ADCP-96-058 • Issue 1 • July 2005

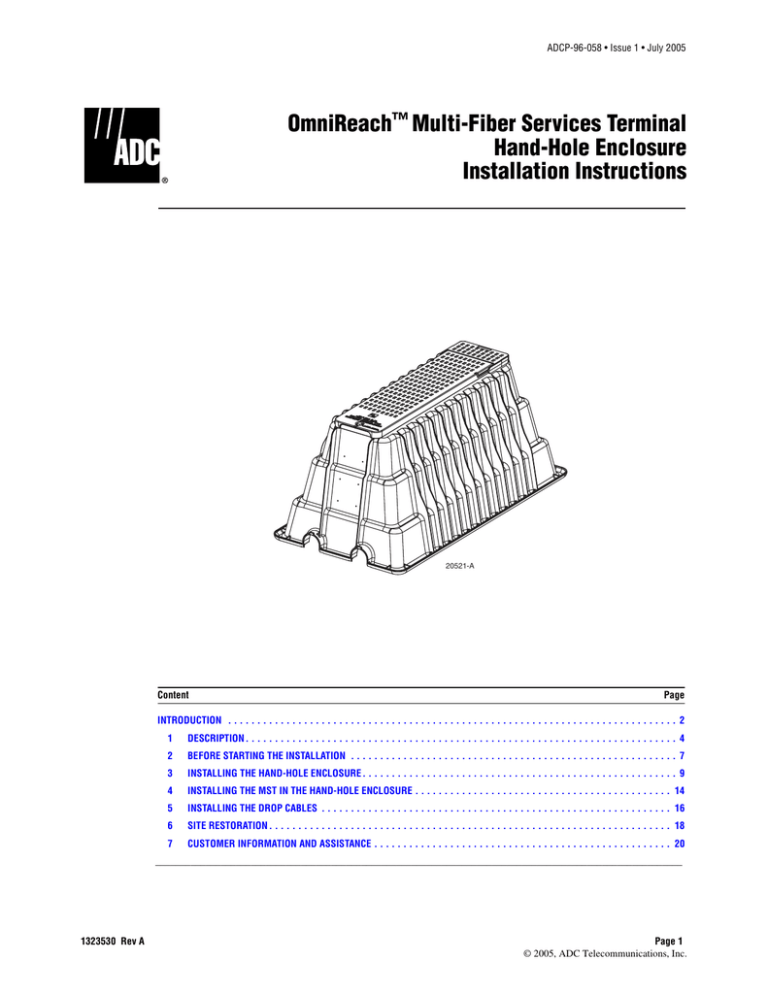

OmniReach™ Multi-Fiber Services Terminal

Hand-Hole Enclosure

Installation Instructions

20521-A

Content

Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2

BEFORE STARTING THE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3

INSTALLING THE HAND-HOLE ENCLOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4

INSTALLING THE MST IN THE HAND-HOLE ENCLOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5

INSTALLING THE DROP CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6

SITE RESTORATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7

CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

_________________________________________________________________________________________________________

1323530 Rev A

Page 1

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

INTRODUCTION

This publication provides a description of the Multi-Fiber Services Terminal (MST) Hand-Hole

Enclosure plus detailed instructions for installation. The hand-hole enclosure mounts below

ground and is designed for use with the various versions of the MST. The hand-hole enclosure

may also be adapted for use with products that are similar in function and design to the MST

and that require a below ground mounting system.

Revision History

ISSUE

DATE

1

07/2005

REASON FOR CHANGE

Initial release

List of Changes

PAGE

IDENTIFIER

All

DESCRIPTION OF CHANGE

Initial release

Trademark Information

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications, Inc.

OmniReach is a trademark of ADC Telecommunications, Inc.

Telcordia is a registered trademark of Telcordia Technologies, Inc.

Related Publications

Listed below are related manuals and their publication numbers. Copies of these publications

can be ordered by contacting the ADC Technical Assistance Center at 1-800-366-3891 (in

U.S.A. or Canada) or 952-946-3000, extension 63475 (outside U.S.A. and Canada).

