WAGO-I/O-SYSTEM 750 XTR

Pos : 2 /D okumentati on allgemein/Ei nband/Ei nband H andbuch - Fronts eite 2015 - mit Doc Variabl en (Standar d) @ 9\mod_1285229289866_0.doc x @ 64941 @ @ 1

Manual

750-495/040-00x

3-Phase POM 690V /XTR

3-Phase Power Measurement Module /XTR

Version 1.1.0

Pos : 3 /Alle Serien (Allgemeine M odul e)/Rec htlic hes, Allgemei nes/Impressum für Standardhandbüc her - allg. Angaben, Ansc hriften, T elefonnummer n und E-Mail-Adres sen @ 3\mod_1219151118203_21.doc x @ 21060 @ @ 1

2

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

© 2016 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone:

Fax:

+49 (0) 571/8 87 – 0

+49 (0) 571/8 87 – 1 69

E-Mail:

info@wago.com

Web:

http://www.wago.com

Technical Support

Phone:

Fax:

+49 (0) 571/8 87 – 5 55

+49 (0) 571/8 87 – 85 55

E-Mail:

support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail:

documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

=== Ende der Liste für T extmar ke Ei nband_vorne ===

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Table of Contents

3

Pos : 5 /D okumentati on allgemein/Verzeic hnisse/Inhalts verz eichnis - Ü berschrift oG und Verzei chnis @ 3\mod_1219151230875_21.doc x @ 21063 @ @ 1

Table of Contents

1

1.1

1.2

1.3

1.4

1.5

Notes about this Documentation ................................................................. 6

Validity of this Documentation ................................................................. 6

Copyright................................................................................................... 6

Symbols ..................................................................................................... 7

Number Notation ....................................................................................... 9

Font Conventions ...................................................................................... 9

2

Important Notes ......................................................................................... 10

2.1

Legal Bases ............................................................................................. 10

2.1.1

Subject to Changes ............................................................................. 10

2.1.2

Personnel Qualifications ..................................................................... 10

2.1.3

Use of the WAGO-I/O-SYSTEM 750 in Compliance with

Underlying Provisions ........................................................................ 10

2.1.4

Technical Condition of Specified Devices ......................................... 11

2.2

Safety Advice (Precautions) .................................................................... 12

3

Device Description ..................................................................................... 15

3.1

View ........................................................................................................ 16

3.2

Connectors............................................................................................... 17

3.2.1

Data Contacts/Internal Bus ................................................................. 17

3.2.2

Power Jumper Contacts/Field Supply ................................................ 17

3.2.3

CAGE CLAMP® Connectors ............................................................. 18

3.3

Display Elements .................................................................................... 21

3.4

Operating Elements ................................................................................. 22

3.5

Schematic Diagram ................................................................................. 22

3.6

Technical Data ........................................................................................ 25

3.6.1

Device ................................................................................................. 25

3.6.2

Voltage Supply ................................................................................... 25

3.6.3

Measuring Inputs ................................................................................ 26

3.6.4

Measured Values ................................................................................ 27

3.6.5

Measuring Errors ................................................................................ 28

3.6.6

Communication .................................................................................. 28

3.6.7

Connection Type ................................................................................ 28

3.6.8

Mechanical Conditions ....................................................................... 29

3.6.9

Climatic Environmental Conditions ................................................... 29

3.7

Approvals ................................................................................................ 30

3.8

Standards and Guidelines ........................................................................ 32

4

4.1

4.2

4.3

4.4

Function Description ................................................................................. 36

Measuring Principle ................................................................................ 36

Measured Values ..................................................................................... 36

Description of Measured Values ............................................................. 38

Measuring Errors and Accuracy.............................................................. 46

5

Process Image ............................................................................................. 48

5.1

Overview of Process Data ....................................................................... 48

5.2

Output Data ............................................................................................. 49

5.2.1

Definition of Control Words .............................................................. 49

5.2.2

Definition of Output Data Words ....................................................... 50

Manual

Version 1.1.0

4

Table of Contents

5.3

5.3.1

5.3.2

5.4

5.4.1

5.4.2

5.4.3

5.5

5.5.1

5.5.2

5.5.3

5.5.4

5.6

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Input Data ................................................................................................ 50

Definition of Status Words ................................................................. 51

Definition of Input Data Words .......................................................... 54

Process Image Descriptions .................................................................... 58

Collection AC Measured Values (010) .............................................. 59

Collections for Harmonics Analysis (020, 021, 022) ......................... 60

Building-up the Measured Values ...................................................... 62

Collections of Measured Values ............................................................. 63

Collection 010 – AC Measured Values .............................................. 63

Collection 020 – Harmonics Analysis on L1 ..................................... 68

Collection 021 – Harmonics Analysis on L2 ..................................... 69

Collection 022 – Harmonics Analysis on L3 ..................................... 70

Examples of Calculating the Measured Values from the Process

Values ...................................................................................................... 71

6

Mounting..................................................................................................... 75

6.1

Mounting Sequence ................................................................................. 75

6.2

Inserting and Removing Devices ............................................................ 76

6.2.1

Inserting the I/O Module .................................................................... 76

6.2.2

Removing the I/O Module .................................................................. 77

7

Connect Devices ......................................................................................... 78

7.1

Connecting a Conductor to the CAGE CLAMP® ................................... 78

7.2

Voltage Measurement ............................................................................. 79

7.3

Current Measurement .............................................................................. 80

7.3.1

Current Measurement on a Motor ...................................................... 80

7.3.2

Current Transformers ......................................................................... 81

7.3.2.1

Accuracy ........................................................................................ 81

7.3.2.2

Types of Current ............................................................................ 81

7.3.2.3

Overcurrent Limiting Factor FS .................................................... 81

7.3.2.4

Protection against Shock Hazard Voltages .................................... 82

7.3.3

‘Rogowski’ Coils ................................................................................ 82

7.3.4

Additional Measuring Instruments in a Current Path ......................... 83

7.4

Power Measurement ................................................................................ 84

8

Commissioning ........................................................................................... 85

8.1

Configuration with WAGO-I/O-CHECK ............................................... 86

8.1.1

“Application” Tab .............................................................................. 89

8.1.2

“Phase L1”, “Phase L2”, “Phase L3” Tabs ........................................ 91

8.1.3

“Neutral Conductor” Tab ................................................................... 93

8.1.4

“I/O Module” Tab............................................................................... 94

8.1.5

“Energy” Tab ...................................................................................... 97

8.1.6

“Factory Settings” Tab ....................................................................... 99

8.2

Displaying the Measured Values via WAGO-I/O-CHECK .................. 101

9

Diagnostics ................................................................................................ 110

10 Use in Hazardous Environments ............................................................ 111

10.1

Marking Configuration Examples ......................................................... 112

10.1.1

Marking for Europe According to ATEX and IEC-Ex .................... 112

10.1.2

Marking for America According to NEC 500 .................................. 117

10.2

Installation Regulations ......................................................................... 118

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

10.2.1

10.2.2

10.2.3

10.2.4

10.2.5

Table of Contents

5

Special Conditions for Safe Use

(TÜV 14 ATEX 148929 X) .............................................................. 119

Special Conditions for Safe Use

(ATEX Certificate TÜV 12 ATEX 106032 X) ................................ 120

Special Conditions for Safe Use

(IEC-Ex Certificate TUN 14.0035X) ............................................... 121

Special Conditions for Safe Use

(IEC-Ex Certificate IECEx TUN 12.0039 X) .................................. 122

Special Conditions for Safe Use according to

ANSI/ISA 12.12.01 .......................................................................... 123

11 Appendix ................................................................................................... 124

11.1

Examples of CSV Data Files................................................................. 124

11.1.1

Snapshot ........................................................................................... 124

11.1.2

Measurement Recording................................................................... 128

