HIGH GAIN TRANSFORMERLESS DC

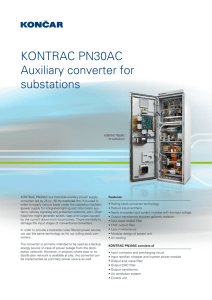

advertisement