to Exolit OP 1260 TP*. Each compound shows at least one specific strength. Exolit OP 1240 is an even more efficient flame retardant in either glass reinforced or unreinforced PET compounds. Only 13 to 15 % of flame retardant in total is needed to reach a UL 94 V-0 rating at 0.8 mm thickness and a high GWIT (see table on the left). For achieving the preferred GWIT level of 775 °C, once again synergistic components are helpful, like melamine cyanurate (MC) or a small amount of polytetrafluoroethylene (PTFE). As indicated in table 1 already, flame retarded PET/PBT blends with excellent properties can be manufactured with Exolit OP 1240 as well. PBT GF30 Formulations based on Exolit OP 1240 in comparison to a brominated flame retardant with antimony oxide FR loading [ %] UL 94 (0.8 mm) Elongation at break [ %] CTI GWIT (1 mm) [ V ] [ °C ] Notched impact strength [kJ/m2 ] Br / ATO 15 V-O 2.4 225 700 8.1 Exolit OP 1240 20 V-O 1.9 600 725 7 Exolit OP 1240 + MC 20 V-O 1.6 500 750 6.4 Exolit OP 1240 + MPP 20 V-O 2 550 750 7.3 Exolit op 1260 TP* 18 V-O 2.6 575 750 8 Exolit op 1240 + mpp + pc 18 V-O 2.3 425 775 6.6 Exolit op 1240 in pet / PBT 15.3 V-O 2.2 560 750 7.2 FR loading Glass fibers GWIT (1 mm) [ %] [ %] UL 94 (0.8 mm) [ °C ] Notched impact strength [kJ/m2 ] Exolit OP 1240 15 30 V-O 725 8.1 Exolit OP 1240 + MC 13 30 V-O 800 8 Exolit OP 1240 15 0 V-O 700 6.6 Exolit OP 1240 + PTFE 15 0 V-O 825 7.2 PET formulations * Test Product 16 exolit® Flame retardants for thermoplastics Polyesters Exolit OP 950 ·Melt blendable phosphinate with a melting point of 208 °C and decomposition > 350 °C ·Forms a highly viscous, polymer melt under polyester processing conditions ·For PET fibers with LOI > 30 % ·Phosphorus content 20 % Exolit OP 950 is an organic zinc phosphinate showing polymerlike properties. In contrast to Exolit OP 1240, it melts during compounding and can therefore be blended into polymers easily. For PET fibers, Exolit OP 950 can be used as an additive flame retardant. With a dosage of 5 % the LOI increases to 33 %. Exolit OP 950 can be used in PBT and PET for injection moulding as well, favourably in combination with Exolit OP 1240 and further synergists. Exolit OP 950 is under registration in various chemical inventories. For the current status please check the material safety datasheet or contact Clariant’s Product Stewartship. Exolit OP 950 is labeled according to CLP (Regulation (EC) No. 1272/2008, as amended) with H318 »Causes serious eye damage« and H410 »Very toxic to aquatic life with long lasting effects«. 17 Thermoplastic elastomers Exolit Exolit Exolit Exolit OP OP OP OP 1230 935 1311 1312 ·UL 94 V-0 / VW-1 passed ·Low smoke toxicity ·Good electrical and mechanical properties ·Good hydrolysis resistance ·Halogen free TPE-Es combine toughness and resilience with excellent resistance to creep, impact, tearing as well as flexural fatigue. Exolit OP 935 can effectively flame retard these elastomers. A loading of 20 - 30 % flame retardant is recommended depending on the chemical structure of the polymer. Adding small amounts of PTFE can prevent dripping in the UL 94 test. In some cases, the addition of nitrogen containing synergists can improve fire resistance. Flame retarded TPE-Es are used for cable extrusion, wire coating, connectors, plugs, conveyer belts or corrugated pipes. Thermoplastic Elastomers (TPE) are materials combining the processing advantages of thermoplastics with the flexible, low modulus properties of elastomers. Block copolymer TPEs include thermoplastic polyurethanes (TPU), copolyesters (TPE-E) and polyether block amides (PEBA). Due to various demands, a huge number of TPE grades are on the market ranging from Shore A 10 to Shore D 75. Exolit OP can effectively balance mechanical properties and flame retardancy