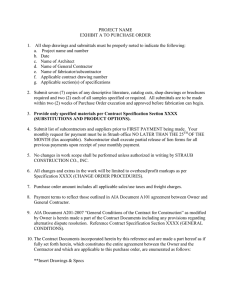

File - Billet Construction Plans

advertisement