Lay-up, Cooling System Service and Fitting Out

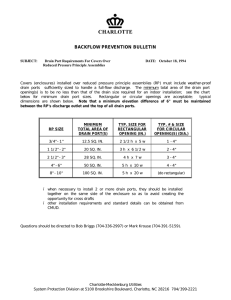

advertisement

Chapter Five Lay-up, Cooling System Service and Fitting Out LAY-UP Boats that are to be stored for more than 4 or 5 weeks should be carefully prepared. This is necessary to prevent damage to the engine and the stern drive unit from freezing, corrosion and/or fuel system contamination. Preparation for lay-up should begin, if possible, while the boat is still in the water. If the boat has been removed from the water, a supply of coolant water must be made available to the engine. This can be accomplished in one of two ways. The stern drive unit can be submerged in a test tank, or a garden hose may be attached to the cooling system using an adapter available at most marine supply stores. The suggestions for lay-up preparation which follow are based on recommendations made by Mercury Marine. See Table 1 (end of chapter) for lubricants recommended by Mercury Marine. In-the-water Preparation 1. Start the engine. Run at idle until it reaches normal operating temperature, then shut the engine off. Drain the engine oil and install a new oil filter (Figure 1). See Chapter Four. 2. Refill the crankcase with the proper amount of fresh SAE 20 SE or SF engine oil. Add one pint of Quicksilver 4-cycle Engine Oil Supplement to crankcase. See Chapter Four. 3. Shut the fuel supply off at the fuel tank. 4. Restart the engine and run for several minutes at 800- 1,200 t-pm to allow the oil to circulate to all internal parts. Check for oil leaks around the new filter while the engine is running. 5. Shut the engine off and wait approximately 5 minutes, then check the oil level on the dipstick (Figure 2, typical location). Add oil, if necessary, to bring the level up to the FULL mark on the dipstick. 6. Remove flame arrestor cover (if so equipped) and flame arrestor (Figure 3) from carburetor intake and restart engine. Increase engine speed to a fast idle (800- 1,200 t-pm) and slowly pour a can of Quicksilver Storage Seal into the carburetor intake to fog the internal surfaces of the induction system. When the can of Storage Seal has approximately 2 ounces left in it, decrease engine speed to a normal idle and kill the engine by quickly pouring the remaining Storage Seal into the carburetor. If the engine does not stall, shut the ignition off immediately. LAY-UP, COOLING SYSTEM SERVICE AND FI’lTING OUT 85 CHAPTER FIVE 86 NOTE If Quicksilver Storage Seal is not available, pour about one cup of SAE 20 SE or SF engine oil into the carburetor. Kill the engine by quickly pouring in about 2 ounces of SAE 20 SE or SF engine oil. 7. Clean the flame arrestor with solvent, blow dry with compressed air (if available) and reinstall on carburetor. 8. Install a new fuel filter canister (Figure 4, typical). If equipped with a sediment bowl (Figure 5, typical), remove and clean bowl, then install a new filter before reinstalling it to the fuel pump. WARNING Be sure to have a Coast Guard-approved fire extinguisher at hand before performing Step 9. 9. Completely drain the fuel tank of all gasoline. WARNING Since gasoline is an extreme fire hazard, always store it in a sealed metal container away from heat, sparks and flame. 10. Remove boat from water, keeping bow higher than stem if possible to assist in draining the exhaust system. Out-of-water Preparation 1. Adjust trailer or cradle so that engine is in a level position. Lower stem drive unit to its “down” position. 2. Loosen drive belt tension and inspect condition of all belts. Replace as required. Tighten accessory unit adjusting bolts without putting tension on drive belts. 3. Drain cooling system as described in this chapter. LAY-UP, COOLING SYSTEM SERVICE AND FITI’ING OUT 05 FUEL PUMP (TYPICAL) A \ and fuel filter Yoke screw 87 4. Check all hoses for deterioration, cracks or other defects and replace as required. 5. Remove the spark plugs and pour one ounce of Quicksilver Storage Seal or SAE 20 SE or SF engine oil into each cylinder. 6. Disconnect coil high tension lead at distributor cap (Figure 6). Ground lead and crank engine over 15-20 seconds with the starter to coat cylinder walls with oil. 7. Wipe up any excess oil from plug holes. Wipe a thin film of Storage Seal or SAE 20 engine oil on spark plug threads. Reinstall spark plugs and connect coil lead. 8. Remove the rocker arm cover(s) and check for signs of condensation in the rocker arm area. Carefully wipe away any oil-water mixture found. Coat valve mechanism and inside of rocker arm cover(s) generously with Storage Seal or SAE 20 engine oil. Reinstall rocker arm cover(s) using new gasket(s). 9. Refill cooling system as described in this chapter. 10. Cover flame arrestor and carburetor with a plastic bag and tape tightly in place. This prevents moisture from entering the carburetor and intake manifold. 11. Remove battery from boat. Tape vent holes closed and clean battery case with baking soda solution to remove corrosion and acid traces, then rinse with cold water. Check electrolyte level in each cell and top up with distilled water, if necessary. Cover terminals with a light coat of petroleum jelly. Store battery in a cool, dry place. NOTE Remove battery from storage every 30-45 days. Check electrolyte level and slow-charge for 5-6 hours at 6 amperes. 