in TPEs. Stress-strain diagram of TPU (UL 94 V-0) with Exolit OP, MC = melamine cyanurate [ MPa ] 25 Tensile stress 20 15 10 5 0 0 100 200 300 400 500 600 700 800 Elongation [ % ] n Exolit OP 1311 (22.5 %) + MC (7.5 %) 18 n Exolit OP 935 (15 %) + MC (15 %) exolit® Flame retardants for thermoplastics 900 Exolit OP in TPE-E (GWIT = Glow Wire Ignition Temperature, GWFI = Glow Wire Flammability Index) UL 94 test (1.6 mm) GWIT (1 mm ) GWFI (1 mm) Elongation at break (DIN 53504*) [ % ] Notched Shore D impact str. (ISO 868) (Charpy, ISO 179/1eA) Melt flow rate Spiral flow [ °C ] Tensile strength (DIN 53504*) [ kJ/m2 ] [ °C ] [ g/10 min ] [ cm ] Exolit OP 935 (20-22 %) TPE-E (Shore D55) V-O 775 960 20.5 322 13.1 56 42 47 Exolit OP 935 (20-22 %) TPE-E (Shore D40) V-1 650 900 16.9 547 no break 38 20 42 TPU is easy to ignite and difficult to flame retard. By adding 25 - 35 % Exolit OP 1311 or OP 1312 the UL 94 class V-0 can be achieved. Exolit OP 1230 can also be combined with other flame retardant synergists. Applications for flame retarded TPU are cable extrusion but also various injection moulded parts and artificial leather. Recommendation of products for TPEs EXOLIT OP 935 Micronized metal phosphinate with d95 of max. 10 μm and d50 of 2 - 3 μm EXOLIT OP 1230 Metal phosphinate with d50 of 20 - 40 μm EXOLIT OP 1311/1312 Powder blends of Exolit OP 1230 and nitrogen synergists 19 Polyolefins Exolit AP 760 Exolit AP 765 Exolit AP 766 Hostavin® NOW ·UL 94 V-0 at 1.6 and 3.2 mm ·Low smoke density ·Low smoke gas corrosivity ·Good electrical and mechanical properties ·Excellent UV stability ·Good recyclability ·Halogen free Exolit AP 760 · Standard grade for PP and PE · Injection molding applications Exolit AP 765 · Better stability for PP extrusion · Less water uptake in compounding Exolit AP 766 · Higher efficiency · Especially for glass fiber reinforced PP 20 In E&E equipment a variety of different thermoplastic materials is used. In many cases they need to be flame retarded in order to comply with fire safety standards. Intumescent flame retardants like the Exolit AP 76x range have been designed for polyolefins to pass the V-0 rating according to the UL 94 flammability test. In PP based compounds loadings of 22 - 30 % of flame retardant are needed to meet the test criteria. exolit® Flame retardants for thermoplastics Technical data of Exolit AP 76x Phosphorus [ % by wt.] Nitrogen [ % by wt.] Density [ g/ml] Bulk density [ g/ml] Moisture content [ % by wt.] Exolit AP 760 20.0 14.0 1.8 0.4 < 0.5 Exolit AP 765* 21.0 18.0 1.7 0.6 < 0.5 Exolit AP 766* 24.0 15.4 1.7 0.6 < 0.5 * For registration status please contact Clariant‘s Product Stewartship. Compound properties of PP homopolymers (V-0, 1.6 mm) containing Exolit AP 76x MFR Tensile modules Tensile yield stress [ g/10 min ] [ mPa ] PP blank 12.0 exolit AP 760 (30 %) [ N/mm2 ] Elongation at break Impact strength (Charpy) [ % ] [ kJ/m2 ] Notched impact strength [ kJ/m2 ] 1550 35 > 50 90 3.0 14.7 2270 24 6.9 19 2.0 Exolit AP 765* (25%) 10.9 2000 25 14.4 21 1.4 Exolit AP 766* (22%) 10.8 1870 25 10.5 26 1.5 Compared to the use of other non-halogenated flame retardants like metal hydroxides the Exolit grades show a better processability. In addition, mechanical properties are less affected due to the lower dosage needed. In case of a starting fire Exolit AP 76x products offer advantages compared to halogenated flame retardants. Peak heat release and smoke density from the polyolefins are much lower resulting in a significantly reduced spread of flame and better chances for people to escape from a fire. Moreover, the lower smoke corrosivity can avoid severe damage of electrical equipment installed close to the fire source. Hostavin NOW solutions Hostavin NOW XP is a new additive that acts simultaneously