AC Breakdown Characteristics of Nomex and Kapton as Insulation

advertisement

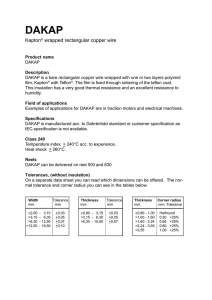

Applied Physics Research; Vol. 6, No. 6; 2014 ISSN 1916-9639 E-ISSN 1916-9647 Published by Canadian Center of Science and Education AC Breakdown Characteristics of Nomex and Kapton as Insulation Material Used in Pancake Tape Coil Structure for Resistive-Type Superconducting Fault Current Limiter H. Sun1, F. Wang1, H. Gao1, X. Liu1, Z. Jin1 & Z. Hong1 1 Department of Electrical Engineering, Shanghai Jiao Tong University, Shanghai, China Correspondence: Z. Hong, Department of Electrical Engineering, Shanghai Jiao Tong University, Shanghai, China. E-mail: zhiyong.hong@sjtu.edu.cn Received: October 10, 2014 doi:10.5539/apr.v6n6p96 Accepted: October 24, 2014 Online Published: November 26, 2014 URL: http://dx.doi.org/10.5539/apr.v6n6p96 Abstract A resistive-type superconducting fault current limiter (SFCL) is one of the most promising superconducting devices in an electrical power system. However, an SFCL has the very obvious disadvantage of a large space requirement when applied in high-voltage-level power networks. Considering the space utilization efficiency, a pancake structure in which superconducting tapes are wound into coils should be adopted. When certain faults occur in a power grid, a relatively high voltage difference will be present in the tape coil. The inner and outer layers are in direct contact; therefore, special measures have to be carried out to overcome high-voltage insulation safety issues. Two commonly used materials are considered in this study: Nomex and Kapton. The basic AC breakdown characteristics in air and liquid nitrogen are explored. A new breakdown-strength testing platform is manufactured to obtain the breakdown voltage. Considering that the edges of the superconducting tape are very thin, the impact of the superconducting-tape thickness on the breakdown strength is explored. Two methods, parallel and vertical lapping, are used to lap the insulation layer onto the tape and are subsequently compared. Finally, a face-to-face electrode structure breakdown test is conducted to simulate the actual working conditions in a tape coil. The results obtained can be used to design and optimize the geometrical structure of the SFCL pancake component. Keywords: SFCL, Pancake component, tape coil, breakdown characteristic, insulation material, lapping method 1. Introduction The discovery of high-temperature superconductivity has raised a great deal of interest in the exploration of its potential applications in a power system. A resistive-type superconducting fault current limiter (SFCL) is regarded to be one of the most promising superconducting applications. Resistive-type SFCLs have attracted significant attention, and many related studies have been carried out worldwide (Hassenzahl, 2000). In our university, a 10-kV resistive-type SFCL has been built and tested (Hong et al., 2012). In 2014, a higher voltage prototype will be designed and demonstrated. Different types of primal designs have been reported. Among them, a design using a stack of pancake components (Hobl et al., 2013) has the best performance for space utilization efficiency. In each component, superconducting tapes are wound into a coil. A relatively high voltage difference will be present between two adjacent layers during faults in power system. Special measures have to be taken to overcome high-voltage issues. Lapping an insulation layer around the tape is one possible solution. Therefore, the selection of insulation materials, lapping methods, and other aspects should be studied. The breakdown characteristics of different polymer materials has been tested (Ombello et al., 2002). Further, the insulation properties have been explored at room temperature (Ul Haq, & Raju, 2006) and cryogenic temperatures (Zhang, Zhang, Tan, Luo, & Tu, 2012). A comparison between the DC and AC breakdown characteristics has also been carried out (Seong, Seo, Hwang, & Lee, 2012). The results obtained from all of these tests are valuable and comprehensive. However, all of these former studies have used a standard electrode configuration. No research has considered the actual electrode structure in a pancake component used in an SFCL. In this paper, we consider Nomex (polyamide) and Kapton (polyimide), which are very commonly used insulation materials and have very good mechanical and dielectric properties in liquid nitrogen (LN2). Tests are conducted to measure the AC breakdown characteristics of these two materials in LN2 and to verify the effectiveness of our newly created test platform. 