An Algorithm for Boost Converter Efficiency Optimization

advertisement

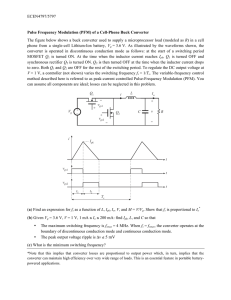

2013 XXIV International Conference on Information, Communication and Automation Technologies (ICAT) October 30 – November 01, 2013, Sarajevo, Bosnia and Herzegovina An Algorithm for Boost Converter Efficiency Optimization Zeljko Ivanovic, Branko Blanusa, Mladen Knezic Faculty of Electrical Engineering Banja Luka, Bosnia and Herzegovina zeljko.ivanovic@etfbl.net Abstract—In this paper, an algorithm based on the technique of variable switching frequency is applied, so that working point of boost converter is at the boundary between continuous and discontinuous working mode aiming at achieving maximum efficiency of the converter. Controller is based on variable switching frequency and measuring the voltage on the main converter switch. The proposed algorithm is verified by the simulations and experimental measurements on a converter prototype. Keywords—efficiency, boost converter, frequency controller I. INTRODUCTION The share of renewable energy sources in production of electrical energy is constantly growing. DC/DC converters are becoming essential part of the system for the production of electrical energy from renewable energy sources [1], [2]. In these applications, due to variability of operating conditions and limitations imposed by primary energy sources, efficiency of the used converter is very important. Also, efficiency is an indicator of success of new topologies and/or new control algorithms. Highly-efficient converters are small, have smaller temperature changes, and also higher reliability [3]. In the systems with wind turbines and synchronous generator, photovoltaic sources and fuel cells, basic topology of DC/DC boost converter (Fig. 1) is often used [1], [4] - [7]. In the papers [4], [5], [8], it was shown that the maximum efficiency of the boost converter in the wind power plant with a permanent magnet generator (PMG) can be achieved if it works at the border between the continuous (CCM) and the discontinuous current mode (DCM). In this paper, an algorithm that uses a variable switching frequency and keeps converter operating point at the border between the DCM and the CCM is applied. Change of the switching frequency is based on the fact that converter often works with the input power less than rated. This is a very common case for the converter in renewable energy sources, as well as battery-operated devices. Range of switching frequency is determined by the specified operating conditions (output voltage ripple, maximum flux density in the inductor core, etc.). The proposed algorithm is verified by the simulations and experimental measurements on the converter. Rated power of used converter is 500W. This paper work consists of five sections. Efficiency of the boost converter as a function of switching frequency is resented in the second section. 978-1-4799-0431-0/13/$31.00 ©2013 IEEE iL L D iD . iLOAD . + + - iSW Tr VIN iC C RL VOUT VG + - . . . - Figure 1. Boost converter. Proposed algorithm, which maintains the converter working point at the border between the DCM and the CCM and simulation results are given in the third section. The experimental set up and the results of measurements are given in the fourth section. Results are summarized in the conclusion. II. BOOST CONVERTER EFFICIENCY Conduction and dynamic losses are main part of boost converter losses. Total power losses PLOSS are equal to [9], [10]: PLOSS = PCOND + WT OT ⋅ f sw , (1) where: PCOND – conduction losses, WTOT – total energy of dynamic losses during one switching period, fsw – switching frequency. Term PDYN = WTOT⋅fsw represents the average dynamic power losses. Conduction losses are directly proportional to the load, and very little dependent on the switching frequency. Dynamic losses are directly proportional to the swithing frequency, and very little dependent on the load. The power losses in the boost converter obtained by simulations (based on the model given in [8]) are presented in Fig. 2. Work of boost converter is simulated in system of wind power plant with a permanent magnet (PM) generator. In this simulation converter input power is 150 W. The frequency fb is boundary between the DCM and CCM. At frequencies lower than fb, converter operates in DCM mode. By decreasing the switching frequency, current ripple grows up and, consequently, effective value of current through the inductor. Increase of the effective value of the current through the elements results in the increase of conductive losses in the converter. Increase of the switching frequency results in lower effective value of current through the elements and thus reduces the conduction losses (dashed line). However, with increase of switching frequency, dynamic losses grow up (dotted line), which at certain switching frequency become larger than the conduction losses. 