Preliminary

EN5364QI

Feature Rich 6A Voltage Mode

Synchronous Buck PWM DC-DC Converter

with Integrated Inductor

RoHS Compliant - Halogen Free

Description

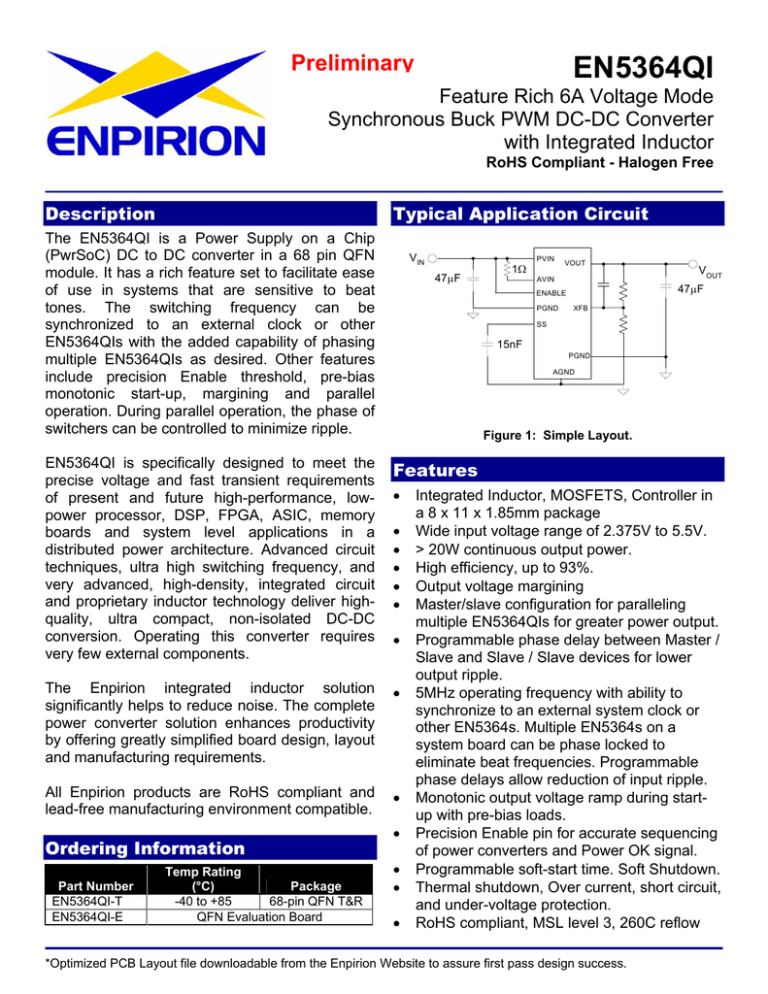

Typical Application Circuit

The EN5364QI is a Power Supply on a Chip

(PwrSoC) DC to DC converter in a 68 pin QFN

module. It has a rich feature set to facilitate ease

of use in systems that are sensitive to beat

tones. The switching frequency can be

synchronized to an external clock or other

EN5364QIs with the added capability of phasing

multiple EN5364QIs as desired. Other features

include precision Enable threshold, pre-bias

monotonic start-up, margining and parallel

operation. During parallel operation, the phase of

switchers can be controlled to minimize ripple.

VIN

47µF

VOUT

47µF

XFB

SS

15nF

PGND

AGND

Figure 1: Simple Layout.

The Enpirion integrated inductor solution

significantly helps to reduce noise. The complete

power converter solution enhances productivity

by offering greatly simplified board design, layout

and manufacturing requirements.

•

All Enpirion products are RoHS compliant and

lead-free manufacturing environment compatible.

•

Temp Rating

Package

(°C)

-40 to +85

68-pin QFN T&R

QFN Evaluation Board

VOUT

AVIN

PGND

Features

Part Number

EN5364QI-T

EN5364QI-E

PVIN

ENABLE

EN5364QI is specifically designed to meet the

precise voltage and fast transient requirements

of present and future high-performance, lowpower processor, DSP, FPGA, ASIC, memory

boards and system level applications in a

distributed power architecture. Advanced circuit

techniques, ultra high switching frequency, and

very advanced, high-density, integrated circuit

and proprietary inductor technology deliver highquality, ultra compact, non-isolated DC-DC

conversion. Operating this converter requires

very few external components.

Ordering Information

1Ω

•

•

•

•

•

•

•

•

•

•

•

Integrated Inductor, MOSFETS, Controller in

a 8 x 11 x 1.85mm package

Wide input voltage range of 2.375V to 5.5V.

> 20W continuous output power.

High efficiency, up to 93%.

Output voltage margining

Master/slave configuration for paralleling

multiple EN5364QIs for greater power output.

Programmable phase delay between Master /

Slave and Slave / Slave devices for lower

output ripple.

5MHz operating frequency with ability to

synchronize to an external system clock or

other EN5364s. Multiple EN5364s on a

system board can be phase locked to

eliminate beat frequencies. Programmable

phase delays allow reduction of input ripple.

Monotonic output voltage ramp during startup with pre-bias loads.