12. Tape exhaust outlets closed to prevent moisture from entering the exhaust manifolds and valve chambers. 13. Cover through-hull fuel tank ventilators with tape to help keep moisture from fuel tank. 14. Clean engine exterior thoroughly and retouch any blemishes with engine touch-up paint. Apply a film of Quicksilver Rust and Corrosion Preventive on exterior surfaces or wipe down with a rag coated with Storage Seal or SAE 20 engine oil to leave a light coating on exterior surfaces. CHAPTER FIVE 88 Stern Drive Unit Refer to Chapter Four for location of lubrication points listed below. 1. Insert a length of wire in drive shaft and gear housing water drain holes to make sure they are open. 2. Lubricate the following components with Quicksilver Multipurpose Lubricant: a. Ride-Guide steering cable end. b. Steering arm pivot socket. c. U-joint shaft and engine coupling shaft splines. d. Drive unit upper and lower pivot pins. e. Gimbal or transmission output housing bearing. f. Power steering control valve. 3. Lubricate U-joint bearings with Universal Joint Lubricant. 4. Lubricate drive unit hinge pins with Anti-corrosion Grease. 5. Remove propeller. Lubricate prop shaft with Perfect Seal (part No. C-92-34227) and reinstall propeller. 6. Inspect bellows condition. Replace if required. 7. On I-Drives, check water pump impeller. Replace if worn, hardened or set. 37 140 AND 161 ENGINE DRAIN LOCATIONS (PD$TTlDE) 4 - I”*, drain plug III~IIIIVIY d; rin plug block petcock CAUTION Do not paint sacrificial zinc rings, plugs or bars, if present. These must be left unpainted in order to prevent galvanic corrosion damage. 8. Remove all marine growths and deposits from stem drive unit. Clean metal surfaces that have become exposed and cover with touch-up paint. 9. Wipe or spray exterior surfaces of stem drive with Rust and Corrosion Preventive. 10. Store boat with stem drive unit in its normal operating position. If the unit is stored in a tilted-up position, the universal joint bellows may develop a “set” that will lead to premature bellows failure once the stem drive is returned to service. Inline engines tend to crack horizontally just below the core plugs or along the upper edge below the cylinder head. A V-block will usually crack near the hydraulic lifters or in the valley of the block below the intake manifold. The following procedures are designed to help you prevent unnecessary engine damage during winter storage. To assure that the cooling system is completely drained, adjust the trailer or cradle so that the front of the engine is higher than the rear. COOLING SYSTEM DRAINING The cooling system must be properly drained for storage during the winter months in areas where temperatures fall below 32’ F (0’ C). If it is not, the engine block may be cracked by expansion of frozen water. Standard Cooling System (Inline Engines) 1. Place containers under manifold and engine block drain points, if space permits. This will prevent water from draining into the boat. LAY-UP, COOLING SYSTEM SERVICE AND FITTING OUT 2. Open the drain valve on the port side of the engine block and remove the exhaust manifold drain plug. Remove exhaust elbow drain plug, if so equipped. See Figure 7 for typical locations. 3 . If equipped with an exhaust elbow riser, remove the drain plug from the front of the riser. 4. If equipped with power steering, remove the drain plug from the lower-aft end of the power steering oil cooler. See Figure 8. 5. Allow cooling system to completely drain, then coat drain plug threads with Perfect Seal and reinstall. Close engine block drain valve. Closed Cooling System (Inline Engines) The fresh water section of a closed cooling system need not be drained during winter months, provided it is kept filled with a 50/50 solution of pure soft water and ethylene glycol antifreeze. However, the seawater section must be drained completely. 08 89 Seawater section (Except Models 60, 470, 485 and 488) 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove the exhaust manifold drain plug. Remove the exhaust elbow drain plug, if so equipped. 3. If equipped with an exhaust elbow riser, remove the drain plug at the front of the riser. 4. If equipped with power steering, remove the drain plug from the bottom of the power steering oil cooler. See Figure 9. 5. Refer to Figure 10 and disconnect the sea water inlet hose (A), remove the drain plug from the aft end of the heat exchanger (B) and remove the zinc electrode (C), if so equipped. 6. Examine zinc electrode (if so equipped) for erosion. If it is less than 25 percent eroded, coat electrode threads with Perfect Seal and reinstall. If more than 25 percent of the electrode is gone, install a new one. 7. Allow seawater section to completely drain, then coat drain plug threads with Perfect Seal and reinstall. Reconnect sea water inlet hose to heat exchanger (A, Figure 10). . POWER STEERING OIL COOLER DRAIN (STANDARD COOLING SYSTEM) 90 09 010 CHAPTER FIVE POWER STEERING OIL COOLER DRAIN (CLOSED COOLING SYSTEM) HEAT EXCHANGER DRAIN LOCATIONS A. Seawater inlet hose B. Drain plug C. Zinc electrode D. Pressure cap E. Circulating pump hose LAY-UP, COOLING SYSTEM SERVICE AND FI’ITING OUT Seawater section (Model 60) Refer to Figure 11 or Figure 12 for this procedure. 