Audible signal liquid level indicator

advertisement

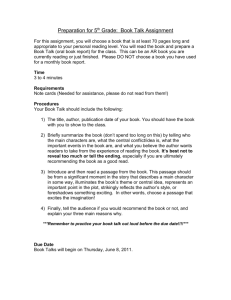

Oct. 28, 1941. H. c. KRONE ETAL 2,260,335 AUDIBLE SIGNAL LIQUID LEVEL INDICATOR Filed May 7, 1941 ‘ 2 Sheets-Sheet 1 INVENTORS . 122160216.’ zvzzeklz/i/Z?dwMyez; ‘ ATTORNEY. Oct. 28, 1941. H. c. KRONE ETAL 2,260,385 AUDIBLE SIGNAL LIQUID LEVEL INDICATOR Filed May 7, 1941' I 2 Sheets-Sheet 2 ATTORNEY; 2,260,385 Patented Oct. 28,1941 UNITED .STATE 5 * PATEN r OFFICE 2,280,385 AUDIBLE SIGNAL LIQUID LEVEL mmca'ron Howard ’ 0. Krone, River Edge, and William Meyer, East Orange, N. 1., assignors to A. W. Wheaton Brass Works, Newark, N. 1., a corpo ration of New Jersey Application Maya, 1941, Serial No. 392,264 5 Claims. (01. 116-109) " ‘ the above This invention relates to improvements in audi ing parts. ble signal liquid level indicators for use in ?lling tanks, cans or other containers; and the inven descrlbed‘views, to indicate correspond In the illustrative embodiment of this inven tion shown in the accompanying drawings, the. audiblersignal device is arranged in- combination tion has reference, more particularly,- to a novel device which. will sound an audible signal when ' with" the ?lling nozzle III of a delivery line or hose the rising level of liquid delivered into a tank,'can leading from a suitable source of liquid supply. Such embodiment includes an annular stopper body I'll through which said ?lling nozzle‘ili ex > operator in charge of the ?lling operations to dis continue delivery of liquid to the tank, can or 10 tends;_-the former being rigidly secured or fas-' ' tened to the latter. Formed in the periphery of other container. I Y said stopper body II is an annular seating chan This invention, in its broader aspects, has for nel l21in which is carried a sealing gasket l3, an object to provide a novel audible signal de which is preferably formed with an inwardly and vice for the purposes stated which will silently ven" the air which is displaced by a liquid de 15 downwardly‘ tapered or inclined external face [4. The ?llingmozzle i0 passes through the stopper live led into a tank, can or the like, until the body I] at a point eccentric to the center of the rising level of the liquid nears the limit of ca- . latter, whereby to provide a space offset from ' - pacity of the latter, and is thereupon brought said ?lling nozzle which is occupied ‘by the signal into contact with a portion of the device in such or other container nears the limit of the capacity I of the latter, thus giving timely notice to the manner as to trap an air column therein subject 2.0 _ to vibration with audible, sound producing effect. , This invention has-for another and more spe device structure. _ a - ‘The signal device structure comprisesan up-, , ' wardlyex'tending boss l5 rising from the top or - outer-surface of said stopper body II, and pref erably formed integrally therewith. _,Formed to having the above mentioned operating character istics, in combination with the ?lling nozzle of a 25 extend through said stopper body ll from its hot tom‘o‘r inner face and through said boss I5 is a liquid delivery line, whereby operative application ci?c object to provide ani‘audible signal; device, I of the ?lling nozzle to the bung or ?lling opening \. , passage ii of inverted U-shape including a for of a tank, can .or the like will automatically re- ‘ late the signal device in operative communication with the interior of said tank, can or the like. Other objects of this inventiomnot at this time more particularly enumerated, will be understood from the following detailed description of the, 30 ward leg I‘! and a rearward leg IS. The wall of said boss l5 contiguous to said forward leg ll of the passage i6 ‘is pierced by a whistle opening IS the upper'margin of_which is de?ned by an inwardly an'd downwardly chamfered lip 20 con verging on the forward leg ll of said passage l6. Inserted in the open end of said forward passage An illustrative embodiment of this invention is 35 leg I1 is a tongue plug 2| having a ?attened face 22 which opposes the side of the passage leg I‘! shown in the accompanying drawings, in which ' in which the whistleopening is provided, thus Fig. 1 is a fragmentary sectional view of a can, providing a throat. passage 23 leading from the to the ?lling opening or bung of which is opera underside of said stopper body ii to the whistle tively applied a ?lling nozzle provided with the audible signal liquid level indicator according to 40 opening I9 so that its discharge end is directed toward ‘the lip 20 of the latter. Connected in this invention; Fig. 2 is a horizontal sectional view, taken on line 2-2 ‘in Fig. 1; and Fig. ~3- \ communication with the open end of the rearward passage leg I8 is a tubular extension 24 thereof, is another horizontal sectional view, taken on line which depends from the under or inner side of 2-.