Precision Enable pin for accurate sequencing

of power converters and Power OK signal.

Programmable soft-start time. Soft Shutdown.

Thermal shutdown, Over current, short circuit,

and under-voltage protection.

RoHS compliant, MSL level 3, 260C reflow

*Optimized PCB Layout file downloadable from the Enpirion Website to assure first pass design success.

20090304

Preliminary

EN5364QI

Applications

•

•

•

•

•

•

Point of load regulation for low-power

processors, network processors, DSPs,

FPGAs, and ASICs

Low voltage, distributed power architectures

with 2.5V, 3.3V or 5V rails

Computing, broadband, networking,

LAN/WAN, optical, test & measurement

DSL, STB, DVR, DTV, Industrial PC

Beat frequency sensitive applications

•

•

Applications requiring monotonic start-up with

pre-bias

Ripple voltage sensitive applications

Noise sensitive applications

Pin Configuration

Below is a top view diagram of the EN5364QI package.

Figure 2: Top View of Package

NOTE: NC pins are not to be electrically connected to each other or to any external signal, ground, or voltage.

However, they must be soldered to the PCB. Failure to follow this guideline may result in part malfunction or

damage.

©Enpirion 2009 all rights reserved, E&OE

2

www.enpirion.com

Preliminary

20090304

EN5364QI

Pin Descriptions

PIN

NAME

FUNCTION

1-4

PGND

5-13

VOUT

14-24

NC

25-26

27-33

SW

PGND

34-43

PVIN

44-46

NC

47

PGND

48

S_OUT

49

S_IN

50

M_S

51

EN_PB

52

ENABLE

53

AVIN

54

POK

55

AGND

56

XFB

57

EAOUT

58

NC

59

SS

60

S_DELAY

61-62

MAR[1:2]

63

VSENSE

64-68

PGND

Output power ground. Refer to layout section for specific layout requirements.

Regulated converter output. Decouple with output filter capacitor to PGND. Refer to

layout section for specific layout requirements

NO CONNECT: These pins should not be electrically connected to each other or to

any external signal, voltage, or ground. One or more of these pins may be connected

internally.

Output Switching Waveform port

Output power ground. Refer to layout section for specific layout requirements.

Input power supply. Connect to input power supply. Decouple with input capacitor to

PGND. Refer to layout section for specific layout requirements

NO CONNECT: These pins should not be electrically connected to each other or to

any external signal, voltage, or ground. One or more of these pins may be connected

internally.

Output power ground. Refer to layout section for specific layout requirements.

Digital Output. Depending on the mode, either a clock signal synchronous with the

internal switching frequency or the PWM signal is output on this pin. These signals

are delayed by a time that is related to the resistor connected between S_Delay and

AGND.

Digital Input. Depending on the mode, this pin accepts either a input clock to phase

lock the internal switching frequency to or a PWM input from another EN5364QI.

This is a Ternary Input put. Floating the pin disables parallel operation. A low level

configures the device as Master and a High level configures the device as a slave.

This is the Enable Pre-Bias Input. When this pin is pulled high, the Device will support

monotonic start-up under a pre-bias load.

This is the Device Enable pin. A high level enables the device while a low level

disables the device.

This is the Input voltage to the controller. A quiet supply!

Power OK is an open drain transistor for power system state indication. POK is a

logic high when VOUT is with -10% to +20% of VOUT nominal. Being a open drain

output several devices may be wired to logically AND the function. Size pull-up

resistor to limit current to 4mA when POK is low.

This is the quiet ground for the controller.

This is the External Feedback input pin. A resistor divider connects from the output to

AGND. The mid-point of the resistor divider is connected to XFB. The output voltage

regulates so as to make the XFB node voltage = 0.600volt.

Optional Error Amplifier output. Allows for customization of the control loop.

NO CONNECT: These pins should not be electrically connected to each other or to

any external signal, voltage, or ground. One or more of these pins may be connected

internally.

A soft-start capacitor is connected between this pin to AGND. The value of the

capacitor controls the soft-start interval.

A resistor is connected between this pin and AGND. The value of the resistor controls

the delay in S_OUT.

These are 2 ternary input pins. Each pin can be a logical Lo, Logical Hi or Float

condition. 7 of the 9 states are used to modulate the output voltage by 0%, ±5%,

±10% or ±15%. The 8th state is used to by-pass the delay in S_OUT.

This pin senses the output voltage when the device is placed in the Back-feed (or

Pre-bias) mode.

Output power ground. Refer to layout section for specific layout requirements.

©Enpirion 2009 all rights reserved, E&OE

3

www.enpirion.com

Preliminary

20090304

EN5364QI

Block Diagram

S_OUT

M_S

PVIN

S_IN

To PLL

Digital I/O

UVLO

MAR1/2

Thermal Limit

Current Limit

Over Voltage

P-Drive

NC(SW)

VOUT

(-)

PWM

Comp

(+)

N-Drive

EAOUT

PLL / Sawtooth

Generator

PGND

Compensation

Network

(-)

XFB

Error

Amp

(+)

ENABLE

SS

Reference

Voltage

selector

Soft Start

EN_PB

EAOUT

MAR1

power

Good

Logic

POK

Bandgap

Reference

MAR2

Figure 3: System block diagram.