Title/Description

ADCP Number

OmniReach Multi-Fiber Services Terminal MST-2, MST-4, MST-6, MST-8,

and MST-12 User Manual

96-040

Multi-Fiber Services Terminal Internal Connector Replacement Instructions

96-045

Page 2

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

General Safety Precautions

Danger: Wet conditions increase the potential for receiving an electrical shock when installing

or using electrically-powered equipment. To prevent electrical shock, never install or use

electrical equipment in a wet location or during a lightning storm.

Danger: Do not look into the ends of any optical fiber. Exposure to laser radiation may result.

Do not assume the laser power is turned-off or that the fiber is disconnected at the other end.

Warning: Before digging, check with all local utilities for the presence of buried cables or

pipes. Contact with underground cables or pipes, especially electric power cables and gas

service lines, could interrupt local utility service and cause serious personal injury and

extensive property damage.

Page 3

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

1

DESCRIPTION

This section provides a description of the hand-hole enclosure plus the product specifications.

1.1

Hand-Hole Enclosure

The hand-hole enclosure, shown in Figure 1, is an Outside Plant (OSP), molded-plastic, belowground mounting system for the MST. It may also be used with other products that are similar in

function and design to the MST. Access to the interior of the enclosure is through a rectangular

30.5 x 7.25 inch opening located on top of the enclosure. The opening is fitted with a hinged

cover that locks in a vertical upright position when opened. The MST mounts on the underside

of the cover and the cable slack is stored in the compartment below. Opening the cover swings

the MST up and out of the enclosure for above-ground access to the optical ports. Cable rings

(optional) within the enclosure provide cable management for distribution and drop cable slack.

The hand-hole enclosure is open at the bottom and must be mounted on compacted fill material

for support. Cutouts in the bottom edge of the enclosure allow the enclosure to be placed over

2.5-inch (outside diameter) distribution cable conduit. Tie points are provided for securing the

distribution cable conduit to the enclosure. Entry/exit points for drop cables are marked on the

ends of the enclosure. A hole must be drilled into the enclosure at each selected drop cable

entry/exit point. A drop cable conduit clamp kit (accessory) is available for securing drop cable

conduit to the enclosure at the selected entry/exit point.

MST MOUNTED ON

HAND-HOLE COVER

DROP CABLE

DROP CABLE

CONDUIT (OPTIONAL)

20603-A

DISTRIBUTION

CABLE CONDUIT

(OPTIONAL)

Figure 1. Multi-Fiber Services Terminal Hand-Hole Enclosure

Page 4

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

When installed, the top of the hand-hole enclosure will be flush with the top of the ground. An

electronic marker disc (option) may mounted on the underside of the cover. This allows the

enclosure to be detected with a frequency marker locator if the enclosure becomes covered by

backfill. The locator transmits a signal to the marker and the marker reflects the signal back to

the locator. The rugged construction of the enclosure and ribbed side-walls allow it to withstand

the weight loads imposed by pedestrian and yard equipment traffic without danger of collapse.

A grounding bar (option) is also available for MST’s that require grounding connections.

1.2

Specifications

The specifications for the hand-hole enclosure are provided in Table 1.

Table 1. ACE-102V Pedestal-Mount Cabinet Specifications

PARAMETER

SPECIFICATION

Cabinet

Enclosure dimensions (L x W x H) – See

Figure 2 for additional information

39.84 x 21.37 x 17.83 inches

(101.2 x 54.3 x 45.3 cm)

Weight

39 lbs (17.7 kg)

Certification

GR-902-CORE

Capacity

1 MST (any version)

Load test rating

Tier 5 or Tier 15 (option)

Color of base

Green or black (option)

Color of cover

Green

Material

PVC

Page 5

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

30.64 IN.

(77.8 CM)

7.46 IN.

(18.9 CM)

39.84 IN.

(101.2 CM)

17.83 IN.

(45.3 CM)

21.37 IN.

(54.3 CM)

20482-A

Figure 2. Hand-Hole Enclosure Dimensions

Page 6

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

2

BEFORE STARTING THE INSTALLATION

This section provides an overview of the installation, the unpacking and inspection procedures,

and lists the tools and materials required for enclosure installation.