11.2

Factory Settings ..................................................................................... 129

11.3

Register Assignment ............................................................................. 131

11.4

Parameter Assignment .......................................................................... 137

List of Figures .................................................................................................... 143

List of Tables ...................................................................................................... 145

=== Ende der Liste für T extmar ke Verzeic hnis_vor ne ===

Manual

Version 1.1.0

6

Notes about this Documentation

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 7 /Alle Serien (Allgemeine M odul e)/Übersc hriften/Neue Übersc hriften/Ebene 1Hinweise z u dies er D okumentation - Ü berschrift 1 @ 4\mod_1237987661750_21.doc x @ 29029 @ 1 @ 1

1

Notes about this Documentation

Pos : 8 /Alle Serien (Allgemeine M odul e)/Sic her heits- und s onstige Hinweise/HinweisHinweis: Dokumentation aufbewahr en @ 4\mod_1237987339812_21.doc x @ 29026 @ @ 1

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

Pos : 9 /Alle Serien (Allgemeine M odul e)/Übersc hriften/Neue Übersc hriften/Ebene 2Gültig keitsbereic h - Ü berschrift 2 @ 12\mod_1338912448776_21.doc x @ 96469 @ 2 @ 1

1.1

Validity of this Documentation

Pos : 10 /Serie 750 ( WAGO-I/O-SYST EM)/Hi nweis e z ur D okumentati on/Gültigkeits bereic h/Gültig keits ber eich Dokumentation Bus kl emme 750- xxxx, aufg elistete Varianten @ 22\mod_1424856072619_21.doc x @ 175705 @ @ 1

This documentation is applicable to the variants of the I/O module 750-495/04000x (3-Phase POM 690V /XTR) listed in the table below.

Pos : 11 /Serie 750 ( WAGO-I/O-SYST EM)/Hi nweis e z ur D okumentati on/Gültigkeits bereic h/Variantenlisten/Variantenliste - 750- 495/040- 00x - 1A, 5A und Rog.Spul e @ 22\mod_1424856331214_21.doc x @ 175739 @ @ 1

Table 1: Variants

Item Number

750-495/040-000

750-495/040-001

750-495/040-002

Description

3-Phase POM 690V/ 1 A /XTR

3-Phase POM 690V/ 5 A /XTR

3-Phase POM 690V/ R.C. /XTR

Pos : 12 /All e Seri en (Allgemei ne Module)/Sicher heits- und s ons tige Hi nweis e/Hi nweisHi nweis: Gül tigkeit der Angaben für aufgelistete Varianten @ 9\mod_1281520778141_21.doc x @ 63085 @ @ 1

Documentation Validity for Variants

Unless otherwise indicated, the information given in this documentation applies to

listed variants.

Pos : 13 /Serie 750 ( WAGO-I/O-SYST EM)/Hi nweis e z ur D okumentati on/Hi nweise/Ac htung: Hinweis z ur D okumentati on Bus kl emmen 750- xxxx @ 4\mod_1237986979656_21.doc x @ 29023 @ @ 1

The I/O module 750-495/040-00x shall only be installed and operated according

to the instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

Pos : 14.1 /All e Seri en ( Allgemei ne Module)/Ü bers chriften/Ebene 2/Ur hebersc hutz - Ü bersc hrift 2 @ 23\mod_1435647042188_21.doc x @ 184808 @ 2 @ 1

1.2

Copyright

Pos : 14.2 /All e Seri en ( Allgemei ne Module)/R ec htliches , Allgemei nes /Urhebersc hutz ausführlich @ 4\mod_1235565145234_21.doc x @ 27691 @ @ 1

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Notes about this Documentation

7

Pos : 14.3 /Dokumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Pos : 14.4 /All e Seri en ( Allgemei ne Module)/Ü bers chriften/N eue Ü berschriften/Ebene 2Symbol e - Ü bersc hrift 2 @ 13\mod_1351068042408_21.doc x @ 105270 @ 2 @ 1

1.3

Symbols

Pos : 14.5.1 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Gefahr/Gefahr: _War nung vor Pers onenschäden allgemei n_ - Erläuter ung @ 13\mod_1343309450020_21.doc x @ 101029 @ @ 1

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos : 14.5.2 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Gefahr/Gefahr: _War nung vor Pers onenschäden durch el ektrisc hen Strom_ - Erläuterung @ 13\mod_1343309694914_21.doc x @ 101030 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos : 14.5.3 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Warnung/Warnung: _Warnung vor Personensc häden allgemei n_ - Erläuterung @ 13\mod_1343309877041_21.doc x @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos : 14.5.4 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Vorsic ht/Vorsicht: _War nung vor Pers onensc häden allgemein_ - Erläuterung @ 13\mod_1343310028762_21.doc x @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos : 14.5.5 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Ac htung/Achtung: _War nung vor Sac hsc häden allgemein_ - Erläuterung @ 13\mod_1343310134623_21.doc x @ 101041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos : 14.5.6 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Ac htung/Achtung: _War nung vor Sac hsc häden durc h elektrostatis che Aufladung_ - Erl äuter ung @ 13\mod_1343310227702_21.doc x @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos : 14.5.7 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Hi nweis /Hinweis: _Wic htiger Hi nweis allgemein_ - Erläuterung @ 13\mod_1343310326906_21.doc x @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos : 14.5.8 /All e Serien ( Allgemei ne Module)/Sicherheits- und sons tige Hi nweis e/Infor mation/Infor mation: _Weiter e Infor mation allgemei n_ - Erl äuter ung @ 13\mod_1343310439814_21.doc x @ 101051 @ @ 1

Manual

Version 1.1.0

8

Notes about this Documentation

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos : 14.6 /Dokumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Notes about this Documentation

9

Pos : 14.7 /All e Seri en ( Allgemei ne Module)/Ü bers chriften/Ebene 2/D arstellung der Z ahlens ys teme - Ü bers chrift 2 @ 23\mod_1435647128078_21.doc x @ 184811 @ 2 @ 1

1.4

Number Notation

Pos : 14.8 /All e Seri en ( Allgemei ne Module)/R ec htliches , Allgemei nes /Zahlens ysteme @ 3\mod_1221059454015_21.doc x @ 21711 @ @ 1

Table 2: Number Notation

Number Code

Decimal

Hexadecimal

Binary

Example

100

0x64

'100'

'0110.0100'

Note

Normal notation

C notation

In quotation marks, nibble separated with

dots (.)

Pos : 14.9 /All e Seri en ( Allgemei ne Module)/Ü bers chriften/Ebene 2/Sc hriftkonventi onen - Ü bersc hrift 2 @ 23\mod_1435647186005_21.doc x @ 184814 @ 2 @ 1

1.5

Font Conventions

Pos : 14.10 /Alle Serien (Allgemeine M odul e)/Rechtliches, Allgemeines/Sc hriftkonventi onen @ 3\mod_1221059521437_21.doc x @ 21714 @ @ 1

Table 3: Font Conventions

Font Type Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Program Files\WAGO Software

Menu items are marked in bold letters.

Menu

e.g.: Save

A greater-than sign between two names means the selection of a

>

menu item from a menu.

e.g.: File > New

Designation of input or optional fields are marked in bold letters,

Input

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

Pushbuttons in dialog boxes are marked with bold letters in square

[Button]

brackets.

e.g.: [Input]

Keys are marked with bold letters in square brackets.

