installation guide

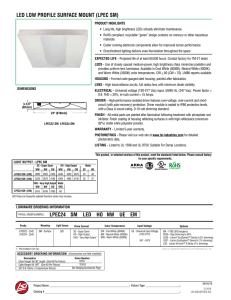

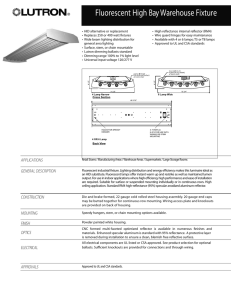

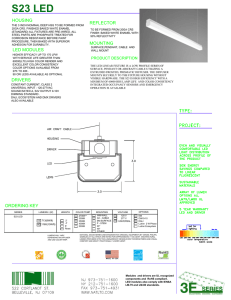

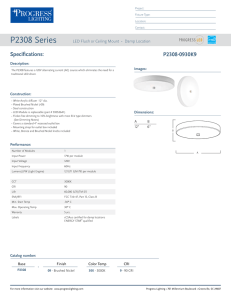

advertisement

Alu m i n A 2 Wall Mounting Installation modular Series ■ The Alumina series wall mounting system is universal across the family of fixture profiles, allowing for ease of installation and wiring as well as forgiveness in mounting point locations. 3■4■6 INSTALLATION SAUD-43 SAUD-44 SAUD-43 SAUD-43INSTRUCTIONS SAUD-44 SAUD-44 SAUD-42 SAUD-42 SAUD-42 1 SAUD-46 SAUD-46 SAUD-46 COMPONENTS FOR WALL AND EDGE MOUNTING FORUM BY 4 3/44”3/4”4 3/4” 2 A 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” A 4 3/44”3/4”4 3/4” B These Installation Instructions apply to the Alumina2, Alumina3, Alumina4, and Alumina6. B /81” /8”1OVERVIEW /8 ” 1 2 3/82”3/8”2 3/8” 7 7 7 2 / 2”/ ”2 / ” DIAGRAMS 7 7 16 16 7 16 2 15/21615”/162”15/16” 4” 4” 4” 4 1/24”1/2”4 1/2” 5 1/25”1/2”5 1/2” 6” 6” 6” SAUD-46 SAUD-42 SAUD-42 SAUD-42 SAUD-43 SAUD-43 SAUD-43 4 3/4” SAUD-44 SAUD-44 SAUD-44 In preparation of installation, remove the wall-side assembly from the package and separate the bracket (B) from the mounting plate (A). SAUD-46 SAUD-46 SAUD-46 The wall mounting system can be used with a standard doublegang j-box as well as a horizontal singlegang box for a more concealed look. Mount the proper cover plate for your specific installation to the wall. All mounting locations must be to building structure. 4 3/4” 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” 5 1/2” 1 7/81”7/8”1 7/8” 2 3/82”3/8”2 3/8” 6” SAUD-46 1 6” 4 3/44”3/4”4 3/4” 4” 4” 4” 4 1/24”1/2”4 1/2” The Alumina modular series is available in four widths (nominally 2”, 3”, 4”, and 6”) and three heights (nominally 3”, 4” 6”). These combina4 3/4” tions allow for maximum flexibility and limitless runs, patterns, and configurations that will meet any space or need. 4 3/4” 5 /2” 2 7/162”7/16”2 7/16” 2 15/21615”/162”15/16” 4 3/44”3/4”4 3/4” The profiles show here are the LED-lamped SAUD Alumina2, 3, 4, and 6, all in the 4” height. 3 5 1/25”1/2”5 1/2” 6” 6” 6” 4 The Alumina series wall mounting system consists of two main components: the wall-side assembly (A) and the the fixture-side assembly (B). Both items come shipped with and attached to the fixure to help ensure proper counts and clarification during assembly EDGE-MOUNT COMPONENTS: If installing an edge-mount assembly,use the wall-mounting installation instructions. A Reattach the wall-side bracket to the plate with the provided hardware. With wall-side brackets installed, pull the power feed wiring through the middle opening of the first fixture. B INCLUDED PARTS & HARDWARE 5 1. HOUSING(S) 2. C ORNERS (OPTIONAL) WALL-MOUNT EDGE-MOUNT 6 1” 1” A For continuous run/pattern installations: after first fixture has been installed, repeat steps 1, 2, 3 and 5 on this page for each subsequent fixture. Proceed with Housing & Run Assembly Installation and Wiring Instructions. Finally, complete the installation by reinstalling the reflectors and lenses. B 3. GEARTRAY(S) 4. LENS WARNINGS Ensure all main power is turned off at electrical panel before servicing D o not attempt installation or maintenance on electrically live product All electrical connections to be made by a qualified electrician or electrical contractor The fixture-side bracket engages with a hook-and-pivoting motion. With the fixture raised and in the (A) position, feed the wiring into the fixture housing and lower/rotate the mating pieces into position (B). The extended lenth of the fixture-side bracket allows for as much as 1” of alignment left or right. Once the fixture is in the desired position, lock it in to place with the provided hardware on the top of the mounting bracket. Forum reserves the right to change this information at any time. Please contact Forum for the latest product information. UPDATED 1/20/16 Forum, Inc. | 100 Chapel Harbor Dr. | Pittsburgh, Pennsylvania 15238 | T: (412) 781-5970 F: (412) 781-5971 | www.forumlighting.com PAGE 1/3 Alu m i n A 2 Suspended Mounting Installation modular Series ■ 3■4■6 The Alumina series cable mounting system is universal across the family of fixture profiles, allowing for ease of installation and wiring as well as forgiveness in mounting point locations. 