-3 in Fig. 1. ’ r‘ r ' ~ Fig.4 isa vertical sectional view, taken on line 45 said stopper body -I l. The length of this exten sion 24 is such as to allow the rising level of I 4-4 in Fig. 2, but drawn on an enlarged scale, the same. . same showing the signal device in initial condition wherein itsilently vents air displaced from the can by the liquid delivered thereinto; and Fig.5 is a similar view. showing the rising level of liquid in‘ contact with a portion of .the' signal device so as to trapv a column of air within the latter sub ject to vibration with‘ audible sound producing effect. liquid delivered into a container through the ?lly ing nozzle ill to contact the free end portion‘ thereof atv a point substantially below the liquid level limit determined by the capacity of the container. Preferably the lower free end of the extension 24 is closed by an end plug 25, and communication between the interior of 8.- contain er being ?lled and the interior of said exten Similar characterslof reference are employed in 55,. sion is provided by one or more openings 26 with 2,260,885 ' 2 signal device with a ?llingnomle will be ob which the wall of the latter is provided. > It has been found preferable that the total area of the vious, since it-permits a single signal means to openingor openings 26 substantially correspond ' serve any number of cans by merely operatively applying the ?lling nozzle to the cans. The to the area of the throat passage 23. In the event the container being ?lled is provided with 5 novel signal device structure per se, however, an independent ?xed vent, such e. g. as the vent vpassage 21 of the ‘can shown in the drawings, and may be built into a tank, can or other container as a permanent ?xture if it is so desired. which will be presently described, then the coin We are aware that variouschanges could be ' made in the above described constructions, and the opening or openings 26 of the extension‘ 24 10 that widely di?‘erent embodiments of this inven tion could be made without departing from the should preferably substantially correspond to that ‘ . bined areas of said ?xed vent passage 21 and of the throat passage 23. scope thereof as de?ned in the following claims. - In the drawings, the reference character 28 indicates the body of a can or container having an'internally threaded bung or ?lling opening 15 29 to normally receive _a closure plug (not shown). To ?ll the can 28, the closure plug be ing removed from the bung or ?lling opening 29, the ?lling nozzle 10 is inserted through the lat " ter into the interior of said can, until the sealing 20 gasket l3 .of the stopper body ll engages thev margins 30 of said bung or ?lling opening. By application of inward thrusting pressure upon 'the ?lling nozzle III, the stopper body II is pressed home so that the sealing gasket l3 will 25 form a hermetically sealing contact with ‘said bung or ?lling opening margins 36. To assist in guiding the stopper body II to such bung or ?lling opening sealing position, the same is provided with inclined radial guide ribs 3| which lead from the peripherypf the stopper body to converge upon the ?lling ‘nozzle l0. It is therefore intended that all matter contained in the foregoing description or shown in the ac companying drawings shall be interpreted as il- ' lustrative and not in a limiting sense. We claim: 1. In combination, a ?lling nozzle, a stopper body through which the ?lling nozzle extendsin ?xed connection therewith, said stopper body being adapted to close a container ?lling opening against air egress when said ?iling nozzle is in serted therethrough, and an audible signal means carried by saidstopper body, said signal means including‘ an inverted U-shaped passage initially open at both ends to the interior of said con tainer, said passage having in one leg a whistle means and having an extension connected with , its other leg provided with air admission means so subject to be closed by rising liquid delivered into said container, whereby to trap a vibrating col ' umn of air within said U-shaped passage to When the ?lling nozzle has been ailixed to the thereupon render said whistle means operative. bung or ?lling opening of the can as above de 2. In combination, a ?lling nozzle, a stopper scribed, ,by manipulation of suitable :control 35 body through which the ?lling nozzle extends in valve mechanism (not shown) with which the ?xed connection therewith, said stopper body same is provided, ?ow of liquid may be initiated having .a sealing gasket means to engage the and directed into the can interior. As the level marginsof a container ?lling opening for seal