1. Place containers under drain points, if possible. This will prevent water from draining into the boat. 2. Remove heat exchanger drain plug. 0 11 MERCRUISER 6 0 (STARBOARD SIDE) 0 12 MERCRUISER 60 (PORT SIDE) 91 3. Remove both drain plugs from the exhaust manifold. 4. Disconnect hose at elbow fitting on bottom of exhaust manifold. 5. Allow seawater section to completely drain, then coat drain plug threads with Perfect Seal and reinstall. 6. Reconnect hose to exhaust manifold elbow fitting. - CHAPTER 92 Seawater section (Models 470, 485 and 488) Refer to Figure 13 (serial No. 4886619 and below) or Figure 14 (serial No. 4886620 and above) for this procedure. 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove the exhaust elbow drain plug and heat exchanger seawater drain plug. 3. If equipped with an exhaust elbow riser, remove the drain plug from the front of the riser. 4. On engines equipped with a water-cooled voltage regulator (serial No. 4886620 and above), disconnect the sea water inlet hose at the regulator. 5. If equipped with power steering, remove the drain plug from the lower-aft end of the power steering oil cooler. See Figure 8. 013 MODEL 470 DRAIN (SERIAL NO. 4888818 6. Allow seawater section to completely drain, then coat drain plug threads with Perfect Seal and reinstall. Reconnect seawater inlet hose to regulator. Fresh water section (except Models 60, 470, 485 and 488) 1. Place containers under drain points, if space permits. This will prevent coolant from draining into the boat. 2. Remove pressure fill cap from reservoir. See D, Figure 10. 3. Open engine block drain valve on port side of block. See Figure 7 for typical location. LOCATIONS AND BELOW) A. B. C. D. E. F. 0. FIVE Pressure fill cap Exhaust elbow drain plug Exhaust manifold drain plug Cylinder block drain plug Fresh water drain plug Seawater drain plug Heat exchanger LAYUP, COOLING SYSTEM SERVICE AND FITTING OUT 4. Disconnect the circulating pump-to-heat exchanger hose (E, Figure 10) from the front of the heat exchanger. Lower hose to let coolant drain. 5. Remove the coolant recovery hose (if so equipped) from the mounting bracket. Drain the coolant. 6. Allow fresh water section to completely drain, then close the engine block drain valve. Reconnect the circulating pump hose to the heat exchanger. 014 MODEL 470 DRAIN LOCATIONS (SERIAL NO. 4888820 AND ABOVE) 93 Fresh water section (Model 60) Refer to Figure 11 and Figure 12 for this procedure. 1. Place containers under drain points, if space permits. This will prevent coolant from draining into the boat. 2. Remove heat exchanger pressure cap. 3. Remove drain plugs from the engine block, heat exchanger and 180 degree elbow fitting. 4. Allow fresh water section to completely drain, then coat the drain plug threads with Perfect Seal and reinstall. 5. Install the heat exchanger pressure cap. Fresh water section (Models 470, 485 and 488) Refer to Figure 13 (serial No. 4886619 and below) or Figure 14 (serial No. 4886620 and above) for this procedure. 1. Place containers under drain points, if space permits. This will prevent coolant from draining into the boat. 2. Remove pressure fill cap from reservoir. 3. Remove heat exchanger, exhaust manifold and engine block drain plugs. 4. Remove the circulating pump drain plug at the bottom of the front cover. See Figure 15. 5. Remove the coolant recovery reservoir (if so equipped) from the mounting bracket. Drain the coolant. \..r --3 6. C. D. E. F. 0. H. I. Exhaust elbow drain plug G Exhaust manifold drain plug Water-cooled voltage regulator Cylinder block drain plug (hidden) Seawater inlet hose Fresh water drain plug Seawater drain plug Heat exchanger H iuv’ CHAPTER FIVE 94 6. Allow fresh water section to completely drain, then coat drain plug threads with Perfect Seal and reinstall. Standard Cooling System (V6 and V8 Engines) 016 DRAIN LOCATIONS (PORT SIDE) . Models 888, 255-S, 233, 898, 228,250 and260 Refer to Figure 16 and Figure 17 (Models 888, 25% and 233) or Figure 18 and Figure 19 (Models 898, 228, 250 and 260) for this procedure. 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove the exhaust manifold and elbow drain plugs from both sides of the engine. Open the engine block drain valve on each side of the engine. 3. If equipped with exhaust elbow risers under the exhaust elbows, remove the drain plug from each riser. NOTE C. Cylinder block petcock [f power steering oil cooler has no drain plug, remove hose A in Figure 18. 4A. Power steering-remove drain plug from lower-aft end of power steering oil cooler. See B, Figure 18. 4B. Non-power steering-disconnect water inlet hose at thermostat housing. Lower hose to let water drain from the lowest part. 5. Disconnect circulating pump hose at the pump and lower the hose to drain the water. 