96 www.ccsennet.org/apr Applied Physics Researrch Vol. 6, No. 6; 2014 The fact thhat a superconnducting tape is very thin m may underminee the breakdow wn strength. F Furthermore, a very sharp edgee will aggravaate a partial disscharge, and m more initial eleectrons are injeected into the dielectric. The use of copper (0.1-mm thicckness) and suuperconductinng (0.3-mm thhickness) tapes as a compaarison will pro ovide further dettails regarding this issue. There are ttwo main methhods to lap thee insulation layyer onto the tappe: parallel lappping and vertiical lapping. In n this research, w we will demonstrate how thhese two methhods work, annd the breakdoown characterristics of these e two methods w will be comppared. The ressults show thhat vertical laapping can ennhance the brreakdown strength. Furthermoore, a face-to-face electrodee structure breeakdown test is conducted to simulate tthe actual worrking conditionss in a tape coil.. 2. Experim mental Setup The pancaake-structure resistive-type r SFCL has beeen conceptuallly designed, aand a schemattic diagram off one componennt is shown in Figure F 1. A layyer of insulatioon material is llapped around the tape. Figure 1. Schematic diagram of one pancake compoonent The breakdown tests useed a 50-Hz AC C power sourcce. Nomex andd Kapton sheetts were preparred and designed to have dimeensions of 70 × 70 mm2. The sheets were cleaned with aalcohol and pllaced in air or LN2 environm ments for 24 h beefore each test. A schemattic diagram of the experimenntal setup is shoown in Figure 2. This setup iis used for perfforming breakd down experimennts and is modiffied from the pprevious setup ((Li et al., 20144). The double-layered glass vvessel has a vac cuum between thhe two layers. In order to preevent the occurrrence of bubbbles in the LN22 from affectinng the experim mental results, theere is a 10-m min interval tim me between evvery two expeeriments. The supporting strructure is mad de of glass-fiberr-reinforced plaastic (G10) beccause of its perrfect electrical and mechaniccal robustness. In addition, an n AC voltage is applied, increeased by 200 V at a time, and maintaineed for 30 s too observe the occurrence off any breakdownn. The initial vooltage is set to be 40% of thee expected breaakdown voltagge. If breakdow wn occurs withiin six increases iin voltage, thee initial voltagge is lowered, and the test iis performed aagain. For each sample, testts are performed five times, andd the average vvalue is used too calculate the bbreakdown streength. Fiigure 2. Experrimental setup for the dielecttric-sheet breakkdown test 97 www.ccsennet.org/apr Applied Physics Researrch Vol. 6, No. 6; 2014 2.1 Dielectric-Sheet Breakdown Test A newly ffabricated electtrode configurration and the entire experim mental structurre are shown inn Figure 3 (a). The configurattion of electroode conforms to the IEC 600243 standardd, and all metaal parts are m made of brass. The high-voltaage and groundd electrodes arre 25 mm in diiameter and heeight and havee 3-mm roundeed edges. Diffferent sample thiicknesses are prepared: p 0.05, 0.08, and 0.113 mm for Nom mex; and 0.033, 0.05, and 0.007 mm for Kapton. Tests are cconducted in aiir and LN2 to make a compaarison. 2.2 Influennce of the Thicckness of the Ta Tape on the Breeakdown Strenggth Another seet of electrodees is fabricatedd according to the IEC602433 standard. Thee high-voltagee electrode is 6 mm in diameteer and 25 mm in height and has 1-mm rouunded edges. S Superconductinng (100 mm inn length, 12 mm m in width, andd 0.3 mm in thickness) and ccopper (100 mm m in length, 122 mm in widthh, and 0.1 mm in thickness) tapes are used aas the ground electrode. e The tapes are presssed beneath a metal slug coonnected to thee ground wire. The entire expeerimental struccture is shownn in Figure 3 (bb). The paralleel lapping methhod is adoptedd, and the tape es are lapped witth Nomex (0.13 mm in thickn kness) and Kappton (0.07 mm in thickness). Figgure. 