2.1

Installation Overview

Installation of the hand-hole enclosure involves the following main tasks:

Hand-Hole Enclosure Installation – Installing the hand-hole enclosure consists of digging a

hole for the enclosure, installing an aggregate support base, installing the distribution cable

conduit, and placing the enclosure in the hole. If armored distribution cable will be installed, a

grounding system must also be installed.

MST Installation – After the hand-hole enclosure is installed, the MST distribution cable must

be uncoiled and routed through the distribution cable conduit to a separate splice enclosure (not

provided). Some slack must be stored within the enclosure and the MST must be secured to the

enclosure cover.

MST Distribution Cable Splicing – The MST distribution cable must be spliced to the system

OSP cable at a separate splice enclosure. Use locally approved practices and procedures for

splicing. Refer to the Multi-Fiber Services Terminal User Manual (ADCP-96-040) for the MST

optical port and fiber designations.

Drop Cable Installation and Connection – The drop cables must be routed into the enclosure

and some slack stored. Service is enabled by connecting the drop cable connectors to the

subscriber distribution ports on the MST.

Site Restoration - The enclosure cover must be closed and secured, the area around the

enclosure must be backfilled, and the landscaping restored.

2.2

Unpacking and Inspection

This section provides instructions for opening the shipping boxes, verifying that all parts have

been received, and verifying that no shipping damage has occurred.

Use the following procedure to unpack and inspect the cabinet and all accessories:

1. Open the shipping carton(s) and carefully unpack the hand-hole enclosure from the

protective packing material.

2. Check the hand-hole enclosure for broken or missing parts. If there are damages or parts

are missing, contact ADC (see Section 7) for an RMA (Return Material Authorization)

and to reorder if replacement is required.

Page 7

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

2.3

Packaged Hardware

The hand-hole enclosure includes various hardware components that are packaged separately

and shipped in a plastic bag with the enclosure. The packaged hardware components are listed

in Table 2.

Table 2. Hand-Hole Enclosure Packaged Hardware

ITEM

2.4

QUANTITY

Adjustable bracket (for mounting MST)

1

Grounding bus bar (option)

1

Cable management brackets for storing excess slack (option)

4

15-inch cable tie (for securing distribution cable conduit)

4

Tools and Materials Required for Installation

The following tools and materials are required for hand-hole enclosure installation:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

9/16-inch nut driver for enclosure cover screw

216B key tool (or 3/8-inch nut driver) for captive screw on MST

Wire cutter

Pliers

Utility knife

Tape measure

Pen or marker

Level

Hole saw and drill (use to cut holes for drop cable entry/exit holes)

Grounding system, copper wire, and grounding clamp (per local requirements)

Excavation and earth moving equipment

Stone aggregate (per local practice)

Tamping equipment

Landscaping equipment and site restoration supplies

The following accessories may be required for hand-hole enclosure installation:

• Drop cable conduit clamp kit

Page 8

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

3

INSTALLING THE HAND-HOLE ENCLOSURE

This section provides instructions for installing the cable management brackets, excavating and

preparing the hole required for the hand-hole enclosure, placing the enclosure in the hole,

installing the grounding system (if required), and installing the distribution cable conduit.

3.1

General Installation Recommendations

The site chosen for the installation must conform to all local codes and any permits required

must be obtained prior to the start of installation. The location must be accessible and must not

expose the worker to possible safety hazards. In addition, the enclosure should not be located in

a place where it is likely to be damaged. The enclosure should be installed directly in line with

the trench that was used for the distribution cable conduit. The enclosure may be used with the

MST-2, MST-4, MST-6, MST-8 or MST-12 which are equipped respectively with 2-, 4-, 6-, 8-,

or 12-fiber distribution cables.

Warning: Before digging, check with all local utilities for the presence of buried cables or

pipes. Contact with underground cables or pipes, especially electric power cables and gas

service lines, could interrupt local utility service and cause serious personal injury and

extensive property damage.