15A DCM Rectifier current CCM 10A Inductor current 5A 0A 200ms I(D2) 205ms I(D3) I(L1) 210ms 215ms 220ms Time In DCM, current through the inductor falls to zero, so that soft switching is realized when switch is turning on. This is a reason why the characteristic of dynamic losses is refracted at frequency fb, as can be seen in Fig. 2. Total losses (solid line) have the minimum around the boundary between the DCM and the CCM, i.e. in this case converter has the highest efficiency. III. CIRCUIT FOR DETECTING THE BOOST CONVERTER OPERATION MODE To achieve maximum efficiency of boost converter when its input power changes, converter working point should be around the border between the CCM and DCM. Converter controller and algorithm based on the measurement of the minimum inductor current aiming at determining operation mode (CCM or DCM) are proposed in [5]. Switching frequency of the converter changes so that operating point leads to boundary between the DCM and the CCM. However, the boost converter is powered through the diode rectifier, so that inductor current has the low frequency component (Fig. 3). Topology with diode rectifier and boost converter is used in low power wind power plant with PM generator and in some power factor correction circuits [6], [7], [11]. Waveforms of the current through the single phase rectifier and the inductor in boost converter are shown in Fig. 3. As it can be seen, inductor current, besides a high frequency, has low frequency AC component. This is due to low impedance of inductor in boost converter for AC voltage on its input. In this case, the capacitor as an output filter in boost converter acts as a part of rectifier circuit. When the converter works at the border between the CCM and DCM, and rectifier diodes conduct, current through the inductor is not close to zero, which might be a problem for the controller based on measuring the current through the inductor (Fig. 3). Also, depending on the metod of current measurement, efficiency of the converter can be decreased. Voltage across the transistor in boost converter without RC snubber circuit, when it works in DCM and CCM, is shown in Fig. 4. Waveforms of the boost converter, which is powered through the single-phase rectifier (Fig. 4), are obtained by PSPICE simulations. As opposed to the current through the inductor, the voltage across the rectifier output has no affect to waveform of voltage across the boost converter transistor. Oscillations in the DCM are result of the energy exchange between the inductor and the parasitic capacitances in the transistor. 15V Control pulse Figure 2. Power losses of boost converter in wind turbine as a function of switching frequency when input power is 150 W. Figure 3. Current through the rectifier and the inductor in boost converter. 10V 5V SEL>> 0V V(V2:+) 400V VDS 200V 0V 125.00ms 125.02ms V(L1:2) 125.04ms 125.06ms 125.08ms 125.10ms Time a) 15V Control pulse fb 10V 5V 0V V(R12:1) 400V VDS 200V SEL>> 0V 125.000ms 125.005ms 125.010ms 125.015ms 125.020ms 125.025ms V(L1:2) Time b) Figure 4. Control signal and voltage across the transistor for a) DCM and b) CCM. Proposed circuit for detecting falling edge at the switch is shown in Fig. 5. Voltage across the switch is lowered by the voltage divider (resistors R1 and R2) and then is led to the delay circuit, which consists of resistor R3 and capacitor C2. Comparator compares the original and delayed signal and gives positive pulse at the output when voltage across the switch drops. Capacitor C1 is used to filter out the high frequency components. Control pulses 15V 10V 5V SEL>> 0V V(R12:1) 400V 300V VDS 200V 100V 0V V(L1:2) 5.0V Comparator output As can be seen in Fig. 4, the transistor voltage in discontinuous mode drops before the rising edge of the next control pulse. In CCM the voltage across the switch drops after the control pulse. The fact that, in DCM, voltage across the transistor drops before the rising edge of the next control pulse, can be used to keep the converter operating point at the boundary between the CCM and the DCM. 2.5V Vds R1 R3 1k 470k 8 3 C1 C2 1n 470p 15k R2 2 R4 2.2k V+ + U1A LM393OUT - 4 1 Vcc 5V V V- 125.01ms 125.02ms b) 125.03ms Time Figure 7. Simulation results of the boost converter in CCM. When voltage VDS is zero, than voltage across the capacitor C2 is greater than the voltage across the capacitor C1, and output of the comparator is positive. 