6. Allow cooling system to completely drain, then coat drain plug threads with Perfect Seal and reinstall. 7. Close engine block drain valves and reconnect hoses. DRAIN LOCATIONS (STARBOARD SIDE) Models 225II- TR, 255II- TR (S/N 4175499 and below), 255II-TRS Refer to Figure 19 and Figure 20 for this procedure. 1. Place containers .under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove the drain plug from each exhaust manifold. Remove the port exhaust elbow drain Ph3. 3. Open the engine block drain valves on each side of the engine. A. 8. C. D. E. Exhaust elbow drain plug (hidden) Exhaust manifold drain plug Thermostat housing water inlet hose Cylinder block petcock (hidden) Thermostat housing to circulating pump hose 017 LAYUP, COOLING SYSTEM SERVICE AND FITTING OUT 4. Disconnect the circulating pump-to-heat exchanger hose (E, Figure 10) from the front of the heat exchanger. Lower hose to let coolant drain. 5. Remove the coolant recovery hose (if so equipped) from the mounting bracket. Drain the coolant. 6. Allow fresh water section to completely drain, then close the engine block drain valve. Reconnect the circulating pump hose to the heat exchanger. 01 4 MODEL 470 DRAIN LOCATIONS (SERIAL NO. 4888820 AND ABOVE) 93 Fresh water section (Model 60) Refer to Figure 11 and Figure 12 for this procedure. 1. Place containers under drain points, if space permits. This will prevent coolant from draining into the boat. 2. Remove heat exchanger pressure cap. 3. Remove drain plugs from the engine block, heat exchanger and 180 degree elbow fitting. 4. Allow fresh water section to completely drain, then coat the drain plug threads with Perfect Seal and reinstall. 5. Install the heat exchanger pressure cap. Fresh water section (Models 470, 485 and 488) Refer to Figure 13 (serial No. 4886619 and below) or Figure 14 (serial No. 4886620 and above) for this procedure. 1. Place containers under drain points, if space permits. This will prevent coolant from draining into the boat. 2. Remove pressure fill cap from reservoir. 3. Remove heat exchanger, exhaust manifold and engine block drain plugs. 4. Remove the circulating pump drain plug at the bottom of the front cover. See Figure 15. 5. Remove the coolant recovery reservoir (if so equipped) from the mounting bracket. Drain the coolant. C. D. E. F. 0. H. I. Exhaust manifold drain plug Water-cooled voltage regulator Cylinder block drain plug (hidden) Seawater inlet hose Fresh water drain plug Seawater drain plug Heat exchanger CHAPTER FIVE 94 6. Allow fresh water section to completely drain, then coat drain plug threads with Perfect Seal and reinstall. Standard Cooling System (V6 and V8 Engines) 016 DRAIN LOCATIONS (PORT SIDE) . Models 888, 255-S, 233, 898, 228, 250 and 260 Refer to Figure 16 and Figure 17 (Models 888, 25% and 233) or Figure 18 and Figure 19 (Models 898, 228, 250 and 260) for this procedure. 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove the exhaust manifold and elbow drain plugs from both sides of the engine. Open the engine block drain valve on each side of the engine. 3. If equipped with exhaust elbow risers under the exhaust elbows, remove the drain plug from each riser. B. Exhaust manifold drain $ug C. Cylinder block petcock NOTE Jf power steering oil cooler has no drain plug, remove hose A in Figure 18. 4A. Power steering-remove drain plug from lower-aft end of power steering oil cooler. See B, Figure 18. 4B. Non-power steering-disconnect water inlet hose at thermostat housing. Lower hose to let water drain from the lowest part. 5. Disconnect circulating pump hose at the pump and lower the hose to drain the water. 6. Allow cooling system to completely drain, then coat drain plug threads with Perfect Seal and reinstall. 7. Close engine block drain valves and reconnect hoses. DRAIN LOCATIONS (STARBOARD SIDE) Models 225II- TR, 255II- TR (S/N 4175499 and below), 255II-TRS Refer to Figure 19 and Figure 20 for this procedure. 1. Place containers .under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove the drain plug from each exhaust manifold. Remove the port exhaust elbow drain plug. 3. Open the engine block drain valves on each side of the engine. A. B. C. D. E. Exhaust elbow drain plug (hidden) Exhaust manifold drain plug Thermostat housing water inlet hose Cylinder block petcock (hidden) Thermostat housing to circulating pump hose 017 LAY-UP, COOLING SYSTEM SERVICE AND FI’lTING OUT POWER STEERING OIL COOLER 95 020 MODELS 225ll=TR, 255lbTR (SERIAL NO. 4175499 AND BELOW) AND 255IbTRS DRAIN LOCATION (STARBOARD SIDE) A. Hose 8. Drain plug 019 MODELS 225ll=TR, ?SSII=TR (SERIAL NO. 4175499 AND BELOW) AND 255ll-TRS DRAIN LOCATIONS (PORT SIDE) ; .- . . IN A. Exhaust elbow drain plu< 8. Exhaust manifold drain plug C. Cylinder block petcock A. Exhaust elbow 8. Exhaust manifold drain plug C. Thermostat housing to circulating pump hose D. Seawater pickup pump E. Cylinder biock drain petcock (hidden) F. Power steering oil cooler drain plug 0. Transmission oil cooler H. Transmission oil cooler outlet hose 4. If equipped with exhaust elbow risers under the exhaust elbows, remove the drain plug from each. 5. Disconnect the circulating pump hose at the pump and lower to let the water drain. 