ANN Food Court Criteria Manual (Food Court)

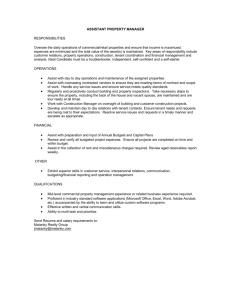

advertisement