as a flame retardant and as a UV light stabilizer. Its innovative technology, based on polymeric aminoether-HALS (hindered amine light stabilizer), makes Hostavin NOW XP compatible with a variety of polymers, especially polyolefins. Typical loadings are between 1 and 3 %. For instance, melt spinning Hostavin NOW in a PP fiber results in a significant increase in the LOI (limiting Oxygen Index) without influencing the color (no yellowing). The tailor-made Hostavin NOW FR XP blend can be added to polyolefin films to reach B2 classification according to the German DIN 4102 without influencing the transparency of the films. 21 Clariant development and Costumer Support Clariant offers a wide range of polymer additives: flame retardants, waxes, antioxidants, UV stabilizers, and antistatic agents. In order to efficiently respond to customers’ needs Clariant’s Additives Business Unit operates its own application technology plastics center. Our dedicated technical service offers support regarding individual recipe development and optimization of flame retardant and additive packages. 22 exolit® Flame retardants for thermoplastics State-of-the-art plastics processing allows compounding and masterbatch preparation including strand and under-water pelletizing as well as die-face cutting. Test specimens are produced via injection molding, profile extrusion and blow moulding of films. Flammability tests (UL 94, LOI, GWFI/ GWIT, DIN 4102 B2, CTI, FMVSS 302) are completed by a wide range of standard methods to characterize plastics properties (e.g. mechanical and rheological data). Clariant’s analytical labs assist with most suitable and up to date methods such as, Nuclear Magnetic Resonance (NMR) spectroscopy, High Pressure and Gas Chromatography (HPLC, GC), Differential Scanning Calorimetry (DSC), Thermo-Gravimetric Analysis (TGA), Fourier-Transform Infrared spectroscopy, elemental analysis etc. which are accurate and reliable analytical techniques for development work. 23 Clariant International Ltd Rothausstrasse 61 4132 Muttenz Switzerland Business Unit Additives Business Line Flame Retardants Phone + 41 (0) 61 469 79 12 Fax + 41 (0) 61 469 75 50 www.exolit.com This information corresponds to the present state of our knowledge and is intended as a general description of our products and their possible applications. Clariant makes no warranties, express or implied, as to the information’s accuracy, adequacy, sufficiency or freedom from defect and assumes no liability in connection with any use of this information. Any user of this product is responsible for determining the suitability of Clariant’s products for its particular application. * Nothing included in this information waives any of Clariant’s General Terms and Conditions of Sale, which control unless it agrees otherwise in writing. Any existing intellectual/industrial property rights must be observed. Due to possible changes in our products and applicable national and international regulations and laws, the status of our products could change. Material Safety Data Sheets providing safety precautions, that should be observed when handling or storing Clariant products, are available upon request and are provided in compliance with applicable law. You should obtain and review the applicable Material Safety Data Sheet information before handling any of these products. For additional information, please contact Clariant. * For sales to customers located within the United States and Canada the following applies in addition: NO EXPRESS OR IMPLIED WARRANTY IS MADE OF THE MERCHANTABILITY, SUITABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE OF ANY PRODUCT OR SERVICE. ®Trademark of Clariant registered in many countries. ©2013 Clariant International Ltd Edition | 06.2013 www.clariant.com