6. If equipped with power steering, remove drain plug from lower-aft end of power steering oil cooler. 7. Disconnect inlet hose at aft end of sea water pickup pump. If engine is not equipped with power steering, also disconnect the pump outlet hose. 8. Disconnect the coil secondary lead from the center distributor tower and ground it to the engine block. 9. Crank engine over to purge any water remaining in the seawater pickup pump. 10. Remove outlet hose from transmission oil cooler fitting on starboard exhaust elbow. Lower 96 C H A P T E R FIVE hose below transmission to drain water from the oil cooler. 021 CA UTION If freezing weather is anticipated during lay-up, Jill transmission oil cooler with antifreeze through the outlet hose until it appears at the power steering oil cooler drain (power steering models) or seawater pickup pump outlet (non-power steering models). Reconnect hose. MODELS 228ll=TR, 255ll=TR (SERIAL NO. 4175100 AND ABOVE), 280ll=TRS, 330ll-TR AND 330ll-TRS DRAIN LOCATIONS 11. After cooling system has completely drained, coat drain plug threads with Perfect Seal and reinstall plugs. 12. Close engine block drain valves, reconnect all hoses and reinstall coil secondary lead. Models 228II- TR, 255II- TR (serial No. 4175500 and above), 28OII- TRS, 33OII- TR and 33OII- TRS Refer to Figure 21 and Figure 22 for this procedure. 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove the drain plug from each exhaust manifold. Remove the port exhaust elbow drain plug, if so equipped. 3. Open the engine block drain valves on each side of the engine. 4. Model 25511-TR and 28011-TRS engines with water distribution blocks-remove drain plug from each distribution block (located under exhaust elbows). See Figure 23. 5. If equipped with exhaust elbow risers, remove the drain plug from each riser. 6. Disconnect the circulating pump hose at the pump and drain the hose of water. 7. If equipped with power steering, remove drain plug from lower-aft end of power steering oil cooler. Late model oil coolers have no drain plug; the cooler is drained in Step 8. 8. Disconnect the inlet/outlet hoses from the aft end of the sea water pickup pump. 9. Disconnect the coil secondary lead from the center distributor tower and ground it to the engine block. 10. Crank engine over to purge any water remaining in the sea water pickup pump. 11. Remove outlet hose from transmission oil cooler fitting on starboard exhaust elbow. Lower 4. Exhaust elbow drainpitig ’ 3. Exhaust manifold drain plug, Z. Cylinder block drain petcock (hidden) 022 MODELS 228ll=TR, 25Sll=TR (SERIAL NO. 4175500 AND ABOVE), 280ll=TRS, 330lbTR AND 330ll-TRS DRAIN LOCATIONS (STARBOARD SIDE) 4. 3. :. I. 5. :. 3. Exhaust elbow drain plug (hidden) Exhaust manifold drain plug Power steering oil cooler drain plug Transmission oil cooler outlet hose Cylinder block drain petcock Seawater pickup pump Thermostat housing to circulating pump hose LAY-UP. COOLING SYSTEM SERVICE AND FITTING OUT 97 hose below transmission to drain water from the oil cooler. CA UTIOA’ If freezing weather is anticipated during lay-up, fill transmission oil cooler with antifreeze through the outlet hose until it appears at the power steering oil cooler drain (power steering models) or seawater pickup pump outlet (non-power steering models). Reconnect hose. 12. After cooling system has completely drained, coat drain plug threads with Perfect Seal and reinstall plugs. 13. Close engine block drain valves, reconnect all hoses and reinstall coil secondary lead. WATER DISTRIBUTION ’ BLOCK DRAIN PLUG Closed Cooling System (V6 and VS Engines) 02 4 HEAT EXCHANGER DRAIN LOCATIONS -._ ? A. Pressure%11 cap 0. Heat exchanger to circulating pump hose C. Seawater drain plug D. Zinc electrode (if so equipped) The fresh water section of a closed cooling system need not be drained during winter months, provided it is kept filled with a 50/50 solution of pure soft water and ethylene glycol antifreeze. However, the seawater section must be drained completely. Seawater section (Models 888, 255S and 233) 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove both exhaust elbow drain plugs. 3. If equipped with exhaust elbow risers, remove the drain plug at the front of each riser. 4. If equipped with power steering, remove the drain plug from the bottom of the power steering oil cooler. See Figure 18. On late models without a drain plug, the oil cooler is drained during Step 7. 5. Refer to Figure 24 and remove the drain plug (C) from the bottom of the heat exchanger. Remove the zinc electrode (D), if so equipped. 6. Examine zinc electrode (if so equipped) for erosion. If it is less than 25 percent eroded, coat electrode threads with Perfect Seal and reinstall. If more than 25 percent of the electrode is gone, install a new one. 7. Disconnect inlet hose from aft end of seawater pickup pump. If equipped with power steering but - CHAPTER FIVE 98 no oil cooler drain plug, also disconnect the pump outlet hose. See Figure 25. 