3.2

Cable Management Bracket Installation (Option)

Install the four cable management brackets (if included with the enclosure) as shown in Figure

3. The cable management brackets are used for storing distribution and drop cable slack.

20648-B

Figure 3. Installing Cable Management Brackets

Page 9

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

3.3

Excavation

The excavation must be deep enough to provide a fill base that will maintain stability for the

enclosure and the MST mounted within it. There must be room for 6 inches (15.25 cm) of

compacted aggregate fill below the enclosure. Excavate a rectangular hole for the enclosure as

shown in Figure 4. Fill the bottom of the hole with stone aggregate, tamping it as it is filled to

build a 6 inch (15.25 cm) layer with a level surface. The stone aggregate will provide a stable

base to support the enclosure.

Note: Use crushed rock 3/8-inch or less in size mixed with stone dust (per local practice)

to create the base. The name of the material may differ in different geographical areas.

Possible names are Class 5, stone dust, aughts (0s) and ones (1s), or stone aggregate

FINAL GRADE LEVEL

18 IN.

(45.7 CM)

SIDE VIEW

24 IN.

(61.0 CM)

STONE AGGREGATE

BASE

COMPACTED SOIL

6 IN.

(15.2 CM)

45 IN.

(114.3 CM)

END VIEW

STONE AGGREGATE

BASE

COMPACTED SOIL

20524-A

26 IN.

(66.0 CM)

Figure 4. Excavation Recommendations for MST Hand-Hole

3.4

Placement of the Hand-Hole Enclosure

Use a straight edge to verify that the top of the enclosure is flush with the top of the ground as

shown in Figure 5. If necessary, add or remove fill to adjust the height of the enclosure. Tamp

any added fill to maintain the base stability.

Page 10

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

20483-A

Figure 5. Adjusting Enclosure the Height

3.5

Grounding System Installation

A grounding system is required if the MST is equipped with armored distribution cable. MST’s

that require grounding are equipped with a grounding stud. The metallic elements of the

armored cable are connected to the internal side of the MST grounding stud.

Install a grounding system (not provided) that meets all local electrical code requirements.

Follow local codes for grounding system installation, use of clamps, wire size, and any other

grounding requirements. Typically, #6 AWG copper wire is used for the grounding wire. Install

the grounding system inside the enclosure where it will not interfere with the conduit or cables.

Leave sufficient slack in the grounding wire to allow it to be attached to the MST grounding

stud and to allow for flexing when the enclosure cover is opened and closed.

A copper grounding bar that attaches to the enclosure cover is available as an option. The

grounding bar may be used to complete the connection between the grounding system and the

MST grounding stud. If a grounding bar is included, secure it to the hand-hold cover as shown

in Figure 6 using the screws provided. Connect the grounding wire (from the grounding system)

to one of the lugs on the grounding bar. Following installation of the MST, use a short length of

#6 AWG copper wire to connect the grounding stud on the MST to one of the lugs on the

grounding bar.

Page 11

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

GROUNDING

BUS BAR

20649-B

Figure 6. Installing the Grounding Bar on the Enclosure Cover

3.6

Distribution Cable Conduit Installation (Optional)

Select the conduit entry/exit hole(s) for the OSP distribution cable conduit as shown in Figure 7.

The conduit may be attached to the enclosure at any of the four points provided. Secure each

section of conduit to the selected entry/exit hole(s) as shown using the cable ties provided.

Leave at least 2 inches of conduit on the inside of the enclosure as shown in Figure 8. The

maximum outside diameter of the conduit that may be attached to the enclosure is 2.5 inches.

Note: Conduit is not required for the MST distribution cable. If preferred, the distribution

cable may be buried directly in the ground and the cable secured directly to the enclosure

using the same attachment method recommended for conduit.

Page 12

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

DETAIL DRAWING OF

DISTRIBUTION CONDUIT

ATTACHMENT METHOD

SECURE CONDUIT TO

HAND HOLE ENCLOSURE

WITH CABLE TIE

20086-C

USE PLIERS TO CINCH CABLE

TIE, THEN CUT OFF EXCESS.

Figure 7. Securing the Distribution Cable Conduit at the selected Entry/Exit Hole

2-IN.

