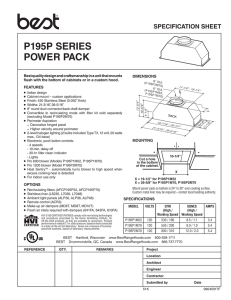

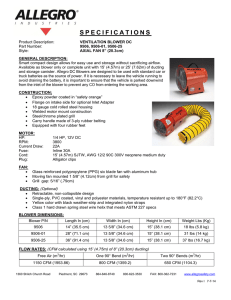

RAS WHISPAIR™ and RGS WHISPAIR™ 10"

advertisement