©Enpirion 2009 all rights reserved, E&OE

4

www.enpirion.com

Preliminary

20090304

EN5364QI

Absolute Maximum Ratings

CAUTION: Absolute Maximum ratings are stress ratings only. Functional operation beyond

recommended operating conditions is not implied. Stress beyond absolute maximum ratings may

cause permanent damage to the device. Exposure to absolute maximum rated conditions for

extended periods may affect device reliability.

PARAMETER

Input Supply Voltage

Voltages on: EN, EN_PB

Voltage on XFB

Voltages on: EAOUT

Voltages on: SS, PWM, S_IN, S_OUT, MAR[1:2]

Voltages on: POK

Storage Temperature Range

Reflow Temp, 10 Sec, MSL3 JEDEC J-STD-020A

ESD Rating (based on Human Body Model)

SYMBOL

MIN

MAX

UNITS

VIN

-0.5

-0.5

-0.5

-0.5

-0.5

-0.5

-65

7.0

VIN

2.5

2.5

3.0

VIN + 0.3

150

260

2000

V

V

V

V

V

V

°C

°C

V

TSTG

Recommended Operating Conditions

PARAMETER

Input Voltage Range

Output Voltage Range

Operating Ambient Temperature

Operating Junction Temperature

SYMBOL

MIN

MAX

UNITS

VIN

2.375

V

VOUT

0.60

TA

TJ

-40

-40

5.5

VIN –

0.1*ILOAD

+85

+125

V

°C

°C

Thermal Characteristics

PARAMETER

Thermal Resistance: Junction to Ambient (0 LFM) (Note 1)

Thermal Resistance: Junction to Case (0 LFM)

Thermal Overload Trip Point

Thermal Overload Trip Point Hysteresis

SYMBOL

TYP

UNITS

θJA

θJC

TJ-TP

20

1.5

+150

20

°C/W

°C/W

°C

°C

NOTES:

1. Based on a four-layer board and proper thermal design in line with JEDEC EIJ/JESD 51 Standards.

©Enpirion 2009 all rights reserved, E&OE

5

www.enpirion.com

Preliminary

20090304

EN5364QI

Electrical Characteristics

NOTE: VIN=5.5V over operating temperature range unless otherwise noted.

Typical values are at TA = 25°C.

PARAMETER

SYMBOL

Input Voltage

Output Regulation

VIN

Feedback Pin

Voltage

VOUT

Feedback Pin

Voltage

VOUT

TEST CONDITIONS

MIN

TYP

2.375

2.375V ≤ VIN ≤ 5.5V,

ILOAD = 1A; TA = 25°C

2.375V ≤ VIN ≤ 5.5V,

0A ≤ ILOAD ≤ 6A

-40 ºC ≤ TA ≤ +85 ºC

Transient Response (IOUT = 0% to 100% or 100% to 0% of Rated Load)

VIN = 5V, 1.2V < VOUT < 3.3V

Peak Deviation

∆VOUT

COUT=50uF

Output Voltage Ripple

VIN = 5.0V, VOUT = 1.2V, IOUT = 6A,

Peak-to-peak

COUT = 5 x 10µF X5R or X7R

∆VOUT-PP

MLCC

Under Voltage Lockout

Under Voltage Lock

VIN Increasing

VUVLO

out threshold

VIN Decreasing

Switching Frequency

Switching

FSWITCH

Free Running frequency

Frequency

Phase-Lock Range (Note 3)

Phase-Lock

PLL Pull range about free running

FPLL

Frequency range

frequency

S_IN Duty Cycle

M_S Pin Float or Low

SYDC

for SYNC

S_IN Duty Cycle

M_S Pin High

SYDC

for PWM

Phase-Delay (Note 3)

Phase Delay

Phase delay programmable via

between S_IN and

resistor connected from S_Delay to

ΦDEL

S_OUT

AGND.

Phase Delay

Delay By-Pass Mode

between S_IN and

ΦDEL

S_OUT

Phase Delay

Accuracy

Phase Delay vs.

Delay in nsec / kΩ

S_Delay Resistor

ΦDEL

Delay in phase angle / kΩ value

@ 5MHz switching frequency

Load Characteristics

Maximum

IOUT

Continuous Output

(Note 1)