[Key]

e.g.: [F5]

Pos : 15 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

10

Important Notes

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 16 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 1Wic htige Erläuterungen - Ü berschrift 1 @ 4\mod_1241428899156_21.doc x @ 32170 @ 1 @ 1

2

Important Notes

Pos : 17.1 /All e Seri en ( Allgemei ne Module)/R ec htliches , Allgemei nes Wic htige Erläuterungen - Einl eitung @ 3\mod_1221059818031_21.doc x @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos : 17.2 /All e Seri en ( Allgemei ne Module)/Ü bers chriften/N eue Ü berschriften/Ebene 2R ec htlic he Grundlagen - Ü berschrift 2 @ 3\mod_1221060626343_21.doc x @ 21726 @ 2 @ 1

2.1

Legal Bases

Pos : 17.3 /All e Seri en ( Allgemei ne Module)/R ec htliches , Allgemei nes Änderungs vor behalt - Ü berschrift 3 und Inhalt @ 3\mod_1221060036484_21.doc x @ 21720 @ 3 @ 1

2.1.1

Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos : 17.4 /Serie 750 (WAGO-I/O-SYST EM)/Wic htige Erläuterungen/Pers onalqualifi kation/Pers onalqualifi kation 750- xxxx - Ü bers chrift 3 und Inhalt @ 3\mod_1224061208046_21.doc x @ 24063 @ 3 @ 1

2.1.2

Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos : 17.5 /Serie 750 (WAGO-I/O-SYST EM)/Wic htige Erläuterungen/Bes timmungsgemäß e Verwendung/Besti mmungsgemäß e Ver wendung 750- xxxx - Übersc hrift 3 und Inhalt @ 3\mod_1224064151234_21.doc x @ 24070 @ 3 @ 1

2.1.3

Use of the WAGO-I/O-SYSTEM 750 in Compliance with

Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Important Notes

11

Appropriate housing (per 2014/34/EU) is required when operating the WAGOI/O-SYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos : 17.6 /All e Seri en ( Allgemei ne Module)/R ec htliches , Allgemei nesT ec hnis cher Z ustand der Geräte - Übersc hrift 3 und Inhalt @ 3\mod_1221060446109_21.doc x @ 21723 @ 3 @ 1

2.1.4

Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos : 17.7 /Dokumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

12

Important Notes

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 17.8 /All e Seri en ( Allgemei ne Module)/Ü bers chriften/N eue Ü berschriften/Ebene 2Sicher heits hi nweis e - Ü berschrift 2 @ 6\mod_1260180299987_21.doc x @ 46724 @ 2 @ 1

2.2

Safety Advice (Precautions)

Pos : 17.9 /All e Seri en ( Allgemei ne Module)/Sicherheits- und s ons tige Hi nweis e/Einl eitung Sicherheits hinweis e H ardware @ 6\mod_1260180170493_21.doc x @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos : 17.10 /Serie 750 ( WAGO-I/O-SYST EM)/Wichtig e Erl äuter ung en/Sic her hei ts- und s onstige Hinweise/Gefahr/Gefahr: Berührungssc hutz vorsehen! -für Mes saufbau @ 15\mod_1366120208015_21.doc x @ 117160 @ @ 1

Install protection against electric shock!

All wiring for the measurement system shall be provided with protection against

shock hazard voltages along with the corresponding safety signs!

Pos : 17.11.1 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Gefahr /Gefahr: Nicht an Geräten unter Spannung ar beiten! @ 6\mod_1260180365327_21.doc x @ 46727 @ @ 1

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos : 17.11.2 /Serie 750 ( WAGO-I/O- SYST EM)/Wic htig e Erl äuter ung en/Sic her hei ts- und s onstige Hi nweise/Gefahr/Gefahr: Ei nbau 0750- xxxx nur i n Gehäus en, Sc hränken oder el ektrisc hen Betriebsräumen! @ 6\mod_1260180556692_21.doc x @ 46731 @ @ 1

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos : 17.11.3 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Gefahr /Gefahr: Unfall verhütungs vorsc hriften beachten! @ 6\mod_1260180657000_21.doc x @ 46735 @ @ 1

Pos : 17.11.4 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Gefahr /Gefahr: Auf normg erec hten Ansc hluss ac hten! @ 6\mod_1260180753479_21.doc x @ 46739 @ @ 1

Pos : 17.12 /Alle Serien (Allgemeine M odul e)/Sic herheits- und sonstige Hinweis e/Gefahr/Gefahr: Leitung en nur i n s pannungsfrei em Z ustand ansc hliess en oder tr ennen @ 16\mod_1372153982130_21.doc x @ 124277 @ @ 1

Only connect or disconnect lines when power is safely isolated!

The lines to the device can carry hazardous voltages and currents. Contact with

the lines when live can result in severe injury or death. Therefore, read and

observe the following safety rules before you perform work on the device:

1.

Disconnect the respective system component from the power supply.

2.

Secure the system component against unintentional restart.

3.

Check if the voltage is positively isolated.

Pos : 17.13 /Alle Serien (Allgemeine M odul e)/Sic herheits- und sonstige Hinweis e/Vorsic ht/Vorsic ht: H eiße Oberfl äc he allgemein @ 6\mod_1264428115588_21.doc x @ 48610 @ @ 1

Hot surface!

The surface of the housing can become hot during operation. If the device was

operated at high ambient temperatures, allow it to cool off before touching it.

Pos : 17.14 /Serie 750 ( WAGO-I/O-SYST EM)/Wichtig e Erl äuter ung en/Sic her hei ts- und s onstige Hinweise/Ac htung/Ac htung: 1A bz w. 5A Eing angsstr om nicht übersc hreiten! @ 15\mod_1366120670473_21.doc x @ 117163 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Important Notes

13

Note the max. continuous input current of 1 A resp. 5 A!

The max. continuous input current is 1 A resp. 5 A. If needed install additional

transformers with an appropriate transforming ratio!

Pos : 17.15.1 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Ac htung/Ac htung: Defekte oder besc hädigte Ger äte aus tausc hen! @ 6\mod_1260180857358_21.doc x @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos : 17.15.2 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Ac htung/Ac htung: Geräte vor kriec henden und is olier enden Stoffen schützen! @ 6\mod_1260181036216_21.doc x @ 46747 @ @ 1

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos : 17.15.3 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Ac htung/Ac htung: Rei nigung nur mit zul ässigen M aterialien! @ 6\mod_1260181203293_21.doc x @ 46751 @ @ 1

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos : 17.15.4 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Ac htung/Ac htung: Kei n Kontakts pray verwenden! @ 6\mod_1260181290808_21.doc x @ 46755 @ @ 1

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos : 17.15.5 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Ac htung/Ac htung: Verpol ung ver mei den! @ 6\mod_1260184045744_21.doc x @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos : 17.15.6 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Wichtige Erläuter ungen/Sic herheits hinweise/Ac htung/Ac htung: El ektr ostatisc he Entl adung vermeiden! @ 6\mod_1260181364729_21.doc x @ 46759 @ @ 1

Manual

Version 1.1.0

14

Important Notes

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Pos : 17.16 /Serie 750 ( WAGO-I/O-SYST EM)/Wichtig e Erl äuter ung en/Sic her hei ts- und s onstige Hinweise/Ac htung/Ac htung: XTR - Is olations prüfungen mit DC durchführen! @ 15\mod_1370843209441_21.doc x @ 122210 @ @ 1

Perform insulation tests with direct current (DC)!

Both the supply voltage and control voltage side are capacitively coupled to the

DIN rail. If the modules are mounted on the DIN rail, application of an AC

voltage between the two potentials can lead to the destruction of the device.

Use only direct current (DC) for insulation testing.

To avoid destroying the device, discharge the device completely before applying

the test voltage again.

Pos : 18 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

15

Pos : 19 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 1Ger ätebesc hrei bung - Ü berschrift 1 @ 3\mod_1233756084656_21.doc x @ 27096 @ 1 @ 1

3

Device Description

Pos : 20 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ei nlei tung/Analogei ngangs klemmen/Gerätebeschr eibung - Ei nleitung 750- 0495/040-00x @ 22\mod_1424856744765_21.doc x @ 175743 @ @ 1

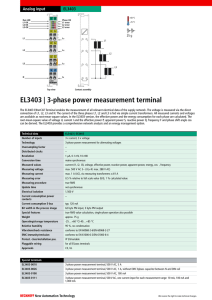

The 3-Phase Power Measurement Module 750-495/040-00x (also called I/O

Module) measures the electrical data in a 3-phase supply network.