3 Electrodde configuratioon: (a) dielectrric-sheet breakkdown test andd (b) the use off copper and superrconducting taapes as the grouund electrode 2.3 Compaarison Betweenn Parallel Lappping and Vertiical Lapping The paralllel and vertical lapping methhods are show wn in Figure 4. The results aacquired are coompared to explore the differences between these two lappping methods. Figure 4. Dem monstration off the lapping m method: (a) paraallel lapping annd (b) verticall lapping 2.4 Face-tto-Face Electroode Breakdow wn Test To simulatte the actual working w condittions in the tappe coil, supercconducting tappe is used as bboth a high-vo oltage electrode aand a ground electrode. Thhe electrode coonfiguration iss shown in Fiigure 5. The eentire experim mental setup is im mmersed in LN N2 in a foam pllastic tank. The high-voltagee and ground electrodes are llapped with No omex 98 www.ccsennet.org/apr Applied Physics Researrch Vol. 6, No. 6; 2014 and Kaptoon insulation laayers, respectivvely, using thee parallel lappiing method. Itt should be pointed out that there are two layyers of insulatiion material beetween the higgh-voltage and ground electroodes. Figuure 5. Face-to-fface electrode configuration 3. Results and Discussion 3.1 Dielecctric-Sheet Breakdown Test Figure 6 annd Figure 7 shhows the relationship betweeen the breakdoown strength annd the thickness of the Nomex or Kapton shheets in air andd LN2. The brreakdown streength is calcullated as the brreakdown volttage divided by y the thickness. In air, the breeakdown strenngth of Nomexx increases as the sheet thicckness increasses. In contrastt, the breakdownn strength of Kapton K decreaases as the sheeet thickness inncreases, and the breakdow wn strength tends to saturate att 91.4 kV/mm. The breakdoown strength oof Kapton is aalmost three tim mes that of Nomex. In LN2 2, the breakdownn strength of both Nomex and Kapton decrease as thhe sheet thickkness increasees. The breakd down strengths ttend to saturatee at 56 and 1166 kV/mm for N Nomex and Kaapton, respectivvely, and the bbreakdown stre ength of Kapton is only two tiimes that of Nomex. Furtherrmore, Kaptonn has better dieelectric propertties than Nomex in both air annd LN2. Compparing with thhe values in airr, the breakdown strength of Nomex is inncreased by at least two times but only 27% % for Kapton. This result maay mean that L LN2 has perm meated into thee Nomex sheet and significanttly enhanced its i dielectric sttrength. This pphenomenon iis called the coomplex insulaation effect (Zh hang, Zhang, Taan, Luo, & Tuu, 2012) and iss used in transsformer insulaation by a com mbination of soolid sheets and d oil; however, iit has not beenn demonstratedd for LN2. Figure 6. Reelationship bettween the breakkdown strengtth and Figure 7. Relatiionship betweeen the breakdo own the thicknesss of the Nomexx sheet sttrength and thee thickness of the Kapton sheet 99 www.ccsennet.org/apr Applied Physics Researrch Vol. 6, No. 6; 2014 3.2 Influennce of the Thicckness of the Ta Tape on the Breeakdown Strenggth To study the influencee of the thickkness of the tape on the breakdown sttrength, the uuse of copperr and supercondducting tapes is compared. The superconducting tapees used in thee experimentss are provided by American Superconducttor with a thicckness of 0.3 mm, and the thickness of the copper tappe is 0.1 mm. The parallel lappping method is adopted. Figgure 8 shows tthe breakdownn voltages of thhe Nomex andd Kapton insulation layers. Thhe breakdown strengths are calculated, annd Table 1 lists the breakdow wn strengths ffrom the sheet test with parallel lapping. Thhe breakdownn strengths of N Nomex and K Kapton are 50.66 and 93.4 kV V/mm, respectiively, when coppper tape is useed as the grounnd electrode. IIn comparison with the breakkdown strengtths of the diele ectric sheet in LN N2, the breakdown strengthh decreases byy 9.6% and 19.5% for Nomeex and Kaptonn, respectively.. The