Current

Current Limit

The OCP Trip level

IOCP

Threshold

Supply Current

©Enpirion 2009 all rights reserved, E&OE

6

MAX

UNITS

5.5

V

0.588

0.600

0.612

V

0.582

0.600

0.618

V

5

%

<20

mV

2.2

2.1

V

5

MHz

4.5

5.5

MHz

20

80

%

10

90

%

20

150

ns

10

ns

20

%

-20

2

3.5

6

ns

°

A

13.5

A

www.enpirion.com

Preliminary

20090304

Shut-Down Supply

Current

IS

EN5364QI

ENABLE=0V

µA

250

Precision Enable Operation

Disable Threshold

VDISABLE

Enable Threshold

Enable Pin Current

Thermal Shutdown

Thermal Shutdown

Hysteresis

Pre-Bias Start-Up

VENABLE

IEN

Pre-Bias Level

Non-Monotonicity

Power OK/GOOD

TSD

VPB

VPB_NM

Allowable Pre-Bias as a fraction of

programmed output voltage for

monotonic start up

Allowable non monotonicity

POK Deglitch Delay

VPOK Logic Low

level

VPOK Logic High

level

Parallel Mode Operation

∆IOUT

1.0

V

1.30

50

V

µA

150

20

°C

°C

1.10

Silicon junction temperature

Range of output voltage as a

fraction of programmed value

when POK is asserted. (Note 2)

Falling edge deglitch delay after

output crossing 90% level

VOUT Range for POK

= High

Current Balance

Max voltage to ensure the

converter is disabled

2.375V ≤ VIN ≤ 5.5V

VIN = 5.5V

20

85

50

mV

90

120

50

%

us

With 4mA current sink into POK pin

0.4

With 2 – 4 converters in parallel,

the difference between any 2 parts.

∆VIN < 50mV; RTRACE < 10mΩ.

%

V

VIN

V

+/-10

%

Output Rise Time

VOUT Rise Time

Accuracy

Logic Levels

Ternary Logic Low

Threshold

Ternary Logic High

Threshold

Binary Logic Low

Threshold

Binary Logic High

Threshold

Ternary pin Input

Current

∆TRISE

TRISE = Css* 65KΩ;

10nF ≤ CSS ≤30nF

-25

+25

%

0.4

V

2.7

V

(Notes 3, 4)

VT-Low

Threshold voltage for Logic Low

VT-High

Threshold voltage for Logic High

(internally pulled high; can be left

floating to achieve logic high)

2.0

0.8

VB-Low

1.8

VB-High

IITERN

The ternary pin has 100kΩ to

AGND and another 100kΩ to an

internal 2.5V supply. It is voltage

clamped to ~2V. If connecting to

VIN recommend using a series

resistor. See Figure-5

©Enpirion 2009 all rights reserved, E&OE

7

See

Figure-5

µA

www.enpirion.com

Preliminary

20090304

EN5364QI

NOTES:

1. Maximum output current may need to be de-rated, based on operating condition, to meet TJ requirements.

2. POK threshold when VOUT is rising is nominally 92%. This threshold is 90% when VOUT is falling. After crossing the

90% level, there is a 256 clock cycle (~50us) delay before POK is de-asserted. The 90% and 92% levels are nominal

values. Expect these thresholds to vary by ±3%.

3. Parameter not production tested but is guaranteed by design.

4. Rise time begins when AVIN > VUVLO and Enable=HIGH.

Features

•

•

Precision Enable Threshold: The Enable threshold is a precision Analog voltage rather

than a digital logic threshold. Precision threshold along with choice of soft-start capacitor helps

to accurately sequence multiple power supplies in a system.

Margining: The nominal output voltage can be increased / decreased by 5, 10 or 15% for

system compliance, reliability or other tests. The POK threshold voltages scale with the

margined output voltages. The following table provides truth table.

MAR-1

MAR-2

Float

Low

High

Low

High

Low

High

Float

Float

Float

Low

Low

High

High

Float

Float

High

Low

Output Modulation

Changes planned to

values listed below

0%

-5%

+5%

-10%

+10%

-15%

+15%

Delay By-Pass

Reserved

Table 1: Margining Truth Table

•

•

•

Pre-Bias Operation: When Device EN_PB is asserted, the device will support a monotonic

output voltage ramp with the output capacitor charged to a pre-bias level. Proprietary

circuit ensures the output voltage ramps monotonically from pre-bias voltage to the

programmed output voltage. Monotonic start-up is guaranteed for pre-bias voltages

between 20% and 85% of the programmed output voltage.

Phase-Lock Operation: With M_S pin floating or at a logical ‘0,’ the internal switching

clock of the DC/DC converter can be phase-locked to a clock signal applied to S_IN.

The clock logic levels are <0.4V and >2.0V. The clock frequency should be within ±10%

of the free running frequency. A delayed copy of the internal switching clock is available

at S_OUT. The magnitude of delay is controlled by the value of the resistor connected

between S_Delay and AGND pins. Multiple EN5364QI devices on a system board may

be daisy chained to reduce or eliminate input ripple as well as avoiding beat frequency

components.

Master / Slave Operation: Multiple EN5364QI devices may be connected in a Master /

Slave configuration to handle very large load currents. One Master device can directly

control up to 4 Slave devices or one Master device may control any number of Slave

devices in a daisy chain. The Master device’s switching clock may be phase-locked to

an external clock source or another EN5364QI. The device is set in Master mode by

pulling the M_S pin low or in Slave mode by pulling M_S pin high. When this pin is in

Float state, parallel operation is not possible. In master mode, the internal PWM signal

©Enpirion 2009 all rights reserved, E&OE

8

www.enpirion.com

Preliminary

20090304

•

•

•

•

•

•

EN5364QI

is output on the S_OUT pin. The PWM signal at S_OUT is delayed relative to the

Master device’s internal PWM signal. (The magnitude of delay is controlled by the value

of the resistor connected between S_Delay and AGND pins.) This PWM signal from the

Master can be fed to one or more Slave devices at its S_IN input. The Slave device acts

like an extension of the power FETs in the Master. The inductor in the slave prevents

crow-bar currents from Master to slave due to timing delays. The Slave device puts out

its own delayed PWM on S_OUT which could feed the next device in the daisy chain.