The 3 phase voltages are measured via connection to L1, L2, L3 and N. The

currents are fed to I1+ and I1−, I2+ and I2−, I3+ and I3−, IN+ and IN− via current

transformers resp. via ‘Rogowski’ coils to RC1+ and RC1−, RC2+ and RC2−,

RC3+ and RC3−, RCN+ and RCN−. Based on these input signals the I/O module

calculates numerous AC values like voltages, currents, powers (active, reactive

and apparent), energies, power factors, phase shift angles and frequencies.

Furthermore, an analysis of harmonic waves is carried out up to the 41st harmonic.

The measured values are available in the process image. Therefore, no high

computing power is required from the higher-level controller.

The calculated values indicate whether the load is inductive or capacitive and

whether it consumes or generates energy. For this purpose a 4-quadrant display is

incorporated in WAGO-I/O-CHECK.

The I/O module provides a great number of measured values for a comprehensive

analysis of the 3-phase-grid. By means of the measured values the operator can

regulate the supply to a drive or machine in the best possible way and protect the

installation from damage/failure.

The I/O module 750-495/040-000 measures currents up to 1 A, 750-495/040-001

measures currents up to 5 A and 750-495/040-002 measures currents via

‘Rogowski’ coils RT500 up to 500 A or via RT2000 up to 2000 A.

Pos : 21 /Serie 750 ( WAGO-I/O-SYST EM)/Wic htige Erläuterungen/Sicherheits- und sonstig e Hinweis e/Hi nweis /Hinweis: Potenti alei ns peis ekl emme ei nsetz en! ( kei ne LK) @ 3\mod_1226499089640_21.doc x @ 25026 @ @ 1

Use a supply module!

Use a supply module for field-side power supply of downstream I/O modules.

Pos : 22 /Serie 750 ( WAGO-I/O-SYST EM)/Wic htige Erläuterungen/Sicherheits- und sonstig e Hinweis e/Hi nweis /Hinweis: XTR - Mis chbetrieb XTR/Standar d @ 15\mod_1367496420828_21.doc x @ 118326 @ @ 1

Mixed operation

Mixed operation (standard/XTR modules) within a node is possible when groups

of modules are electrically isolated on the field side (i.e., electrically isolated

power supply).

Pos : 23 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ei nlei tung/Ei ns atz ber eich/Ei ns atz ber eich 750- xxxx/040- 000 alle XTR- Koppler/-C ontr oller ohne Eins chr änkung @ 15\mod_1368425919479_21.doc x @ 119444 @ @ 1

The I/O module can be operated with all fieldbus couplers/controllers of the

WAGO-I/O-SYSTEM 750 XTR.

Observe the instructions for mixed operation when used in mixed operation

behind standard fieldbus couplers/controllers.

Pos : 24 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

16

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 25 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2Ansicht - Ü bersc hrift 2 @ 4\mod_1240984217343_21.doc x @ 31958 @ 2 @ 1

3.1

View

Pos : 26 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansic ht/Anal ogei ngangskl emmen/Ansicht 750-0495/040-00x @ 22\mod_1424856790380_21.doc x @ 175747 @ @ 1

Figure 1: View 750-495/040-000 (left) and 750-459/040-002 (right)

Pos : 27 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansic ht/Ansic ht C ageCl amp® _Leg ende mit LED s_ohne Leis tungs kontakte @ 16\mod_1371816091053_21.doc x @ 124052 @ @ 1

Table 4: Legend for Figure “View”

Pos. Description

1 Marking possibility with

Mini-WSB

2 Status LEDs

3 Data contacts

4 CAGE CLAMP® connectors

5 Release tab

Details See Section

--“Device Description” > “Display Elements”

“Device Description” > “Connectors”

“Device Description” > “Connectors”

“Mounting” > ”Inserting and Removing

Devices”

Pos : 28 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

17

Pos : 29 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2Anschl üss e - Ü berschrift 2 @ 4\mod_1240984262656_21.doc x @ 31961 @ 2 @ 1

3.2

Connectors

Pos : 30 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansc hl üss e/Datenkontakte/Kl emmenbus - Ü bersc hrift 3 @ 6\mod_1256294684083_21.doc x @ 43660 @ 3 @ 1

3.2.1

Data Contacts/Internal Bus

Pos : 31.1 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansc hl üsse/Datenkontakte - F eldbus koppler/-c ontroll er, Abbildung und Besc hrei bung @ 3\mod_1231771259187_21.doc x @ 26002 @ @ 1

Communication between the fieldbus coupler/controller and the I/O modules as

well as the system supply of the I/O modules is carried out via the internal bus. It

is comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 2: Data Contacts

Pos : 31.2 /Serie 750 (WAGO-I/O-SYST EM)/Wic htige Erläuterungen/Sicherheits- und sonstig e Hinweis e/Achtung/Achtung: Bus kl emmen nic ht auf Goldfeder kontakte leg en! @ 7\mod_1266318463636_21.doc x @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos : 31.3 /Serie 750 (WAGO-I/O-SYST EM)/Wic htige Erläuterungen/Sicherheits- und sonstig e Hinweis e/Achtung/Achtung: ESD - Auf g ute Erdung der U mgebung ac hten! @ 7\mod_1266318538667_21.doc x @ 50708 @ @ 1

Ensure that the environment is well grounded!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the devices, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos : 32 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansc hl üss e/Leistungs kontakte/F el dvers orgung - Übersc hrift 3 @ 6\mod_1256294692864_21.doc x @ 43664 @ 3 @ 1

3.2.2

Power Jumper Contacts/Field Supply

Pos : 33 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansc hl üss e/Leistungs kontakte nic ht vorhanden @ 8\mod_1281073936319_21.doc x @ 62530 @ @ 1

The I/O module 750-495/040-00x has no power jumper contacts.

Pos : 34 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

18

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 35 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansc hl üss e/CAGE CLAMP- Anschl üss e - Ü berschrift 3 @ 6\mod_1256296337770_21.doc x @ 43674 @ 3 @ 1

3.2.3

CAGE CLAMP® Connectors

12 CAGE CLAMP® connectors make up the measuring inputs. The 3-phase

supply network and the loads/generators are clamped here. See also section

“Connect Devices”.

Pos : 36 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Ansc hl üss e/Analogei ngangs klemmen/Ansc hlüsse 750-0495/040- 00x @ 22\mod_1424859904404_21.doc x @ 175770 @ @ 1

3 CAGE CLAMP® connectors each form the measuring channels:

•

Measuring channel 1: L1, I1+ and I1− (voltage and current of phase L1)

•

Measuring channel 2: L2, I2+ and I2− (voltage and current of phase L2)

•

Measuring channel 3: L3, I3+ and I3− (voltage and current of phase L3)

•

Measuring channel 4: IN+ and IN− (current of neutral conductor)

Figure 3: CAGE CLAMP® Connectors 750-495/040-000 and 750-495/040-001

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

19

Table 5: Legend for Figure “CAGE CLAMP® Connectors 750-495/040-000 and 750-495/040-001”

Measuring

channel

1

2

3

4

Connector

L1

I1+

I1−

L2

I2+

I2−

L3

I3+

I3−

N

IN+

IN−

Function

Voltage of phase L1

Current of phase L1

Voltage of phase L2

Current of phase L2

Voltage of phase L3

Current of phase L3

Neutral conductor

(reference for all measurements)

Current N

Figure 4: CAGE CLAMP® Connectors 750-495/040-002

Manual

Version 1.1.0

20

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Table 6: Legend for Figure “CAGE CLAMP® Connectors 750-495/040-002”

Measuring

channel

1

2

3

4

Connector

L1

RC1+

RC1−

L2

RC2+

RC2−

L3

RC3+

RC3−

N

RCN+

RCN−

Function

Voltage of phase L1

Current of phase L1 via ‘Rogowski coil’

Voltage of phase L2

Current of phase L2 via ‘Rogowski coil’

Voltage of phase L3

Current of phase L3 via ‘Rogowski coil’

Neutral conductor

(reference for all measurements)

Current N via ‘Rogowski coil’

Pos : 37 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

21

Pos : 38 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2Anzeigeel emente - Ü bers chrift 2 @ 4\mod_1240984390875_21.doc x @ 31964 @ 2 @ 1

3.3

Display Elements

Pos : 39 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Anz eigeelemente/Anal ogei ngangs klemmen/Anz eigeel emente 750- 0494, - 0495 @ 16\mod_1371738731125_21.doc x @ 123880 @ @ 1

LED A indicates the operating status, LEDs B … H indicate possible errors.

