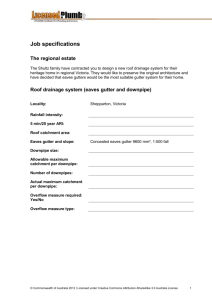

installation

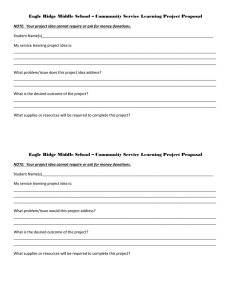

advertisement