copper tappe has very shharp edges; thuus, the electricc field around these edges iss highly non-uuniform. The initial electrons aare more likelyy to be producced here, and the partial disscharge could be very intensse. The breakd down strengths oof Nomex and Kapton are 566.8 and 101.1 kkV/mm when the supercondducting tape is used as the grround electrode. In comparisonn with the breaakdown strenggth of the dieleectric sheet in LN2, the breaakdown streng gth of Nomex is almost the sam me, yet the brreakdown strenngth of Kaptoon decreases byy 12.8%. From m the experim mental results, wee can concludde that a veryy low thicknesss will lead too a decrease iin the breakdoown strength. This influence iis more obvious for Kaptonn. For Nomex, the influence is minimal w when the thicknness is greater than 0.3 mm. Figure 8. Breakdownn strength whenn copper and ssuperconductinng tapes are used as the grouund electrode fo or Nomeex and Kaptonn Table 1. Breakdown streengths of Nomeex and Kaptonn using parallel lapping Material Sheet Test (kV/mm)) Copper Tape Useed (kV/mm)) Superconnducting Tape Useed (kV/mm)) Nomex 56 50.6 56.8 Kapton 116 93.4 101.1 3.3 Compaarison Betweenn Parallel Lappping and Vertiical Lapping Figure 9 sshows the breaakdown voltagges of the insuulation layer w when it is lappped onto a coppper tape using the parallel annd vertical meethods. Both N Nomex and K Kapton are testted, and a coppper tape is uused as the ground electrode. For parallel lapping, l the bbreakdown streengths are 500.6 and 93.4 kkV/mm for Noomex and Kapton, respectivelly. For verticaal lapping, the breakdown sttrengths are 600.6 and 104.9 kV/mm for N Nomex and Kapton, respectivelly. Compared with the expeerimental data of parallel lappping method, the vertical laapping method d can increase breakdown streength by 19.8% % and 12.3% for Nomex annd Kapton, resspectively. Partts of the insulation layer are ddouble-layeredd when verticaal lapping is uused. This is m may be the reeason why verrtical lapping has h a 100 www.ccsennet.org/apr Applied Physics Researrch Vol. 6, No. 6; 2014 higher breakdown strenggth. However, this enhancem ment is very lim mited because vertical lappinng is more like ely to introduce air bubbles annd other impuurities. In addiition, the breaakdown voltagges are more ddispersed when n the vertical lappping method is adopted. W When the breakkdown point iss in a one-layeer area, the breeakdown volta age is relatively llow; however,, the breakdow wn voltage is reelatively high when the breaakdown point iis in a double-layer area. 3.4 Face-tto-Face Electroode Breakdow wn Test To simulaate the actual working condditions in a taape coil, facee-to-face breakkdown tests aare conducted. The high-voltaage and groundd electrodes aare made of suuperconductingg tape lapped in the insulattion layer with h the parallel lappping methodd. The high-voltage and grouund electrodess are pressed ttogether face-tto-face with a G10 slug and T Teflon screws. Two layers oof insulation m material exist between the electrodes in this structure. The breakdownn voltages aree presented in Figure 10. It is shown thatt the breakdow wn voltages arre only 1.3 and d 1.2 times of thhe value of onne layer of insuulation for Noomex and Kaptton, respectiveely. The breakdown strength hs are only 38.1 aand 62.9 kV/m mm for Nomexx and Kapton, respectively, inn this insulatioon structure annd decrease by 32.9% and 37.8% %, respectively.. The results shhow that the fa face-to-face inssulation structuure will lead too a very signifficant decrease inn the breakdow wn strength and will affect K Kapton more thhan Nomex. Figure 99. Breakdown strength s of parrallel and vertical lapping for Nomex and K Kapton Figgure 10. Breakkdown strengthh of a face-to-fface insulation struucture for Nom mex and Kapton 4. Conclussion The basic insulation prooperties of Nom mex and Kaptoon sheets are ttested in air annd LN2 using a newly fabric cated test platforrm. The breakddown strengthhs of both insullation materialls will greatly increase in LN N2. The breakd down strength off Kapton is higgher than that oof Nomex, andd the complex insulation effeect is observedd for Nomex. On the