As a practical matter, paralleling more than 4 devices may be very difficult from the view

point of maintaining very low impedance in VIN and VOUT lines.

Phase Delay: When multiple EN5364QIs are used on a board, the phase delay function

may be used advantageously for reducing input / output ripple. The phase delay can be

used in two ways. First, the EN5364QIs can all be phase locked by feeding the S_OUT

of one device into the S_IN of the next device in a daisy chain. All the switchers are now

switching at a common frequency. However, the phase delay among the switching

waveforms may be controlled by an appropriate choice of a resistor that is connected

from the pin S_Delay to AGND. The magnitude of this delay is approximately 2ns/kΩ or

3.5°/kΩ (@5MHz) of resistance subject to a minimum / maximum delay as given in the

table of electrical characteristics. Second, when multiple EN5364QIs are used in parallel

to support a large load, one device acts as a master device whose PWM output is fed to

other EN5364QIs operating as slaves. Although all the devices are switching at the

same frequency and duty cycle, their phases can be controlled by an appropriate choice

for S_Delay resistor. The Master / Slave parallel mode operation is described in more

detail in a separate application note.

Over Current Protection: When the load current exceeds the over current protection

trip level the power FETs are placed in a high impedance state and the device enters a

hiccup mode. The output is disabled for 8192 clock cycles (~1.6ms) followed by a

normal soft-start. The device remains in hiccup mode as long as the fault persists.

Power OK / Good: Power good (POK) signal is asserted when the output voltage is

between 90% and 120% of the nominal. When VOUT is rising the POK threshold is

nominally at 92% of steady state VOUT. When VOUT is falling, the nominal threshold is

90% of steady state voltage. If VOUT exceeds 120% of programmed value, POK is deasserted and the power NFET is turned on. This event could cause the input power

supply to EN5364QI to enter a over current condition.

Soft-start circuit: to limit the in-rush current when the converter is powered up. The

soft-start interval is programmable through choice of Soft-start capacitance.

Thermal shutdown: When the device gets beyond the safe operating temperature, the

output is shutdown. Adequate hysteresis is provided to prevent chatter at trip point.

Under-voltage lockout: UVLO circuit disables the converter output when the input

voltage is less than approximately 2.2V to ensure that operation does not begin before

there is adequate voltage to properly bias all internal circuitry.

©Enpirion 2009 all rights reserved, E&OE

9

www.enpirion.com

Preliminary

20090304

EN5364QI

Output Voltage Setting / Phase-Lead Capacitor Details

VOUT

RA = 30, 000*Vin (value in Ω)

RA

CA

4.72*10−6

CA =

RA

(Cout & CA in Farads , RA in Ω )

XFB

RB

RB =

AGND

Figure 4:

Vref

Vout − Vref

RA

Output voltage resistor divider and phase-lead capacitor calculation. The above formulas ensure

optimum loop bandwidth for any Vin and Vout combination. The equations need to be followed in the

order written above.

2.5V

R1

100k

Maximum value of

Rext = (VIN -2)*67k

Rext

VIN

To Gates

100k

D1

Vf ~ 2V

R2

100k

Input pin current

= (VIN-2)/Rext

R3

7k

AGND

EN5364QI

Figure 5: Figure shows means to select Rext value to be used when connecting MAR-1, MAR-2 and / or M_S pins

to VIN.

©Enpirion 2009 all rights reserved, E&OE

10

www.enpirion.com

Preliminary

20090304

EN5364QI

Phasing Multiple EN5364QIs (An Example)

P/AVIN

R1

EN5364QI

S_IN

CO1

R3

S_OUT

VOUT2

XFB

C11

R11

EN5364QI

S_IN

CO2

R13

P/AVIN

S_D ELAY

C1

VOUT

S_D ELAY

XFB

P/AVIN

S_OUT

VOUT1

P/AGN D

P/AVIN

S_IN

VOUT

P/AGN D

(Optional)

S_D ELAY

XFB

EXT_CLK

X1_2

X1_1

VOUT

P/AGN D

X1

S_OUT

VOUT3

C21

R21

EN5364QI

CO3

R23

R2

R12

R22

P/AGND

Figure 6: Example of Synchronizing multiple EN5364QIs in a daisy chain with phase delay.

VDRAIN- 1

Delay ~ 140°

VDRAIN- 2

VDRAIN- 3

Delay ~ 120°

Figure 7: Example of a possible way to synchronize and use delays advantageously to minimize input ripple.

R3 ~ 39kΩ, R13 ~ 33kΩ. (Refer to Figure 6 for R3 and R13.)