8. Disconnect the coil secondary lead from the center distributor tower and ground it to the engine block. 9. Crank engine over to purge any water remaining in the seawater pickup pump. 10. Allow seawater section to completely drain, then coat drain plug threads with Perfect Seal and reinstall plugs. 11. Close engine block drain valves, reconnect all hoses and reinstall coil secondary lead. 025 seawater section (Models 898, 228, 250 and 260) Refer to Figure 26 and Figure 27 for this procedure. 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. 2. Remove both exhaust elbow drain plugs. 3. If equipped with water distribution blocks under exhaust elbows, remove drain plug from each block. See Figure 28. 4. If equipped with exhaust elbow risers, remove the drain plug at the front of each riser. 5. Remove the heat exchanger drain plug. 6. If equipped with power steering, remove the drain plug from the bottom of the power steering oil cooler. See Figure 18. On late models without a drain plug, the oil cooler is drained during Step 7. 7. Disconnect inlet/outlet hoses from the aft end of the seawater pump. Be sure to reconnect hoses to their proper fitting. 8. Disconnect the coil secondary lead from the center distributor tower and ground it to the engine block. 9. Crank engine over to purge any water remaining in the seawater pickup pump. 10. Allow seawater section to completely drain, then coat drain plug threads with Perfect Seal and reinstall plugs. 11. Close engine block drain valves, reconnect all hoses and reinstall coil secondary lead. Models 225II- TR, 255II- TR (serial No. 4175499 and below and 255II-TRS) 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. A. Outlet hose B. Inlet (hose shown disconnected) C. Seawater pickup pump A. Exhaust elbow drain plug B. Exhaust manifold drain plug C. Cylinder block drain petcock MODELS 898,228,2SO AND 280 ENGINE DRAIN LOCATIONS (STANDARD COOLING SYSTEM, PORT SIDE) LAY-UP, COOLING SYSTEM SERVICE AND FI’ITING OUT 0 280 27 MODELS 888,228,250 AND ENGINE DRAIN LOCATIONS (STANDARD COOLINQ SYSTEM, STARBOARD SIDE) A. B. C. D. E. Exhaust elbow drain plug (hidden) Exhaust manifold drain plug Thermostat housing inlet hose Thermostat housing to circulating pump hose Cylinder block drain petcock 0 28 ?=PASSAGE DISTRIBUTION BLOCK DRAIN LOCATIONS A. Water distribution block B. Drain plug 029 HEAT EXCHANGER DRAIN LOCATIONS A. B. C. D. Pressure fill cap Heat exchanger to circulating pump hose Seawater drain plug Zinc electrode (if so equipped) 2. Remove exhaust elbow drain plug. 3. If equipped with exhaust elbow risers, remove the drain plug at the front of each riser. 4. If equipped with power steering, remove the drain plug from the bottom of the power steering oil cooler. See Figure 18. On late models without a drain plug, the oil cooler is drained during Step 7. 5. Remove the drain plug from the bottom of the heat exchanger. 6. Refer to Figure 29 and remove the zinc electrode (D), if so equipped. Examine zinc electrode for erosion. If it is less than 25 percent eroded, coat electrode threads with Perfect Seal and reinstall. If more than 25 percent of the electrode is gone, install a new one. 7. Disconnect inlet hose from aft end of seawater pickup pump. If equipped with power steering but no oil cooler drain plug, also disconnect the pump outlet hose. See Figure 25. 8. Disconnect the coil secondary lead from the center distributor tower and ground it to the engine block. 9. Crank engine over to purge any water remaining in the seawater pickup pump. 10. Remove outlet hose from transmission oil cooler fitting on starboard exhaust elbow. Lower CHAPTER FIVE 100 hose below transmission to drain seawater from the oil cooler. CAUTION If freezing weather is anticipated during lay-up, fill transmission oil cooler with antifreeze through the outlet hose until it appears at the power steering oil cooler drain (power steering models) or seawater pickup pump outlet (non-power steering models). Reconnect hose. 11. Allow seawater section to completely drain, then coat drain plug threads with Perfect Seal and reinstall plugs. 12. Reconnect all hoses and reinstall coil secondary lead. Seawater section (Models 228II- TR, 255II-TR serial No. 4175500 and above, 28OII- TRS, 33OII- TR and 33OII- TRS) 1. Place containers under drain points, if space permits. This will prevent water from draining into the boat. NOTE Older Model 255II- TR and 28OII- TRS engines do not have an exhaust elbow drain plug. 2. Remove port exhaust elbow drain plug, if so equipped. 3. Remove drain plugs from aft end of both distribution blocks. See Figure 28. 4. If equipped with exhaust elbow risers, remove the drain plug at the front of each riser. 5. If equipped with power steering, remove the drain plug from the bottom of the power steering oil cooler. See Figure 18. On late models without a drain plug, the oil cooler is drained during Step 8. 6. Remove the drain plug from the bottom of the heat exchanger. 