1 INSTALLATION SAUD-43 SAUD-44 SAUD-43 SAUD-43INSTRUCTIONS SAUD-44 SAUD-44 COMPONENTS FOR SUSPENDED MOUNTING SAUD-42 SAUD-42 SAUD-42 SAUD-46 SAUD-46 SAUD-46 FORUM BY 4 3/44”3/4”4 3/4” Turn off the power to the fixture’s circuit. With the first power-fed fixure supported in the air, raise the cable assemblies to their respective mounts, and connect the power cord (A) to the celing’s power feed (B). B C 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” Install the junction box cross bar (C) in the powerfeed side. The suspension cable assembly threads to the 1/4-20 stud in the cross bar. Be sure that the included SJ cord is laced through the 5” canopy cover (D) and secured by the cord grip (E). Follow governing electricical code for making your connections in the junction box. Number of conductors in the cable will vary with fixture specification. These Installation Instructions apply to the Alumina2, Alumina3, Alumina4, and Alumina6. 7 /81”7/8”1OVERVIEW /8 ” 1 7 2 3/82”3/8”2 3/8” 2 / 2”/ ”2 / ” DIAGRAMS 7 7 7 16 16 16 15 15 15 16 16 16 2 /2 ”/ 2” / ” D 4” 4” 4” 4 1/24”1/2”4 1/2” 5 1/25”1/2”5 1/2” 6” 6” 6” SAUD-46 SAUD-42 SAUD-42 SAUD-42 SAUD-43 SAUD-43 SAUD-43 SAUD-44 SAUD-44 SAUD-44 E B SAUD-46 SAUD-46 SAUD-46 A A 4 3/4” 4 3/4” 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” 5 1/2” 1 7/81”7/8”1 7/8” 2 3/82”3/8”2 3/8” 6” SAUD-46 4” 4” 4” 4 1/24”1/2”4 1/2” The Alumina modular series is available in four widths (nominally 2”, 3”, 4”, and 6”) and three heights (nominally 3”, 4” 6”). These combina4 3/4” tions allow for maximum flexibility and limitless runs, patterns, and configurations that will meet any space or need. 4 3/4” 5 1/2” 2 7/162”7/16”2 7/16” 2 15/21615”/162”15/16” 4 3/44”3/4”4 3/4” 6” The profiles show here are the LED-lamped SAUD Alumina2, 3, 4, and 6, all in the 4” height. INCLUDED PARTS & HARDWARE 4 3/44”3/4”4 3/4” A 2 3 B 5 1/25”1/2”5 1/2” 6” 6” 6” The Alumina series cable mounting system consists of two main components: the powerfeed assembly (A) and the the non-powerfeed assembly (B). Both items come shipped with and attached to the fixure to help ensure proper counts and clarification during assembly. In preparation of installation, ensure that crossbars, canopy covers, cablegrippers and cord grips are all accounted for. The cable mounting system us to be used with a standard j-box on the powerfeed side and 1/4-20 thread-all on the non-powerfeed side. Be sure to follow all governing code related to structural integrity and use of materials. Thread the non-powerfeed side cable onto the 1/4-20 threaded rod secured to structure. Be sure that the 2” canopy cover is in place before attaching. With fixture now mounted, you can slowly lower it into place. Fine adjustments to height and leveling can be made at the gripper assemblies located on the upper surface of the fixure. 4 For continuous run/pattern installations: after first power-fed fixture has been installed, repeat step 2 for each subsequent fixture and corner. 1. HOUSING(S) 2. C ORNERS (OPTIONAL) Proceed with Housing & Run Assembly Installation and Wiring Instructions. Finally, complete the installation by reinstalling the reflectors and lenses. #2 installation 3. GEARTRAY(S) 4. LENS #3 installation #1 installation Power-feed fixture WARNINGS Ensure all main power is turned off at electrical panel before servicing D o not attempt installation or maintenance on electrically live product All electrical connections to be made by a qualified electrician or electrical contractor Forum reserves the right to change this information at any time. Please contact Forum for the latest product information. UPDATED 1/20/16 Forum, Inc. | 100 Chapel Harbor Dr. | Pittsburgh, Pennsylvania 15238 | T: (412) 781-5970 F: (412) 781-5971 | www.forumlighting.com PAGE 2/3 Alu m i n A 2 Housing & Run Assembly Installation modular Series ■ 3■4■6 INSTALLATION SAUD-43 SAUD-44 SAUD-43 SAUD-43INSTRUCTIONS SAUD-44 SAUD-44 SAUD-42 SAUD-42 SAUD-42 1 SAUD-46 SAUD-46 SAUD-46 2 FORUM BY 4 3/44”3/4”4 3/4” 3 B Housing 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” A Joining Pin These Installation Instructions apply to the Alumina2, Alumina3, Alumina4, and Alumina6. 