©Enpirion 2009 all rights reserved, E&OE

11

www.enpirion.com

Preliminary

20090304

EN5364QI

Typical Performance Characteristics

Efficiency

Efficiency

95

90

90

85

E fficiency (% )

E fficiency (% )

95

1.2

2.5

80

75

85

1.2

80

2.5

75

3.3

70

65

60

70

0

1

2

3

4

5

0

6

1

2

3

4

5

6

Load (Amps)

Load (Amps)

Efficiency vs. Load: VIN = 3.3V; VOUT = 2.5, 1.2V

Efficiency vs. Load: VIN = 5.0V; VOUT = 3.3, 2.5, 1.2V

Start-up waveform: VIN = 5.5V, VOUT = 3.3V, Load = 6A

Ch.1 – Enable, Ch.2 – VOUT, Ch.3 - POK

Start-up waveform: VIN = 5.5V, VOUT = 1.2V, Load = 6A

Ch.1 – Enable, Ch.2 – VOUT, Ch.3 – POK

Output Ripple: VIN = 5.0V, VOUT = 1.2V, COUT = 1x47uF

(1206) + 1x10uF (0805)

Output Ripple: VIN = 3.3V, VOUT = 1.2V, COUT = 1x47uF

(1206) + 1x10uF (0805)

©Enpirion 2009 all rights reserved, E&OE

12

www.enpirion.com

Preliminary

20090304

EN5364QI

Load Transient: 0-6A Step. VIN = 5.0V, VOUT = 1.2V

Load Transient: 0-6A Step. VIN = 3.3V, VOUT = 1.2V

Start-up waveform in Back-feed (Pre-bias mode)

VBF = 400mV, VOUT = 2.5V

Start-up waveform in Back-feed (Pre-bias mode)

VBF = 1.9V, VOUT = 2.5V

Delay (ns)

Delay vs. S_Delay Resistance

180

160

140

120

100

80

60

40

20

0

Series1

0

20

40

60

80

100

S_Delar R (kohm)

Delay vs. S_Delay Resistance

©Enpirion 2009 all rights reserved, E&OE

13

www.enpirion.com

Preliminary

20090304

EN5364QI

Theory of Operation

Synchronous Buck Converter

The EN5364QI is a synchronous, programmable

power supply with integrated power MOSFET

switches and integrated inductor. The nominal

input voltage range is 2.375-5.5V. The output

voltage is programmed using an external resistor

divider network. The feedback control loop is a

type III, voltage-mode and the device uses a lownoise PWM topology. Up to 6A of continuous

output current can be drawn from this converter.

The 5MHz operating frequency enables the use

of small-size input and output capacitors.

The power supply has the following protection

features:

• Over-current protection with hiccup mode.

• Short Circuit protection.

• Thermal shutdown with hysteresis.

• Under-voltage lockout circuit to disable the

converter output when the input voltage is

less than approximately 2.2V

Output Voltage Programming

The EN5364 output voltage is programmed using

a simple resistor divider network. A phase lead

capacitor is required for stabilizing the loop.

Figure 4 shows the required components and the

equations to calculate their values.

Input Capacitor Selection

The EN5364QI requires between 40-80uF of

input capacitance. Low ESR ceramic capacitors

are required with X5R or X7R dielectric

formulation. Y5V or equivalent dielectric

formulations must not be used as these lose

capacitance with frequency, temperature and

bias voltage (please see Table 2).

In some applications, lower value ceramic

capacitors maybe needed in parallel with the

larger capacitors in order to provide high

frequency decoupling.

Output Capacitor Selection

The EN5364QI has been optimized for use with

output capacitance between 47µF and 150µF.

The phase lead capacitor value depends on the

the output capacitance as shown in Figure-4.

Low ESR ceramic capacitors are required with

X5R or X7R dielectric formulation. Y5V or

equivalent dielectric formulations must not be

used as these lose capacitance with frequency,

temperature and bias voltage (please see Table

3).

The EN5364 output voltage is determined by the

voltage presented at the XFB pin. This voltage is

set by way of a resistor divider between VOUT and

AGND with the midpoint going to XFB.

Description

MFG

P/N

47uF, 10V,

X5R, 1206

Taiyo Yuden

LMK316BJ476ML-T

22uF, 10V,

X5R, 1206

Taiyo Yuden

Murata

LMK316BJ226ML-T

GRM31CR61A226ME19L

Table 2: Recommended input capacitors.

©Enpirion 2009 all rights reserved, E&OE

Description

MFG

P/N

47uF, 10V,

X5R, 1206

Taiyo Yuden

LMK316BJ476ML-T

47uF, 6.3V,

X5R, 1206

Taiyo Yuden

Murata

JMK316BJ476ML-T

GRM31CR60J476ME19L

22uF, 6.3V,

X7R, 1206

Taiyo Yuden

Murata

JMK316B7226ML-T

GCM31CR70J226KE23L

10uF, 10V,

X7R, 0805

Taiyo Yuden

Murata

LMK212C106KG-T

GRM21BR71A106KE51L

Table 3: Recommended output capacitors.