(5.08 CM)

20085-B

Figure 8. Two-Inch Conduit Margin On Inside of Enclosure

Page 13

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

4

INSTALLING THE MST IN THE HAND-HOLE ENCLOSURE

This section provides instructions for routing the MST distribution cable to a separate splice

enclosure and for mounting the MST in the hand-hole enclosure.

4.1

Routing the MST Distribution Cable

Use a 9/16-inch nut driver to back out the captive capscrew that secures the hand-hole cover in

the closed position. Open the cover and rotate it upward until it locks in a vertically upright

position. Unwind the MST distribution cable from the coil or spool as described in the MultiFiber Services Terminal User Manual (ADCP-96-040). Feed the distribution cable into the

conduit (if installed) as shown in Figure 9. Leave enough slack within the enclosure to wrap

twice around the base of the enclosure and to form a service loop when the MST is attached to

the cover. Store the distribution cable slack using the cable management brackets on the sides of

the enclosure. If the distribution cable was not routed into conduit, secure the cable to the entry/

exit hole using the cable ties provided. Follow local practice and procedure to splice the stub

end of the distribution cable to the network cable at a separate splice enclosure (not provided).

CABLE

MANAGEMENT

RINGS

(BOTH SIDES)

ROUTE DISTRIBUTION CABLE TWICE AROUND

THE CABLE MANAGEMENT RINGS ON THE

INSIDE OF THE HAND HOLE ENCLOSURE.

20650-B

Figure 9. Routing the MST Distribution Cable

Page 14

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

4.2

Mounting the MST in the Hand-Hole Enclosure

Use the following procedure to mount the MST in the hand-hole enclosure:

1. Attach the adjustable mounting bracket to the bottom of the hand-hole cover as shown in

Figure 10. Select the mounting position that corresponds to the type of MST.

CAPTIVE SCREW

(INCLUDED WITH MST)

216B KEY

TOOL

MST

MOUNTING

BRACKET

MOUNTING POSITION

FOR MST-2 AND MST-4

MOUNTING POSITION

FOR MST-6 AND MST-8

MST-8

MOUNTING POSITION

FOR MST-12

20608-B

Figure 10. Mounting the MST in The Hand-Hole Enclosure (MST-8 Shown)

2. Place the bottom end of the MST in the adjustable mounting bracket and secure the top

end of the MST to the hand-hole cover using the captive screw provided with the MST.

3. Thread the MST captive screw into the cover and tighten securely using the 216B key tool

(3/8-inch socket).

4. Adjust the distribution cable slack to provide an adequate service loop for opening and

closing the hand-hole cover. Verify that the distribution cable does not kink or bind when

the cover is operated and that the recommended minimum bend radius is maintained.

5. If the MST is equipped with a grounding stud, connect the grounding system grounding

wire to the MST grounding stud. Refer to the Multi-Fiber Services Terminal User Manual

(ADCP-96-040) for additional information.

Page 15

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

5 INSTALLING THE DROP CABLES

This section provides instructions for routing the drop cables into the hand-hole enclosure both

with and without conduit installation.

5.1

Drop Cable Installation With Conduit

When required, drop cable conduit may used to protect the subscriber drop cables. Conduit for

drop cables may be routed into the hand-hole enclosure at specified points located on the ends

of the enclosure. A kit is available for securing the conduit at the entry point to the enclosure.

The maximum outside diameter of the conduit that may be routed into the enclosure is 2

inches.

Use a drill bit (equal in size to the outside diameter of the conduit) to drill a hole in the

enclosure at one of the points specified in Figure 11. Insert each section of conduit into the

selected entry/exit hole(s) as shown. Leave at least 2 inches of conduit on the inside of the

enclosure as shown in Figure 12. Place a neoprene sleeve over the end of each section of conduit

at the 2-inch mark. Place a hose clamp over each neoprene sleeve and tighten the clamp screw to

a maximum torque of 8 to 10 lbs-ft.