of the liquid delivered into the can rises, the air ing the same against air egress when said ?lling within the can is displaced'by the liquid and 40 nozzle. is inserted therethrough, and an audible‘ compressed so as to seek escape from the can signal means carried by said stopper body, said interior. Since both legs of the U-shaped pas sage are initially in communication ‘with the can signal means including an inverted U-shaped passage initially open at both ends to the in terior of. said container, said passage having in ' interior respectively through the throat passage 23 and the opening or openings 26, the escaping - one leg a whistle means and having an exten air may ?ow outwardly both through the leg l8 , sion connected with its other leg provided with air admission means'subject to be closed by ris from, its extension 24 and through 'the legv l'I 'from'the throat passage 23, and thence to the atmosphere through the whistle opening 19, such paths of ?ow being indicated by the arrows in ing liquid delivered into said container, whereby to trap a vibrating column of air within said U shaped passage to thereupon render said whistle ' Fig. 4. Under these conditions, outward move ment of air through‘bothlegs of the U-shaped ‘ , passage l6 will substantially balance- each other, means operative. ’ ’ 3. In combination, a ?lling nozzle, a stopper body through which the ?lling nozzle extends in ?xed connection therewith, said stopper body so that no vibrating air column is formed in the passage, and consequently the air vents through 55 having a sealing gasket means to engage the margins of a container ?lling opening for seal the whistle opening I9 without producing any whistling sound. . ing the same against air egress when said ?lling ' . As the levelot the liquid rising in the can in nozzle is therethrough, and an audible terior reaches and passes the opening or open signal means carriedby said stopper body, said ings 26 in the extension 24 communication of air 60 signal means/including an inverted U-shaped therethrough and into the passage leg I8 is pre passage the legs of which open through the un vented, and consequently a column of air is derside of said stopper body, a tubular‘extension trapped in the U-shaped passage beyond the prolonging one leg of said passage for projection whistle opening l9. Air, however, continues to into said container interior, said extension hav pass outwardly through the throat passage 23, 65 ing air admission means adjacent its free end and- thence through the whistle opening IS. _The . for communication with the container interior ' movement of this outgoing. air sets up a virbra tion of the trapped air column, whereby an 7 audible whistling signal is produced (see' Fig. 5). ' subject to be closed by rising liquid within the latter, the other leg of said passage having'a lateral whistle openingto communicate with the . ' This audible signal is sounded as the level of 70 atmosphere, and a tongue ‘plugga?ixed in the liquid in the can ‘nears the limit of the can open end of'said latter passage leg, said tongue ' capacity, and consequently the operator isgiven plug being shaped to provide an outgoing throat timely notice to shut oil? supply of liquid through passage terminating adjacent to said. whistle ' the ?lling nozzle into the can. > The advantage of combining the novel audible 75 opening. .. ~ ' ' 4. An audible signal means ‘for association 3 2,260,385 with a container to be-?lled with a liquid con tent, said signal means including ‘an inverted to the container interior, a tubular extension prolonging one leg of'said passage for projection U-shaped passage initially open at both ends to into said container interior, said extension hav the interior of said container, said passage hav ing air admission means adjacent to its free end for communication with the container interior ing in one leg a whistle means and having an extension connected with its other leg ‘provided with air admission means subject to be closed by rising liquid delivered into said container, where by to trap a vibrating column of air within said 'U-shaped passage to thereupon render said 10 whistle means 'operative. , 5. An audible signal means for association with a container to be'?lled with a liquid con subject to be closed by rising liquid within the latter, the other leg of said passage having a lateral whistle opening to communicate with the 7 atmosphere, and a tongue plug a?ixed in the open 7end of said latter passage leg, said tongue plug being shaped to provide an outgoing throat passage terminating adjacent to said whistle opening.v tent, said signal means including an inverted U shaped passage the legs of which are both open 15 > ' - ~ HOWARD C. KRONE. WILLIAM MEYER.