0 Figure 5. Circuit for detection of falling edge of voltage across the transistor. By comparing the positive pulses at the output of the comparator with control pulses, it can be concluded in which mode converter works. If the coverter operates in discontinuous mode, a positive pulse at comparator output will appear before the control pulse. Greater time between pulses at comparator output and control pulses means that converter works deeper in DCM. When the converter operates in CCM, pulse at comparator output appears after the control pulse. Simulation results of circuit from Fig. 5 in DCM and CCM are shown in Fig. 6 and Fig. 7, respectively. Control pulses 0V 125.00ms V(R4:1) 15V 10V 5V 0V V(V2:+) Proposed boost converter controller is shown in Fig. 8. It consists of two independent controllers, voltage controller and frequency controller. Algorithm of frequency controller based on measuring the voltage on the switch is shown in Fig. 9. Pulses at the comparator output and control pulses are compared and the time between the rising edges of these two signals is calculated (Diff). This time is compared with two thresholds Up and Down, which are positive and Up > Down. If Diff is greater than the threshold Up, converter is deeper in DCM, and it is necessary to increase the switching frequency in order to return operating point back to the border between the DCM and the CCM. When Diff is less than Down, converter is (or will be) in the CCM, so it is necessary to reduce switching frequency in order to maintain operating point around the boundary between the DCM and the CCM. When working point is around the border between the DCM and the CCM, Diff would be between the thresholds Up and Down. 400V VDS 200V 0V Comparator output V(L1:2) 5.0V 2.5V SEL>> 0V 125.00ms V(R4:1) 125.04ms a) 125.08ms 125.11ms Time Figure 6. Simulation results of the boost converter in DCM. Figure 8. Block diagram of proposed boost converter controller. In this case, the switching frequency remains constant, until the value of operating point is changed, for example due to changes of input power etc. Switching frequency is changed with the step ∆f. Value of the switching frequency is bounded from below and above with constants fmin and fmax, respectively. Converter must enter the steady-state before the new value of switching frequency is generated. Choice of constants Up and Down defines sensitivity of frequency controller, as well as the value of the converter working point in a steady state. By choosing appropriate thresholds (Up and Down) it is possible to stop the change of switching frequency when working point of converter is close to border between the DCM and the CCM. Clearly, in this case and in the steady state, converter works in DCM, but very close to border with CCM. In the proposed algorithm, the frequency controller can work with only one threshold with which Diff time is compared, but in that case switching frequency would always change. IV. EXPERIMENTAL RESULTS To verify the proposed algorithm, measurements were performed on a prototype whose characteristics are: input voltage VIN=100-300 V; output voltage VOUT=300 V (0-100% of the load); maximum output power POUT=500 W; maximum switching frequency fsw=100 kHz and maximum ripple of output voltage ∆VOUT < 3V. Block diagram of the experimental set up is shown in Fig. 10. Instead synchronous generator, autotransformer was used. Frequency controller in Fig. 8 and measurement of converter efficiency are implemented in HUMUSOFT MF624 card and Real-Time Windows Target of MATLAB-Simulink. Resistor 75 Ω and MOSFET were used as variable electronic load. Oscilloscope HP Infinium 500MHz was used for recording characteristic waveforms. Boost inductor VDS VPULSE Sw + - Yes fSW(n-1) < fMAX - Df Diff < Down Yes Time stamp fSW(n-1) > fMIN + Df Yes Yes fSW(n) = fSW(n-1) + Df fSW(n) = fSW(n-1) - Df Figure 9. Algorithm applied in frequency controller. L . D VDS . VOUT ,iLOAD + Tr CF 220V 50Hz ELECTRONIC LOAD C + - . . . PIC24FJ +Dfsw -Dfsw PERSONAL COMPUTER MATLAB SIMULINK + REAL TIME WINDOWS TARGET MF624 I/O CARD HUMUSOFT Figure 10. Block-diagram of experimental set up. Due to the relatively high switching frequency, acquisition card cannot compare the control pulses and pulses at the comparator output (Fig. 5). Therefore, microcontroller PIC24FJ64GA002 was used. Depending on which output is active (+∆fsw or -∆fsw), switching frequency increases or decreases. It was assumed that the microcontroller outputs are updated every second (Time stamp). Switching frequency was changed with the step of 1 kHz, with the range 20kHz-100kHz. Waveform of the drain-source voltage and pulses at the comparator output (Fig. 5) in DCM are shown in Fig. 11. The results of measurements shown in Fig. 11 verify