Output ripple voltage is primarily determined by

the aggregate output capacitor impedance. At

the 5MHz switching frequency output impedance,

14

www.enpirion.com

20090304

Preliminary

denoted as Z, is comprised mainly of effective

series resistance, ESR, and effective series

inductance, ESL:

Z = ESR + ESL.

Placing multiple capacitors in parallel reduces

the impedance and hence will result in lower

ripple voltage.

1

Z Total

=

1

1

1

+

+ ... +

Z1 Z 2

Zn

Typical ripple versus capacitor arrangement is

given below:

Typical Output Ripple (mVp-p)

(as measured on EN5364QI

Evaluation Board)

1x47uF + 1x10uF

<30

5 x 10 uF

<20

Table 4. Output ripple vs capacitor configuration.

Output Capacitor

Configuration

Compensation

The EN5364 uses of a type III compensation

network. Most of this network is integrated.

However a phase lead capacitor is required in

parallel with upper resistor of the external

feedback network (see Figure 4). Total

compensation is optimized for use with a

minimum of 47µF output capacitance and will

result in a wide loop bandwidth and excellent

load transient performance for most applications.

The equations shown in Figure 4 are valid for

Cout up to 150µF at the voltage sensing point.

Additional capacitance may be placed beyond

the voltage sensing point outside the control

loop. Voltage mode operation provides high

noise immunity at light load. Further, Voltage

mode control provides superior impedance

matching to ICs processed in sub 90nm

technologies.

In exceptional cases modifications to the

compensation may be required. The EN5364QI

provides the capability to modify the control loop

response to allow for customization for specific

applications. For more information, contact

Enpirion Applications Engineering support.

©Enpirion 2009 all rights reserved, E&OE

EN5364QI

Enable Operation

The ENABLE pin provides a means to start

normal operation or to shut down the device. The

Enable threshold is precisely set by a voltage

reference. This allows precision sequencing of

multiple EN5364QIs. When the ENABLE pin is

asserted high, the device will undergo a normal

soft start. As the output voltage ramps up (ramp

rate controlled by choice of soft-start capacitor) a

second device may be Enabled using this ramp.

The second device will start up after a well

defined time given by the ramp rate and the

precise threshold level.

Soft-Start Operation

The SS pin in conjunction with a small external

capacitor between this pin and AGND provides

the soft start function to limit the in-rush current

during start-up. During start-up of the converter

the reference voltage to the error amplifier is

gradually increased to its final level by an internal

current source of typically 10uA charging the soft

start capacitor. The typical soft-start time for the

output to reach regulation voltage, from when

AVIN > VUVLO and Enable crosses its logic high

threshold, is given by:

TSS = CSS * 65KΩ (seconds)

Where the soft-start time TSS is in seconds and

the soft-start capacitance CSS is in Farads.

Typically, a capacitor of around 15nF is

recommended. A proper choice of SS

capacitance can be used advantageously for

power supply sequencing using the precision

Enable threshold.

During a soft-start cycle, when the soft-start

capacitor voltage reaches 0.60V, the output has

reached its programmed regulation range. Note

that the soft-start current source will continue to

charge the SS capacitor beyond 0.6V. During

normal operation, the soft-start capacitor will

charge to a final value of ~1.5V.

Soft Shutdown

When the Enable signal is de-asserted, the soft-

15

www.enpirion.com

20090304

Preliminary

start capacitor is discharged in a controlled

manner. Thus the output voltage ramps down

gradually. The internal circuits are kept active for

the duration of soft-shutdown, thereafter they are

deactivated.

POK Operation

The POK signal is an open drain signal from the

converter indicating the output voltage is within

the specified range. The POK signal is asserted

when the rising output voltage crosses 92%

(nominal) of the programmed output voltage.

POK is de-asserted ~50us (256 clock cycles)

after the falling output voltage crosses 90%

(nominal) of the programmed voltage. POK is

also de-asserted if the output voltage exceeds

120% of the programmed output. If the feedback

loop is broken, POK will remain de-asserted

(output < 92% of programmed value!) but the

output voltage will equal the input voltage. If

however, there is a short across the PFET, and

the feedback is in place, POK will be de-asserted

as a over voltage condition. Also, the power

NFET is turned on resulting in a large input

supply current. This is turn is expected to trip the

OCP of the power supply powering the

EN5364QI.

POK is an open drain output. It requires an

external pull up. Multiple EN5364QI’s POK pins

may be wired NOR with a single pull up. The

open drain NFET is designed to sink up to 4mA.

The pull-up resistor value should be chosen to

limit the current from exceeding this value when

POK is logic low.

Over-Voltage Protection

There is no over voltage protection caused by a

open at XFB node.

©Enpirion 2009 all rights reserved, E&OE

EN5364QI

Over-Current Protection

The current limit function is achieved by sensing

the current flowing through a sense P-FET.

When the sensed current exceeds the current

limit, both NFET and PFET switches are turned

off. If the over-current condition is removed, the

over-current protection circuit will re-enable the

PWM operation. If the over-current condition

persists, the circuit will continue to protect the

load.