Figure 5: Display Elements

The meaning of these indications is as follows:

Table 7: Legend for Figure “Display Elements”

LED

A

B

C

D

E

F

G

H

Pos : 40 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

State

Message

No operational readiness or

the internal data bus communication is interrupted.

Off

Note: If the watchdog was disabled, the LED is always

green. See section “Commissioning” > “Configuration

with WAGO-I/O-CHECK“.

Operational readiness and correct internal data bus

Green

communication

Off

No error

General error message for L1:

Red

Under-/overvoltage or overcurrent

Off

No error

General error message: Clipping of a current measuring

Red

path IL1, IL2 or IL3

Off

No error

High measuring error, caused by undershooting the min.

Red

voltage at L1, L2 or L3

Off

No error

General error message for L2:

Red

Under-/overvoltage or overcurrent

Off

No error

General error message for L3:

Red

Under-/overvoltage or overcurrent

Off

No error

General error message: Clipping of a voltage measuring

Red

path L1, L2 or L3

Off

No error

Yellow Error of the phase sequence L1-L2-L3

22

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 41 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2Bedi enelemente - Ü bersc hrift 2 @ 4\mod_1239191655456_21.doc x @ 30439 @ 2 @ 1

3.4

Operating Elements

Pos : 42 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Bedienel emente/Bedi enel emente Bus kl emme 750- xxxx nic ht vor handen @ 4\mod_1236322031125_21.doc x @ 28063 @ @ 1

The I/O module 750-495/040-00x has no operating elements.

Pos : 43 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2Sc hematisc hes Schaltbild - Übersc hrift 2 @ 4\mod_1240984441312_21.doc x @ 31967 @ 2 @ 1

3.5

Schematic Diagram

Pos : 44 /Serie 750 ( WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Schematisc he Sc haltbil der/Anal ogeing angs kl emmen/Sc hematisc hes Sc haltbild 750-0495/040-00x @ 22\mod_1424858436413_21.doc x @ 175754 @ @ 1

Function Earth FE!

In order to get a function earth, the connection N is connected to the mounting rail

via a 1 nF capacitor and a spring contact. If the rail is correctly connected to PE,

the immunity to interference is increased.

The 3 voltage measuring paths are not isolated from the 4 current measuring

paths!

The connection N forms the internal reference for all electrical measurements.

Potential differences between N and the current inputs may result in measurement

errors or even destruction of the I/O module!

Do not connect the current inputs to PE!

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

Figure 6: Schematic Diagram for 750-495/040-000 and 750-495/040-001

Manual

Version 1.1.0

23

24

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Figure 7: Schematic Diagram for 750-495/040-002

Pos : 45 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

Pos : 46 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2T ec hnis che D aten - Ü bersc hrift 2 @ 3\mod_1232967587687_21.doc x @ 26924 @ 2 @ 1

3.6

Technical Data

Pos : 47.1 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/T echnisc he Daten/VS (Variablensteuer ung)/T echnisc he D aten Gerät (VS) - XTR @ 15\mod_1369311215011_21.doc x @ 120260 @ 3 @ 1

3.6.1

Device

Table 8: Technical Data – Device

Width

Height (from upper edge of DIN 35 rail)

Length

Weight

Degree of protection

24 mm

61 mm

100 mm

91 g

IP20

Pos : 47.2 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/T echnisc he Daten/Anal ogeing angs kl emmen/T ec hnis che D aten 750-0495/040- 00x @ 22\mod_1424871845891_21.doc x @ 175880 @ 3333 @ 1

3.6.2

Voltage Supply

Table 9: Technical Data ‒ Voltage Supply

Supply voltage for the internal

electronics

Current consumption max.

Manual

Version 1.1.0

5 VDC

(system voltage via internal bus)

100 mA

25

26

Device Description

3.6.3

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Measuring Inputs

Table 10: Technical Data ‒ Measuring Inputs

Number of inputs

Input voltage max.

Input resistance typ. (voltage)

Input current max.

750-495/040-000

750-495/040-001

750-495/040-002

Input resistance typ. (current)

750-495/040-000

750-495/040-001

7 (3 voltage measuring inputs,

4 differential current measuring inputs)

Phase-to-phase voltage Lx-Ly:

690 VAC,

phase voltage Lx-N: 400 VAC

1429 kΩ

1A

5A

via ‘Rogowski’ coil 500 A / 2000 A

22 mΩ

5 mΩ

750-495/040-002 44 kΩ

Frequency range

frequency of supply network

analysis of harmonics

Max. frequency

Signal form

Nominal voltage spike

Category of overvoltage *)

Degree of contamination

*)

45 Hz … 65 Hz

0 Hz … 3300 Hz

15.9 kHz

Any periodic signal (considering the

max. operating frequency)

5.0 kV (EN 60870-2-1 / Class VW3)

6.0 kV (UL 508)

6.0 kV (EN 60664-1 / < 4000 m above

sea level)

4.0 kV (EN 60664-1 / 4000 m …

5000 m above sea level)

III (EN 60664-1 / < 4000 m above sea

level)

II (EN 60664-1 / 4000 m … 5000 m

above sea level)

2 (EN 60664-1)