7. Refer to Figure 29 and remove the zinc electrode (D), if so equipped. Examine zinc electrode for erosion. If it is less than 25 percent eroded, coat electrode threads with Perfect Seal and reinstall. If more than 25 percent of the electrode is gone, install a new one. 8. Disconnect inlet hose from aft end of seawater pickup pump. If equipped with power steering but no oil cooler drain plug, also disconnect the pump outlet hose. See Figure 25. 9. Disconnect the coil secondary lead from the center distributor tower and ground it to the engine block. 10. Crank engine over to purge any water remaining in the seawater pickup pump. 11. Remove outlet hose from transmission oil cooler fitting on starboard exhaust elbow. Lower hose below transmission to drain seawater from the oil cooler. CAUTION If freezing weather is anticipated during lay-up, fill transmission oil cooler with antgreeze through the outlet hose until it appears at the power steering oil cooler drain (power steering models) or seawater pickup pump outlet (non-power steering models). Reconnect hose. 1 2 . Allow seawater section to completely drain, then coat drain plug threads with Perfect Seal and reinstall plugs. 13. Reconnect all hoses and reinstall coil secondary lead. Fresh water section (all V-8 engines) Refer to Figure 16 and Figure 17 for Models 888, 2553, 233, 898, 228, 250 and 260. Refer to Figure 19 and Figure 20 for Models 22511-TR, 25511-TR (serial No. 4175499 and below) and 25511-TRS. Refer to Figure 21 and Figure 22 for Models 22811-TR, 25511-TR (serial No. 4175500 and above), 28011-TRS, 33011-TR and 33011-TRS. LAY-UP, COOLING SYSTEM SERVICE AND FITTING OUT 101 COOLING SYSTEM FILLING In Preparation For Storage Under normal circumstances, the fresh water section of a closed cooling system would not be drained until just before the boat is to be returned to service from winter storage. The procedures that follow pertain to standard cooling systems and are designed to provide additional protection against freeze damage during winter temperatures. CAUTION Do not run the engine after performing the storage cooling service procedures that follow. Before returning the boat to service, drain the coolant as described in this chapter and tighten all fasteners and clamps to specifications. Mine engines 1. Remove the water distribution block cover (Figure 30, typical). 2. Remove the thermostat and gasket. Discard the gasket. 3. Disconnect the hose at the manifold front end cap (Figure 31, typical). 4. Pour a 50/50 solution of pure soft water and ethylene glycol antifreeze into the water distribution block until the cylinder head, block and manifold are full. 5. Reinstall thermostat with a new gasket. Tighten water distribution block cover securely (Figure 30). 6. Install the hose to the manifold front end cap (Figure 31). 1. Place containers under drain points, if possible. This prevents coolant from draining into the boat. 2. Remove the pressure fill cap from the heat exchanger reservoir. See Figure 24. 3. Remove exhaust manifold drain plugs and open drain valves on both sides of the engine. 4. Disconnect the circulating pump hose at the pump and drain the water in it. 5. Remove the coolant recovery reservoir (if so equipped) from its mounting bracket. Drain reservoir. 6. Allow fresh water section to completely drain, then coat drain plug threads with Perfect Seal and reinstall plugs. 7. Close engine block drain valves and reconnect pump hose. V6 and V8 engines 1. Loosen the hose clamps at the front manifold end caps. See A, Figure 32 (typical) for GM engines and Figure 33 (typical) for Ford engines. Remove hoses from end caps. 2. Remove thermostat housing cover. See B, Figure 32 (typical) for GM engines and Figure 34 (typical) for Ford engines. 3. Remove thermostat and gasket. Discard the gasket. 4. Pour a 50/50 solution of pure soft water and ethylene glycol antifreeze into the thermostat housing until it is full. 5. Pour the coolant solution into the opening of each manifold end cap until the level reaches the top of the cap. s CHAPTER FIVE 102 6. Install the thermostat with a new gasket. Tighten the thermostat housing cover screws snugly (B, Figure 32 or Figure 34, typical). 7. Connect the hoses to the front manifold end caps and snug down the clamps (A, Figure 32 or Figure 33, typical). Returning Engine to Service Most ethylene glycol antifreeze solutions used in closed cooling systems tend to become corrosive to aluminum after approximately 3 years of use or if a blown head gasket allows exhaust gases to enter the cooling system. While such corrosive tendencies will not cause significant damage to the engine, they do produce loose particles that can eventually plug the coolant side of the heat exchanger. The increasing usage of aluminum components in engines, water pumps, manifolds and radiators has led to the development of an antifreeze formula recommended for use with aluminum engines. Mercury Marine recommends that this new type antifreeze formulation be used in all Met-Cruiser closed cooling systems. Check the antifreeze container to see if it meets one of the major specifications, such as Ford automakers’ specification ESE-M97B44-A or GM specification 1825M. 1. Remove the pressure fill cap from the reservoir or heat exchanger. 