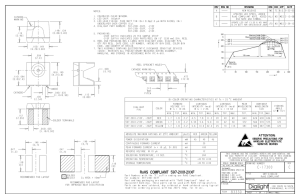

597-27xx-602F/607F

advertisement

DOMINANT WAVELENGTH IF =20mA COLOR DIALIGHT CATALOG P/N WATER CLEAR EPOXY LENS MIN. TYP. MAX. 597-2723-602F, GREEN 567 571 576 597-2723-607F YELLOW 582 589 597 597-2751-602F, 597-2751-607F (nm) RED 631 567 GREEN 571 .039 (1.0) 576 LUMINOUS INTENSITY (mcd) @IF =20mA; 25 C SPECTRAL LINE HALF WIDTH PEAK EMISSION WAVELENGTH IF =20mA (nm) IF =20mA TYP MIN. 574 15 18.0 591 15 639 574 PK (nm) CLEAR EPOXY LENS FORWARD VOLTAGE (V) @ I F = 20mA; 25 C MAX. TYP. MAX. 35.0 112.0 2.0 2.4 10 28.0 75.0 118.0 2.0 2.4 10 20 18.0 45.0 2.0 2.4 10 15 18.0 35.0 2.0 2.4 10 TYP. 112.0 REV VIEWING REVERSE CURRENT ANGLE ( A); 25 C (2 0 1/2) (DEG.) TYP MAX. @V @V @V @V R = 5 V 130 R = 5 V 130 R = 5 V 130 R = 5 V 130 .016 (.40) P.C. BOARD .061 #.002 (1.55 #.05) ECN NO REVISIONS NEW RELEASE B GRN MIN LUM INT "18.0" WAS "20.0"; YEL MIN LUM INT "28.0" WAS "20.0"; YEL TYP LUM INT "75.0" WAS "30.0"; GRN & YEL MAX REVERSE CURRENT "10" WAS "100";"WAVE" WAS "INFRARED" IN ABS MAX RATINGS TABLE; RED LINEAR DERATION "0.42" WAS "0.4"; MSL LEVEL IN NOTE 8 WAS "4"; "168" WAS "72" IN NOTE 9; ADDED NOTE 13. C ADDED MIN AND MAX DOMINANT WAVELENGTH; ADDED MAX LUMINOUS INTENSITY. AJF KLJ MES 5-2-08 NO 9-16-09 R .018 (R.45) C2 +.012 .315-.004 +.30 (8.00-.10) .138 #.002 (3.5 #.05) LED DICE FEED DIRECTION CATHODE IDENTIFICATION C1 C2 R.010 (R.25) NO .069 #.004 (1.75 #0.1) LUMINOUS DIRECTION C1 KLJ .157 #.004 (4.00 #0.1) REINFORCING PIN (CATHODE) .118 (3.0) DATE TWC N.O. MES 3-21-06 A CATHODE .009 #.004 (0.23 #0.1) DRN CKD APP .052 #.004 (1.32 #0.10) .039 (1.0) .079 (2.0) .157 #.004 (4.00 #0.1) .079 #.002 (2.00 #.05) .079 (2.0) TAPING SPECIFICATION NO SCALE COMMON ANODE POLARITY A(+) SHORT C2(-) 7.0 #.08 (178 #2.0) .197 (5.0) C1(-) LONG .795 (20.2) TYP .512 (13.0) TYP GREEN CATHODE WAVELENGTH LUMINOUS .036 DIRECTION (.9) SQ. CL RoHS COMPLIANT LABEL OR EQUIVALENT MARKINGS RoHS COMPLIANT 2.36 #.039 (60.0 #1.0) .079 (2.0) NOTES: 7. 8. 9. 10. 11. 12. 13. AlInGaP FOR RED, GREEN, YELLOW EPOXY COLOR: WATER CLEAR. SOLDER PAD: COPPER BASE, GOLD PLA TED. SOLDER ADHERANCE PER MIL. STD. 20 2E, METHOD 208C. PARTS TAPED AND REELED PER ANSI/EIA 481-1-A-1994 SPECS. PARTS SUPPLIED 3,000 PIECES PER REEL WITH ALL PARTS ON ONE REEL FROM SAME LOT AND SAM E BIN CATEGORY. REEL PACKED IN ANTI-HUMIDITY ALUM INIUM FOIL BAG, HEAT SEALED WITH SILICA GEL. LABEL ON BAG TO CONTAIN SAME INFO RMATION AS LABEL ON REEL. DEVICE HAS A MOISTURE SENSITIVITY LEVEL "3" CAUTION LABEL APPLIED AS PER JEDEC STD. .033. STORAGE CONDITION: 5 TO 30 C $ @ 70% RH MAX. BAKING IS