P ro D uctcatalog - Integra Enclosures

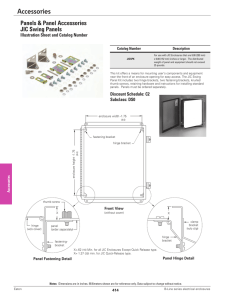

advertisement