Nominal voltage 400 V / 690 V in the 3-phase-grid

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

3.6.4

Device Description

27

Measured Values

Table 11: Technical Data ‒ Measured Values

Measuring procedure

Calculated values

Update cycle of process data

RMS voltage Lx - N

Min./max. RMS voltage Lx - N

RMS voltage Lx - Ly

Arithmetic mean value voltage Lx - N

Peak value voltage Lx - N

RMS current Lx

Min./max. RMS current Lx

Arithmetic mean value current Lx

Peak value current Lx

RMS current N

Active power Lx

Min./max. active power Lx

Reactive power Lx

Apparent power Lx

All energy values

Supply network frequency Lx

Min./max. supply network

frequency Lx

Phase angle phi Lx

Power factor cos phi Lx

Power factor PF Lx

Power factor LF Lx

Harmonics analysis

• Current

• Voltage

• HD/THD current

• HD/THD voltage

Manual

Version 1.1.0

Calculation of true RMS for voltages

and currents, sample rate 8 kHz

synchronous on all 7 measuring inputs,

24 bits resolution

Phase-to-phase voltages, powers,

energies, power factors, network

frequencies, harmonics analysis up to

the 41st harmonic

40 ms

50 ms

340 ms

To be set, 5 s ... 900 s

200 ms

40 ms

50 ms

To be set, 5 s ... 900 s

200 ms

40 ms

40 ms

50 ms

340 ms

40 ms

400 ms

280 ms

280 ms

340 ms

340 ms

280 ms

280 ms

260 ms

260 ms

260 ms

260 ms

28

Device Description

3.6.5

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Measuring Errors

Table 12: Technical Data – Measuring Errors

AC voltage

AC current

AC active power

Phase angle

Frequency

750-495/040-000 ≤ 0.3 % of full-scale value

750-495/040-001 ≤ 0.4 % of full-scale value

750-495/040-002 ≤ 0.4 % of full-scale value

750-495/040-000 ≤ 0.5 % of full-scale value

750-495/040-001 ≤ 0.5 % of full-scale value

750-495/040-002 ≤ 0.5 % of full-scale value

750-495/040-000 ≤ 0.7 % of full-scale value

750-495/040-001 ≤ 0.8 % of full-scale value

750-495/040-002 ≤ 0.7 % of full-scale value

750-495/040-000 ± 0.3°

750-495/040-001 ± 0.3°

750-495/040-002 0 to −1.6°

750-495/040-000

750-495/040-001

750-495/040-002

Harmonics measured values

750-495/040-000

750-495/040-001

750-495/040-002

± 0.01 Hz

± 0.01 Hz

± 0.01 Hz

--≤ 1 % of full-scale value

Pos : 47.3 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/T echnisc he Daten/VS (Variablensteuer ung)/T echnisc he D aten Kommuni kation (VS) @ 4\mod_1242119312796_21.doc x @ 32970 @ 3 @ 1

3.6.6

Communication

Table 13: Technical Data – Communication

Bit width

Input and output data with

128 bits process data and

64 bits control/status each

Pos : 47.4 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/T echnisc he Daten/VS (Variablensteuer ung)/T echnisc he D aten Ansc hluss techni k (VS) ohne T abelle LK @ 18\mod_1395045829421_21.doc x @ 148018 @ 3 @ 1

3.6.7

Connection Type

Table 14: Technical Data – Field Wiring

Wire connection

Cross section

Stripped lengths

CAGE CLAMP®

0.25 mm² … 2.5 mm² / AWG 24 … 14

8 mm … 9 mm / 0.33 in

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

29

Table 15: Technical Data – Internal Bus

Data contacts

Slide contact, self-cleaning, hard gold

plated

Pos : 47.5 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/T echnisc he Daten/VS (Variablensteuer ung)/T echnisc he D aten M ec hanisc he Bedingungen ( VS) - XTR @ 15\mod_1369387569701_21.doc x @ 120364 @ 3 @ 1

3.6.8

Mechanical Conditions

Table 16: Technical Data – Mechanical Conditions

Vibration resistance

1)

Max. 5g 1)

Follow the installation instructions

Pos : 47.6 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/T echnisc he Daten/VS (Variablensteuer ung)/T echnisc he D aten kli matisc he U mweltbedingungen ( VS) - XTR @ 15\mod_1369387559187_21.doc x @ 120360 @ 3 @ 1

3.6.9

Climatic Environmental Conditions

Table 17: Technical Data – Climatic Environmental Conditions

Operating temperature range

Storage temperature range

Relative humidity 1)

Elevation above sea level

without temperature derating

with temperature derating

max.

1)

Pos : 48 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

−40 °C … +70 °C

−40 °C … +85 °C

95 %

0 m … 2000 m

2000 m … 5000 m:

5000 m

0.5 K per 100 m

Short-term condensation per Class 3K7/IEC EN 60721-3-3 and E DIN 40046-721-3 (except

wind-driven precipitation, water and ice formation)

30

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 49 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2Z ul assungen - Ü berschrift 2 @ 3\mod_1224055364109_21.doc x @ 24030 @ 2 @ 1

3.7

Approvals

Pos : 50.1 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Z ulass ungen/Infor mati on: Weitere Infor mationen zu Zul ass ung en 750- xxxx @ 3\mod_1227190967156_21.doc x @ 25221 @ @ 1

More information about approvals.

Detailed references to the approvals are listed in the document “Overview

Approvals WAGO-I/O-SYSTEM 750”, which you can find via the internet

under: www.wago.com > SERVICES > DOWNLOADS > Additional

documentation and information on automation products > WAGO-I/O-SYSTEM

750 > System Description.

Pos : 50.2 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Z ulass ungen/Allgemein/Z ulass ung (Einzahl!) Bus kl emme 750- xxxx Allgemein, ohne Variantenangabe @ 22\mod_1426064828924_21.doc x @ 177332 @ @ 1

The following approval has been granted to 750-495/040-00x I/O modules:

Pos : 50.3 /All e Seri en ( Allgemei ne Module)/Z ulassungen/Standardz ulassungen/C E (Konformi täts kennz eichnung) @ 3\mod_1224494777421_21.doc x @ 24276 @ @ 1

Conformity Marking

Pos : 50.4 /Dokumentation allgemei n/Glieder ungs elemente/------Leerz eile------ @ 3\mod_1224662755687_0.doc x @ 24460 @ @ 1

Pos : 50.5 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Z ulass ungen/Allgemein/Z ul. in Vorberei tung Bus kl emme 750- xxxx Allgemei n, ohne Variantenang abe - Einl eitung @ 4\mod_1241084431984_21.doc x @ 32069 @ @ 1

The following approvals are pending for 750-495/040-00x I/O modules:

Pos : 50.6 /All e Seri en ( Allgemei ne Module)/Z ulassungen/Standardz ulassungen/cU Lus (U L508) @ 3\mod_1224055013140_0.doc x @ 24020 @ @ 1

CULUS

UL508

Pos : 50.7 /All e Seri en ( Allgemei ne Module)/Z ulassungen/Standardz ulassungenKC - Korea C ertific ate - AI @ 20\mod_1406533217893_21.doc x @ 160376 @ @ 1

Korea Certification

MSIP-REM-W43-AIM750

Pos : 50.8 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/Z ulass ungen/Ex/Z ulass ungen Bus kl emme 750- xxxx Ex, ohne Variantenangabe - Ei nleitung @ 4\mod_1237191218000_21.doc x @ 28423 @ @ 1

The following Ex approvals have been granted to 750-495/040-00x I/O modules:

Pos : 50.9 /All e Seri en ( Allgemei ne Module)/Z ulassungen/Ex-Zul ass ungen/cU Lus /cU Lus (AN SI/ISA 12.12.01) Cl ass I, Di v2 ABCD T 4 @ 3\mod_1224054791812_0.doc x @ 24014 @ @ 1

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

Pos : 50.10 /D okumentati on allgemei n/Gli ederungsel emente/------Leerz eile------ @ 3\mod_1224662755687_0.doc x @ 24460 @ @ 1

Pos : 50.11 /Serie 750 ( WAGO-I/O-SYST EM)/Gerätebeschr eibung/Zul ass ung en/Ex/Zul. in Vorbereitung Bus kl emme 750- xxxx Ex, ohne Variantenang abe - Einl eitung @ 7\mod_1274259264803_21.doc x @ 56610 @ @ 1

The following Ex approvals are pending for 750-495/040-00x I/O modules:

Pos : 50.12.1 /Alle Serien (Allgemeine M odul e)/Z ulass ungen/Ex-Z ul ass ungen/Sons tige/ATEX allgemein @ 16\mod_1373352135578_0.doc x @ 125803 @ @ 1

ATEX

Pos : 50.12.2 /Alle Serien (Allgemeine M odul e)/Z ulass ungen/Ex-Z ul ass ungen/IEC Ex (TÜ V N ord)/IEC Ex allgemei n @ 16\mod_1373353532946_0.doc x @ 125807 @ @ 1

IECEx

Pos : 50.13 /D okumentati on allgemei n/Gli ederungsel emente/------Leerz eile------ @ 3\mod_1224662755687_0.doc x @ 24460 @ @ 1