FINAL GRADE LEVEL

DRILL POINTS

FOR DROP CABLE

ENTRY/EXIT HOLES

DRILL POINTS

FOR DROP CABLE

ENTRY/EXIT HOLES

20091-B

Figure 11. Drop Cable Entry/Exit Points

Page 16

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

CLAMP

NEOPRENE

SLEEVE

CONDUIT

20609-B

Figure 12. Connecting Drop Cable Conduit To Hand-Hole Enclosure

5.2

Drop Cable Installation Without Conduit

Conduit is not required for the drop cable. The drop cable may be buried directly in the ground

and the cable routed directly into the hand-hole enclosure at any of the specified points (see

Figure 11) located on the ends of the enclosure. Use an appropriately sized drill bit to drill a

hole in the enclosure at one of the points specified. The hole should be as large as the drop cable

connector and dust cap assembly. Insert the drop cable into the enclosure and pull through

enough cable slack to provide two loops around the base of the enclosure plus a service loop.

Page 17

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

6

SITE RESTORATION

This section provides instructions for closing up the hand-hole enclosure and restoring the

installation site to its original condition.

6.1

Closing Up the Hand-Hole Enclosure

Before closing the hand-hole enclosure cover, brush away any dirt or gravel from around the

edge of the enclosure opening. Make sure that all sides of the lip that surrounds the enclosure

opening are clear of dirt. To close the hand-hole cover, pull upward on the end of the cover to

release the latching mechanism as shown in Figure 13. Rotate the cover forward to the closed

position. Clear away any dirt or gravel that may have been forced under the hinge protector and

then press down on the hinge protector to make sure it is fully closed. Use a 9/16-inch nut driver

to tighten the captive screw in the end of the cover.

ROTATE FORWARD

PULL UP

20605-A

Figure 13. Closing the Hand-Hole Enclosure

6.2

Back Filling the Excavation

Add subsoil evenly around the hand-hole enclosure as shown in Figure 14 and tamp. Fill to

approximately 6 inches (15.2 cm) from the top of the excavation. Depending on the landscaping

requirements, complete the back-fill with topsoil or decorative rock. The top surface of the

hand-hole enclosure cover should be level with the surrounding grade.

Page 18

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

FINAL GRADE LEVEL

TOPSOIL

SIDE VIEW

BACKFILL

STONE AGGREGATE

BASE

COMPACTED SOIL

TOPSOIL

END VIEW

BACKFILL

STONE AGGREGATE

BASE

COMPACTED SOIL

20526-A

Figure 14. Back Filling the Excavation

Page 19

© 2005, ADC Telecommunications, Inc.

ADCP-96-058 • Issue 1 • July 2005

7

CUSTOMER INFORMATION AND ASSISTANCE

PHONE:

EUROPE

Sales Administration: +32-2-712-65 00

Technical Assistance: +32-2-712-65 42

EUROPEAN TOLL FREE NUMBERS

Germany: 0180 2232923

UK:

0800 960236

Spain:

900 983291

France: 0800 914032

Italy:

0800 782374

U.S.A. OR CANADA

Sales: 1-800-366-3891 Extension 73000

Technical Assistance: 1-800-366-3891

Connectivity Extension 73475

Wireless Extension 73476

ASIA/PACIFIC

Sales Administration: +65-6294-9948

Technical Assistance: +65-6393-0739

ELSEWHERE

Sales Administration: +1-952-938-8080

Technical Assistance: +1-952-917-3475

WRITE:

ADC TELECOMMUNICATIONS, INC

PO BOX 1101,

MINNEAPOLIS, MN 55440-1101, USA

ADC TELECOMMUNICATIONS (S'PORE) PTE. LTD.

100 BEACH ROAD, #18-01, SHAW TOWERS.

SINGAPORE 189702.

ADC EUROPEAN CUSTOMER SERVICE, INC

BELGICASTRAAT 2,

1930 ZAVENTEM, BELGIUM

PRODUCT INFORMATION AND TECHNICAL ASSISTANCE:

connectivity.tac@adc.com

wireless.tac@adc.com

euro.tac@adc.com

13944-M

asiapacific.tac@adc.com

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice.

In no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period. This publication may be

verified at any time by contacting ADC's Technical Assistance Center.

© 2005, ADC Telecommunications, Inc.

All Rights Reserved

Printed in U.S.A

Page 20