The OCP trip point is nominally set to 225% of

maximum rated load. In the event the OCP circuit

trips, the device enters a hiccup mode. The

device is disabled for ~1.6msec and restarted

with a normal soft-start. This cycle can continue

indefinitely as long as the over current condition

persists.

Thermal Overload Protection

Thermal shutdown will disable operation when

the Junction temperature exceeds approximately

150ºC. Once the junction temperature drops by

approx 20ºC, the converter will re-start with a

normal soft-start.

Input Under-Voltage Lock-Out

When the input voltage is below a required

voltage level (VUVLO) for normal operation, the

converter switching is inhibited. The lock-out

threshold has hysteresis to prevent chatter.

Parallel Device Operation

The EN5364QI is capable of paralleling up to a

total of four converters to provide up to 24A of

continuous current. Please refer to the Parallel

Operation Application note, available on the

Enpirion website www.enpirion.com, for details

on parallel operation.

16

www.enpirion.com

Preliminary

20090304

EN5364QI

Layout Recommendations

Under Development

Figure 8: Layout of power and ground copper.

Figure 9: Use of thermal & noise suppression vias.

Recommendation 1: Input and output filter

capacitors should be placed as close to the

EN5364QI package as possible to reduce EMI

from input and output loop currents. This

reduces the physical area of the Input and

Output AC current loops.

These vias can be the same size as the

thermal vias discussed in recommendation 3.

Recommendation 5: The system ground

plane referred to in recommendations 3 and 4

should be the first layer immediately below the

surface layer. This ground plane should be

continuous and un-interrupted below the

converter and the input/output capacitors

shown in figure 8.

Recommendation 2: Place a slit in the

input/output capacitor ground copper starting

just below the common connection point of the

device GND pins as shown in figures 8 and 9.

Recommendation 6: As with any switch-mode

DC/DC converter, do not run sensitive signal or

control lines underneath the converter

package.

Recommendation 3: The large thermal pad

underneath the component must be connected

to the system ground plane through as many

vias as possible. The drill diameter of the vias

should be less than 0.33mm, and the vias must

have at least 1 oz. copper plating on the inside

wall, making the finished hole size around

0.26mm. This connection provides the path for

heat dissipation from the converter. Please see

figures: 9, 10 and 11.

Please refer to the Gerber files and

summarized layout notes available on the

Enpirion website www.enpirion.com for more

layout details.

NOTE: Figures 8 and 9 show only the critical

components and traces for a minimum footprint

layout. ENABLE, Vout-programming, and

other small signal pins need to be connected

and routed according to the specific

application.

Recommendation 4: Multiple small vias

should be used to connect ground terminal of

the input capacitor and output capacitors to the

system ground plane as shown in figure 6.

©Enpirion 2009 all rights reserved, E&OE

17

www.enpirion.com

20090304

Preliminary

EN5364QI

Design Considerations for Lead-Frame Based Modules

Exposed Metal on Bottom of Package

Lead frame offers many advantages in thermal performance, in reduced electrical lead resistance, ,

and in overall foot print. However, they do require some special considerations.

In the assembly process lead frame construction requires that, for mechanical support, some of the

lead-frame cantilevers be exposed at the point where wire-bond or internal passives are attached.

This results in several small pads being exposed on the bottom of the package.

Only the large thermal pad and the perimeter pads are to be mechanically or electrically connected to

the PC board. The PCB top layer under the EN5364QI should be clear of any metal except for the

large thermal pad. The “grayed-out” area in Figure 7 represents the area that should be clear of any

metal (traces, vias, or planes), on the top layer of the PCB.

Figure 8 demonstrates the recommended PCB footprint for the EN5364QI. Figure 9 shows the shape

and location of the exposed metal pads as well as the mechanical dimension of the large thermal pad

and the pins.

Figure 10: Lead-Frame exposed metal. Grey area highlights exposed metal that is not to be mechanically or

electrically connected to the PCB.

©Enpirion 2009 all rights reserved, E&OE

18

www.enpirion.com

20090304

Preliminary

EN5364QI

Figure 11: Recommended footprint for PCB.

©Enpirion 2009 all rights reserved, E&OE

19

www.enpirion.com

20090304

Preliminary

EN5364QI

Package Dimensions

Figure 12. Package dimensions.

©Enpirion 2009 all rights reserved, E&OE

20

www.enpirion.com

20090304

Preliminary

EN5364QI

Contact Information

Enpirion, Inc.

685 Route 202/206

Suite 305

Bridgewater, NJ 08807

Phone: 908-575-7550

Fax: 908-575-0775

Enpirion reserves the right to make changes in circuit design and/or specifications at any time without notice. Information furnished by Enpirion is

believed to be accurate and reliable. Enpirion assumes no responsibility for its use or for infringement of patents or other third party rights, which may

result from its use. Enpirion products are not authorized for use in nuclear control systems, as critical components in life support systems or equipment

used in hazardous environment without the express written authority from Enpirion.

©Enpirion 2009 all rights reserved, E&OE

21

www.enpirion.com