bassis of the concceptual design of a pancake--structure resisstive-type SFC CL, superconduucting tapes sh hould be lapped with an insulaation layer. Thhe breakdown sstrength of thee insulation maaterial will siggnificantly decrease when lappped onto the taape. This is moost likely becaause the tape iis very thin annd has very sharp edges at which w partial disccharge is moree likely to occuur. It is also shhown that Kapton is far moree sensitive to tthe thickness of o the tape than N Nomex. Whenn the tape thickkness is greaterr than 0.3 mm, the breakdow wn strength of N Nomex remain ns the same. Thee influence of the t thickness oof the tape on tthe breakdownn strength is veerified. Two laapping method ds are used in thiis study: paralllel and verticaal lapping. Thee comparison bbetween these two methods shows that vertical lapping haas better insulation perform mance, but thee increase is very limited owing to the greater chanc ce of introducinng bubbles andd impurities. F Further, face-too-face breakdoown tests are cconducted to simulate the actual a working coonditions in a tape coil. The coil structure will greatly w weaken the breaakdown strenggth of the insulation layer. The results obtaineed can be usedd to design andd optimize the geometrical sttructure of panncake resistive-type SFCL com mponents. 101 www.ccsenet.org/apr Applied Physics Research Vol. 6, No. 6; 2014 Acknowledgments The authors are with the Department of Electrical Engineering, Shanghai Jiao Tong University, Shanghai 200240, China. This work was sponsored by Science and Technology Commission of Shanghai Municipality of China (Project 14DZ1100200). The authors would like to thank the Key Laboratory of Control of Power Transmission and Conversion (Ministry of Education), The Shanghai Engineering Center for Superconducting Materials and System, and the State Energy Smart Grid R&D Center (Shanghai) for the support on assistance in experimental affairs. References Hassenzahl, W. V. (2000). Applications of superconductivity to electric power systems. Power Engineering Review, IEEE, 20, 4-7. http://dx.doi.org/10.1109/39.841342 Hobl, A., Goldacker, W., Dutoit, B., Martini, L., Petermann, A., & Tixador, P. (2013). Design and production of the ECCOFLOW resistive fault current limiter. IEEE transactions on applied superconductivity, 23(3), 5601804-5601804. http://dx.doi.org/10.1109/TASC.2013.2238288 Hong, Z., Sheng, J., Zhang, J., Lin, B., Ying, L., Li, Y., & Jin, Z. (2012). The development and performance test of a 10 kV resistive type superconducting fault current limiter. Applied Superconductivity, IEEE Transactions on, 22(3), 5600504-5600504. http://dx.doi.org/10.1109/TASC.2011.2180278 Li, S., Sun, H., Chen, Y., Wang, F., Jin, Z., Yin, Y., ... & Hong, Z. (2014). A Study of Surface Flashover and Breakdown Characteristics in Liquid Nitrogen for SFCL Application. http://dx.doi.org/10.1109/TASC. 2013.2289927 Ombello, F., Attolini, G., Caracino, P., Nassi, M., Spreafico, S., & Montanari, G. C. (2002). Insulating materials evaluation for cold dielectric superconducting cables. Dielectrics and Electrical Insulation, IEEE Transactions on, 9(6), 958-963. http://dx.doi.org/10.1109/TDEI.2002.1115490 Seong, J. K., Seo, I. J., Hwang, J. S., & Lee, B. W. (2012). Comparative evaluation between DC and AC breakdown characteristic of dielectric insulating materials in liquid nitrogen. Applied Superconductivity, IEEE Transactions on, 22(3), 7701504-7701504. http://dx.doi.org/10.1109/TASC.2011.2178222 Ul Haq, S., & Raju, G. G. (2006). DC breakdown characteristics of high temperature polymer films. Dielectrics and Electrical Insulation, IEEE Transactions on, 13(4), 917-926. http://dx.doi.org/10.1109/TDEI.2006. 1667753 Zhang, H., Zhang, G., Tan, R., Luo, M., & Tu, Y. (2012, March). Study on DC Breakdown Characteristics of Polyimide at Cryogenic Temperature. In Power and Energy Engineering Conference (APPEEC), 2012 Asia-Pacific (pp. 1-4). IEEE. http://dx.doi.org/10.1109/APPEEC.2012.6307392 Copyrights Copyright for this article is retained by the author(s), with first publication rights granted to the journal. This is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/). 102