2. Fill the fresh water section with a 50/50 mixture of pure soft water and ethylene glycol antifreeze until the fluid level reaches the top of the filler neck. CAUTION Water must flow through seawater pump in Step 3 or possible damage to the pump and engine may result. 3. Start the engine and run at fast idle (l,OOO- 1,500 rpm), adding coolant to the reservoir or heat exchanger as necessary to maintain the coolant level at the top of the filler neck. When engine reaches normal operating temperature and coolant level remains constant, reinstall pressure fill cap. 4. If equipped with a coolant recovery system, remove the reservoir cap and fill with coolant to the “FULL” mark on the reservoir. 5. Check for leaks while the engine is running and note the position of the engine temperature gauge-it should be normal. WARNING Do not remove the pressure Jill cap when the engine is warm or hot. You may be seriously scalded or burned by coolant escaping under pressure. 6. Shut engine off and allow to cool for 30 minutes. Turn pressure fill cap to first detent and allow any pressure to escape, then remove the cap. 7. Recheck the coolant level in the reservoir or heat exchanger and add coolant as required to bring the level to the top of the filler neck. 8. If equipped with a coolant recovery system, add coolant as required to bring the reservoir level to a LAY-UP, COOLING SYSTEM SERVICE AND FI’lTING OUT point between the “ADD” and “FULL” marks when the engine is at normal operating temperature. FITTING OUT Preparing the boat for use after storage is relatively easy if the engine and stem drive unit were properly prepared before storage. The following suggestions for fitting out are based on recommendations made by Mercury Marine. 1. Clean the engine and stem drive unit with a solvent such as kerosene to remove accumulated dirt and preservative oil. Retouch any paint blemishes. NOTE If the boat is to be left in the water for an extended period, it may be advisable to cover the underwater surfaces, including the stern drive unit, with an antifouling paint. Do not use a paint containing copper or mercury, as these elements may hasten galvanic corrosion damage. 2. Remove protective covers installed on flame arrestor, carburetor, exhaust outlets and fuel tank ventilators. 3. Drain antifreeze from standard cooling systems, if installed. 4. Make sure that all drain valves and plugs are tightly closed and that all cooling system hoses are securely clamped in place. 5. Inspect all hoses for cracks, weak walls and leaks. Replace any that appear questionable. 6. Check all through-hull fittings for leaks and proper valve operation. 7. Remove, clean and install flame arrestor. 8. Check fuel system. Refill tanks if they were drained. Turn the fuel shut-off valve(s) on and check all fuel lines for leaks. Quicksilver Quicksilver Quicksilver Quicksilver Quicksilver Quicksilver Quicksilver 9. Check battery electrolyte level and fill if necessary. Make certain battery has a full charge. Clean battery terminals and lightly lubricate with petroleum jelly. Install battery, making certain cables are connected with proper polarity. Cover battery terminals with a light coat of petroleum jelly. 10. Drain preservative oil from stem drive unit. ^ Refill with oil of the proper viscosity and grade. See :‘i:, :0c$cS ,..,, : ’ Chapter Four. Il. Check oil level in crankcase. Add oil if V ” necessary. If oil was not changed at time of lay-up or if engine has been in storage for an extended period, change the oil and oil filter. 12. Check power steering and power trim pump oil levels and top up, if necessary. 13. Readjust drive belt tension. 14. Make a thorough check of the boat, engine and stem drive unit for loose or missing nuts, bolts and screws. Pay particular attention to the stem drive transom connection. Tighten, replace or take such other corrective actions as may be necessary, 15. Examine sacrificial zinc elements, if present, and replace if more than 25 percent eroded. 16. Remove distributor cap and examine distributor breaker points (if so equipped). Replace points if any wear is evident. If old points are to be reused, clean thoroughly with alcohol or acetone to remove all traces of oil. Install and set points using a dwell meter. Clean and install distributor cap. See Chapter Four. 17. Provide a source of water for engine cooling. Make certain a Coast Guard-approved fire extinguisher is handy, then start engine. Allow engine to warm up, making certain that water is circulating properly and the engine does not overheat. 18. Proceed with engine tune-up. See Chapter Four for instructions and specifications. Part No. Type 4-cycle Engine Oil Supplement 4-cycle Storage Seal Rust and Corrosion Preventive Multipurpose Lubricant Universal Joint Lubricant Anti-corrosion Grease Perfect Seal 103 C-92-78372-l 2 C-92-54778 C-92-83280 C-92-83250 C-92-58299 C-92-83290 c-92-34227