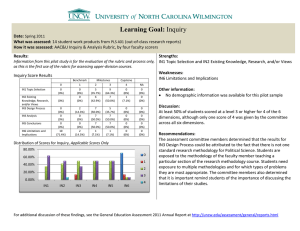

installation and operation manual

advertisement