REQUIRED IF THE PACK HAS BEEN OPENED FOR 168 HOURS OR MORE. BAKING RECOMMENDED CONDITION: 60 # 5 C $ FOR 24 HOURS. TAPE AND REEL LED'S MAY REQUIRE RE-TAPING AFTER TWELVE MONTHS. DIALIGHT PART NUMBER: 597-2723-607F, -602F; 597-2751-607F, -602F THIS ASSEMBLY CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE DEVICES (ESDS). MAINTAIN ALL PRECAUTIONARY MEASURES DURING ASSEMBLY, HANDLING AND STORAGE IN ACCORDANCE WITH 1PC-A-610. -602F SUFFIX DESIGNATES 20 PC SAMPLE STRIP -607F SUFFIX DESIGNATES 7 INCH REEL ABSOLUTE MAXIMUM RATINGS AT 25 C. REVERSE VOLTAGE C $ 300.0 255 C $ 10 SEC 275.0 250.0 200.0 mW mA 30 30 30 mA 0.4 0.4 0.42 mA/ C 5 STORAGE TEMPERATURE -55 TO +85 C 260 FOR 5 SECONDS C THIS DRAWING AND THE CONTENTS HEREIN ARE CONFIDENTIAL AND THE SOLE PROPERTY OF DIALIGHT. REPRODUCTION OF THIS DRAWING OR CONSTRUCTION OF ANY PARTS WITHIN THIS DRAWING ARE FORBIDDEN WITHOUT THE WRITTEN CONSENT OF DIALIGHT. 125.0 SCALE: 20:1 100.0 MORE THAN 220 C $ 10~40 SEC 50.0 0.0 160 C $ MORE THAN 60 SEC 50.0 100.0 150.0 200.0 TIME 250.0 300.0 RECOMMENDED RoHS SOLDER PROFILE 350.0 400.0 SEC. C-17385 TOLERANCES: UNLESS OTHERWISE SPECIFIED FRACTIONS: #1/64 DECIMALS (.XX): #.01 DECIMALS (.XXX): #.005 DECIMALS (.XXXX): #.0005 ANGLES: #1 $ TITLE C RIGHT ANGLE SURFACE MOUNT LED RoHS COMPLIANT MATERIAL FINISH: FSCM REV DRAWING NUMBER ALL DIM'S IN: INCHES (MM) 75.0 0.0 Part Numbers with the "F" suffix ending are RoHS Compliant. For example: 597-2723-607F Reel and bag packaging are marked with "RoHS Compliant" label or equivalent markings. These parts can be used with RoHS reflow profile. Parts can be wave soldered, dip soldered or hand soldered using typical lead-free soldering process with max 260°C temp. for 5 sec. 220 C $ 150.0 25.0 C PEAK TEMP 230 C $ 175.0 V -55 TO +85 PEAK TEMP 255 C $ PRE-HEAT 140 C $~200 C $ 60~120 SEC 225.0 OPERATING TEMPERATURE RANGE WAVE SOLDERING CONDITION NO SCALE RoHS COMPLIANT 597-27XX-602F, -607F 75 DC FORWARD CURRENT REEL SPECIFICATION RECOMMENDED SOLDERING PAD 80 80 OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES (QUANTITY: 3,000 PCS/REEL) .008 (.2) 80 75 PEAK FORWARD CURRENT (1/10 DUTY CYCLE,0.1ms PULSE WIDTH) ATTENTION: YELLOW CATHODE 75 POWER DISSIPATION 2X .059 (1.5) SQ. RED CATHODE UNITS YELLOW LABEL TO CONTAIN: DIALIGHT LOGO DIALIGHT CATALOG PART NUMBER, QUANTITY, DATE OF MANUFACTURE, LOT NUMBER, RANK OF LUMINOUS INTENSITY, COUNTRY OF ORIGIN. PWB CENTER RED GREEN 25°C $ DERATING LINEAR FROM 50 C,RED 0.57 (14.40) TYP TEMPERATURE 1. 2. 3. 4. 5. 6. 1501 ROUTE 34 SOUTH FARMINGDALE, NJ 07727 83330 SHEET 1 OF 1 FAMILY TABLE: TABLES: