Electric Power Systems Laboratory

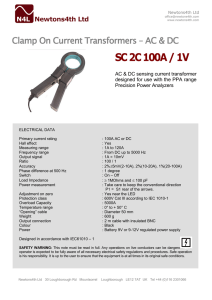

advertisement

u n i v e r s i t y o f p i t t s b u r g h | S wa n s o n s c h o o l o f e n g i n e e r i n g Electric Power Systems Laboratory Facility Dedicated January 2014 T he new Electric Power Systems Lab at the University of Pittsburgh, sponsored in-kind by Eaton, is a multi-use facility for both research and educational activities. Located on the Swanson School of Engineering’s new Energy Floor in Benedum Hall, the lab provides opportunities for faculty and graduate students to perform advanced work in the areas of AC and DC micro-grid developments, smart grid technologies, power electronics devices and systems, renewable energy systems and integration, controls and communications, automation and relaying, distribution engineering, power quality, electrical safety, energy management, energy storage, and other emerging electric power technology areas. The educational components integrate new course developments in electric power engineering focused on these same emerging areas, utilizing the equipment and technologies of the laboratory. The design of the facility was inspired by Eaton’s Power System Experience Center in Warrendale, Pa. • Technical Specifications: Maximum power capacity: 480-V, 200-A, and 75 kVA. • Core equipment: Main electrical infrastructure, motor control centers, switchboard, protection, M-G sets, UPS, data-servers, power factor correction, isolation transformers, and other miscellaneous components • External components (as of 2014): Solar PV panels, donated by John A. Swanson, PhD ’66 and located on the Benedum Hall roof, are integrated into the lab (including both AC and DC interfaces). • Future enhancements: Provisions have also been made for incorporating a gas-fired generator and potentially a micro-wind turbine. Sag and surge generators are currently under construction, which will also be integrated into the main infrastructure. The Workbenches Six custom-designed workbenches are innovative features of the Laboratory. The workbenches were designed, prototyped, and tested by Eaton and Pitt throughout 2013, and are intended for integration into the overall laboratory environment, and are compatible with the other power system equipment and components. Each bench is capable of functioning as a stand-alone entity. The overall objective of the workbench design is to seamlessly combine the configurable load banks and programmable logic controller (PLC) into the workstations, providing a wide array of functionality, while minimizing space within the facility. Each bench includes resistive, inductive, capacitive, and harmonic loads, with auxiliary connections for other loads and the capability to feed an external motor control center (MCC). Advanced metering devices are integrated to communicate readings throughout the entirety of the lab and allow students to clearly view all of the electrical phenomena within the bench. > > > Gregory Reed, PhD Director, Electric Power Initiative Associate Director, Center for Energy Associate Professor, Electrical and Computer Engineering Department Swanson School of Engineering 412-383-9862 gfr3@pitt.edu University of Pittsburgh Swanson School of Engineering Department of Electrical and Computer Engineering 1140 Benedum Hall 3700 O’Hara Street Pittsburgh, PA 15261 412-624-8001 www.engineering.pitt.edu/ECE u n i v e r s i t y o f p i t t s b u r g h | S wa n s o n s c h o o l o f e n g i n e e r i n g Electric Power Systems Laboratory MCC 6 Motors 1 2 3 Motors 4 5 6 MCC 5 MCC 4 MCC 3 S Main IF Return MCC 1 MCC 2 MCC h Lab Benc 3 ch Lab Ben 6 h Lab Benc 2 h Lab Benc 5 h Lab Benc 1 h Lab Benc 4 Fed from 8HL1-13, Lab Fee der 480V 15, 17 100A Reactor Z=5% 75 kVA Fed from PC Penthouse 4 – East 100 A 160A Lab Fee EPO der 100A 100A 480V Pan elboard 480 V Pan 75A Rooftop Genera tor el in Mai 30A 3P 30A 3P n IFS for 20A 3P Special 20A 3P 20A 1P Testing 20A 1P in Main (480V fed 20A 1P 20A 3P IFS from 8HL 1-13,15 20A 1P ,17) 20A 1P 30A 3P SPD 75 kVA 480V/2 08V Delta/W ye 25 kW Fed from 8LDP2 (Southe ast elec – 2, 4, 6 trical clos et) PRC-1 250 kA 480 V Wye 200A 80A 100A Special Testing (480V) Main IFS 100A Switchb oard (20 200A ATS PX 8 V, 60 PowRC ommand Lighting Panel and “No rmal” Power Loads Hz) PX8000 SPD 208V Pan 150A 100 kA 208 V Wye elboard 150A 200A 30A 3P 200A Sag Genera tor (Future ) Reactor Z=18% Normal Source #1 in Mai n IFS (PN 30A 3P L-1 – larg 20A 3P er panel 20A 3P 20A 1P Existing (MicroinveSolar rters) 200A 20A 1P next to 60A 3P 480V pan el) 60A 3P 20A 1P PX 60A LB2 Cable Tray Soft Start Drive LB3 Cable Tray Lab Bench 1 Cable Tray MCC 1 60A Soft Start Drive ATL 60A LB4 MCC 3 Soft Start Drive ATL ATL to MG SETS elboard 60A LB5 60A LB6 Cable Tray MCC 4 Soft Start Drive Lab Bench 5 Cable Tray MCC 5 Soft Start Drive ATL Lab Bench 6 n IFS (PN 60A L-2 – sma ller pan el below to MG SETS 40A 2P 40A 2P DC from Roof (Future) To future wind input to MG SETS Combine r Box on Roo f 5 kW Solar Inverter 480 V pan el) 100A 120V “normal” power (typical) 100A Combine r Box in Lab 100A AutoVar UPS Cable Tray Servers MCC 6 Cable Tray Collector MCC Soft Start From Lab Source 1 Drive ATL to MG SETS #2 in Mai Cable Tray 100A Lab Bench 4 Cable Tray ATL to MG SETS 208V Pan Cable Tray Lab Bench 3 Cable Tray 100A 3P To Collector MCC PX8000 Cable Tray Lab Bench 2 Cable Tray MCC 2 20A 1P Cable Tray 200A Phase Shifting Tx (optional/ typical) 120V “no rmal” power to lab benche s 225A 30A 3P LB1 Circuits 2, 4, 6, 8 – ligh Circuits ts 1, 3, 5, UPS (sw 7 itchboa rd power) control to MG SETS HMT Delta/ Wye Isolation transforme for use rs with for phas benches e shifting 5hp 5hp 5hp 5hp 5hp 5hp PC-3 Pan el (Roof) 30 kVA ATL with C441 Overloads To Load Source 2 100A 3P to MG SETS RLP-1 100A 3P 3 Position Switch (Roof) 20A 3P 20A 3P 20A 3P Panel (Ro of) Wire nut connection 20A 3P RLP-2 Panel (Ro of) The information printed in this document was accurate to the best of our knowledge at the time of printing and is subject to change at any time at the University’s sole discretion. The University of Pittsburgh is an affirmative action, equal opportunity institution. 02/2014