the simulation results, and the correctness of the proposed circuits for detecting falling edge of drain-source voltage across the switch. Control pulses and pulses at comparator output, in both converter operating modes are shown in Fig. 12. Dependence of the converter efficiency as a function of its input power is shown in Fig. 13. It can be seen that by using the proposed algorithm, in comparison with the standard approach with a fixed switching frequency, higher efficiency of converter can be achieved. The difference in efficiency goes up to 6% in favor of the proposed algorithm. V. Diff = TSW-TPULSE Diff > Up . RECTIFIER In order to reduce the dimensions of reactive elements, standard converter usually works in CCM at relatively high switching frequency. Therefore, the switching frequency of 100 kHz was selected for a converter that works with fixed switching frequency, and it was compared with the proposed algorithm. x x VIN ,iIN CONCLUSION Renewable energy sources often operate at power less than rated. Applying the proposed algorithm higher efficiency can be achieved in comparing to the case when converter works with fixed switching frequency. This allows better utilization of renewable energy and less heat of converter. The proposed algorithm, for variable input power, maintains converter operating point at the boundary between the DCM and the CCM, and thus ensures maximum converter efficiency. This algorithm was verified through simulations and the experimental measurements on the boost converter prototype. Experimental measurements have shown that it is possible to achieve higher converter efficiency when technique of variable switching frequency is applied. In the future work, we planned to establish correlation between the parameter Diff and a change of switching frequency ∆f, aiming at speeding up the proposed algorithm. Comparator output VDS voltage Figure 11. Drain-source voltage and pulses at the comparator output in DCM of the converter. Figure 13. Converter efficiency as a function of input power for fixed and variable switching frequency obtained by experimental measurements. REFERENCES [1] Comparator output Control pulses Diff > up a) Comparator output Control pulses Diff < down b) Figure 12. Control pulses and pulses at the comparator output for: a) DCM of the converter; b) CCM of the converter. Frede Blaabjerg, Zhe Chen, and Soeren Baekhoej Kjaer: “Power Electronics as Efficient Interface in Dispersed Power Generation Systems,” IEEE Transactions on Power Electronics, Vol. 19, No. 5, September 2004. [2] Zhe Chen, Josep M. Guerrero, Frede Blaabjerg: „A review of the State of the Art of Power Electronics for Wind Turbines,“ IEEE Transactions on Power Electronics, Vol. 24, No. 8, August, 2009, pp. 1859-1875. [3] R. W. Erickson, D.Maksimovic: “Fundamentals of Power Electronics”, (Kluwer Academic Publishers, 912 pages, 2nd edn 2001). [4] Z. Ivanovic, B. Dokic, B. Blanusa, M. Knezic: “Boost Converter Efficiency Optimization in Wind Turbine”, 14th International Power Electronics and Motion Control Conference EPE-PEMC 2010, Part T3, pp. 1–5, Ohrid, September 2010. DOI:10.1109/EPEPEMC.2010.5606839. [5] Z. Ivanovic, B. Blanusa, M. Knezic: “Algorithm for Efficiency Optimization of the Boost Converter in Wind Turbine”, 15th International Power Electronics and Motion Control Conference EPEPEMC 2012 ECCE Europe, pp. DS3c.9-1- DS3c.9-6, Novi Sad, Serbia, September 2012. DOI: 10.1109/EPEPEMC.2012.6397345. [6] Frede Blaabjerg, Remus Teodorescu, Zhe Chen, Marco Liserre: “Power Converters and Control of Renewable Energy Systems”, First International Conference of Energy Innovation, Barcelona, Spain, 2005. [7] S. Jiao, D. Patterson and S. Camilleri: “Boost Converter Design for 20kW Wind Turbine Generator”, NT Center for Energy Research, Northern Territory University, Darwin, Sept 26 – 29, 1999. [8] Zeljko Ivanovic, Branko Blanusa, Mladen Knezic, “Power Loss Model for Efficiency Improvement of Boost Converter,” XXIII International Symposium on Information, Communication and Automation Technologies, Sarajevo, October 27-29, 2011. [9] Barry Arbetter, Robert Erickson, Dagan Maksimović: “DC-DC Converter Design for Battery-Operated Systems”, IEEE Power Electronics Specialists Conference, Atlanta, GA, June 18-22, 1995, pp. 103-109. [10] R. Erickson, Dragan Maksimović: “High Efficiency DC-DC Converters for Battery-Operated Systems with Energy Management”, Worldwide Wireless Communications, Annual Reviews on Telecommunications, 1995. [11] Laszlo Huber, Yungtaek Jan, Milan M. Jovanovic: “Performance Evaluation of Bridgeless PFC Boost Rectifiers”, IEEE Transactions on Power Electronics, Vol. 23, No. 3, May 2008, DOI: 10.1109/APEX.2007.357510