7 /81”7/8”1OVERVIEW /8 ” 1 7 2 3/82”3/8”2 3/8” 2 / 2”/ ”2 / ” DIAGRAMS 7 7 7 16 16 16 15 15 15 16 16 16 2 /2 ”/ 2” / ” 4” 4” 4” 4 1/24”1/2”4 1/2” B SAUD-46 SAUD-42 SAUD-42 SAUD-42 SAUD-43 SAUD-43 SAUD-43 SAUD-44 SAUD-44 SAUD-44 Lens SAUD-46 SAUD-46 SAUD-46 Remove the lens and geartray to gain access to the joining hardware at the fixture ends of each run configuration 4 3/4” 4 3/4” 4 3/44”3/4”4 3/4” 4 3/44”3/4”4 3/4” 5 1/2” 1 7/81”7/8”1 7/8” 2 3/82”3/8”2 3/8” 6” SAUD-46 4” 4” 4” 4 1/24”1/2”4 1/2” The Alumina modular series is available in four widths (nominally 2”, 3”, 4”, and 6”) and three heights (nominally 3”, 4” 6”). These combina4 3/4” tions allow for maximum flexibility and limitless runs, patterns, and configurations that will meet any space or need. 4 3/4” 5 1/2” 2 7/162”7/16”2 7/16” 2 15/21615”/162”15/16” 4 3/44”3/4”4 3/4” 6” 3. GEARTRAY(S) 4 3/44”3/4”4 3/4” 5 1/25”1/2”5 1/2” 6” 6” 6” Wiring & Lamping Slide the fixtures together along the alignment tabs to engage the housing profile of the ajoining units. Use the included gasket strips along the exposed faces for a true fit and to prevent light leak. Tighten set screws in alignment tabs. Attach the housings (A & B) by using the suplied hardware in the header brackets to draw the pieces together tightly. Set screws in the alignment tabs aid this as well. Repeat steps 1–3 for continuous run/pattern installation, including corners. PRIOR TO WIRING, FIXURE(S) MUST BE MOUNTED/HUNG AND ADJOINED IN THE FINAL INSTALLED POSITION. LED & FLUORESCENT FLUORESCENT The profiles show here are the LED-lamped SAUD Alumina2, 3, 4, and 6, all in the 4” height. INCLUDED PARTS & HARDWARE 1. HOUSING(S) Set Screws Geartray 5 1/25”1/2”5 1/2” 6” 6” 6” A Standard geartrays come wired with 18GA solid core wire and provided self drilling hardware. Lamps not included. Install T5 lamps into geartray slots. (LED comes preinstalled with geartray) 2. C ORNERS (OPTIONAL) 4. LENS WARNINGS Ensure all main power is turned off at electrical panel before servicing D o not attempt installation or maintenance on electrically live product All electrical connections to be made by a qualified electrician or electrical contractor Forum reserves the right to change this information at any time. Please contact Forum for the latest product information. UPDATED 1/20/16 FLUORESCENT PRODUCT CODE DESCRIPTION MANUFACTURER [none] Non-Dimming Universal Lighting Technologies D10V 0-10V Dimming Fulham D2FP Mark 7 Dimming Phillips Advance DLH3D3 Lutron Hi-lume 3D 3-wire Dimming Lutron DLH3D5 Lutron Hi-lume 3D 5-wire Dimming Lutron DLE3 Lutron EcoSystem 3-wire Dimming Lutron DLE5 Lutron EcoSystem 5-wire Dimming Lutron DLEH5 Lutron EcoSystem H-Series 5-wire Dimming Lutron EM1 550 Lumen Battery Pack Iota EM2 1100 Lumen Battery Pack Iota F Fusing Cooper Bussmann GLR-1/2 PRODUCT CODE DESCRIPTION MANUFACTURER [none] Non-Dimming Universal Lighting Technologies D10V 0-10V Dimming Fulham DLA2 Lutron Hi-lume 1% 2-wire LED driver (120V forward phase only) Lutron DLA3 Lutron Hi-lume 1% 3-wire LED driver Lutron DLH3 Lutron Hi-lume 3-wire Dimming Lutron DLA5 Lutron Hi-lume 1% EcoSystem LED driver Lutron DLEH5 Lutron EcoSystem H-Series 5-wire Dimming Lutron DLE55 Lutron 5-Series EcoSystem LED driver Lutron DALI Digitally Addressable Lighting Interface EM1 550 Lumen Battery Pack Iota EM2 1100 Lumen Battery Pack Iota F Fusing Cooper Bussmann GLR-1/2 LED Forum, Inc. | 100 Chapel Harbor Dr. | Pittsburgh, Pennsylvania 15238 | T: (412) 781-5970 F: (412) 781-5971 | www.forumlighting.com PAGE 3/3