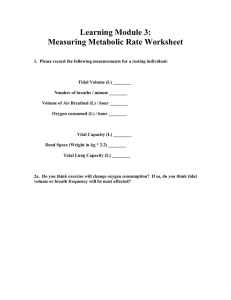

tidal energy system for on-shore power generation

advertisement