Pos : 50.14 /Serie 750 ( WAGO-I/O-SYST EM)/Gerätebeschr eibung/Zul ass ung en/Sc hiff/Ei nleitungssätze/Zul . in Vorberei tung Bus kl emme 750- xxxx Sc hiff, ohne Variantenangabe - Ei nleitung @ 7\mod_1274259318897_21.doc x @ 56614 @ @ 1

The following ship approvals are pending for 750-495/040-00x I/O modules:

Pos : 50.15 /Alle Serien (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulas sungen/GL ( Ger manisc her Ll oyd) C at. A, B, C, D (EMC 1), H @ 15\mod_1370521488638_0.doc x @ 122022 @ @ 1

GL (Germanischer Lloyd)

Cat. A, B, C, D (EMC 1), H

Pos : 50.16.1 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/ABS (American Bur eau of Shippi ng) @ 3\mod_1224055151062_0.doc x @ 24023 @ @ 1

ABS (American Bureau of Shipping)

Pos : 50.16.2 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/BSH ( Bundes amt für Seesc hifffahrt und H ydrographie) @ 5\mod_1246341825156_21.doc x @ 36334 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

Federal Maritime and Hydrographic Agency

Pos : 50.16.3 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/BV ( Bur eau Veritas) @ 3\mod_1224492116171_0.doc x @ 24220 @ @ 1

BV (Bureau Veritas)

Pos : 50.16.4 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/DN V (Det N ors ke Veritas) Clas s B @ 3\mod_1224492540562_0.doc x @ 24224 @ @ 1

DNV (Det Norske Veritas)

Class B

Pos : 50.16.5 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/KR (Korean Register of Shipping) @ 3\mod_1224492806109_0.doc x @ 24232 @ @ 1

KR (Korean Register of Shipping)

Pos : 50.16.6 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/LR (Ll oyd’s R egister) Env. 1, 2, 3, 4 @ 3\mod_1224492890453_0.doc x @ 24236 @ @ 1

LR (Lloyd’s Register)

Pos : 50.16.7 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/N KK (Ni ppon Kaiji Kyokai) @ 3\mod_1224493002656_0.doc x @ 24240 @ @ 1

NKK (Nippon Kaiji Kyokai)

Pos : 50.16.8 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/PRS ( Pols ki Rej estr Statków) @ 3\mod_1224497273250_0.doc x @ 24295 @ @ 1

PRS (Polski Rejestr Statków)

Pos : 50.16.9 /Alle Serien (Allgemeine D okumente) (Allgemeine M odul e)/Z ulass ungen/Schiffsz ulass ungen/RIN A (R egistro Italiano Navale) @ 3\mod_1224493078359_0.doc x @ 24244 @ @ 1

RINA (Registro Italiano Navale)

Pos : 50.16.10 /D okumentation allgemein/Gliederungselemente/------Leerzeile------ @ 3\mod_1224662755687_0.doc x @ 24460 @ @ 1

Pos : 51 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

Env. 1, 2, 3, 4

31

32

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 52 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 2N or men und Ri chtli nien - Ü berschrift 2 @ 4\mod_1242804031875_21.doc x @ 33646 @ 2 @ 1

3.8

Standards and Guidelines

Pos : 53.1 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/N ormen und Ric htlini en/Nor men und Ric htlini en Bus kl emme 750- xxxx, ohne Variantenang abe - Einl eitung @ 7\mod_1274278887584_21.doc x @ 56645 @ @ 1

750-495/040-00x I/O modules meet the following standards and guidelines:

Pos : 53.2 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/N ormen und Ric htlini en/Nor men und Ric htlini en XTR - Mechani k und Klima Komponenten-HB @ 18\mod_1394633219581_21.doc x @ 147751 @ @ 1

Table 18: Climatic and Mechanical Environmental Conditions

Standard

Transport

EN 60870-2-2

Test Value

Ct2(2k4) (except precipitation / water /

moisture)

Mechanical Environmental Conditions

EN 60870-2-2

Bm

EN 60721-3-1

1M3

EN 60721-3-3

3M5

EN 60068-2-6

Acceleration 5g

IEC 60068-2-27 Shock

15g, 11 ms, 1000 shocks per axis and

direction, half-sine

25g, 6 ms, 1000 shocks per axis and direction,

half-sine

EN 50155

Random vibration:

EN 61373

Category 1, classes A and B

Shock 5g, 30 ms:

Category 1, classes A and B

*)

Shipbuilding

Ambient categories A … D, H

(5g, 25 Hz … 150 Hz)

Climatic Environmental Conditions

EN 60721-3-1

1K5 (except precipitation and ice formation)

EN 60721-3-3

3K7 (except wind-driven precipitation, water

and ice formation)

EN 60870-2-2

C3 (except wind-driven precipitation and ice

formation)

*)

Shipbuilding

Ambient categories A … D, H

(−40 °C … +70 °C)

*)

The list of ship certifications issued is available in the section “Approvals”.

Pos : 53.3 /Dokumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

Pos : 53.4 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/N ormen und Ric htlini en/EM V-Nor men Contr oller 750- xxxx/EM V-Nor men Bus klemme 750- xxxx/0040-0000, nur Standar dversi on - Ei nlei tung XTR @ 18\mod_1395909426189_21.doc x @ 149708 @ @ 1

The I/O module 750-495/040-00x meets the following EMC standards as these

standards relate to the I/O module:

Pos : 53.5 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/N ormen und Ric htlini en/Nor men Störfestig keit XTR @ 18\mod_1394030613258_21.doc x @ 147348 @ @ 1

Table 19: EMC – Immunity to Interference

Standard

Test Value

Electrostatic Discharge

• EN 61000-4-2

8 kV (contact discharge)

• EN 60255-22-2

8 kV (air discharge)

• IEEE C37.90.3

High-frequency Electromagnetic Fields

• EN 61000-4-3 + A1: + A2

20 V/m (80 MHz … 1 GHz)

• EN 60255-22-3

10 V/m (1 GHz … 3 GHz)

• IEEE C37.90.2

Fast Electrical Transient Disturbances / Burst

• EN 61000-4-4

4 kV

• EN 60255-22-4

• IEEE C37.90.1

Surge Voltage / Surge

• EN 61000-4-5

2 kV (conductor/conductor)

• EN 60255-22-5

4 kV (conductor/ground)

Conducted Disturbances, Induced by High-frequency Fields

• EN 61000-4-6

10 V (150 kHz … 80 MHz)

• EN 60255-22-6

Magnetic Fields With Electrical Frequencies

• EN 61000-4-8

300 A/m continuous / 1000 A/m for 1 s

Pulse-shaped Magnetic Fields

• EN 61000-4-9 + A1

300 A/m

Damped Oscillatory Magnetic Fields

• EN 61000-4-10 + A1

100 A/m

Voltage Dips, Short-term Interruptions and Voltage Fluctuations

• EN 61000-4-11

Standard not applicable

Damped Sinusoidal Oscillations

• EN 61000-4-12

2 kV (conductor/conductor)

4 kV (conductor/ground)

Harmonics and Interharmonics

• EN 61000-4-13 + A1

Standard not applicable

Conducted Asymmetric Disturbances

• EN 61000-4-16 + A1 + A2

30 V continuous

300 V for 1 s

Line Frequency Disturbances

• EN 60255-22-7

Class A

(150 V conductor/conductor / 300 V

conductor/ground)

Alternating Components of the Voltage to DC Line Connections

• EN 61000-4-17+A2

15 %

Manual

Version 1.1.0

33

34

Device Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Table 19: EMC – Immunity to Interference

Standard

Test Value

Damped Oscillatory Waves

• EN 61000-4-18 + A1

1.25 kV conductor/conductor

• EN 60255-22-1

2.5 kV conductor/ground

• IEEE C37.90.1

Voltage Dips, Short-term Interruptions and Voltage Fluctuations to DC Supply

Inputs

• EN 61000-4-29

Standard not applicable

• EN 60255-11

Harmonics

• Shipbuilding*)

max. 2 W

DC: 3 Veff,

AC: 10 % to 15th harmonic

10 % … 1 % for 15th to 100th harmonic

1 % for 100th to 200th harmonic

*)

The list of ship certifications issued is available in the section “Approvals”.

Pos : 53.6 /Serie 750 (WAGO-I/O-SYST EM)/Ger ätebesc hrei bung/N ormen und Ric htlini en/Nor men Stör aus sendung XTR @ 18\mod_1394087664442_21.doc x @ 147358 @ @ 1

Table 20: EMC – Emission of Interference

Standard

Test Value *)

Enclosure Emission of Interference

• EN 61000-6-3 + A1

30 dB(µV/m), QP, 30 MHz … 230 MHz

• EN 55022 Class B

37 dB(µV/m), QP, 230 MHz … 1 GHz

70 dB(µV/m), Peak, 1 GHz … 3 GHz

50 dB(µV/m), AV, 1 GHz … 3 GHz

74 dB(µV/m), Peak, 3 GHz … 6 GHz

54 dB(µV/m), AV, 3 GHz … 6 GHz

• EN 61000-6-4 + A1

40 dB(µV/m), QP, 30 MHz … 230 MHz

• EN 60255-26

47 dB(µV/m), QP, 230 MHz … 1 GHz

• EN 55011 + A1 Class A

76 dB(µV/m), Peak, 1 GHz … 3 GHz

• EN 55022 Class A

56 dB(µV/m), AV, 1 GHz … 3 GHz

80 dB(µV/m), Peak, 3 GHz … 6 GHz

60 dB(µV/m), AV, 3 GHz … 6 GHz

**)

• Shipbuilding (EMC 1)

80 dB(µV/m) …50 dB(µV/m), QP,

150 kHz … 300 kHz

50 dB(µV/m) … 34 dB(µV/m), QP,

0.3 MHz … 30 MHz

54 dB(µV/m), QP, 30 MHz … 2 GHz

24 dB(µV/m), QP, 156 MHz … 165 MHz

**)

• Shipbuilding (EMC 2)

80 dB(µV/m) … 50 dB(µV/m), QP,

150 kHz … 30 MHz

60 dB(µV/m) … 54 dB(µV/m), QP,

30 MHz … 100 MHz

54 dB(µV/m), QP, 100 MHz … 2 GHz

24 dB(µV/m), QP, 156 MHz … 165 MHz

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Device Description

35

Table 20: EMC – Emission of Interference

Standard

Test Value *)

Conducted Emission of Interference – Line Connection AC Voltage

• EN 61000-6-3 + A1

Standard not applicable

• EN 55022 Class B

• EN 61000-6-4 + A1

Standard not applicable

• EN 55011 + A1 Class A

Conducted Emission of Interference – Line Connection

• Shipbuilding**) (EMC 1)

96 dB(µV) … 50 dB(µV), 10 kHz … 150 kHz

60 dB(µV) … 50 dB(µV),

150 kHz … 350 kHz

50 dB(µV), 0.35 MHz … 30 MHz

**)

• Shipbuilding (EMC 2)

120 dB(µV) … 69 dB(µV),

10 kHz … 150 kHz

79 dB(µV), 150 kHz … 500 kHz

73 dB(µV), 0.5 MHz … 30 MHz

Conducted Emission of Interference – Line Connection DC Voltage

• EN 61000-6-3 + A1

79 dB(µV) QP, 0.15 MHz … 0.5 MHz

• EN 60255-26

66 dB(µV) AV, 0.15 MHz … 0.5 MHz

• EN 55022 Class A

73 dB(µV) QP, 0.5 MHz … 30 MHz

60 dB(µV) AV, 0.5 MHz … 30 MHz

*)

**)

Pos : 54 /D okumentation allgemei n/Glieder ungs elemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.doc x @ 21810 @ @ 1

Manual

Version 1.1.0

QP = Quasi Peak Detector; AV = Average Detector

If necessary, please find different data in the section “Approval” (regarding approval for EMC 1

or EMC 2).

36

Function Description

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Pos : 55 /All e Seri en (Allgemei ne Module)/Ü berschriften/N eue Ü berschriften/Ebene 1F unkti ons besc hrei bung - Ü bersc hrift 1 @ 4\mod_1239025975389_21.doc x @ 30003 @ 1 @ 1

4

Function Description

Pos : 56.1 /Serie 750 (WAGO-I/O-SYST EM)/F unktions beschr eibung/Funkti onsbesc hrei bung 750-0495 - Mes sprinzip, Mes s werte @ 16\mod_1376383129418_21.doc x @ 128568 @ 222 @ 1

4.1

Measuring Principle

The 3-phase power measurement module operates using 7 analog/digital

converters for acquiring the current and voltage values in all three phases and the

current of the neutral wire.

The 3 phases and the neutral wire are connected to the current measuring inputs of

the I/O module in a differential way, i.e. the current transformers resp.

‘Rogowski’ coils are connected to two clamps (+ / ̶ ). Low pass filters on the 7

measuring inputs have a limit frequency of 15.9 kHz. Each input signal is scanned

at a frequency of 8 kHz, quantized with 24 bits and further processed digitally.

Acquisition and processing of the measured values of all three phases and the

neutral wire is performed simultaneously in the very same way.

4.2

Measured Values

The 3-phase power measurement module makes the following AC measured

values available per phase (Lx, Ly = L1, L2 or L3):

Voltage:

• RMS value voltage Lx – N

• Maximum RMS value voltage Lx – N

• Minimum RMS value voltage Lx – N

• Arithmetic mean value voltage Lx – N

• Peak value voltage Lx – N

• RMS value phase-to-phase voltage Lx – Ly

Current:

• RMS value current Lx

• Maximum RMS value current Lx

• Minimum RMS value current Lx

• Arithmetic mean value current Lx

• Peak value current Lx

• RMS value current N

Power:

• Active power Lx

• Maximum active power Lx

• Minimum active power Lx

• Reactive power Lx

• Apparent power Lx

Energy:

• Active energy Lx

• Active energy acquisition Lx

• Active energy delivery Lx

• Active energy total

• Active energy acquisition total

Manual

Version 1.1.0

WAGO-I/O-SYSTEM 750 XTR

750-495/040-00x 3-Phase POM 690V /XTR

Function Description

37

• Active energy delivery total

• Reactive energy Lx

• Reactive energy inductive Lx

• Reactive energy capacitive Lx

• Reactive energy total

• Reactive energy inductive total

• Reactive energy capacitive total

• Apparent energy Lx

Frequency:

• Supply network frequency Lx

• Maximum supply network frequency Lx

• Minimum supply network frequency Lx

Harmonics:

Harmonics analysis for a selected phase

(Lsel = L1 or L2 or L3)

• RMS value current fundamental wave Lsel

(first harmonic)

• RMS value voltage fundamental wave Lsel

(first harmonic)

• THD (Total Harmonic Distortion)

current Lsel

• THD (Total Harmonic Distortion)

voltage Lsel

For the selected phase Lsel, three selectable harmonics can

be analyzed:

harmonic A: 2nd to 41st

harmonic B: 2nd to 41st

harmonic C: 2nd to 41st

• RMS value current harmonic A

• RMS value voltage harmonic A

• HD (Harmonic Distortion) current harmonic A

• HD voltage harmonic A

• RMS value current harmonic B

• RMS value voltage harmonic B

• HD current harmonic B

• HD voltage harmonic B

• RMS value current harmonic C

• RMS value voltage harmonic C

• HD current harmonic C

• HD voltage harmonic C

Power factors:

Manual

Version 1.1.0

• cos phi Lx (fundamental wave)

• Power factor PF Lx (all harmonics)

38